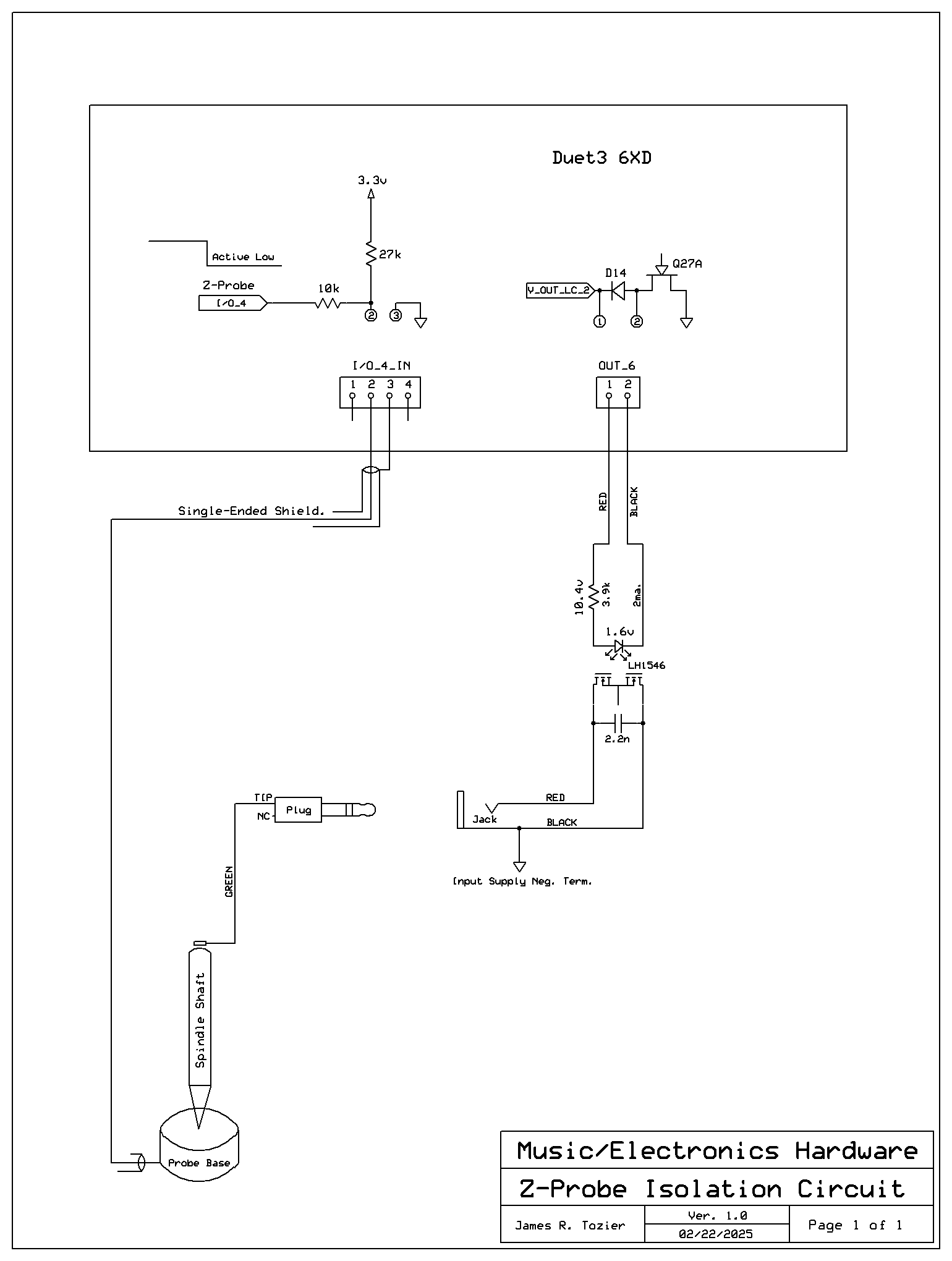

FYI, This is the schematic for my Z-Probing, with an isolated spindle motor. The tool collet is only at circuit ground, during the Probing cycle.

FYI, This is the schematic for my Z-Probing, with an isolated spindle motor. The tool collet is only at circuit ground, during the Probing cycle.

Posts made by Valveman

-

RE: Add Relay to Z-Probe macroposted in CNC

-

RE: Add Relay to Z-Probe macroposted in CNC

@dc42 Sorry, I forgot to reply the subject as 'Solved'.

