@jay_s_uk if i did that, would i be able to reuse my config? Also I tried upgrading when my sd card gave out, but nothing worked, so i had to revert to whatever fw i had and a compatible dwc.

Posts made by vlex

-

RE: G32 keeps exceeding bounds of M557posted in Tuning and tweaking

-

RE: G32 keeps exceeding bounds of M557posted in Tuning and tweaking

@dc42 it's an inductive LJ12A3-4-Z/BX. From what I've tested it triggers consistently at 0.69 height for the nozzle (the sensor is higher than the nozzle by another 0.4mm or so).

-

RE: G32 keeps exceeding bounds of M557posted in Tuning and tweaking

@jay_s_uk sure thing:

; called to perform automatic delta calibration via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Fri Feb 24 2023 13:57:20 GMT+0000 (Greenwich Mean Time) M561 ; clear any bed transform G28 ; home all towers ; Probe the bed at 3 peripheral and 3 halfway points, and perform 6-factor auto compensation ; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g. G30 P0 X0 Y40.43 H0 Z-99999 G30 P1 X38.22 Y-22.07 H0 Z-99999 G30 P2 X-47.63 Y-27.5 H0 Z-99999 G30 P3 X0 Y15.47 H0 Z-99999 G30 P4 X14.87 Y-8.59 H0 Z-99999 G30 P5 X-23.82 Y-13.75 H0 Z-99999 G30 P6 X0 Y0 H0 Z-99999 S6 ; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors ; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)The diff between the posted above

config.gand the current one is here:;Current ; Previously posted ; Set delta radius, diagonal rod length, printable radius and homed height M665 R105.6 L218 B85 H333.5 ; M665 R105.6 L218 B85 H360 ; define mesh grid M557 X-50:50 Y-50:75 R75 S20 ;M557 X-50:50 Y-50:75 R55 S10Atm there's no

config-override.gso not posting one and theheightmap.csvatm looks like this (not sure whether it helps for me to post it, but can't hurt, can it?):RepRapFirmware height map file v2, min error -1.601, max error 1.398, mean -0.163, deviation 0.747 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum -50.00,50.00,-50.00,75.00,75.00,20.00,20.00,6,7 0, -0.896, -1.552, -1.479, -1.331, -0.823 -0.137, -0.397, -0.472, -0.389, -0.280, -0.023 0.056, -0.385, -0.198, -0.004, 0.360, 0.852 0.284, 0.220, 0.220, 0.329, 0.729, 1.180 -0.159, -0.699, -0.389, 0.082, 0.683, 1.398 -0.782, -0.665, -0.476, -0.190, 0.501, 1.342 0, 0, -1.601, -0.950, 0, 0 -

RE: G32 keeps exceeding bounds of M557posted in Tuning and tweaking

@dc42 That makes sense.

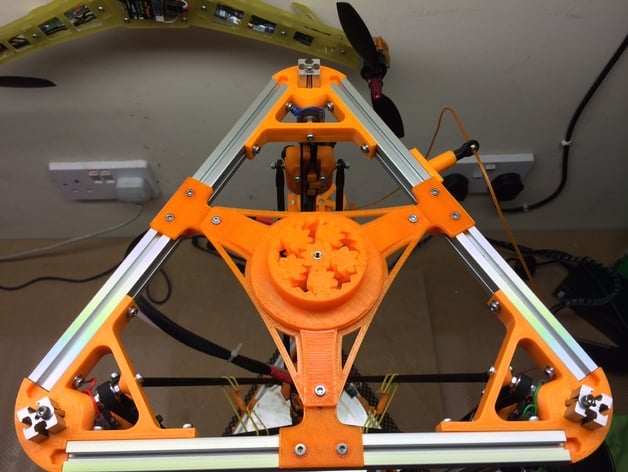

I've got a weird new problem though - after init of the duet, the prints are not great, dare i say even bad - usually there's gaps between the hotend and the bed or sometimes it drags across the bed. After running G29 it seems to work slightly better, BUT as soon as I run G32 I think the geometry goes right out of the window. I'm trying to print a spool holder and one of the parts is a big triangle with a circle inside it:

All is good and dandy until the G32, after it all of the sudden the circle becomes an ellipse and a quite elongated one. I'm assuming something ain't right in the setup above (I'm reusing it except I added springs under the bolts of the bed so it's now about 10-12mm higher, so the Z-height is less now). The elongation is across practically the Y-axis (imagine a line between the furthermost pillar on the pic above and the centre of the section).Any ideas what I'm doing wrong OR how to troubleshoot this? Thanks in advance!

