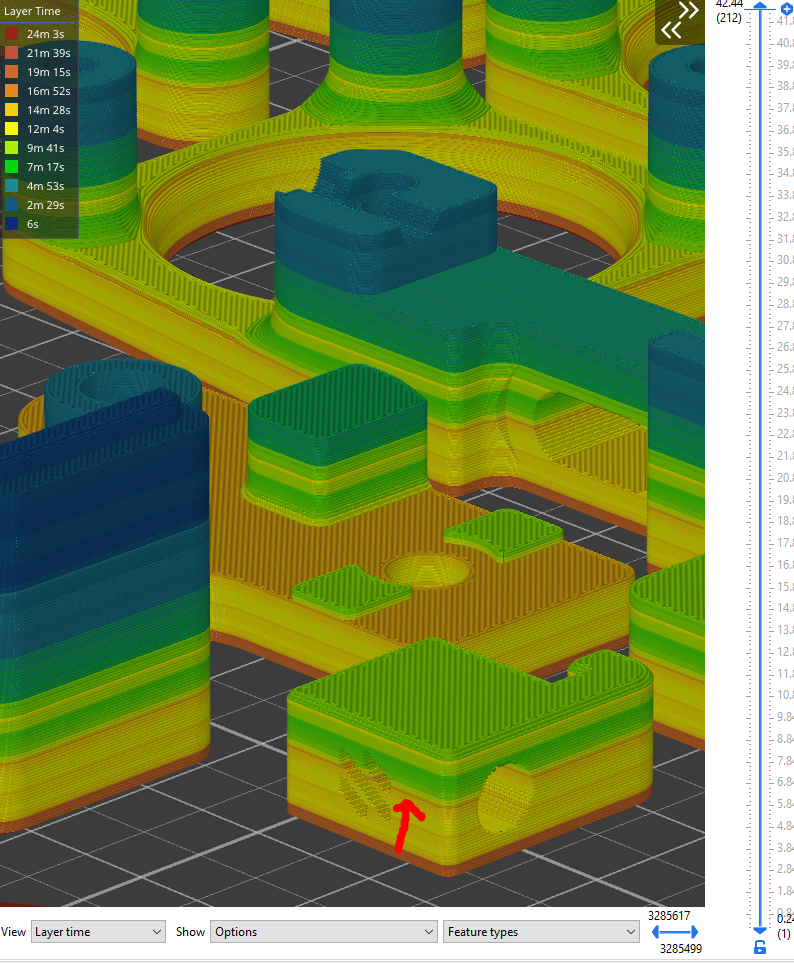

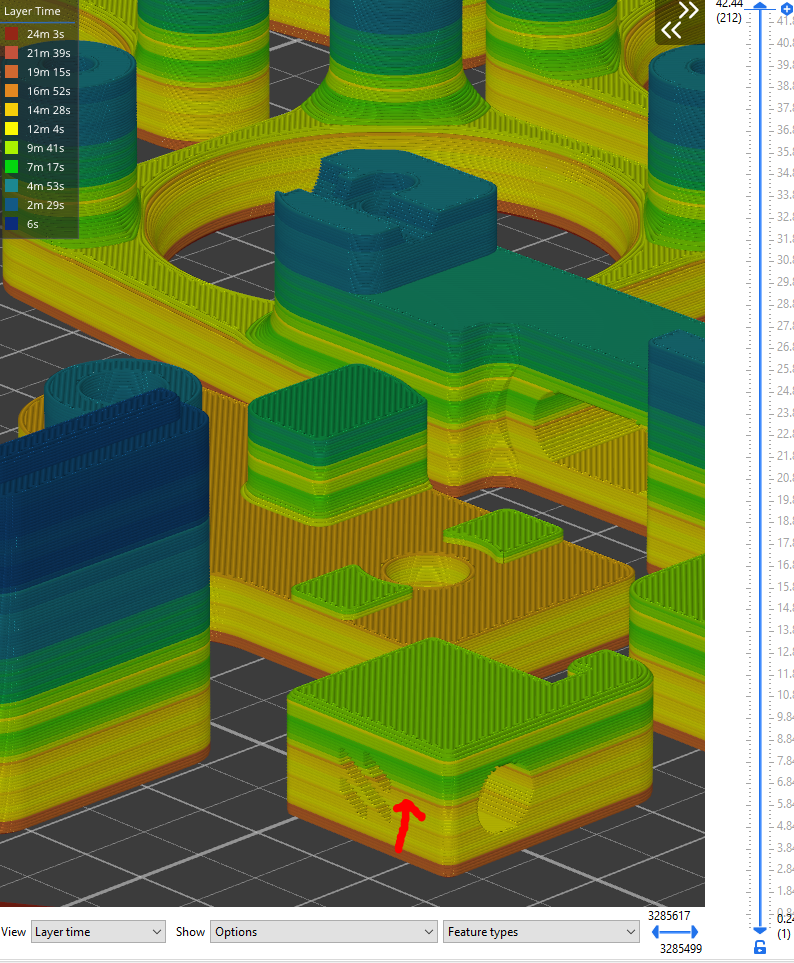

@dc42 i can tell theres a layer time difference, due to that layer being the top surface for some other objects on the plate. perimeter print direction stays consistent though.

