@o_lampe Yes, that's why I asked. It looks like a value of 100 would double the switch speed to around 94 mm/s, I just want to make sure before I start messing up with parameters.

My print profiles are either "fast" (everything above 100 mm/s, except first layer), or "slow" (80 mm/s maximum), so there would not be a problem switching modes mid-print.

Posts made by war4peace

-

RE: TMC5160 - StealthChop versus SpreadCycleposted in Tuning and tweaking

-

TMC5160 - StealthChop versus SpreadCycleposted in Tuning and tweaking

Hi all,

I have a RatRig V-Core 3 500 CoreXY printer, with Duet 3 6HC and Toolboard 1.1.

Motor configuration is fairly simple:; Drives M569 P0.0 S1 D2 ; physical drive 0.0 goes forwards M569 P0.1 S1 D2 ; physical drive 0.1 goes forwards M569 P0.2 S1 D2 ; physical drive 0.2 goes forwards M569 P0.3 S1 D2 ; physical drive 0.3 goes forwards M569 P0.4 S1 D2 ; physical drive 0.4 goes forwards M569 P20.0 S1 D2 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E20.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolationEverything works well, in general, but I have one issue I might need some help with.

I have tested movement at various speeds, and I have noticed a resonance noise between F4000 and F6000.

Example:

Head is at X250, Y250.

Command isG1 X50 F5000.

The head moves to X50 as instructed, and while that happens, there is a loud "buzzing" noise which, interestingly enough, seems to come from the printing head assembly, not the motors themselves.

I have tested the limits at which this noise fades out to nothing. The lower limit seems to be around F3900 (65mm/s) and the upper limit is at around F6000 (100mm/s), for both X and Y, as well as motor-specific movement (forcing S1 and S2 to only rotate one of the motors). Above and below that speed, the buzzing noise disappears, I have tested up to F30000 (500 mm/s) and everything is fine.My question is, at speeds between 65 and 100mm/s (or, more generally, at speeds below 100 mm/s), would it be OK to use StealthChop instead? Or are those speeds too high for StealthChop?

Here's

M569 P0.4output:M569 P0.4 Drive 4 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x08053, toff 3, tblank 1, thigh 200 (46.9 mm/sec), hstart/hend/hdec 5/0/0, pos 312I have read the documentation for M569:

Vnnn (firmware 2.02 and later) tpwmthrs parameter for those stepper driver chips that support it. This is the interval in clock cycles between 1/256 microsteps below which the drivers will switch from stealthChop to to spreadCycle mode. Only applies when the driver is configured in stealthChop mode. Typical value are from 100 (high speed) to 4000 (low speed). Send M569 P# (where # is the driver number) with no additional parameters to see how this translates into mm/sec.

I also looked at Tuning Stepper Motor Drivers article, and I don't need StallGuard or CoolStep features, I'd rather have them disabled for now.

My confusion is related to article's "StealthChop Tuning" section mentioning things such as "[parameter] low/high enough for the speeds you are using". The problem is, I am using speeds as low as 30mm/s (F1800) and as high as 250mm/s (F15000), depending on filament type, model, etc. I could, of course, add the relevant commands in filament's config.g file, and use M703 to load them specifically when printing with that filament, and also add relevant commands to a model's G-Code if I want that specific model to override default filament config for some reason, but before that, I'd like to have some ballpark minimum/maximum values for StealthChop.

Ideally, I'd like the X/Y motors to use StealthChop at all speeds under 100 mm/s, and switch to SpreadCycle at speeds above 100mm/s - would those speeds be too much for StealthChop?

And if not, what is the proper value for the M569 V parameter? The article says "100" is for high speed (how high is 100?) Should I just go gung-ho on it using trial and error?Thank you in advance for your replies, as always, I thoroughly appreciate your help.

-

RE: Input Shaper tuning - help requiredposted in Tuning and tweaking

After many tries and configuration changes, I am starting to suspect something is loose in my print head assembly.

I will disassemble, check and reassemble the print head tomorrow and update with my findings. -

RE: Input Shaper tuning - help requiredposted in Tuning and tweaking

@dc42

I have a CoreXY printer, the RatRig V-Core 3 500x500x500, as mentioned in my first post on the thread. Could be that the long belt paths are not helping at high(er) accelerations.