-

RE: G32 keeps exceeding bounds of M557posted in Tuning and tweaking

The G30 commands in bed.g are allowed to exceed the normal bed limits, because on delta machines it is advantageous to probe between the towers outside the usual printable bed radius, where the mechanics supports that.

@dc42 Well, this confuses me - I've got a mini kossel and executing G32 is exactly what broke my effector, because a couple of times I wasn't fast enough to hit the emergency break before the effector twisted the rods on one of the axis. Is this meant for only effectors using magnetic joints, or can you give me an example where this probing outside of the printable area won't kill the suspension of the effector like it did mine? If this is not limited to only magnetic suspension it means that either my printer is somehow defective (although it very well might be Layer8, due to the numerous improvements I've done), OR I'm severely overestimating the build radius of my printer...

P.S. Can the orthogonal axis correction in M557 be useful if the pillars geometry is off or askew? Or is it only available for cartesian machines?

P.P.S. and slightly offtopic: Whilst fiddling with the settings, my sd card gave up so I had to work out the fw to get the right DWC and had to get a vanilla configuration from the RRFCT and good that I posted here my config.g, to effectively back it up, lol. This saved me from reconfiguring everything from scratch

-

RE: G32 keeps exceeding bounds of M557posted in Tuning and tweaking

OMG, is G32 deprecated? I just now realized that the docs say G29 is bound by M557, not G32... Running G29 seems to abide by the mesh defined in M557......

Ref: https://docs.duet3d.com/User_manual/Reference/Gcodes#m557-set-z-probe-point-or-define-probing-grid

Edit: Is there a way for me to remove G32 from the UI, so I (or anybody else) don't use it by mistake?

-

G32 keeps exceeding bounds of M557posted in Tuning and tweaking

So I've got a delta run by a duet2wifi (hw 1.04, fw 2.05.1, server 1.23) and I've got it set up as follows:

config.g

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Feb 22 2021 09:18:29 GMT+0000 (Greenwich Mean Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"XXXXXXXXX" ; set printer name M665 R105.6 L218 B85 H360 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X100.00 Y100.00 Z100.00 E100.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z-0.1 S1 ; set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; set active high endstops ; Z-Probe M558 P5 I1 H10 F120 T6000 ; set Z probe type to inductive NPN NO type and the dive height + speeds G31 P500 X20 Y17 Z0.69 ; set Z probe trigger value, offset and trigger height M557 X-50:50 Y-50:75 R55 S10 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S286 ; set temperature limit for heater 1 to 285C ; Fans M106 P0 C"Hotend Fan" S0 I0 F500 H1 T45 ; set fan 0 name, value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P1 S1 I0 F500 H-1 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off ; Tools M563 P0 S"Hotend" D0 H1 F0 ; define tool 0 ;G10 P0 X1.7 Y-0.4 Z0 ; set tool 0 axis offsets G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous T0 ; select first tool M501 ; load config-override.g M307 H2 A-1 C-1 D-1 ; map E1 to LEDsconfig-override.g

; config-override.g file generated in response to M500 at 2023-02-21 11:55 ; This is a system-generated file - do not edit ; Delta parameters M665 L209.360:209.360:209.360 R106.827 H341.119 B75.0 X3.711 Y10.092 Z0.000 M666 X-3.596 Y1.408 Z2.188 A0.00 B0.00 ; Heater model parameters M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B1 M307 H1 A307.7 C241.9 D3.7 S1.00 V11.4 B0 M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0 G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00So in theory the G32 should not exceed the

R55 S10OR theX-50:50 Y-50:75of the M557, BUT the damned thing keeps on driving the effector into one of the pillars (that's how I broke the effector already once ) Now, the question is - am I doing something wrong and overriding the M557 bounds anywhere, or what? Cause to me it should be pretty straight forward with these boundaries..

