@phaedrux I tried prusa slicer. Same issue but elsewhere in the part.

Latest posts made by Tommygunz

-

RE: Duet Wifi Wall Splitposted in Tuning and tweaking

-

RE: Duet Wifi Wall Splitposted in Tuning and tweaking

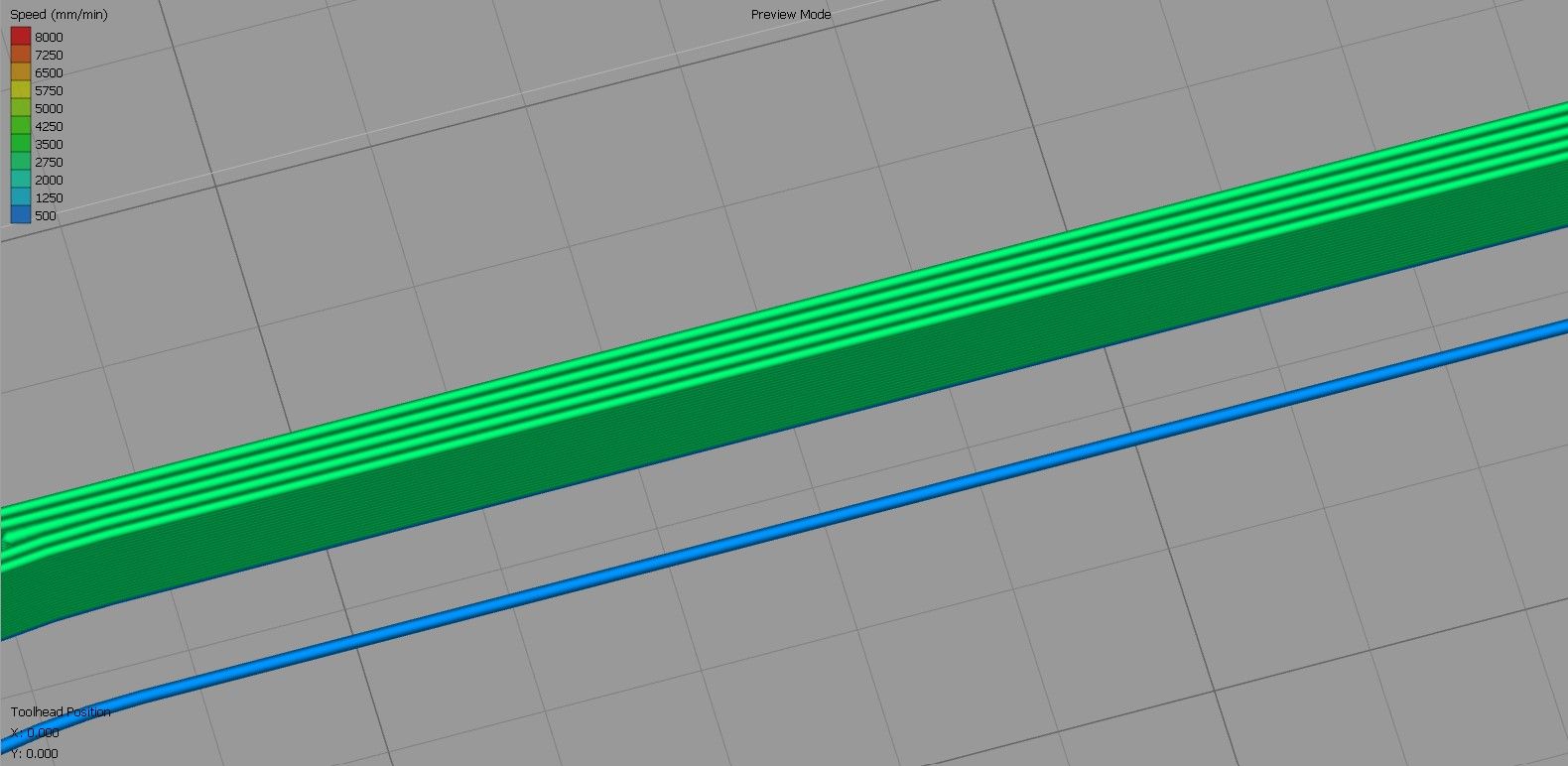

Here is a close-up picture of the gap. The two perimeters are not touching at all with the other 3 lines. I also boosted the extrusion multiplier which did nothing at all.

-

RE: Duet Wifi Wall Splitposted in Tuning and tweaking

@phaedrux I use an extrusion width of 0.4mm. My walls are 2mm thick which the wall should be composed of 5 lines of equal thickness. There should be no infill although Simplify3D thinks that the line between the inner and outer perimeter is a "thin wall". I currently have "allow extrusion fill" checked, and a perimeter overlap of 50%.