It has a kinematic bed, and while Y movements move the 20x20 extrusion together with the head assembly, and X movements only move the head assembly, both motors contribute to the movement, and most of the ringing is visible after an X movement ends and an Y movement begins.I'll try ZVDD using accelerations between 1200 and 6800 and update this thread.

-

RE: Input Shaper tuning - help requiredposted in Tuning and tweaking

Some updates on Input Shaper... I have followed the good old method outlined in the Klipper documentation, and found (through manual measurements) that ringing occurs at 29.4 Hz. Applied "zvd" algorithm and printed the ringing tower at accelerations between 1200 and 6800. Ringing is almost, but not fully gone up to around 4400-4600 acceleration, then it becomes more prominent again.

Maybe damping factor would help? Or should I try different algorithms, such as zvdd?

-

RE: Input Shaper tuning - help requiredposted in Tuning and tweaking

@dc42

Thank you for your reply.

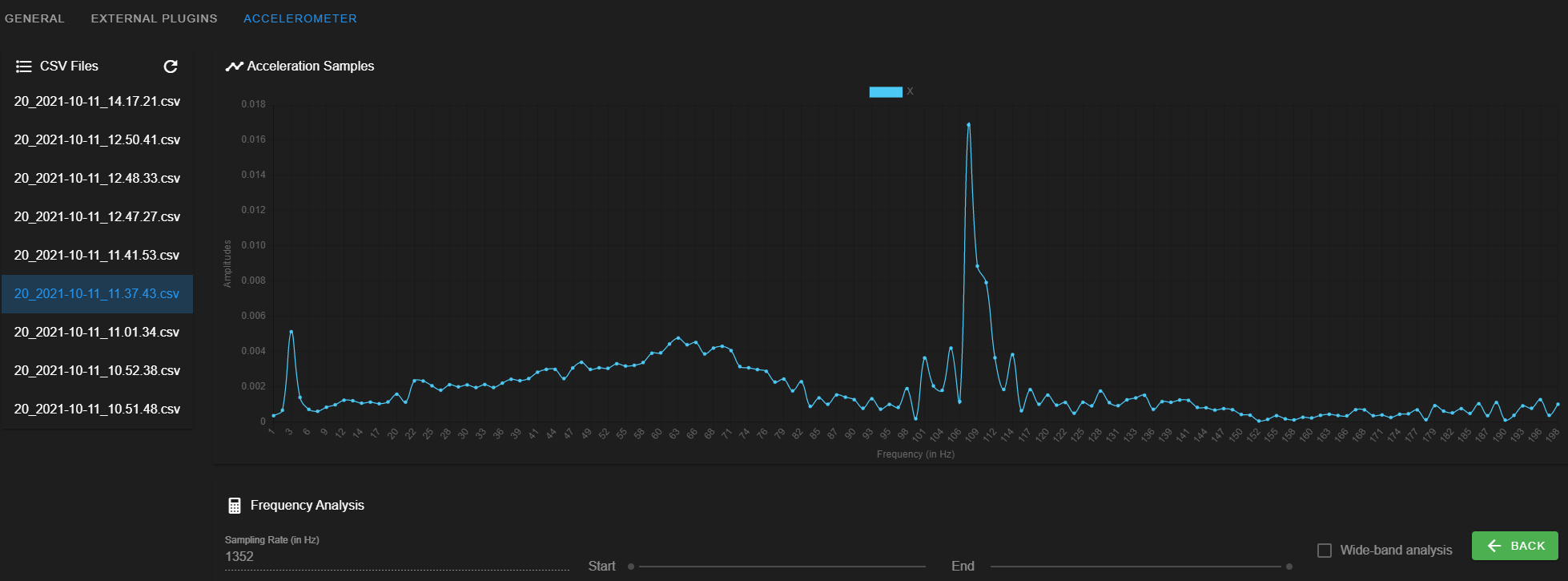

The 107 Hz value seems to come from faint motor vibrations or heat sink fan vibrations - it's present throughout the sample.

I switched to using a Klipper ringing tower which makes it clear which axis has ringing. The X axis has definitely more prominent ringing than Y axis.

