@petrzmax yes I'm using Capricorn tubing in fact. I recently replaced my single-drive extruder with dual drive, and replaced the bowden tube at the same time because the one I was using before was so short that when the print carriage was in certain regions of the build plate I got very tight radius curves, which causes other problems. When I replaced the tube I went deliberately long, with the plan to cut it down a little after I've got some other things taken care of. I think I can cut down the tube by a good 100-200mm without getting too-small curve radius, since I also re-oriented the tubing a little. Hopefully when I cut the tubing down my bowden problems will reduce a little. Btw, I just had to stop a print of this wing panel and start a new one. I thought that the 0.25 pressure advance had solved my problem, but the problem was back. It's a combination of factors. What I'm seeing specifically is this single-walled print having underextrusion in the first few centimeters after the start of a new layer, leading to the layers in that region being incomplete. It's not a problem I see in my solid prints, but these single-wall complicated sparse parts are really tough to print well.

Posts made by Sethipus

-

RE: Inconsistent Extrusion?posted in Tuning and tweaking

-

RE: Inconsistent Extrusion?posted in Tuning and tweaking

Good luck with your rebuild. Note that 0.4 is a very high value for pressure advance. If you read this Duet FAQ article on pressure advance it says that moderate bowden systems might use 0.1, long bowden systems using 0.2, and direct systems as little as 0.05. Have you testing with settings in the 0.05-0.2 range?

Also, I and many others prefer to align the seams so that most of the print looks good and fairly uniform, and only that one seam looks bad. In S3D I'll usually position a print so that either a corner or the back of an object is oriented with point I specify as the one to align on. Also makes it easy to run tests like pressure advance on an object like a single-walled cube, with the seam on one corner.

Btw, I'm running some extremely challenging prints right now for a 3D-printed radio-controlled airplane, with complex parts using single-walled printing. After many test runs I've had to crank my pressure advance up to 0.25, which is higher than I've ever used before. I've got a very long (perhaps 650-700mm) long bowden tube. The bowden system is so "flexy" inside, given how much pressure is required for the filament to make the required flow rate, that I have to use a full 5.4mm of retraction. If you consider that a direct drive extruder would probably use maybe 1mm under similar conditions, that implies I get over 4mm of filament compression in my bowden tube, and all of that has to be retracted/unretracted with every nozzle move, complicating the start and ending of lines, etc. I've got my extruder speeds cranked up really high to help with this, and thankfully the BMG clone's dual extruder gears and my stepper seem up to the task. I really wonder how much easier (and better) my prints would be if I just went direct drive.

-

RE: Inconsistent Extrusion?posted in Tuning and tweaking

If you consider this part right circled in red, where a perimeter wall started in these two places, especially in the upper one you can see the line a little thicker coming into the seam and a little thinner coming out of it. If the nozzle is moving from left to right in this photo (I don't know if it is or not) this looks like a classic example of where pressure advance may help. Assuming the nozzle is moving left to right at these seams, it looks like pressure could be a little too high as it decelerates into the end of the line, and too low as it speeds up out of the start of the line. Have you tried experimenting with pressure advance?

If the slicer has different layers moving the nozzle in different directions (two layers left to right, two layers right to left, etc.) and there are effects that pressure advance could help with that could explain the alternating patterns you see in the first of the photos you showed.

You could try creating a single hollow cube, with seams aligned, and print it, and every few layers input a higher pressure advance figure and see if your corners and the start/end seam point look different. Example pressure advance command would be "M572 D0 S0.15", with pressure advance set to 0.15. You might try printing the single-walled cube starting with pressure advance at 0 and then every few lines manually run the g-code to set pressure advance, incrementing by 0.05 or so, say from 0 - .20, and see how that effects the corner blobbing and the seam start/end points.

-

RE: Does pressure advance depend on layer height?posted in General Discussion

It's my understanding that acceleration of the extruder is the only thing it takes into consideration. With thinner layers (but same X/Y speed) your extruder velocity will be lower, so if your jerk is high enough you may see a different "acceleration profile" as it were, but then pressure advance would be multiplied by whatever acceleration there is. This assumes negligible non-linear extrusion effects, or well-correct non-linear extrusion at any rate.

-

RE: Gap following a move without extrusionposted in Tuning and tweaking

That seems to be a very high pressure advance for a direct drive. Have you tried it with something more like .1 or thereabouts?

-

RE: A Repeating Artifactposted in General Discussion

@b0m0a0k I almost got the Micro Swiss hotend at one point, but since I was successfully printing PETG through the stock hotend, I never actually bought it, and once I settled on building a new printer from plans the idea became redundant. There's nothing wrong with the stock hotend though. For people printing just PLA I'm not sure I see the point. I haven't looked at pricing on those things lately, but if the MicroSwiss hotend is in roughly the same ballpark as an E3D like the Titan Aero, I don't think you can beat the E3D. They're the gold standard. For one thing, the nozzles are nearly a universal standard, and the extruder is geared, which means (along with a great controller like the Duet Wifi) more steps/mm for finer and quieter control of extrusion, you can use a lighter extruder stepper, etc.

I read about people getting clogs in their printer, and I simply never get them. I think I've gotten a legit clog maybe once ever in thousands of hours or printing, and if I recall it was an experiment with carbon fiber PETG filament, and the single-drive extruder I was using at the time had stripped out the filament so filament sat in the nozzle and cooked.

