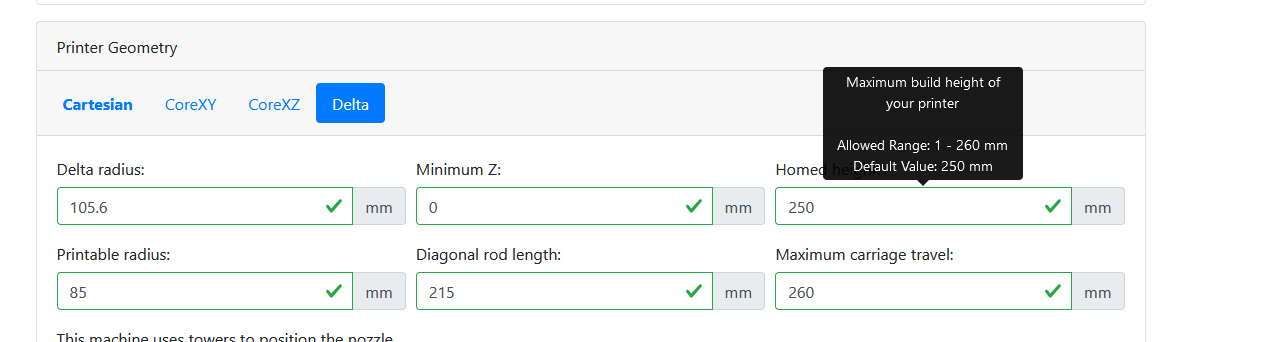

@alankilian set the configurator to Delta and as below:

Latest posts made by simon0362

-

RE: Heater and other problems after v2 to V3.3 upgradeposted in Firmware installation

-

RE: Heater and other problems after v2 to V3.3 upgradeposted in Firmware installation

@dc42 thanks David, I have just found that the correct syntax for M584 is "E3:4" and not as I had: "E3 E4".

@alankilian, I regenerated a new config and then merged the two versions to attempt to maintain context - and I found the configurator to be unclear for some things and not let others happen (my bed height is 303mm, max allowed in theconfigurator is 250mm for instance)

still unclear why neither temperature sensor is reading and the bed is shown as 'unconnected"

-

Heater and other problems after v2 to V3.3 upgradeposted in Firmware installation

Hi all,

Looking for some support after an extremely frustrating day.

I have a home built Delta connected to a Duet2 Ethernet, PanelDuo, PT100 RTD board.

This morning after a largely unsuccessful print (other issues related to filament) I decided to finally update from the existing v2.something to v3.

read the install guide, updated the single .bin file for v3.0 and then started looking at the crazy list of config changes.Problems:

Heaters (1 x bed on 0, 2 x nozzle on 1 and 2) not working, sensors not seen - if I activate the bed heater, it generates an error "Error: Temperature reading fault on heater 0: sensor open circuit"

temperature on both operating heaters is -273.1C

Bed appears to heat on startup, although the sensor is apparently ignored.

Reading the config file for syntax errors produces a string of problems (below)Any aid gladly received.

Simon; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Tue Apr 17 2018 23:13:51 GMT+0200 (Romance Daylight Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; manualo calibration 25-03-20

M665 R173.334 L334.238 B125 H303.804 X0.016 Y0 Z 0.000 ; Set delta radius, diagonal rod length, ;**Probe too high, reduce numberM666 X0.80 Y0.60 Z-0.5 A0.0 B0.0 ; Put your endstop adjustments here, or let auto calibration find them

; Network

M550 P"Kossel" ; Set machine name

M552 P192.168.1.58 S1; IP address (0 = use DHCP);*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes backwards - extruder 1

M569 P4 S0 ; Drive 4 goes backwards - extruder 2

M584 X0 Y1 Z2 E3 E4 ; set drive mappingM350 X16 Y16 Z16 E16:16 I1 ; Configure microstepping with interpolation

M92 X100 Y100 Z100 E450:830 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200:1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E12000:12000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000:1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1000:800 I30 ; Set motor currents (mA) and motor idle factor in per cent ***SD changed from 800-1000 for Nylon E0 feed

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

;M574 X2 Y2 Z2 S1 ; Set active high endstops Old code

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop; Z-Probe

M558 P1 H2 F120 T6000 ; Set Z probe type to unmodulated and the dive height + speeds

