@chrishamm

today, the error appeared a little diffent no spamming of Error: failed to retrieve WiFi status message: SPI timeout<\n> in console instead a proper error message in the output of M122

=== Diagnostics ===<\n>

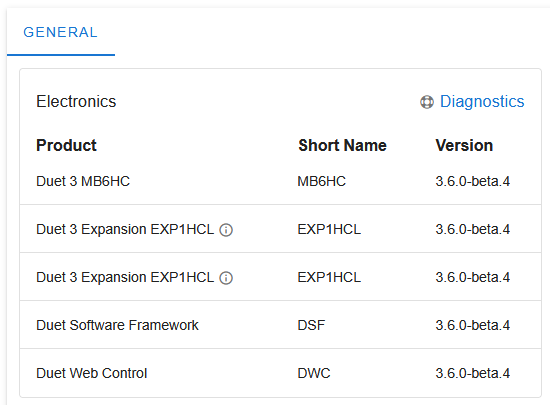

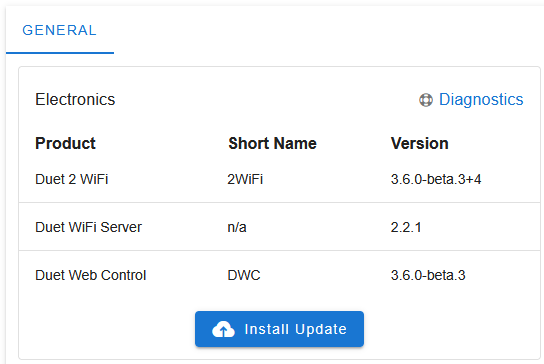

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.6.0-beta.3+4 (2025-02-05 09:48:00) running on Duet WiFi 1.02 or later + DueX5v0.11<\n>

Board ID: 08DJM-9178L-L4MSJ-6J1FL-3S86J-TB2LN<\n>

Used output buffers: 1 of 26 (21 max)<\n>

=== RTOS ===<\n>

Static ram: 23776<\n>

Dynamic ram: 68336 of which 0 recycled<\n>

Never used RAM 27884, free system stack 172 words<\n>

Tasks: NETWORK(1,nWait 6,15.2%,217) HEAT(3,nWait 5,0.1%,283) Move(4,nWait 5,0.0%,361) DUEX(5,nWait 5,0.0%,23) MAIN(1,running,83.6%,692) IDLE(0,ready,1.1%,29), total 100.0%<\n>

Owned mutexes: WiFi(NETWORK) USB(MAIN)<\n>

=== Platform ===<\n>

Last reset 20:16:44 ago, cause: software<\n>

Last software reset at 2025-02-07 14:18, reason: User, Gcodes spinning, available RAM 25444, slot 2<\n>

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a<\n>

Error status: 0x00<\n>

MCU temperature: min 28.5, current 29.4, max 30.5<\n>

Supply voltage: min 23.8, current 24.0, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes<\n>

Heap OK, handles allocated/used 99/7, heap memory allocated/used/recyclable 2048/1316/1180, gc cycles 3395<\n>