) Now, the question is - am I doing something wrong and overriding the M557 bounds anywhere, or what? Cause to me it should be pretty straight forward with these boundaries..Cheers!

-

RE: D2WF induct Zprobe wiring - won't the high voltage fry my duet?posted in Duet Hardware and wiring

Thanks @dc42 FWIW I did end up wiring it as show in the diagram before waiting for input here it didn't fry the board, so I was happy for a while. Then configured the zprobe correctly, spent like 2 hours correcting the geometry and adding setting to the gcode so it works and it finally did, BUT THEN I broke the effector, so I'm back at square one. I'm logging here the links I used for posterity and for the off chance someone else is in my shoes in the future:

https://duet3d.dozuki.com/Wiki/Connecting_a_Z_probe#Section_Overview

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

https://duet3d.dozuki.com/Wiki/G32

https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer#Section_Auto_calibration

https://docs.duet3d.com/User_manual/Reference/GcodesAlas the new docs don't have any of the useful steps in the old ones, but good they're still there.

I guess the thread can be closed..

-

D2WF induct Zprobe wiring - won't the high voltage fry my duet?posted in Duet Hardware and wiring

Howdy all. It's been a while since I've played with my duet delta and finally got around to printing myself a new better effector with a slot for an inductive zprobe: https://www.thingiverse.com/thing:4571352

Now I'm a bit confused about the wiring: it is an LJ12A3-4-Z/BX which is an NPN NO inductive sensor, according to its specs takes 10-30VIN, HOWEVER, I'm a bit confused with the wiring of the kagigger to my duet2 wifi (v1.04):

- I wired the brown to board VCC (+12V)

- I wired the blue to board VDD (GND)

- The remaining black is the sense, which according to the wiring diagram on the old docs page says SHOULD be capable of being wired directly into the ZPROBE_IN on the header (wiring diagram pic):

But I AM a bit worried wiring the ZPROBE directly. For a while I was thinking of putting in like a buck converter in line to drop it to 3.3V, but wanted to doublecheck with y'all whether this should be okay as-is @12V operational voltage for the probe.

Also I was gonna ask why the hell it also keeps on showing ZProbe 1000 on the UI, and then remembered I hadn't reconfigured the duet from the old limit switch (doh). So I'm gonna fix the config and report again. Hope I don't burn the board in the process

Cheers,

V -

RE: Duet2WiFi net connection inconsistent between VIN and USBposted in Duet Hardware and wiring

It connects to the network with the strongest signal.

@Phaedrux that's great to know. That said, in my case it caused issues and if this were documented anywhere it would've helped me solve my issue a lot sooner.

-

RE: Duet2Wifi either non-levelled bed or weird offsetsposted in Duet Hardware and wiring

So I got a new e3d volcano that i just assembled and ran a quick calibration cube test, which came out kinda okayish.. I think something is wrong with my geometry though - I run delta calibration with the points generated by the reprap config tool online (though I've moved one a bit because the irregular effector interferes with one of the belts). Everything seems to run just fine but then when I run a print with a raft or any other base adhesion aid it seems as if everything is skewed ever so slightly - in one corner seems the nozzle scrapes the bed, in the opposite it seems as if it's squirting molten filament in the air and gobbles it up in big goops during every consecutive pass. Used the edge of a metal ruler to ensure the bed is straight and it is as far as I can see i.e. within 0.1mm edge-to-edge. Perhaps it is worth noting that the bed is a weapons grade chinesium aluminum bed with the heater towards the electronics in the base of the delta and the bare aluminum surface towards the hotend. Not sure whether that is of any importance, or whether I'm doing something insanely stupid by having it all set up like that and I overlook something obvious, so confessing my sins upfront.