-

RE: Duet Wifi Wall Splitposted in Tuning and tweaking

Here is my config:

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Wed Feb 24 2021 16:32:46 GMT-0600 (Central Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Anet A8" ; set printer name

M575 P1 B57600 S1 ;Set baud rate Duet Board.

M575 P0 B57600 S1 ;Set baud rate USB; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.28 Y100.65 Z399.10 E413.72 ; set steps per mm

M566 X600.00 Y600.00 Z18.00 E1500.00 ; set maximum instantaneous speed changes (mm/min)

M203 X7200.00 Y7200.00 Z180.00 E6000.00 ; set maximum speeds (mm/min)

M201 X2000.00 Y2000.00 Z100.00 E12000.00 ; set accelerations (mm/s^2)

M906 X1100 Y500 Z500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-13 Y5 Z0 S1 ; set axis minima

M208 X220 Y220 Z240 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin !xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin !ystop

M574 Z1 S1 P"!zstop" ; configure active-high endstop for low end on Z via pin !zstop; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-32.1 Y2.919 Z0.614 ; set Z probe trigger value, offset and trigger height

M556 S81 X0.35 Y-1.0 Z0.35 ; set orthogonal axis compensation parameters

M557 X20:180 Y20:212 S32 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 R0.167 C510.3 D2.06 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.238 C55.7 D9.19 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S290 ; set temperature limit for heater 1 to 275C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q100 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q50 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S150 H-1 ; set fan 2 value. Thermostatic contol is turned off; Tools

M563 P0 S"Extruder 1" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

G29 S1; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

T0 ; select first tool -

Duet Wifi Wall Splitposted in Tuning and tweaking

Hello. A couple months ago, I made a post of a wall split in the x direction that occurred on the perimeters of my prints. After spending a lot of time diagnosing the issue, re-flashing the firmware seemed to fix the problem. About a month ago, the wall split issue re-appeared, but in the y direction. I tried re-flashing the firmware but that did not solve the issue. I'm not to sure what is the cause of this issue. Any help would be greatly appreciated!

-

RE: Duet 2 Wifi Perimeter Gapsposted in Tuning and tweaking

@Veti I tightened everything up. No difference at all. Closely watching my printer, it seems like it stops short when printing the first two perimeters hence the large gap. Im not sure what else to try.

-

RE: Duet 2 Wifi Perimeter Gapsposted in Tuning and tweaking

@Veti I got those values from the calibration cube test. Ill check out the free-play of the X and Y axis.

-

RE: Duet 2 Wifi Perimeter Gapsposted in Tuning and tweaking

Also using Overture PETG at 240 print temp, 80 degree heat, 40mm/s print speed.

-

Duet 2 Wifi Perimeter Gapsposted in Tuning and tweaking

Hello. For some time, I've been struggling with a minor print quality issue with my printer. With every print, there are gaps between the perimeter and infill, mostly in the X direction (seems like the inner two perimeters are offset from the third). I tried: tuning my slicer (Simplify3D), calibrating extrusion and X/Y steps, playing with belt tension, installing a new X axis belt, modifying my X carriage so it slides smoother, swapping X and Y axis motors, enabling pressure advance. I know it is not my slicer because my bone stock Ender 3 with the same settings does not have this issue. The print comes out great! Im not sure if the issue lies within my firmware.

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.78 Y100.67 Z397.27 E414.69 ; set steps per mm

M566 X500.00 Y500.00 Z150.00 E1500.00 ; set maximum instantaneous speed changes (mm/min)

M203 X8400.00 Y8400.00 Z250.00 E6000.00 ; set maximum speeds (mm/min)

M201 X2000.00 Y2000.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

M906 X650 Y650 Z650 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-34 Y-10 Z0 S1 ; set axis minima

M208 X220 Y220 Z240 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-low endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-low endstop for low end on Y via pin ystop

M574 Z1 S1 P"!zstop" ; configure active-low endstop for low end on Z via pin zstop; Z-Probe

M558 P9 C"^zprobe.in" H5 F100 T2000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X20:210 Y20:210 S30 ; define mesh grid

M950 S0 C"exp.heater3"

G31 X53 Y6 Z2.898 P25; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q100 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S70 H-1 ; set fan 1 value. Thermostatic control is turned off

M950 F2 C"fan2" Q50 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S150 H-1 ; set fan 2 value. Thermostatic contol is turned off; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M572 D0 S0.3 ; Enable pressure advance; Custom settings are not defined

; Miscellaneous

T0 ; select first tool

M501

-

RE: Printer Pausing Near End of Printposted in General Discussion

It was the software. Updated it to 3.1.1 and the problem went away!