Events: 0 queued, 0 completed<\n>

Date/time: 2025-02-08 10:34:46<\n>

Slowest loop: 11.48ms; fastest: 0.21ms<\n>

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0<\n>

=== Storage ===<\n>

Free file entries: 8<\n>

SD card 0 detected, interface speed: 20.0MBytes/sec<\n>

SD card longest read time 8.8ms, write time 0.0ms, max retries 0<\n>

=== Move ===<\n>

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00<\n>

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00<\n>

no step interrupt scheduled<\n>

Driver 0: standstill, SG min n/a<\n>

Driver 1: standstill, SG min n/a<\n>

Driver 2: standstill, SG min n/a<\n>

Driver 3: standstill, SG min n/a<\n>

Driver 4: standstill, SG min n/a<\n>

Driver 5: standstill, SG min n/a<\n>

Driver 6: standstill, SG min n/a<\n>

Driver 7: standstill, SG min n/a<\n>

Driver 8: standstill, SG min n/a<\n>

Driver 9: standstill, SG min n/a<\n>

Driver 10: <\n>

Driver 11: <\n>

=== DDARing 0 ===<\n>

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]<\n>

Segments left 0<\n>

Code queue is empty<\n>

=== Heat ===<\n>

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0<\n>

=== GCodes ===<\n>

Movement locks held by null<\n>

HTTP is idle in state(s) 0<\n>

Telnet is idle in state(s) 0<\n>

File is idle in state(s) 0<\n>

USB is ready with "M122" in state(s) 0<\n>

Aux is idle in state(s) 0<\n>

Trigger is idle in state(s) 0<\n>

Queue is idle in state(s) 0<\n>

LCD is idle in state(s) 0<\n>

Daemon is doing "G4 P100" in state(s) 0 0, running macro<\n>

Autopause is idle in state(s) 0<\n>

=== Filament sensors ===<\n>

check 0 clear 247744131<\n>

Extruder 0: pos 2160.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0<\n>

=== DueX ===<\n>

Read count 0, 0.00 reads/min<\n>

=== Network ===<\n>

Slowest loop: 210.96ms; fastest: 0.07ms<\n>

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)<\n>

HTTP sessions: 0 of 8<\n>

=== WiFi ===<\n>

Interface state: active<\n>

Module is connected to access point <\n>

Failed messages: pending 0, notrdy 0, noresp 208248<\n>

Failed to get WiFi status<\n>

Socket states: 0 6 0 0 0 0 0 0<\n>

ok<\n>

But weird things started after changing the WIFI Module state again with

M552 S-1

M552 S0

M552 S1

ok<\n>

WiFi module stopped<\n>

ok<\n>

ok<\n>

WiFi module started<\n>

=== Diagnostics ===<\n>

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.6.0-beta.3+4 (2025-02-05 09:48:00) running on Duet WiFi 1.02 or later + DueX5v0.11<\n>

Board ID: 08DJM-9178L-L4MSJ-6J1FL-3S86J-TB2LN<\n>

Used output buffers: 1 of 26 (21 max)<\n>

=== RTOS ===<\n>

Static ram: 23776<\n>

Dynamic ram: 68336 of which 0 recycled<\n>

Never used RAM 27884, free system stack 172 words<\n>

Tasks: NETWORK(1,ready,0.9%,217) HEAT(3,nWait 5,0.1%,283) Move(4,nWait 5,0.0%,361) DUEX(5,nWait 5,0.0%,23) MAIN(1,running,97.7%,692) IDLE(0,ready,1.4%,29), total 100.0%<\n>

Owned mutexes: USB(MAIN)<\n>

=== Platform ===<\n>

Last reset 20:18:00 ago, cause: software<\n>

Last software reset at 2025-02-07 14:18, reason: User, Gcodes spinning, available RAM 25444, slot 2<\n>

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a<\n>

Error status: 0x00<\n>

MCU temperature: min 29.0, current 29.6, max 30.1<\n>

Supply voltage: min 23.8, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes<\n>

Heap OK, handles allocated/used 99/7, heap memory allocated/used/recyclable 2048/596/460, gc cycles 3399<\n>