Posts made by Turbo

-

RE: Artifact Line Possibly Related To Layer Time?posted in Tuning and tweaking

-

RE: Artifact Line Possibly Related To Layer Time?posted in Tuning and tweaking

@o_lampe not using solid infill at _ layers. difference between the two layes is about 2-2.5mm, but artifacting doesnt show on the lower one. taper off is not in use due to use of klipper

-

RE: Artifact Line Possibly Related To Layer Time?posted in Tuning and tweaking

@dc42 No its only related to this bed, although similar artifacts can be predicted by the layer time visualizer, and 9/10 times it shows exactly where the line wil be

-

RE: Artifact Line Possibly Related To Layer Time?posted in Tuning and tweaking

@phaedrux printer was preheated/heatsoaked for 2 hours before printing. most of the thermal expansion is done by then

-

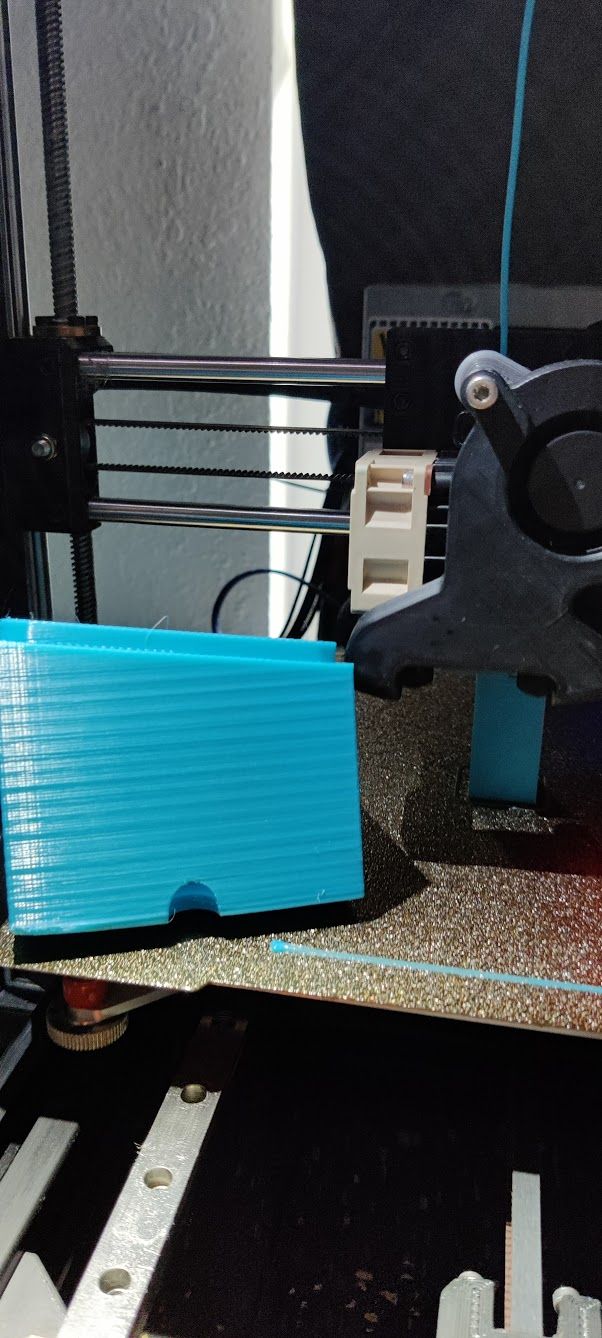

Artifact Line Possibly Related To Layer Time?posted in Tuning and tweaking

Having some issues with a line showing up in my print. Upon investigating, it looks and measures (approx 5mm from plate) like the line is exactly lined up with a change in layer time in the slicer. Any thoughts on the cause and possibly how to resolve the issue? this was approx a 14 hr plate.

-- Printing ABS+ -- Direct Drive -- CoreXY Voron 2.4 -- locked to 30% cooling after first 3 layers

-

RE: Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

@paulhew Well aware that extrusion mult = flow. I tried an lgx extruder cause why not, but got some z banding issues outta nowhere and the for some reason wasn't able to reach as high of a volumetric flow rate (despite current adjustments and temp increases), so i went back to clockwork. As for the x axis. its already on the single MGN12.