G31 P499 X0 Y22 Z2.103 ; Set Z probe trigger value, offset and trigger height Z1.93

M557 R100 S20 ; Define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T4700 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limitM140 H0 ; map heated bed to heater 0

M143 H0 S100 ; set temperature limit for heater 0 to 100C;M305 P1 X200 S"Left" ; PT100 daughter board, channel PD1 = Head 1 *** remove this for LH head ***

;M305 P2 X201 S"Right" ; PT100 daughter board, channel PD2 = Head 2 old codeM308 S1 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 1

M143 H2 S280 ; Set temperature limit for heater 2 to 280C;M307 H1 A375.1, C178.5, D4.1 S1 ; original PID parameters for heater 1 not used

M307 H1 A403.4, C180.0, D5.5 S1 ; PID parameters for heater 1 *** remove this for LH head ***

M307 H2 A499.6, C216.2, D5.1 S1 ; PID parameters for heater 2, autotuned 1/9/19; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1

M950 F2 C"fan2" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P2 S1 H-1 ; set fan 0 value. Thermostatic control is turned off; Tools

;M563 P0 D0 H1 S" Single" ; Define tool 0 *** remove this for LH head ***

;G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets *** remove this for LH head ***

;G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C *** remove this for LH head ***

M563 P1 D1 H0 H2 S"Double" ; Define tool 1

G10 P1 X0 Y0 Z0 ; Set tool 1 axis offsets 18mm between nozzles, symmetric about zero (either here or in Cura, not both!!)

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Error: GCodes: Attempt to read a GCode unsigned array that is too long: M350 X16 Y16 Z16 E16:16 I1

Error: GCodes: Attempt to read a GCode float array that is too long: M92 X100 Y100 Z100 E450:830

Error: GCodes: Attempt to read a GCode float array that is too long: M566 X1200 Y1200 Z1200 E1200:1200

Error: GCodes: Attempt to read a GCode float array that is too long: M203 X18000 Y18000 Z18000 E12000:12000

Error: GCodes: Attempt to read a GCode float array that is too long: M201 X1000 Y1000 Z1000 E1000:1000

Error: GCodes: Attempt to read a GCode float array that is too long: M906 X1000 Y1000 Z1000 E1000:800 I30

Error: M558: Missing Z probe pin name(s)

Error: G31: Invalid Z probe index

Warning: M307: heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365C.Warning: M950: Sensor number 2 has not been defined

Error: M307: Heater 1 not found

Warning: M307: heater 2 appears to be over-powered. If left on at full power, its temperature is predicted to reach 524C.Error: M563: Tool creation: bad drive number

Error: G10: Attempt to set/report offsets and temperatures for non-existent tool: 1

Error: G10: Attempt to set/report offsets and temperatures for non-existent tool: 1 -

RE: Does an M104 with a tool select alsoswitch to that toolposted in General Discussion

Ok, I think I understand now - my start code turns both heaters on as well as the bed and waits until they get to temperature. I then squirt a bit from each nozzle prior to the 'real' code starting. However....because the last selected tool is #1 after the initial squirt and because Cura doesn't specify directly to start using T0 at this point, everything gets out of sync until the first specified toolchange.

Hey ho, these dual setups are not trivial!

Thanks again for your inputSimon

-

RE: Does an M104 with a tool select alsoswitch to that toolposted in General Discussion

Thanks David - so looking at the following snip:

T1

G92 E0

M105

M109 S220.1

M104 T0 S195

;MESH:single box - Part 1(1).stl(1)

G0 F3600 X-6.253 Y37.329 Z0.2

G1 F1500 E-3I read as:

switch to T1, read the (T1) temperature, set the default T0 to 220.1°C and wait, then dump T0 back to 195°C, then print using T0.....which I guess is a Cura problem

-

Does an M104 with a tool select alsoswitch to that toolposted in General Discussion

Trying to understand dual extruder use with Duet and Cura - so maybe this is a Cura forum question...

Anyway, my Kossel is setup with dual extruders and I have a test print being sliced in Cura 3.6 - the active extruder always seems to be at the wrong temperature or playing catch-up.

Looking through the code, I am confused about where the tools are switched - Cura adds "T0" and "T1" at various points but I have the impression that the "M104 Sxxx T1" (or T0) also toggles the current tool.