I have now used the traditional method to divide ringing pitch to print speed and came with a value of 29.35, testing it now for various accelerations (1200 to 6800).Forgot to mention Jerk is at 600 mm/min for X, Y and E.

One question: what is „damping factor” and how does it affect Input Shaper algorithm? Also, I looked at M593 document, but it doesn't say much about damping factor.

-

Input Shaper tuning - help requiredposted in Tuning and tweaking

Hi all,

I have recently (during the weekend) installed the Toolboard 1.1 on my RatRig V-Core 3. It has been configured and is (mostly) working as expected (there is a hotend/heatsink fan misconfiguration I am fighting with, but that's another story).

Input Shaper is what I am struggling with at the moment.Firstly, here's the current configuration:

Acceleration for X, Y and E axis is 10K mm/s^2, well within the capabilities of the printer. Accelerometer orientation is defined according to the wonderful document here.M955 P20.0 I10After that, I have run a test command for X axis, according to documentation:

G1 X-50 G4 S2 G1 X50 F20000 M400 M956 P20.0 S1000 A0Analyzing the data using the Accelerometer embedded plugin yielded this result:

There are two spikes, one at 107.6 +/-0.7 Hz, and a smaller one at 3.4 +/- 0.7 Hz.I have then used M593 to use that frequency:

M593 P"zvd" F107.6Finally, printed a 50x50x50mm empty cube with two walls, using a 0.6mm nozzle at 100mm/s speed for all features, 0.2mm layer height. There is ringing present in all prints. It almost seems as Input Shaper is not being applied. Running M593 during print shows it is active, here's an example from the console while printing the cube with a slightly different frequency every 25 layers (10 changes):

M593 Input shaping 'zvd' at 107.7Hz damping factor 0.10, min. acceleration 10.0, impulses 0.334 0.822 with durations (ms) 4.67 4.67Looking at the printed part, there is no ringing/ghosting change throughout its height. I am, therefore, stuck at this step, not knowing how to further troubleshoot what's going on.

Any help would be much appreciated!

Thank you in advance for advice! -

RE: Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

@dc42

I apologize, the schematic was primitive and did not exactly respect the pin layouts. When I physically connect the fan, I will look up pin order and connect appropriately.

Thank you very much for the VOUTLC jumper block mention, I would have surely missed it. VN position means leaving the 12V pin free, I assume? I apologize for asking these questions, I looked up "VN" in the Duet 3 6HC Wiring Diagram and there was no reference. -

RE: Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

Sorry about the necro, but I wanted to continue this topic to keep things consistent.

I have managed to buy a better fan, the Delta PFB0412EN-E, here's the specifications document.

As mentioned before, I have a Duet 3 6HC which has three 4-pin PWM fan headers.

