@phaedrux I had this volcano way before the silicone socks ever came about.

I have some of the hose printrbot used on their ubis got end but the heat makes it tear. Maybe it was meant for a lower heat.

Posts made by trublu89

-

RE: auto calibrationposted in Tuning and tweaking

-

RE: auto calibrationposted in Tuning and tweaking

@phaedrux I didn't add the 501 I just entered m500.

It said temperature excursion went from 230 to 250. I think the fan might have been too high I tried to make it to where it cuts on but low not on high but it still is 60 or 80 percent.

-

RE: auto calibrationposted in Tuning and tweaking

@fcwilt also what would cause temperature excursion. I have paid tuned several times with and without the fan on.

-

RE: auto calibrationposted in Tuning and tweaking

@fcwilt this is g29 initially and then g29 with s1 at startup code right?

-

RE: auto calibrationposted in Tuning and tweaking

@phaedrux nope is there a way to just move one z motor instead of all?

-

RE: auto calibrationposted in Tuning and tweaking

I didn't realize there was a gap in my m671

That's how I came up with .192 homing to where the paper grabbed the nozzle and g92 z=0 g30 s1 to get the mean results.

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Fri Dec 17 2021 18:35:59 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F108000 ; lift Z relative to current position G1 H1 X-565 Y-535 F1800 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-565 ; home X axis G1 H1 Y-535 ; home Y axis G1 X5 Y5 F108000 ; go back a few mm G1 H1 X-565 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-535 ; then move slowly to Y axis endstop G90 ; absolute positioning G1 X32 Y50 F108000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed; config-override.g file generated in response to M500 at 2022-05-14 23:47 ; This is a system-generated file - do not edit ; Heater model parameters M307 H1 R1.925 K0.303:0.261 D5.51 E1.35 S0.90 B0 V12.2 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00What is the config overide g? I never really looked in there.

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.0 (2022-03-15 18:58:31) running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DGM-956GU-DJMSN-6JKF2-3S86L-TBRVG Used output buffers: 3 of 24 (16 max) === RTOS === Static ram: 23868 Dynamic ram: 74744 of which 0 recycled Never used RAM 13468, free system stack 184 words Tasks: NETWORK(ready,12.4%,247) HEAT(notifyWait,0.0%,332) Move(notifyWait,0.0%,364) DUEX(notifyWait,0.0%,24) MAIN(running,87.0%,440) IDLE(ready,0.5%,30), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:02:37 ago, cause: power up Last software reset at 2022-05-14 19:46, reason: User, GCodes spinning, available RAM 13264, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 0 MCU temperature: min 29.6, current 36.9, max 37.2 Supply voltage: min 12.3, current 12.4, max 12.5, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min n/a Driver 1: standstill, SG min n/a Driver 2: standstill, SG min n/a Driver 3: standstill, SG min n/a Driver 4: standstill, SG min n/a Driver 5: standstill, SG min n/a Driver 6: standstill, SG min n/a Driver 7: standstill, SG min n/a Driver 8: standstill, SG min n/a Driver 9: standstill, SG min n/a Driver 10: Driver 11: Date/time: 2022-05-15 16:48:09 Cache data hit count 4294967295 Slowest loop: 135.24ms; fastest: 0.19ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 1.2ms, write time 60.6ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0 sensor: ok === DueX === Read count 1, 0.38 reads/min === Network === Slowest loop: 111.91ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.26 WiFi MAC address 5c:cf:7f:76:72:b4 WiFi Vcc 3.39, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24952 WiFi IP address 10.0.0.18 WiFi signal strength -66dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 4 0 0 0 0 0 0 0M98 P"config.g" HTTP is enabled on port 80 FTP is disabled TELNET is disabledIt stops before reaching it in the rear right corner I adjusted the screw manually and eventually it will still do it.