Duet is a ethernet version at 2.01 if that makes a difference.All thoughts welcomed!

-

RE: Duet, level bed and G29/32posted in Tuning and tweaking

@dc42 said in Duet, level bed and G29/32:

The ripple effect is caused by backlash, probably cause by a loose belt, loose pulley, sticky carriage, loose or sticky joint, or insufficient motor current. Based on the pattern it looks to me that the Y tower is OK but the X tower has a big problem. It's less easy to be certain about the Z tower, but it's probably OK too.

"backlash" - Thanks, that helps to start understanding the issues and to look closely at the setup - which may have developed any of the causes over the last 18 months.

"X tower has a big problem" - trying to understand the reason why you say the X tower - the ripple appears to be perpendicular to Z tower - or is this a case of me coinfusing terms?

I assumed (hey ho!) that X is the most negative 'x' in cartesian coords - in my case around -80, whereas Y is the most positive 'x' in cartesian coords. Z I assumed to be the most negative 'y' in cartesian coords.Anyway, thanks for the feedback, most welcome.

-

Duet, level bed and G29/32posted in Tuning and tweaking

Hi all, looking for some of your collective wisdom!

I have a Kossel delta that I built about 18 months ago equipped with classic Marlin and RAPPS. This was working well and printing large and small items successfully.Recently I upgraded to a Duet (Ethernet, not wifi FWIW) and finally started using DC's IR board.

For setup, I took the majority of the Marlin settings as a first stab and this has clearly got me to a point where everything is 'close' to being right.

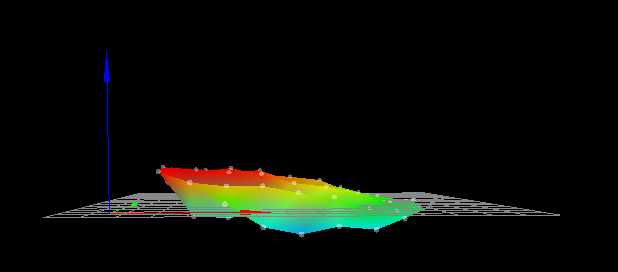

Running the auto-calibrate function now gives me "Calibrated 6 factors using 16 points, deviation before 0.309 after 0.103" after calibrating the 16 different trigger heights for the IR board across the platter.

Running the mesh grid compensation with 20mm step gives "69 points probed, mean error 0.072, deviation 0.116".

Looking at the output shows two things:

a) a clear tilt away from the rear Z pillar towards the +/- X axis

b) a more minor tilt in the Y+/- axis

c) a ripple effect running directly perpendicular with the X axis, i.e. presumably caused by the movements of the Z tower carriage

different angle showing the bed tilt:

This picture is effectively identical even after I applied a bed tilt correction in both A and B to M666 in the config file, suggesting that A/B bed tilt is not having an effect.So after all of this, onto the questions....:

-

suggestions about the cause of the ripple from Z tower and a fix

-

how do I fix the bed tilt which is ensuring that I cannot print anything apart from small items near the centre?

-

thoughts on why the effector is tilting the IR board in an apparently similar manner to the bed tilt even though I have applied 'H' adjustments

Config file below:

; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Tue Apr 17 2018 23:13:51 GMT+0200 (Romance Daylight Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M665 R176.515 L334.238 B120 H300.53 X0.0 Y0.0 Z 0.000 ; Set delta radius, diagonal rod length, printable radius and homed height H300.753 R176.214

M666 X-0.50 Y0.00 Z0.0 A-0.15 B-0.083 ; Put your endstop adjustments here, or let auto calibration find them; Network

M550 Kossel ; Set machine name

M552 S1 ; Enable network

M552 P192.168.1.58 ; IP address (0 = use DHCP);*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes backwards - extruder

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X100 Y100 Z100 E450 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E12000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M558 P1 H5 F120 T6000 ; Set Z probe type to unmodulated and the dive height + speeds

G31 P499 X0 Y0 Z2.911 ; Set Z probe trigger value, offset and trigger height was -2.818

M557 R100 S20 ; Define mesh grid; Heaters

;M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M305 P1 X200 ; PT100 daughter board, channel PD1

M143 H0 S100 ; Set temperature limit for heater 0 to 100C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

If you get this far through the post, thanks for reading and I hope you can help!

BR

Simon -