Events: 0 queued, 0 completed<\n>

Date/time: 2025-02-08 10:36:03<\n>

Slowest loop: 100.04ms; fastest: 0.21ms<\n>

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0<\n>

=== Storage ===<\n>

Free file entries: 9<\n>

SD card 0 detected, interface speed: 20.0MBytes/sec<\n>

SD card longest read time 2.2ms, write time 0.8ms, max retries 0<\n>

=== Move ===<\n>

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00<\n>

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00<\n>

no step interrupt scheduled<\n>

Driver 0: standstill, SG min n/a<\n>

Driver 1: standstill, SG min n/a<\n>

Driver 2: standstill, SG min n/a<\n>

Driver 3: standstill, SG min n/a<\n>

Driver 4: standstill, SG min n/a<\n>

Driver 5: standstill, SG min n/a<\n>

Driver 6: standstill, SG min n/a<\n>

Driver 7: standstill, SG min n/a<\n>

Driver 8: standstill, SG min n/a<\n>

Driver 9: standstill, SG min n/a<\n>

Driver 10: <\n>

Driver 11: <\n>

=== DDARing 0 ===<\n>

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]<\n>

Segments left 0<\n>

Code queue is empty<\n>

=== Heat ===<\n>

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0<\n>

=== GCodes ===<\n>

Movement locks held by null<\n>

HTTP is idle in state(s) 0<\n>

Telnet is idle in state(s) 0<\n>

File is idle in state(s) 0<\n>

USB is ready with "M122" in state(s) 0<\n>

Aux is idle in state(s) 0<\n>

Trigger is idle in state(s) 0<\n>

Queue is idle in state(s) 0<\n>

LCD is idle in state(s) 0<\n>

Daemon is idle in state(s) 0<\n>

Autopause is idle in state(s) 0<\n>

=== Filament sensors ===<\n>

check 0 clear 248049807<\n>

Extruder 0: pos 2160.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0<\n>

=== DueX ===<\n>

Read count 0, 0.00 reads/min<\n>

=== Network ===<\n>

Slowest loop: 200.10ms; fastest: 0.00ms<\n>

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)<\n>

HTTP sessions: 0 of 8<\n>

=== WiFi ===<\n>

Interface state: idle<\n>

Module is idle<\n>

Failed messages: pending 0, notrdy 0, noresp 0<\n>

Firmware version 2.2.1<\n>

MAC address 00:00:00:00:00:00<\n>

Module reset reason: Turned on by main processor, Vcc 3.46, flash size 4194304, free heap 53932<\n>

Clock register 00002002<\n>

Socket states: 0 6 0 0 0 0 0 0<\n>

ok<\n>

=== Diagnostics ===<\n>

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.6.0-beta.3+4 (2025-02-05 09:48:00) running on Duet WiFi 1.02 or later + DueX5v0.11<\n>

Board ID: 08DJM-9178L-L4MSJ-6J1FL-3S86J-TB2LN<\n>

Used output buffers: 1 of 26 (21 max)<\n>

=== RTOS ===<\n>

Static ram: 23776<\n>

Dynamic ram: 68336 of which 0 recycled<\n>

Never used RAM 27884, free system stack 170 words<\n>

Tasks: NETWORK(1,ready,7.1%,217) HEAT(3,nWait 5,0.1%,283) Move(4,nWait 5,0.0%,361) DUEX(5,nWait 5,0.0%,23) MAIN(1,running,92.8%,692) IDLE(0,ready,0.0%,29), total 100.0%<\n>

Owned mutexes: USB(MAIN)<\n>

=== Platform ===<\n>

Last reset 20:18:18 ago, cause: software<\n>

Last software reset at 2025-02-07 14:18, reason: User, Gcodes spinning, available RAM 25444, slot 2<\n>

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a<\n>

Error status: 0x00<\n>

MCU temperature: min 29.4, current 29.5, max 30.1<\n>

Supply voltage: min 23.9, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes<\n>

Heap OK, handles allocated/used 99/7, heap memory allocated/used/recyclable 2048/624/488, gc cycles 3400<\n>

Events: 0 queued, 0 completed<\n>

Date/time: 2025-02-08 10:36:20<\n>

Slowest loop: 2.95ms; fastest: 0.21ms<\n>

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0<\n>

=== Storage ===<\n>

Free file entries: 8<\n>

SD card 0 detected, interface speed: 20.0MBytes/sec<\n>

SD card longest read time 2.2ms, write time 0.0ms, max retries 0<\n>

=== Move ===<\n>

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00<\n>

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00<\n>

no step interrupt scheduled<\n>

Driver 0: standstill, SG min n/a<\n>

Driver 1: standstill, SG min n/a<\n>

Driver 2: standstill, SG min n/a<\n>

Driver 3: standstill, SG min n/a<\n>

Driver 4: standstill, SG min n/a<\n>

Driver 5: standstill, SG min n/a<\n>

Driver 6: standstill, SG min n/a<\n>

Driver 7: standstill, SG min n/a<\n>

Driver 8: standstill, SG min n/a<\n>

Driver 9: standstill, SG min n/a<\n>

Driver 10: <\n>

Driver 11: <\n>

=== DDARing 0 ===<\n>

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]<\n>

Segments left 0<\n>

Code queue is empty<\n>

=== Heat ===<\n>

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0<\n>

=== GCodes ===<\n>

Movement locks held by null<\n>

HTTP is idle in state(s) 0<\n>

Telnet is idle in state(s) 0<\n>

File is idle in state(s) 0<\n>

USB is ready with "M122" in state(s) 0<\n>

Aux is idle in state(s) 0<\n>

Trigger is idle in state(s) 0<\n>

Queue is idle in state(s) 0<\n>

LCD is idle in state(s) 0<\n>

Daemon is doing "G4 P100" in state(s) 0 0, running macro<\n>

Autopause is idle in state(s) 0<\n>

=== Filament sensors ===<\n>

check 0 clear 248114856<\n>

Extruder 0: pos 2160.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0<\n>

=== DueX ===<\n>

Read count 0, 0.00 reads/min<\n>

=== Network ===<\n>

Slowest loop: 0.33ms; fastest: 0.00ms<\n>

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)<\n>

HTTP sessions: 0 of 8<\n>

=== WiFi ===<\n>

Interface state: idle<\n>

Module is idle<\n>

Failed messages: pending 0, notrdy 0, noresp 0<\n>

Firmware version 2.2.1<\n>

MAC address 00:00:00:00:00:00<\n>

Module reset reason: Turned on by main processor, Vcc 3.47, flash size 4194304, free heap 53932<\n>

