@wombat37

Seems that I had forgotten to update the DWC files in \www.

Layer Chart is now working nicely

Sorry...

Best posts made by Wombat37

-

RE: Layer number always Nullposted in Duet Web Control

-

RE: Hot-End Thermistor Temperature calibrationposted in Tuning and tweaking

Thanks everyone for the quick responses.

I totally agree that using a better quality thermistor is a good way to go. However, there are many more variables that affect the accuracy of temperature control. I just moved this same thermistor between two different boards with the same settings and saw a 20°C difference when measured independently. Something was different with the board, the cabling, the PSU, thermal lag, the firmware, etc., etc. I don't think a bad thermistor caused this.

Jay_s_uk stated that a 3950 thermistor has poor resolution at the top end. With a 12-bit ADC, this equates to about 19 counts/°C at 240°C. With the 104Gt (beta = 4267), it's much worse at about 12 counts/°C and a lower ceiling for the top temperature. So, I don't quite understand your comment about it being worse.

Proper calibration using independent temperature measurements is always a more reliable approach than just typing in expected numbers and then assuming that everything is working correctly. I know it's easy to dismiss stuff as cheap rubbish but unless you make measurements like this, it's difficult to have a basis for such claims.

Also, before you challenge my method of making these measurements, I used an expensive Omega probe thermocouple inside the nozzle which had been calibrated beforehand using melting pure tin metal (231.9°C) and not just ice and steam.

Back to my original question, is there any way of getting access to the raw data values from the ADC in RRF?

I apologize if I'm coming across a bit snarky - it's not intended. I do appreciate your input, I just like to fully understand things before I accept or dismiss them.

-

RE: Hot-End Thermistor Temperature calibrationposted in Tuning and tweaking

I don't think it would be fully automatic but more macro-guided.

The macro would ask the user to adjust 3 or 4 temperatures and then do the calculations to determine values for R25 and Beta. I'm still thinking on how to handle the LowOffset and HighOffset settings, my board doesn't automatically calculate these.

Regarding the quality of the B3950 vs B4267 and other higher Beta thermistors, it might not be so much an issue of resolution but of noise and stability (and robustness). Lower resolution but less noise might be a better combination.

-

RE: Hot-End Thermistor Temperature calibrationposted in Tuning and tweaking

I seem to be on a roll, now

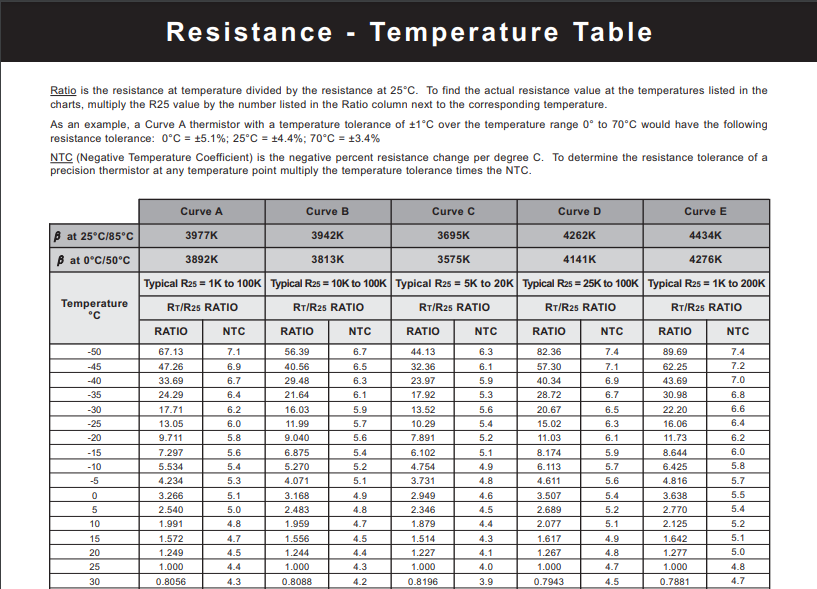

I've started reviewing the data sheets for expensive "high quality thermistors". Whereas the resistance seems to be stable (<1%) at a given temperature, the absolute resistance can be very variable. The specs seem be all over the place for Selco thermistors as shown in the table below. The Beta values change significantly between 0-50°C and 25-85°C ranges and the R25 value varies by almost 5% in some instances. The R25 variance doesn't affect things too much but the change in Beta certainly does and measurements are going to be way-off once the high temperatures are reached if we use Beta values for low temperatures in the M308 entry. So, in my mind, unless anybody can convince me otherwise, buying an expensive, high quality thermistor does not mitigate the need for proper temperature calibration. If the thermistor Beta and R25 varies between devices, then all the more need for calibration. QED.

-

RE: Hot-End Thermistor Temperature calibrationposted in Tuning and tweaking

I seem to be losing this argument

My understanding is that a thermistor can match the performance of a platinum RTD - if it's properly calibrated!

It is the calibration that is the challenge because it's very non-linear and variable.

If we can make this easy then anyone's system currently using a thermistor (which I assume is the vast majority of us) could, without making any hardware modifications, get better temperature control of the hot-end (even with cheap thermistors). This would lead to consistent performance over long periods and and more reliable portage of methods between different systems.

Why wouldn't we want to do this?

-

RE: Hot-End Thermistor Temperature calibrationposted in Tuning and tweaking

Your point for an accurate thermometer is well taken but I'm not sure why you would need an oven/bath to do this. Air baths are notorious for thermal gradients (I used to help design and evaluate gas chromatographs). Pushing a well calibrated 1-mm (or smaller) diameter thermocouple probe through the heat-break and into the inside of the nozzle would be my approach.

I have a fourth suggestion:

- Publish thermistor Beta values for the 180-260°C range. I will try to put together some suggestions for these based on manufacturers' published R vs T tables.

This must be much better than using the Beta values published for a 0-25°C range.

Maybe this will be enough to eliminate the need for calibration.

-

RE: Hot-End Thermistor Temperature calibrationposted in Tuning and tweaking

I used pure metallic tin last time - which worked well (m.p 231.9°C). I can also look at the boiling points of silicone oil or something like dodecane. Solder probably won't be very pure and as an alloy, its composition may vary. Also, it may not have a sharp melting point like pure substance. However, we're not during purity analysis (melting points can be used as a measure of purity) here so a few degrees error probably won't hurt.

Looks like there is some interest in this topic, so I will keep looking into this. I'll post up an algorithm over the next few days and see what people think of that and get some more ideas.

-

RE: Hot-End Thermistor Temperature calibrationposted in Tuning and tweaking

I didn't realize that these solders were eutectic. Most alloys typically melt over a range of temperature.

Regarding tin, it's not too expensive to get reasonable purity - perhaps less than the solder you recommend:

I agree about boiling points being a bit erratic because of superheating. However, many things supercool so care has to be taken to determine melting points as well.

I feel it would be enough to use just one calibration point (in addition to ice or steam) for the digital thermometer for a narrow range of operating temperatures - say, something in the 180 to 260°C range. I don't really care if the temperature below that is accurate - it's never used except to tell me that the hot-end is now cold enough to touch. There's an easy way to find that out anyway. We can still do the cubic coefficient determination by taking more measurements with the thermocouple probe. Solving 3rd-order equations may be a bit challenging for RRF macros, though.