Hello

I am having problem with my extruder motor, could you advice me on how to solve this issue please.

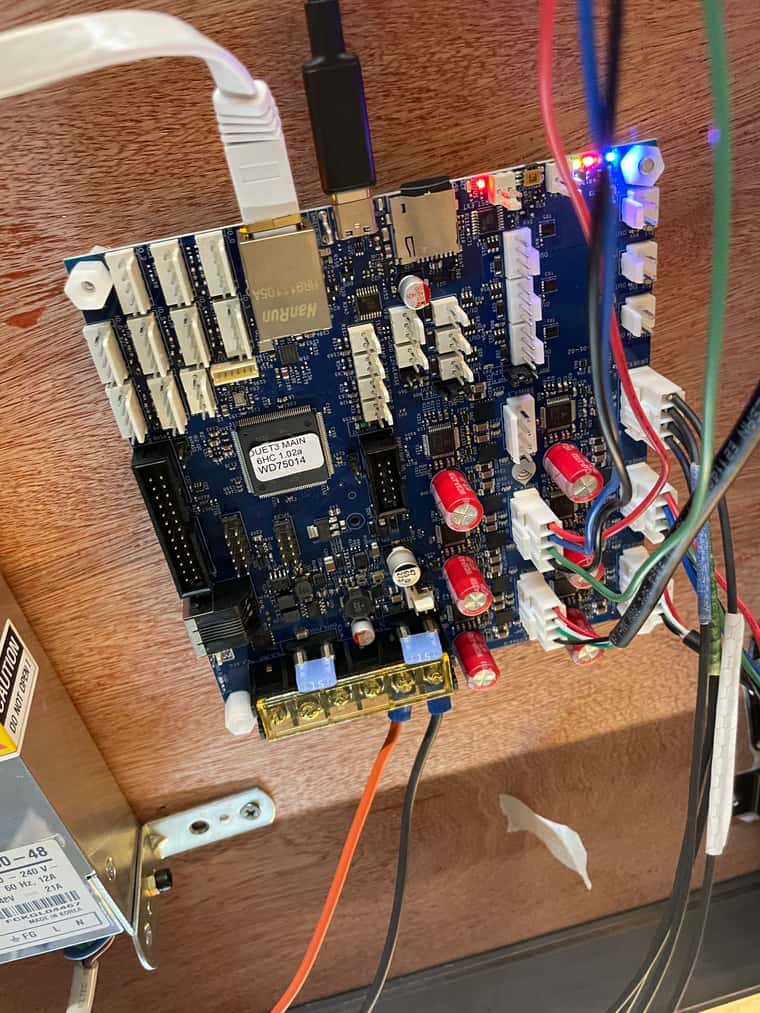

I have built Hangprinter with Duet 3 6HC and five stepper motor. Four Nema 23 for A, B, C, D motors and a Nema 34 for the extruder. All the motors work when i send g.code command except for the extruder motor. It seems Web controller doesn't recognise the extruder driver as the extruder controller on the Web Control is grey. I have check the connection and the motor itself and they are working.

Below is my config.g and the set up of the wire connection I have at the moment.

Thank you

Sophia

Config.g file :

; Enable network

; M552 S1

M552 S1 P192.168.50.101

M550 P"hangprinter" ; change the name from the IP address of 192.168.50.101

;General Machine Settings/Conventions

G21 ;work in mm

G90 ;absolute coordinates

M83 ;relative extruder moves

;G4 S2 ; wait for expansion boards to start

;Heaters and Temp Sensor

;bandheater

;M140 H-1 ; disable heated bed (overrides default heater mapping)

;M308 S1 P"temp0" Y"pt1000" A"Extruder Sensor"; configure sensor 1 as PT1000 on pin temp1

;M950 H1 C"out1" Q10 T1 ; create nozzle heater output on out1 and map it to sensor 1, limit pwm frequency to 10Hz

;M307 H1 B0 R0.050 C1800 D36.57 S1.00 V12.1 ; FAILED AUTOTUNE RESULTS ; disable bang-bang mode for heater and set PWM limit