Clock register 00002002<\n>

Socket states: 0 6 0 0 0 0 0 0<\n>

ok<\n>

ok<\n>

=== Diagnostics ===<\n>

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.6.0-beta.3+4 (2025-02-05 09:48:00) running on Duet WiFi 1.02 or later + DueX5v0.11<\n>

Board ID: 08DJM-9178L-L4MSJ-6J1FL-3S86J-TB2LN<\n>

Used output buffers: 1 of 26 (21 max)<\n>

=== RTOS ===<\n>

Static ram: 23776<\n>

Dynamic ram: 68336 of which 0 recycled<\n>

Never used RAM 27884, free system stack 170 words<\n>

Tasks: NETWORK(1,ready,6.3%,217) HEAT(3,nWait 5,0.1%,283) Move(4,nWait 5,0.0%,361) DUEX(5,nWait 5,0.0%,23) MAIN(1,running,93.6%,692) IDLE(0,ready,0.0%,29), total 100.0%<\n>

Owned mutexes: USB(MAIN)<\n>

=== Platform ===<\n>

Last reset 20:18:29 ago, cause: software<\n>

Last software reset at 2025-02-07 14:18, reason: User, Gcodes spinning, available RAM 25444, slot 2<\n>

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a<\n>

Error status: 0x00<\n>

MCU temperature: min 28.9, current 29.0, max 29.7<\n>

Supply voltage: min 23.9, current 24.0, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes<\n>

Heap OK, handles allocated/used 99/7, heap memory allocated/used/recyclable 2048/804/668, gc cycles 3400<\n>

Events: 0 queued, 0 completed<\n>

Date/time: 2025-02-08 10:36:32<\n>

Slowest loop: 2.96ms; fastest: 0.21ms<\n>

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0<\n>

=== Storage ===<\n>

Free file entries: 8<\n>

SD card 0 detected, interface speed: 20.0MBytes/sec<\n>

SD card longest read time 2.2ms, write time 0.0ms, max retries 0<\n>

=== Move ===<\n>

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00<\n>

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00<\n>

no step interrupt scheduled<\n>

Driver 0: standstill, SG min n/a<\n>

Driver 1: standstill, SG min n/a<\n>

Driver 2: standstill, SG min n/a<\n>

Driver 3: standstill, SG min n/a<\n>

Driver 4: standstill, SG min n/a<\n>

Driver 5: standstill, SG min n/a<\n>

Driver 6: standstill, SG min n/a<\n>

Driver 7: standstill, SG min n/a<\n>

Driver 8: standstill, SG min n/a<\n>

Driver 9: standstill, SG min n/a<\n>

Driver 10: <\n>

Driver 11: <\n>

=== DDARing 0 ===<\n>

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]<\n>

Segments left 0<\n>

Code queue is empty<\n>

=== Heat ===<\n>

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0<\n>

=== GCodes ===<\n>

Movement locks held by null<\n>

HTTP is idle in state(s) 0<\n>

Telnet is idle in state(s) 0<\n>

File is idle in state(s) 0<\n>

USB is ready with "M122" in state(s) 0<\n>

Aux is idle in state(s) 0<\n>

Trigger is idle in state(s) 0<\n>

Queue is idle in state(s) 0<\n>

LCD is idle in state(s) 0<\n>

Daemon is doing "G4 P100" in state(s) 0 0, running macro<\n>

Autopause is idle in state(s) 0<\n>

=== Filament sensors ===<\n>

check 0 clear 248160411<\n>

Extruder 0: pos 2160.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0<\n>

=== DueX ===<\n>

Read count 0, 0.00 reads/min<\n>

=== Network ===<\n>

Slowest loop: 0.29ms; fastest: 0.00ms<\n>

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)<\n>

HTTP sessions: 0 of 8<\n>

=== WiFi ===<\n>

Interface state: changingMode<\n>

Module is trying to connect<\n>

Failed messages: pending 0, notrdy 0, noresp 0<\n>

Firmware version 2.2.1<\n>

MAC address 00:00:00:00:00:00<\n>

Module reset reason: Turned on by main processor, Vcc 3.46, flash size 4194304, free heap 47360<\n>