Already went through the rail alignment process, and considered the improved duct, but im getting fantastic overhangs with the current setup so i dont want to change it too much (always on 25% 65% for bridging. Maybe thats too muchand is making the abs shrink too quickly?).My v0 is also for on the go, and rarely gets turned on while im home. The pi has its own network setup so i dont need wifi to use it.

-

RE: Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

@phaedrux im 99% sure its mechanical, but idk where to look. ive already made sure theres no racking/friction issues. as for tension on the filament, im hitting the expected volumetric flow of the mosquito hotend without skipping (0.5a on motor), so i dont think its an issue?

-

RE: Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

@ccs86 i dont believe it to be a software issue though. im trying to think of any mechanical issues that could be causing it, besides friction. Because ive quadruple checked that theres no racking or bad movement on all axis

-

RE: Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

@paulhew so ive gone through that checklist, and i keep getting stuck on flow, cause my parts are coming out undersized. i did a 45 deg cube, and it showed perfect on one edge, and undersized by around .15-.2mm across a 20mm cube. Logic says that theres some friction on that drive right? well i cant find any, no racking, equal tension, nothing i can find is wrong. heat soak is done for about an hour as well, until i see the hotend thermistor hit 50c (kinda as a chamber temp gauge. i know its on the low end but it worked fine for my other printer).. thoughts?

I havent gotten much valuable info from the discord since things just keep moving and getting buried unanswered, so i came back to where i know i could get some good answers, as i have 2 other printers running duet. Didnt know they were banning people for talking about an issue. its not issue no. 6 is it?

This thing is causing me more headaches than any other printer. while its a great design, i just cant keep smacking my head against the wall like this. -

RE: Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

@engikeneer ill try a 45 deg rotated cube to see what happens

-

RE: Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

@ccs86 it is direct drive. It is a Voron 2.4 printer. Gcode looks fine and doesnt have any anomalies. firmware is klipper so i dont know what good itll do being posted here.

-

RE: Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

@ccs86 doing a standard 30mm box, measurements range fron 29.8-29.9mm, with the lowest measurements near the center of each edge. There is no pressure advance enabled as to keep it out of the equation.

-

RE: Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

doing a single walled print yields similar results, with two being undersized, and two being oversized when compared to the line width.

-

Inequal Wall Thickness When Testing Flowposted in Tuning and tweaking

Doing some double walled tests to determine flow after calibrating steps/mm, and each wall is showing a different measurement.

line width is set to 0.4, so the expected outcome is 0.8mm wall thickness with two perims, however all 4 faces measure different. Measurements vary anywhere between 0.75mm up to 1.1mm. This is a repeatable issue and have recorded it on 7 different boxes, with no changes with different slicers. No retraction or pressure advance is enabled. What could be my issue?0.4mm line width set to 80mm/s locked

2 walls

this is tuning for abs on my corexy system -

Z Banding only on certain, usually larger objectsposted in Tuning and tweaking

Not sure why, but only on larger prints am i seeming to get this odd z banding issue with prints. I switched software from superslicer to cura, and the issue followed. This sounds like a leadscrew issue right? I would be convinced it was, if the issue was reproducable on smaller objects. the effect only seems to be present when a long straight on the print is present, because even my larger print with more direction changes looks good. Maybe something is wrong with the .stl? would someone else be able to test that theory for me (https://www.thingiverse.com/thing:2083528)? I'm not sure at this point, and ive even had similar issues on my belted z axis machine, so i cant tell if its a software or hardware deal. the filament seems to be consistent, but ill try another brand in the meantime.

Ive tried different leadscrews, top and no top support, different couplers and the threaded brass piece (name is blanking right now), pid tuning on bed and hotend, Different lubrication, realignment of the x axis. nadaAny advice helps, but understand i have tried many things, short of just getting rid of the leadscrews for a corexz approach.

. See image below

-

RE: Pulley VS beltsposted in Tuning and tweaking

@fcwilt yes. with some slight modifications that wouldnt change anything. i also have a linear rail compatible version.

-

RE: Pulley VS beltsposted in Tuning and tweaking

@fcwilt referring to the z axis? no not really, besides the bed and its frame. but id be happy to share the cad files if that's something you're looking into. the rest of the build is pretty standard dbot, aside from gantry being dual extruder

-

RE: Pulley VS beltsposted in Tuning and tweaking

@fcwilt

This is my build. uses a belted z axis and linear rails for the z axis. this pic shows rollers, but ive since updated it, and alot of other things. works really well with a planetary gear reducer one a single nema 17 motor.