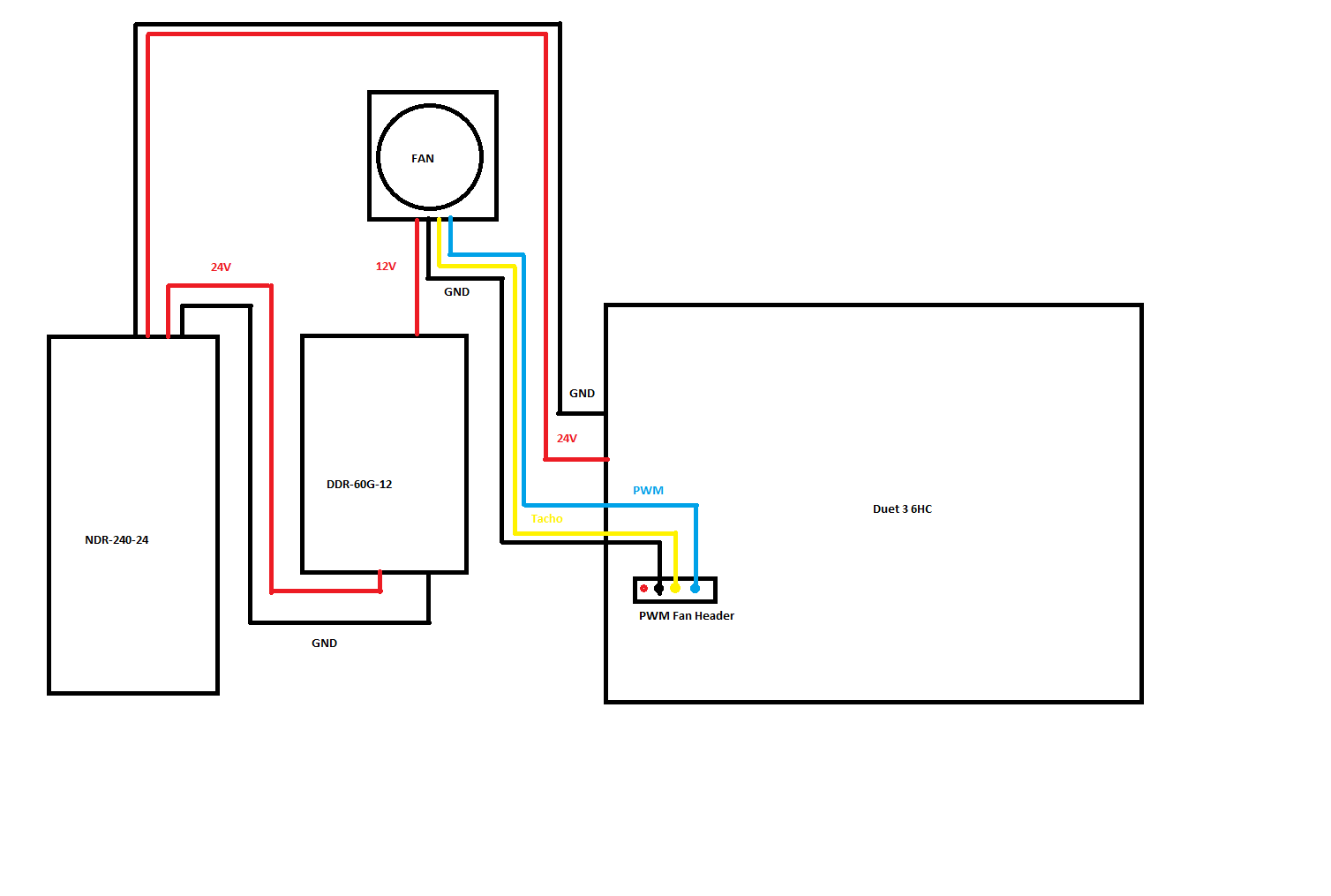

The fan is powered using a DC/DC converter (Mean Well DDR-60G-12) which is itself powered from the same PSU as the one powering the Duet (Mean Well NDR-240-24).I have received a very informative reply from @dc42 above. Based on it, I have devised the following, beautifully hand-painted circuitry.

I'd like to confirm this is how hardware is supposed to be connected... I'm not an electronics expert...

Thank you in advance for your replies!

-

RE: DWC - custom colors for temperature chartposted in Duet Web Control

@chrishamm

Thank you. I want to show them, but the colors are so close together that they become confusing.

Too bad about hard-coding them, it would have been nice if they were configurable (at the minimum, through a hex color code within a configuration file). Maybe a feature for future versions...My question is now answered, thanks again.

-

RE: DWC - custom colors for temperature chartposted in Duet Web Control

Anyone? Just would like to know if this option is possible or configurable somewhere.

-

DWC - custom colors for temperature chartposted in Duet Web Control

Hi everyone,

I have installed a couple more temperature sensors on my 3D printer (using Duet 3 6HC), and I am wondering whether (and how) could the temperature colors be customized in the temperature chart.

-

RE: Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

@deckingman I'm afraid there is some misunderstanding here.

The topic is not about saving time and money, there's plenty of either. It's about performance in a small package, with specific requirements. I appreciate you trying to help, it was just not what I needed, that's all

-

RE: Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

Problem number one:

Shipping Alert: Product available only to OEM/EMS and design business customers. Product is not shipped to consumers in the EU.Problem number two: it's not the right size. I need a 7530 fan, not a 9533 fan.

Problem number three: it's heavier than the 12V 7530 fan. 190 grams versus 140 grams.

Problem number four: has less air pressure than the 12V fan, air pressure takes precedence.