Clock register 00002002<\n>

Socket states: 0 6 0 0 0 0 0 0<\n>

ok<\n>

=== Diagnostics ===<\n>

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.6.0-beta.3+4 (2025-02-05 09:48:00) running on Duet WiFi 1.02 or later + DueX5v0.11<\n>

Board ID: 08DJM-9178L-L4MSJ-6J1FL-3S86J-TB2LN<\n>

Used output buffers: 1 of 26 (21 max)<\n>

=== RTOS ===<\n>

Static ram: 23776<\n>

Dynamic ram: 68336 of which 0 recycled<\n>

Never used RAM 27884, free system stack 170 words<\n>

Tasks: NETWORK(1,ready,7.5%,217) HEAT(3,nWait 5,0.1%,283) Move(4,nWait 5,0.0%,361) DUEX(5,nWait 5,0.0%,23) MAIN(1,running,92.4%,692) IDLE(0,ready,0.0%,29), total 100.0%<\n>

Owned mutexes: USB(MAIN)<\n>

=== Platform ===<\n>

Last reset 20:18:31 ago, cause: software<\n>

Last software reset at 2025-02-07 14:18, reason: User, Gcodes spinning, available RAM 25444, slot 2<\n>

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a<\n>

Error status: 0x00<\n>

MCU temperature: min 28.8, current 29.0, max 29.2<\n>

Supply voltage: min 23.9, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes<\n>

Heap OK, handles allocated/used 99/7, heap memory allocated/used/recyclable 2048/1144/1008, gc cycles 3400<\n>

Events: 0 queued, 0 completed<\n>

Date/time: 2025-02-08 10:36:34<\n>

Slowest loop: 2.39ms; fastest: 0.23ms<\n>

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0<\n>

=== Storage ===<\n>

Free file entries: 8<\n>

SD card 0 detected, interface speed: 20.0MBytes/sec<\n>

SD card longest read time 2.1ms, write time 0.0ms, max retries 0<\n>

=== Move ===<\n>

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00<\n>

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00<\n>

no step interrupt scheduled<\n>

Driver 0: standstill, SG min n/a<\n>

Driver 1: standstill, SG min n/a<\n>

Driver 2: standstill, SG min n/a<\n>

Driver 3: standstill, SG min n/a<\n>

Driver 4: standstill, SG min n/a<\n>

Driver 5: standstill, SG min n/a<\n>

Driver 6: standstill, SG min n/a<\n>

Driver 7: standstill, SG min n/a<\n>

Driver 8: standstill, SG min n/a<\n>

Driver 9: standstill, SG min n/a<\n>

Driver 10: <\n>

Driver 11: <\n>

=== DDARing 0 ===<\n>

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]<\n>

Segments left 0<\n>

Code queue is empty<\n>

=== Heat ===<\n>

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0<\n>

=== GCodes ===<\n>

Movement locks held by null<\n>

HTTP is idle in state(s) 0<\n>

Telnet is idle in state(s) 0<\n>

File is idle in state(s) 0<\n>

USB is ready with "M122" in state(s) 0<\n>

Aux is idle in state(s) 0<\n>

Trigger is idle in state(s) 0<\n>

Queue is idle in state(s) 0<\n>

LCD is idle in state(s) 0<\n>

Daemon is doing "G4 P100" in state(s) 0 0, running macro<\n>

Autopause is idle in state(s) 0<\n>

=== Filament sensors ===<\n>

check 0 clear 248167507<\n>

Extruder 0: pos 2160.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0<\n>

=== DueX ===<\n>

Read count 0, 0.00 reads/min<\n>

=== Network ===<\n>

Slowest loop: 0.26ms; fastest: 0.00ms<\n>

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)<\n>

HTTP sessions: 0 of 8<\n>

=== WiFi ===<\n>

Interface state: changingMode<\n>

Module is trying to connect<\n>

Failed messages: pending 0, notrdy 0, noresp 0<\n>

Firmware version 2.2.1<\n>

MAC address 00:00:00:00:00:00<\n>

Module reset reason: Turned on by main processor, Vcc 3.46, flash size 4194304, free heap 47380<\n>

Clock register 00002002<\n>

Socket states: 0 6 0 0 0 0 0 0<\n>

ok<\n>

Error: WiFi module reported: Authentication failed<\n>

WiFi module is idle<\n>

Hope this helps to track that bug down