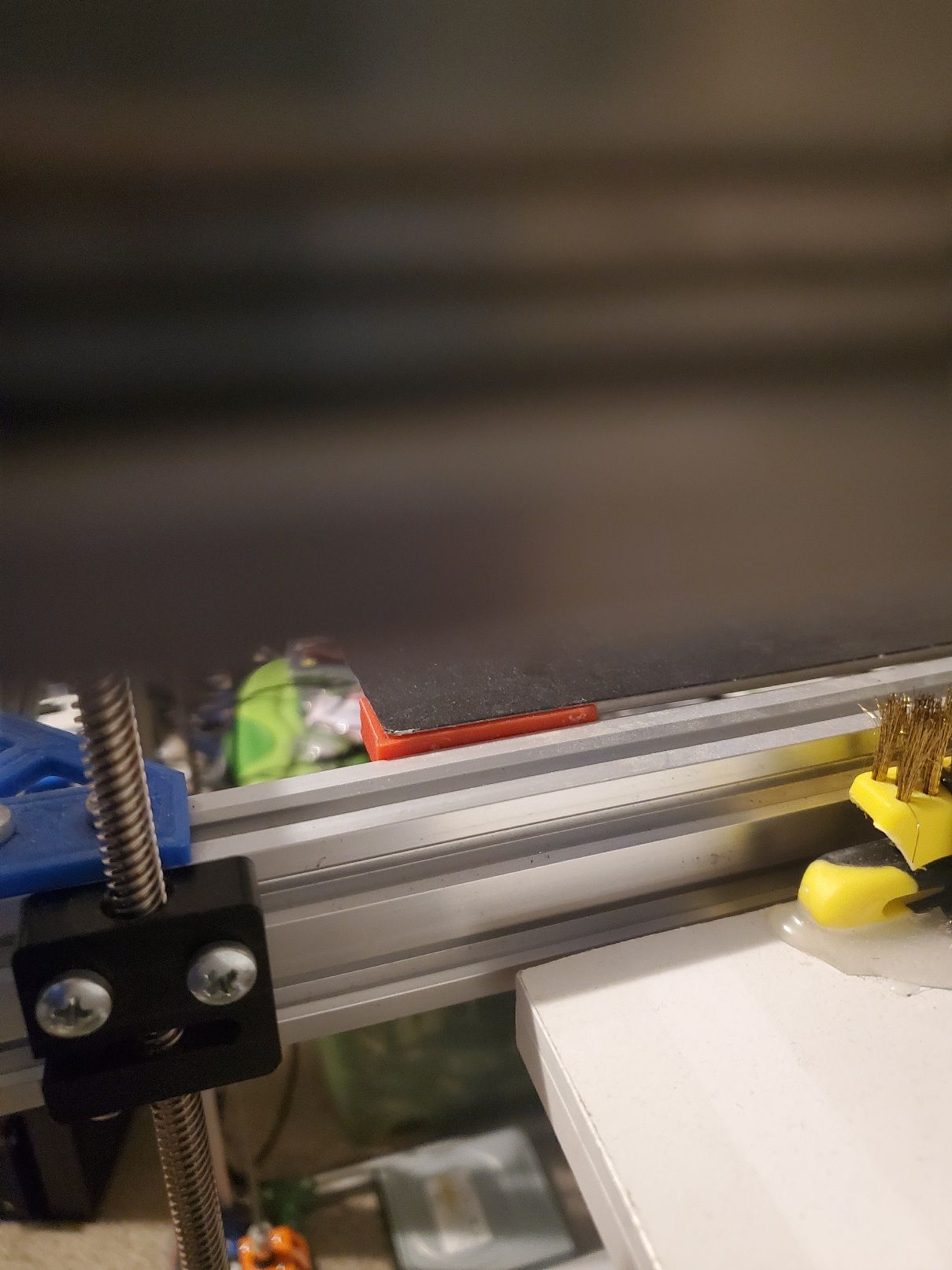

The build surface I have is buildtak.