Here's the gcode the reprap tool generated:

; bed.g ; called to perform automatic delta calibration via G32 ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Feb 22 2021 09:18:29 GMT+0000 (Greenwich Mean Time) M561 ; clear any bed transform G28 ; home all towers ; Probe the bed at 3 peripheral and 3 halfway points, and perform 6-factor auto compensation ; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g. G30 P0 X0 Y84.9 H0 Z-99999 G30 P1 X68 Y-47 H0 Z-99999 ; <- moved this one to avoid interference with the belt. G30 P2 X-73.53 Y-42.45 H0 Z-99999 G30 P3 X0 Y42.4 H0 Z-99999 G30 P4 X36.72 Y-21.2 H0 Z-99999 G30 P5 X-36.72 Y-21.2 H0 Z-99999 G30 P6 X0 Y0 H0 Z-99999 S6 ; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors ; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)I decided that may be the self calibration is not good enough for the funky heated bed I've got so I followed the calibration guide here and used the escher bed calibration wizard to generate new code:

; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 16 points, 7 factors, probing radius: 80, probe offset (0, 0) G28 G30 P0 X0.00 Y80.00 Z-99999 H0 G30 P1 X51.42 Y61.28 Z-99999 H0 G30 P2 X78.78 Y13.89 Z-99999 H0 G30 P3 X69.28 Y-40.00 Z-99999 H0 G30 P4 X27.36 Y-75.18 Z-99999 H0 G30 P5 X-27.36 Y-75.18 Z-99999 H0 G30 P6 X-69.28 Y-40.00 Z-99999 H0 G30 P7 X-78.78 Y13.89 Z-99999 H0 G30 P8 X-51.42 Y61.28 Z-99999 H0 G30 P9 X0.00 Y40.00 Z-99999 H0 G30 P10 X34.64 Y20.00 Z-99999 H0 G30 P11 X34.64 Y-20.00 Z-99999 H0 G30 P12 X0.00 Y-40.00 Z-99999 H0 G30 P13 X-34.64 Y-20.00 Z-99999 H0 G30 P14 X-34.64 Y20.00 Z-99999 H0 G30 P15 X0 Y0 Z-99999 S7It constantly runs into errors like "Z probe already triggered at start of probing move" due to from what I can see the hotend not going back up between moves and essentially dragging the hotend across the bed towards the mid-test-points.

P.S. While writing this I notice the wizard generated code has no H-values like the reprap one does. I'll experiment with that and report.

-

RE: Duet2WiFi net connection inconsistent between VIN and USBposted in Duet Hardware and wiring

Hmm may be the card was indeed slow - ran a couple of tests with AJA (for the lack of a better tool on this machine) and it dipped below the rated by class 4 4MB/s sequential writes:

Disk Write Test Number of frames = 193 Write rate = 1 frames/second Write rate = 5 MB/second Minimum rate = 3 MB/Sec <-- this should not happen Maximum rate = 7 MB/SecDug in my drawer and found an elecom class4 card that was much faster (avg 14-15MB/s) and moved all files to it, though that didn't end up solving the issue, however, I think I did solve it eventually:

When I got the board, it had 1 testing network stored and I initially added my IOT guest network's SSID, but later changed my mind and moved the board to my main network. Today I dropped all unnecessary ones with

M588and all of the sudden the board consistently connects to the wifi every single time. May be it's worth looking into the firmware what logic the board uses which ssid to connect to or at least to specify in the setup guide to look out for, but this definitely explains also the multiple blink sets instead of having just the one as it does now.In any case I think we can consider the matter resolved. Thanks for the help!

-

RE: Duet2Wifi weird extruder jitterposted in Duet Hardware and wiring

The new volcano arrived a couple of days ago and I just finished assembling and reconfiguring the

config.gto the new dimensions - the jitter turns out as suspected was due to a blockage in either the cold side or the heatbreak. Either way the new hotend now works just fine, except there's obviously some geometry quirks i need to take care (in a separate thread though).This matter could be considered resolved. Thanks for the help!