;M307 H1 B0 R0.319 C1028.9 D36.57 S1.00 V12.1 ; AUTOTUNE RESULTS FROM 2022-03-26

;M143 H1 S300 ; set temperature limit for heater 0 to 240C

;second temp sensor

;M308 S2 P"temp0" Y"pt1000" A"Barrel Sensor"; configure sensor 2 as PT1000 on pin temp2

;Fans

;Heatsink Fans 1 and 2

;M950 F1 C"!out4+out4.tach" Q25000 ; Fan 1 uses out4, but we are using a PWM fan so the output needs to be inverted, and using out4.tach as a tacho input

;M106 P1 H-1

;M950 F2 C"!out5+out5.tach" Q25000 ; Fan 2 uses out5, but we are using a PWM fan so the output needs to be inverted, and using out5.tach as a tacho input

;M106 P2 H-1

;Kinematics and Drives

;Drives: x4 NEMA23's for Hangprinter Axis and x1 NEMA34 for extruder

M18 ;disable default driver assignments;

M569 P0 S0 ; drive 0 for extruder axis

M569 P1 S1 ; drive 1 (X motor output aka A) goes forwards

M569 P2 S1 ; drive 2 (Y motor output aka B) goes forwards

M569 P3 S1 ; drive 3 (Z motor output aka C) goes forwards

M569 P4 S0 ; drive 4 for D axis, goes forwards; need to create another "U" axis for D motor

;M569 P5 S0 ; drive 5 (feeder motor) goes backwards (CW looking from behind motor )

M584 X1 Y2 Z3 E0 U4 ;assign drives to axes and create U axis for D motor. Feeder motor is assigned as a second extruder hence E0:5 where 5 is stepper drive 5 which feed motor is connected

;Step settings

M350 X16 Y16 Z16 U16 E16 I1 ; configure microstepping with interpolation

;M92 X192 Y192 Z192 U192 ; set steps/mm for each spool. DO NOT CHANGE THIS PARAMETER

M92 E1000 ; set steps/mm for extruder and feed motor

;Speed and Accelerations

M566 X250.00 Y250.00 Z250.00 U250.0 E200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z6000.00 U6000.00 E9000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z500.00 U250.00 E200.00 ; set accelerations (mm/s^2)

;Set Currents

M906 X2500 Y2500 Z2500 E3000 U2500 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

;Kinematics

M669 K6 ; Configures the Duet 3 to identify as Hangprinter Kinematics

;set anchor distances

M669 K6 A0.0:-1596.0:-68.0 B1388.0:802.0:-68.0 C-1382.0:797.0:-68.0 D0.0:0.0:2660.0 ; set Hangprinter kinematics parameters

M669 P1000.0 ; Hangprinter printable radius (unused for now)

M669 S100 T0.5 ; Segments per second and min segment length

M666 Q0.0033333 ; buildup compensation factor for ABCD

M666 R75.0:75.0:75.0:75.0 ; ABCD radii

M666 U2:2:2:4 ; Mechanical advantages on ABCD spools - 2 stands for doubled lines

M666 O1:1:1:1 ; Number of lines per spool or "coil mode" (each line has it's own coil). 1 = coil style

M666 L20:20:20:20 ; Motor gear teeth of ABCD axes

M666 H254:254:254:254 ; Spool gear teeth of ABCD axes...CAN TUNE THIS AS NEEDED TO GET RIGHT MOVEMENT

M666 J200:200:200:200 ; Full steps per ABCD motor revolution ...CAN TUNE THIS AS NEEDED TO GET RIGHT MOVEMENT

M208 S0 Z1540 ; maximum height 1750mm or some distance below D anchor. CHANGE THIS ACCORDING TO YOUR SETUP

M208 S1 Z-2 ; minimum height -5mm

; Uncomment M564 S0 if you don't want G0/G1 moves to be limited to a software defined volume

; M564 S0

; Tool Definitions

M563 P0 D0 ;assign extruder drive(D0), if you have Heater or Fan assign as Heater (h1) and Fan(F1) to tool0(P0),

G10 P0 R0 S0 ;set initial tool0 active and standby temperatures to 0C

;M568 P0 S1 ;enable mixing for tool 0

;M567 P0 E1:0.05 ;set mixing ratios for tool 0