-

RE: auto calibrationposted in Tuning and tweaking

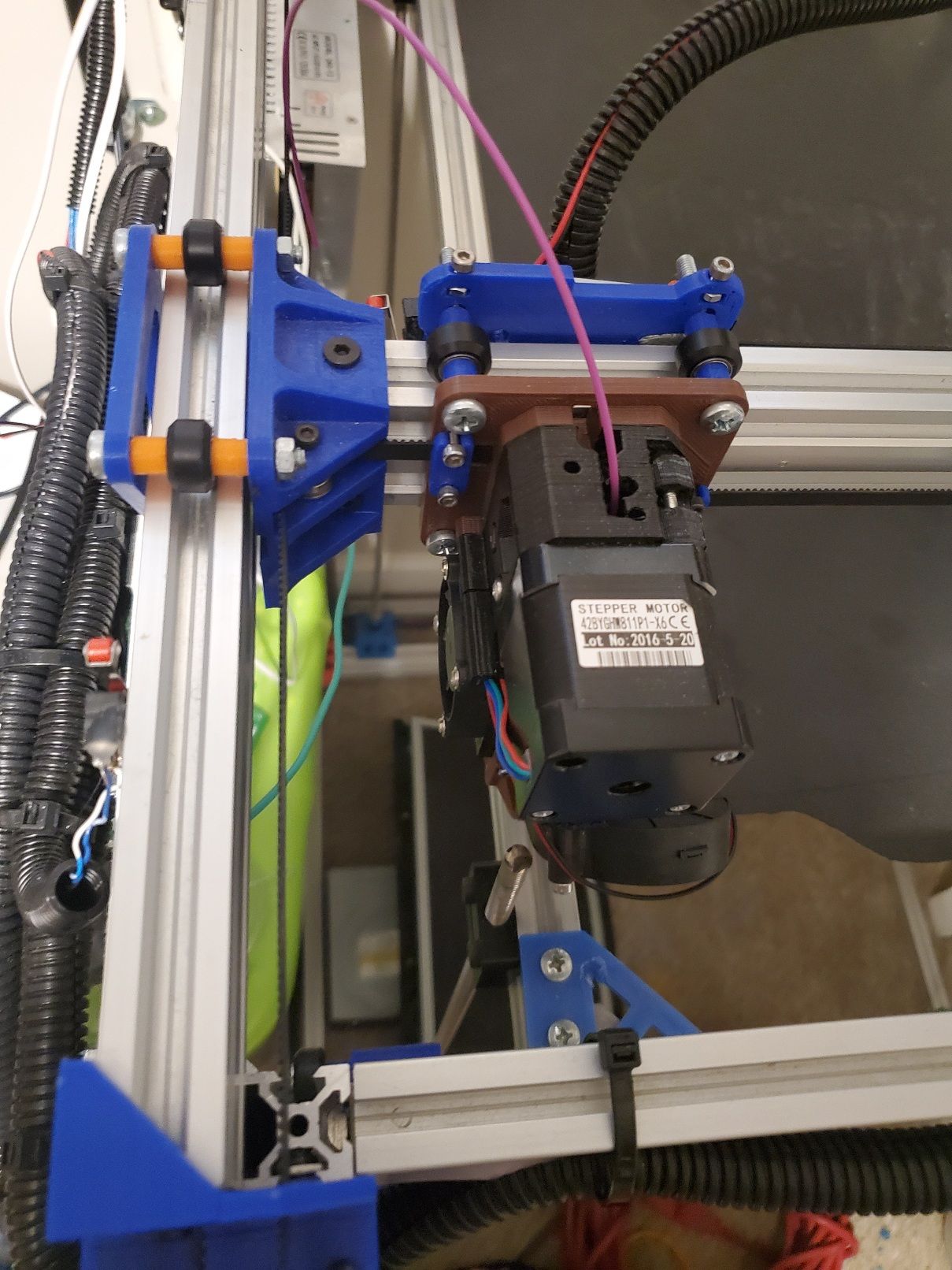

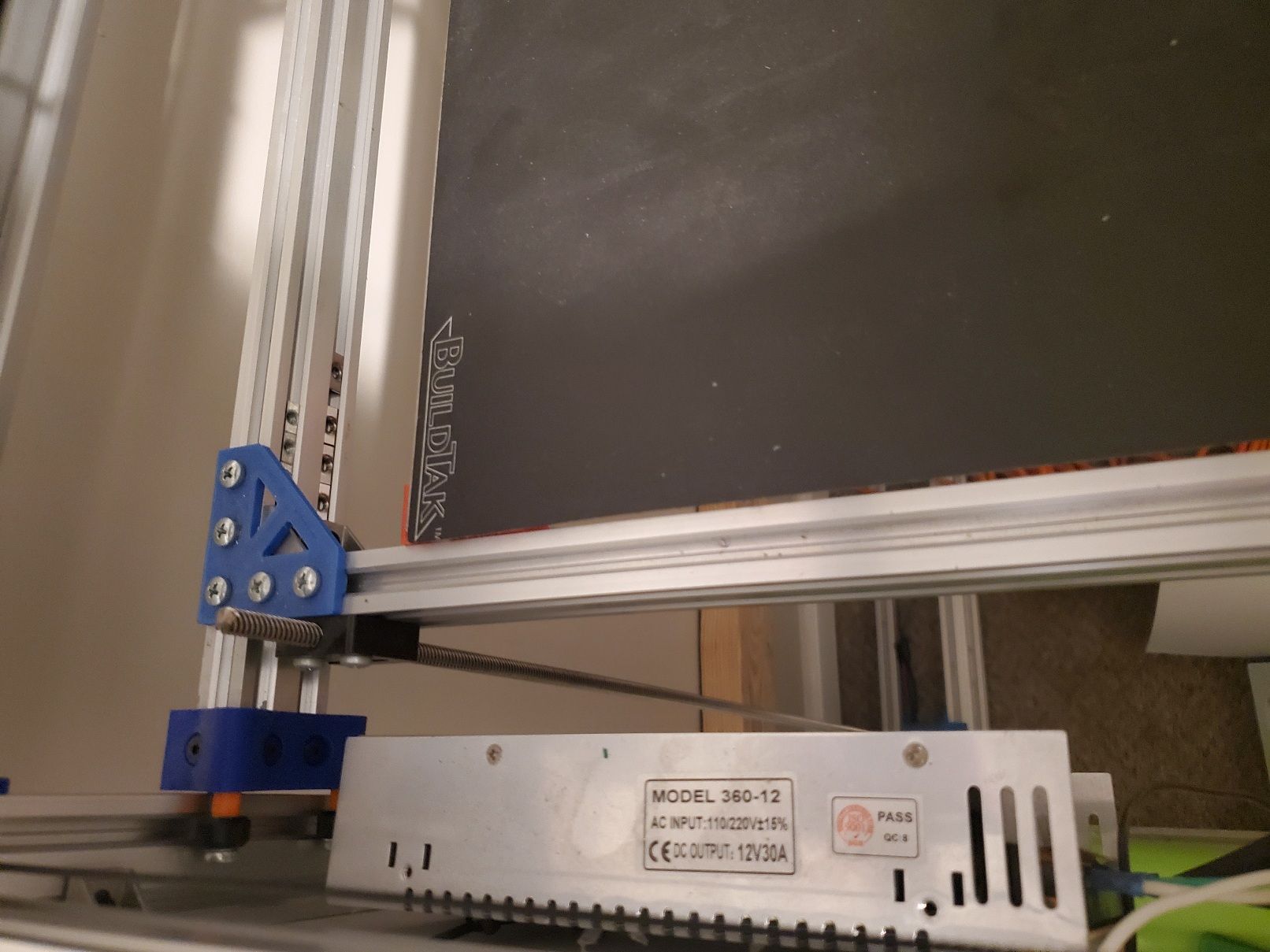

I have the ir probe and my lead screws are independent driven by motors.

-

RE: auto calibrationposted in Tuning and tweaking

right before it tries to trigger it will just stop and error out probe was not triggered during move.

-

RE: auto calibrationposted in Tuning and tweaking

@phaedrux it won't even crash it will just stop before reaching it. And sometimes the margin of error is -9.

Now I'm getting a temperature excursion error I'm printing at 230 it will jump to 250 I paid tuned several times. Tried with fan on didn't realize the fan comes on with the newer firmware.

-

RE: auto calibrationposted in Tuning and tweaking

@fcwilt I've been out of the 3d printing loop for a while lol. I'm using the ir height sensor. I never really set offsets for the probe it just worked.

so would I use a G92 to set z to zero?

-

auto calibrationposted in Tuning and tweaking

Hello all, I have been fighting with trying to get this corexy calibrated to get a consistent first layer all day. It seems like one minute it's fine then the next its back out of skew.