-

RE: Duet2Wifi either non-levelled bed or weird offsetsposted in Duet Hardware and wiring

I might have used a longer screw for one of the sides of the hotbed which might've skewed it or made it wobbly (doh) . Once I fix the other issues with the hotend/extruder I'll revisit this one too to see whether there's any additional compensation I should go for.

Cheers!

-

RE: Duet2Wifi weird extruder jitterposted in Duet Hardware and wiring

It appears I had a blockage - I swapped the bowden a while ago and it came with new PTFE tubing fittings which apparently aren't as deep as the old ones, creating a void in the cool side of the hotend thus creating space to clog with molten filament that won't melt away the next time i turn on the heat element. It is weird that the fan won't turn on until the hotend reaches the specified temperature as this allows for heat creep up the hotend to the cool side. In any case this hotend was due a swap so I'll order one from e3d which probably would be better to begin with than this cheap chinesium I bought the printer with.

Any idea how to keep PWM on the fan but have it on as soon as the heater goes on? I assume it'd be some g-code command I need to slip into the

config.g? -

RE: Duet2WiFi net connection inconsistent between VIN and USBposted in Duet Hardware and wiring

Apologies, completely forgot about the

config.g:+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Feb 22 2021 09:18:29 GMT+0000 (Greenwich Mean Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"SomeHostName" ; set printer name M665 R105.6 L218 B85 H317 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X100.00 Y100.00 Z100.00 E100.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z-0.1 S1 ; set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; set active high endstops ; Z-Probe M558 P4 H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height M557 R85 S20 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S350 ; set temperature limit for heater 1 to 350C ; Fans M106 P0 C"Hotend Fan" S0 I0 F500 H-1 ; set fan 0 name, value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H-1 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off ; Tools M563 P0 S"Hotend" D0 H1 F0 ; define tool 0 G10 P0 X2.8 Y-2.2 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous T0 ; select first tool M501 ; load config-override.g M307 H2 A-1 C-1 D-1 ; map E1 to LEDsNot that it should matter but since i moved the hotend fan from the PWM headers to a constantly on one.

As to the SD card - I use whatever I got installed and shipped with when i bought the board from E3D in the UK. In this case it's a SanDisk Edge (never heard of the edge lineup before). Happy to swap the card for a brand new SanDisk Ultra if that's what you reckon causes the issue?

-

RE: Duet2WiFi net connection inconsistent between VIN and USBposted in Duet Hardware and wiring

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 2.05.1 running on Duet WiFi 1.02 or later Board ID: 0JD0M-9P6M2-NW4SS-6J9DJ-3S46K-1TY3M Used output buffers: 3 of 24 (9 max) === RTOS === Static ram: 25712 Dynamic ram: 92636 of which 364 recycled Exception stack ram used: 408 Never used ram: 11952 Tasks: NETWORK(ready,628) HEAT(blocked,1232) MAIN(running,388) IDLE(ready,160) Owned mutexes: === Platform === Last reset 00:08:35 ago, cause: power up Last software reset at 2021-02-22 23:52, reason: User, spinning module GCodes, available RAM 11944 bytes (slot 2) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d Error status: 0 Free file entries: 9 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest block write time: 7.6ms, max retries 0 MCU temperature: min 30.3, current 39.0, max 39.1 Supply voltage: min 10.5, current 11.6, max 12.0, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: ok, SG min/max 0/327 Driver 1: ok, SG min/max 0/475 Driver 2: ok, SG min/max 0/493 Driver 3: ok, SG min/max not available Driver 4: standstill, SG min/max not available Date/time: 2021-02-23 21:03:30 Cache data hit count 1550935955 Slowest loop: 19.37ms; fastest: 0.06ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Move === Hiccups: 0, FreeDm: 140, MinFreeDm: 136, MaxWait: 265901ms Bed compensation in use: none, comp offset 0.000 === DDARing === Scheduled moves: 190, completed moves: 150, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.5 === GCodes === Segments left: 0 Stack records: 2 allocated, 0 in use Movement lock held by null http is idle in state(s) 0 telnet is idle in state(s) 0 file is doing "G1 X22.124 Y18.129 E0.02169" in state(s) 0 serial is idle in state(s) 0 aux is idle in state(s) 0 daemon is idle in state(s) 0 queue is idle in state(s) 0 autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 84.62ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 - WiFi - Network state is running WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.23 WiFi MAC address f4:cf:a2:e2:09:11 WiFi Vcc 3.38, reset reason Turned on by main processor WiFi flash size 4194304, free heap 23168 WiFi IP address 192.168.11.11 WiFi signal strength -52dBm, reconnections 0, sleep mode modem Socket states: 0 0 0 0 0 0 0 0Yes, the LED stops blinking (usually it does do two sets of blinks though, i.e. 3 blinks, short stop while it's on then another 3 blinks and then solid again). I noticed today also that it didn't boot correctly over usb either - I tried 2-3 times and the web ui never booted, plus the serial terminal couldn't connect - tried on two separate ports just in case.