-

RE: Add Relay to Z-Probe macroposted in CNC

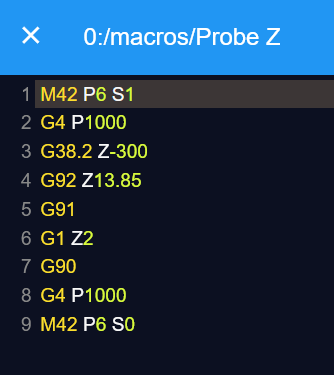

Well, it took this old geezer long enough, but it works perfectly. -

RE: Add Relay to Z-Probe macroposted in CNC

Thanks so much for your assistance. My son has been texting the same info, but I'm still learning to fully understand implementation. M42 will have a P value [got that part], but is the S value a 1=0n and 0=off?

-

RE: Add Relay to Z-Probe macroposted in CNC

My 6XD board has OUT_6, 2-Pin KK available. Can it be used as my on/off 12vdc for a small signal relay?

-

Add Relay to Z-Probe macroposted in CNC

My 'Job' for Z-Probing is:

1 G38.2 Z-300

2 G92 Z13.85

3 G91

4 G1 Z2

5 G90

I want to the same 'Job' to include powering on a 12vdc relay, until the probing has finished.

Can all you smart people educate me?

Thanks in advance, Ron. -

RE: DWC revision for CNC useposted in CNC

Thanks for the great advice. Hope to finish an ongoing project this weekend, then plan to update. Don't want to take any unnecessary chances, that might cause unexpected results.

-

DWC revision for CNC useposted in CNC

I'm currently running with 3.4.5 and just wondering if I should upgrade to a more current version, for operating my augmented Indy-Mill engraving aluminum router.

Thanks, Ron -

RE: Are Z offsets possible?posted in CNC

Well....... Duh. Yes Sir, that's what I need! excuse my novice ignorance. I'm guilty of reading thru the tutorials much too fast. I will try my best to comprehend that whole Mesh process. Might need help to fully grasp the challenge. I've never tried to 'edit' the Gcode before, for fear of ruining it. Give me some time to experiment. Should I post my config.g for scrutiny?

-

Are Z offsets possible?posted in CNC

After running a bed-leveling macro, is it possible to 'record' multiple values of Z-probing made across the bed surface? Then implement those values to create offsets for Z, that results in a near perfectly flat surface. While my talents lie mostly with electronic design and playing guitar, I'm a fish out of water when it comes to programming.

-

RE: Simple bed leveling programposted in CNC

Having great success using LightBurn to create a path for fly-cutting a thin layer off the sacrificial table.

-

RE: Cancel Print/Job not immediate.posted in CNC

@droftarts Well, that's a lot of information for me to digest! Lol. Might I see an example of code where M669 has been implemented?

-

RE: Cancel Print/Job not immediate.posted in CNC

@jay_s_uk said in Cancel Print/Job not immediate.:

M669 T1 S1

Thanks for the suggestion, but I'm not very keen on how to implement what you're talking about.

-

RE: Simple bed leveling programposted in CNC

@Valveman I'm expecting a new cutter today. Plan to post my results asap.

-

Cancel Print/Job not immediate.posted in CNC

If some reason, I choose to cancel a Job that is running, cancel only takes affect after the current motion has completed. Is that normal, as I'm new to all of this? Is an update to DWC or the 6XD a solution?

-

RE: Simple bed leveling programposted in CNC

@o_lampe said in Simple bed leveling program:

nested for X/ for Y loops

You got me thinking. So I just made an additional 'layer' to my projects' file, and labeled it bed-leveling. I then exported that G-code file to my SD card, and viola, it works! first time ever making anything move from scratch. Thanks so much for your assistance.

Ron -

Simple bed leveling programposted in CNC

I'm not much of a programmer. Electronics and music are my forte. Completed the rebuild of my bench-top cnc router, and need a simple X-Y program that I can run a fly-cutter up and down the bed, in order to level it out. I use LightBurn to draw my projects, then use it to send G-code to the DWC, which then controls my 6XD mainboard. Everything is working really well, but the removable wood base needs to be leveled with a cutter, before attempting any engraving.

-

RE: G-code file rotationposted in Gcode meta commands

@Valveman My thinking is that the tilted layout, is the result of the Fusion-generated code done by my son. I'm going to have him send me an older version, prior to it being tilted, and see what happens. By the way, how can I post the code for you all to examine?