I'm running a core xy with 4 lead screws. I tried using g32 and now g29 both work fine one minute then one of the points wont trigger. ```

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Fri Dec 17 2021 18:35:59 GMT-0600 (Central Standard Time) G28 ; home G30 P0 X50 Y25 Z-99999 ; probe near a leadscrew G30 P1 X50 Y420 Z-99999 ; probe near a leadscrew G30 P2 X480 Y420 H-2 Z-99999 ; probe near a leadscrew G30 P3 X480 Y25 H-1 Z-99999 S4 ; probe near a leadscrew and calibrate 3 motors; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M569 P5 S0 M569 P6 S0 M584 X0 Y1 Z2:4:5:6 E3 ; set drive mapping M350 X16 Y16 Z16:16:16:16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00:400.00:400.00:1600.00 E158.49 ; set steps per mm M566 X900.00 Y900.00 Z20.00:20.00:20.00:20.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X24960.00 Y24960.00 Z24960.00:24960.00:24960.00:24960.00 E7980.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z80.00:80.00:80.00:80.00 E500.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z950:90:950:950 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X520 Y480 Z790 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on x via pin ystop M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P1 C"zprobe.in" H6 F120 T10000 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z0.192 ; set Z probe trigger value, offset and trigger height M557 X45:485 Y50:424 S80 ; define mesh grid ; Heaters ;M140 H-1 ; disable heated bed (overrides default heater mapping) ;M308 S0 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor ;M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0 ;M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;M143 H0 S270 ; set temperature limit for heater 0 to 270C ;M570 S360 ; allow one minute for fault detection ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ; Heaters ;M308 S0 P"bedtemp" Y"thermistor" T100000 B4267 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp ;M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 ;M143 H0 S130 ; set temperature limit for heater 0 to 130C ;M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H-1 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4267 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S275 ; set temperature limit for heater 1 to 275C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;Lead screw position M671 X45:45:485:485Y45:424:424:45 s5 ; Tools M563 P0 D0 H1 F0 ;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets ;G10 P0 R0 S0 T0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory ; Automatic power saving M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power lossattached are my bed and config files.

-

RE: Homing crashesposted in Tuning and tweaking

@fcwilt the standard 8mm from open builds.

I had a stepper motor with gearbox never thought to use that.

-

RE: Homing crashesposted in Tuning and tweaking

@fcwilt

Originally it was a 3 lead screw system but the weight causes it to fall so I recently added the fourth and haven't been able to begin calibrating of dialing in the 1.2 nozzle. -

RE: Homing crashesposted in Tuning and tweaking

@fcwilt

I'm kinda stuck with what I have right now. Maybe I can reduce the size of the bed by moving y back. That should clear hitting the fan or lead screw. -

RE: Homing crashesposted in Tuning and tweaking

Attached is where I home to. So I should move my limit switches?

-

RE: Homing crashesposted in Tuning and tweaking

@fcwilt

I home to the front left corner. If I home y without moving I will strike the z axis lead screw or fan. -