Problem number five: the 7530 fan I had linked was successfully tested in 3D printing, as a matter of fact it was used to cool the Benchy in the Speedboat challenge bed slinger world record (https://www.youtube.com/watch?v=3rQoG3aUKMI). The fans you have linked have not been tested.I'd rather invest in a 25 bucks 24V-12V converter, rather than experiment with something that's bigger, heavier, less performing and harder to obtain, just because it's 24V.

Appreciate the recommendation, but it's not what I am looking for.

@dc42 thank you, I will test, check and install as recommended.

-

RE: Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

@feeshfeud said in Connecting High power 12V fan to Duet 3 6HC:

Connections in detail: The board connection (Duet3 mainboard) is one of the 4 pin fan headers (e.g. out 4), via a fan extension cable where I've snipped the power/grnd wires (leaving PWM/tach). That extension then connects to a 4 pin 'fan splitter' y cable which connects to both pump motors' stock signal connectors.

[0] I'm not in front of my machine right now, so I might be misremembering and the pumps might just not have a tach signal -- which would obviously explain why it doesn't work.

That might be why the tach signal isn't working. I (used to) have two pumps as well (in my PC), and I used one tach signal from each pump, connected to separate tach pins.

You can use one pump as "master" with the tach signal, and from the other use just the PWM wire.@dc42 thank you for your response. I can get a Mean Well DDR-60G-12 which provides more than enough power. Just to be extra-sure, the DC-DC converter should only provide the positive wire (one wire in total), or both positive and ground?

-

RE: Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

@mrehorstdmd said in Connecting High power 12V fan to Duet 3 6HC:

@war4peace Try printing one of these: https://vimeo.com/268264890

It uses a brushless motor from a HDD, and a $10 driver that accepts PWM input to control the speed. The output is designed to fit a standard CPAP hose. It will deliver more air than you'll ever need and should be quieter than a squirrel cage blower.The assembly that I am using (EVA) already has a GIT contrib which allows for a 7530 fan to be installed. There is no need to look for another solution, all I need is to know how to connect a 2.3A 12V fan to the Duet 3 6HC motherboard.

@fcwilt said in Connecting High power 12V fan to Duet 3 6HC:

How are you defining "powerful"

The URL for the 12V fan is above, in this topic.

I'll link it again here, just in case.

Click me.@feeshfeud I happen to have some watercooling knowledge, wondering why are you using parallel setup for the D5 pumps, rather than have them connected in series.

How did you connect the wires? +/- to the charger, and tach + pwm to the board? If so, which board connector have you used for the tach and PWM wires? Could you please provide me some more detail around that? -

RE: Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

Appreciate your info. I'm in the same stage, I know enough to make things go poof, but I also know enough to know I don't know enough... if that makes any sense.

-

RE: Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

@nurgelrot

Nope. I have checked and the most powerful 24V blower is around a tenth the power of the 12V one.

I'm stuck with 12V as an option, therefore I need a solution in that regard.24V options versus 12V options.

Most powerful 12V (also has 4 wires).

Most powerful 24V (only has 3 wires). -

Connecting High power 12V fan to Duet 3 6HCposted in Duet Hardware and wiring

Hi everyone,

I apologize if this had been discussed before, however my weak search-fu on the forums yielded no specific results, so here I am, making another potentially-annoying topic

At any rate... I have a CoreXY printer (RatRig V-Core 3) with Duet 3 6HC, Toolboard 1.0 (not yet installed) and PanelDue 5i. Everything is installed, configured and works well.

With that being said, I have been looking at beefing up my part cooling fan, because at high speeds and accelerations, part cooling is lagging, even with a 6K RPM 5015 blower at full speed. I have the possibility of installing a high powered 12V fan, but its current rating is 2.3A - therefore I need some help correctly installing it.

I can either buy a dedicated 12V Mean Well DIN Rail PSU for the fan itself (example), and only connect tacho and PWM pins to the Duet 3 (would that work?). Alternatively, if you think it's possible to connect and power it from the Duet 3 directly, please let me know how to do so. The hotend cooling fan is 24V, by the way.

Thank you in advance for your help!

-

RE: Firmware bundle 3.3.0 releasedposted in Firmware installation

Installed 3.3.0 today, from 3.3 RC-3, everything went well, and simulating a file now updates the "Simulated Time" column.

I'm still to test the issue of long print jobs (40+ hours) not updating the "Print Time" column, but that's something that will only be visible after I finish the next long print job.