Measured the 3.3 and 5V buses - the 3.3 bus reads 3.29-3.30 - even though I'm not measuring with a fluke meter, but with some chinesium with questionable accuracy, it should be within spec. The 5V bus was 4.98-5.00 too. The VIN is at 11.80, so I might tweak the pot to get an even 12V in the PSU, though I doubt it to be the issue given the steady voltages on these two buses.

-

Duet2Wifi either non-levelled bed or weird offsetsposted in Duet Hardware and wiring

I just got a Duet2WiFi to replace my kossel's MKSMini that got the extruder driver blown. Just finished the rewiring and initial setup and I'm experiencing a few issues for which I'll cut separate threads so if I get to resolve them, others can easily find the fixes for their issues in the future.

2/22/2021, 11:17:12 PM M115 FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2020-02-09b1So Problem #3 is I started printing a calibration cube to check the dimensions and calibration and I noticed on one side the hotend as if scraping the hotbed and on the other squirting tons of filament. I obviously stopped the print, but it was weird. Did auto-calibration a bunch of times and it didn't register any significant geometry skews to compensate for. That said I noticed that the nozzle wasn't spot on the center of the hotbed and whilst homing there was some minor X and Y offset I fixed in the

config.gwith aG10. I'm yet to retry the test (experiencing more pressing issues atm with it) but what else could I do to compensate if autoleveling doesn't fix the issue? -

Duet2Wifi weird extruder jitterposted in Duet Hardware and wiring

I just got a Duet2WiFi to replace my kossel's MKSMini that got the extruder driver blown. Just finished the rewiring and initial setup and I'm experiencing a few issues for which I'll cut separate threads so if I get to resolve them, others can easily find the fixes for their issues in the future.

2/22/2021, 11:17:12 PM M115 FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2020-02-09b1So Problem #2 is with the extruder: With the MKSMini I used to hook the printer via USB to my computer and used RepetierHost to drive the prints (with somewhat variable quality) but the whole point of getting a network enabled board like the duet was to make sure I can print stuff without locking the laptop to drive it. Long story short I hooked the printer to Cura via the Cura Duet plugin and started printing a calibration cube to verify my calibration and dimensions. Pretty soon the extruder (bowden) started experiencing some weird jitter, i.e. it acted as if it were pushing filament in the tube and by extension the hotend, but every mm or so it retracted. At first I decided I might've messed up the wiring (I didn't) or that the motor is bad - after all the issue with my previous controller was the extruder driver. May be one of the phases was bad? Even though I had it tested before with

M302 P1and through the DWC UI. It extrudes and retracts just fine, so it wasn't that. I cross-referenced with another motor (swapped it with X) and the motor seemed to be just fine.Now the question is could it be the slicer? With Repetier I used Slic3r so may be I messed up the cura config? It does act as if either the hotend was cold and the extruder wasn't able to push filament through, or as if there was jenky signal being sent to it. What should I check to troubleshoot this further?