Homing crashesposted in Tuning and tweaking

Hello all,

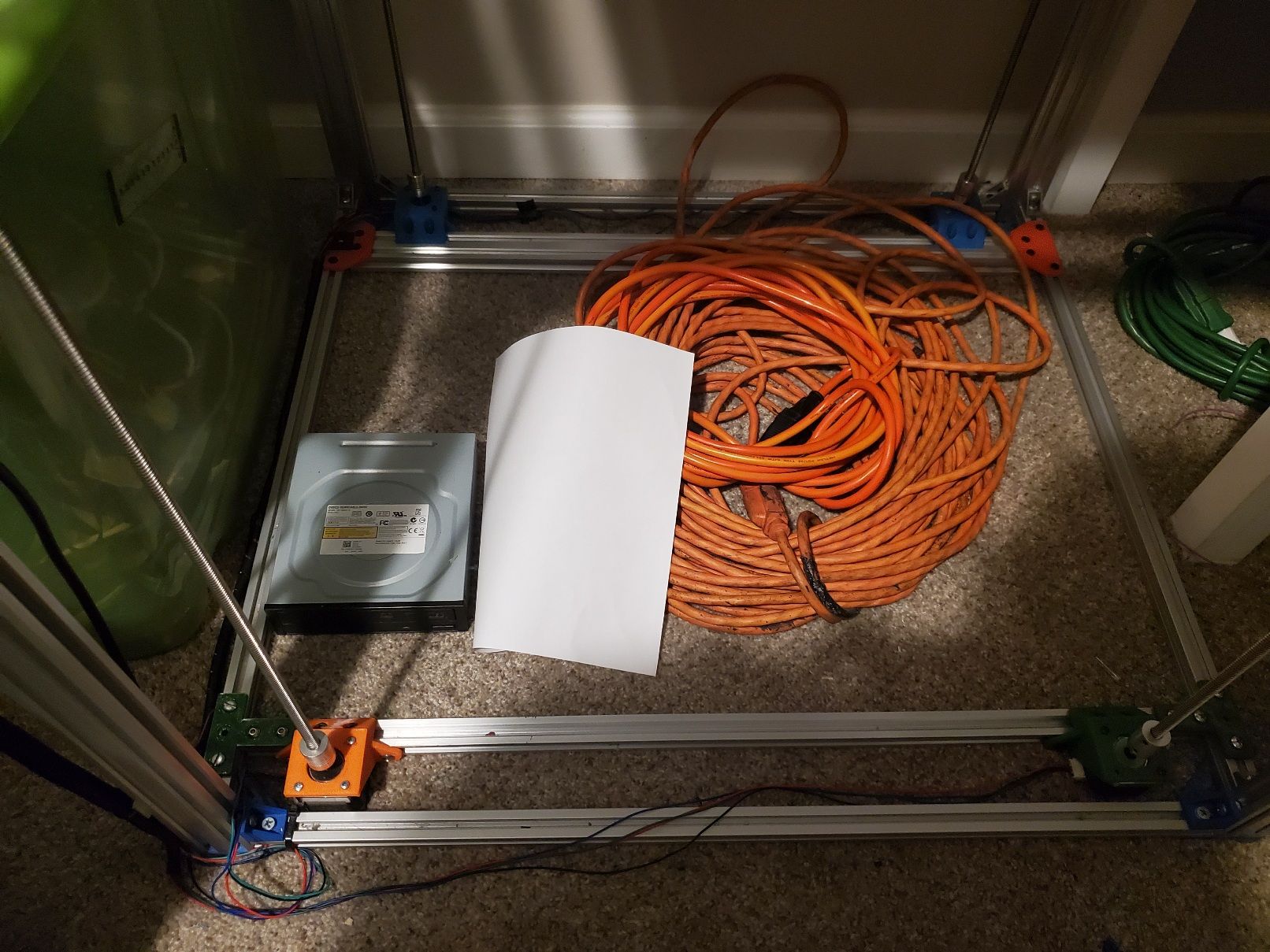

I have a core xy with 4 lead screws. The problem I am having is when trying to home x or y I either crash into the lead screw or the fan crashes into the frame when homing.

I tried to replicated whats in my home z since it moves to the middle of the bed but it's almost like my commands get ignored.

I'm using the most recent reprap 3

heres my home xG91 ; relative positioning G1 H2 Z5 F108000 ; lift Z relative to current position G1 H1 y40 F2600 ; move quickly to x axis endstop and stop there (first pass) G1 H1 x-600 G1 x5 F108000 ; go back a few mm G1 H1 x-5 F150 ; move slowly to x axis endstop once more (second pass) G1 H2 Z-5 F108000 ; lower Z again G90 ; absolute positioningand heres my home y

G91 ; relative positioning G1 H2 Z5 F108000 ; lift Z relative to current position G1 H1 X40 F3600 ; move quickly to Y axis endstop and stop there (first pass) G1 H1 Y-535 G1 Y5 F108000 ; go back a few mm G1 H1 Y-535 F360 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F108000 ; lower Z again G90 ; absolute positioningand here is my home z

G91 ; relative positioning G1 H2 Z5 F108000 ; lift Z relative to current position G90 ; absolute positioning G1 X35 Y50 F10800 ; go to first probe point G30 ; home Z by probing the bed -

RE: Multi color printing with Prusa's MMU V2 & Duet?posted in General Discussion

I have slicer setup as 5 extruders and the mixing option is checked. When I go to marcros and click them individually they run like they are supposed to.

-

RE: Multi color printing with Prusa's MMU V2 & Duet?posted in General Discussion

I think I got everything finally setup correctly. I am a bit confused on setting up prusa slic3r to tell it to use the macros.