I don't know if you've heard of this before, but most times when I'm reloading filament I'll do what's known as the "Atomic Pull." And when I switch between PLA and PETG or some other filament (ASA, nylon, etc.) I do this 100% of the time. Simply, an atomic pull is where I pull the existing filament out (leaving some melted filament down in the melt chamber) and push in a length of cleaning filament, until what's coming out is mostly the clear cleaning filament. It's not necessary for it to be 100% clear. In the Duet Wifi web control set the nozzle temp to 0. As the temperature falls below around 200 or so give one last little short push on the cleaning filament to push through another couple milimeters of it, then let it sit. As the temperature falls to around 90 C or so simply pull the filament out with a pair of pliers or whatever. If you do it with the temperature too high the cleaning filament will break off leaving the filament in the melt chamber, same if you let it cool too far below 90 C. If you pull it out in this sweet spot temperature zone you'll pull the cleaning filament out of the melt chamber, and you'll have a perfect "casting" of the melt chamber that will remove anything and everything in there, so the melt chamber is perfectly clear for putting in the new filament.

Sorry to be so chatty, just got kind of enthused on the topic of that particular type of printer, and all the many upgrades and mods people do on them. With the Duet Wifi you've already done the best possible mod on that printer bar none. No more shuttling an SD card back and forth between the computer and printer, massively quieter printing, nearly unlimited configuration simplicity, etc. Good times.

ETA: one other topic is on the extruder itself. With the Micro Swiss hotend you'd be stuck with the stock extruder, which is functional, or if you went Titan Aero you'd get a nice geared extruder along with the E3D hotend in a nice, compact package, but it's still single drive (one toothed gear pulling on the filament). I'm now using dual drive (two toothed gears pulling on the filament rather than one toothed gear with a flat bearing pushing the filament against it) and dual-drive is quite simply fantastic. I'm using a Bondtech BMG clone that works amaziningly. If you can find or design a print carriage for your printer that combines a Bondtech-style extruder with an E3D hotend in a compact-enough package you'd have the best of all solutions. With the Micro Swiss hotend you're locked in to their nozzles, and it's just a hotend, leaving you with a simplistic stock extruder. If you're gonna go, go big.

-

RE: A Repeating Artifactposted in General Discussion

@b0m0a0k said in A Repeating Artifact:

@mrsdelish Thanks for this. I had been researching what I could do by way of an upgrade to the extruder or the hotend but was a little undecided because everyone has a different take.

My options so far are;

Micro Swiss Mk10 All Metal Hotend Kit with cooling block. (Straight replacement)

E3D Titan Aero HotEnd and Extruder

Various other suggested mods.

Don't get me wrong, I enthusiastically modded and upgraded my Wanhao (Monoprice Maker Select actually; it's the same printer), but I would like to opine that whatever was causing the behavior you saw in your initial posting would not be improved by upgrading the hotend, or the extruder for that matter. There's nothing wrong with the hotend and extruder (it's direct drive) on that printer, unless you want to print at nozzle temps higher than around 240-245 C or so for very long. I printed tons of PETG on that printer (including all the parts for my initial build of my D-Bot), and eventually replaced the teflon tube in the hotend and found it fairly blackened and charred. The problems you are seeing are 100% settings issues.

To that end, I would recommend against tweaking extrusion multiplier and whatnot as a fix to your problems. That's a kludge that should be used last, after everything else is dialed in to what they should be. I'd set your e-steps back to what they ought to be. Using e-steps to try to "fix" problems is the wrong approach. Do the measurements and actually measure how many steps it takes, and use that value. Measure your filament and input that value. If it's within a couple thousandths of 1.75mm then it doesn't really matter here or there, but I recently was printing with some filament that was so much smaller I could actually see it with my naked eye, and measured it out at 1.62mm, which is definitely enough to make a difference.

Once you're printing with relative extrusion, then dial in your retraction. Once that's done, then modify your acceleration/max speed/jerk settings, and you should be printing really nicely. You can do all this with Cura too. There's nothing magical about Slic3r compared to Cura that caused the massive improvement in results you saw. It's just settings, and you can change whatever you need to in both and get pretty much the same results. Massive tweaking of the extrusion multiplier will just cause havoc from filament to filament and print to print.

Btw, I think I paid like $250-300 for that Maker Select printer, and by the time I was done with little upgrades and mods and whatnot I don't doubt I'd paid upwards of $600-700 total, including the Duet Wifi, which means I could have just bought a $600-700 print to start and probably been better served (other than the Duet Wifi, which I consider mandatory on any printer I will use). Oh well, I learned a massive amount with that printer, and so in the end it served me well.

-

RE: Motor noise and print qualityposted in Tuning and tweaking

@grizewald said in Motor noise and print quality:

@sethipus That's a very conclusive result!

My efforts to add a twist to the belts ran into a few snags. First I noticed that the clamp which holds my hot end had broken (at the rear where it wasn't visible until I took the printer apart in preparation for twisting the belts), so I had to print a new one in PETG this time to make it less likely to happen again.

Then I needed to redesign my part cooling duct so that I could get better access to the eccentric nut which tightens the hot end carriage wheel against the v-slot profile.I ran into a huge snag too. When I replaced my toothed idlers with smooth ones, I also replaced the corner brackets with ones that allowed both pulleys to be replaced without disassembling the printer (for some reason the original D-Bot corner brackets require disassembly to swap out one of the pulleys). The remixed corners I used also stuck down about 20mm or so further along the frame rails. For some reason I overlooked the fact that my Z-axis end stop no longer would fit where it had previously been mounted. Long story short, some severe violence using a bandsaw and a drill allowed me to jerry-rig the z-stop mount enough to fit it in between the bottom of the new corner brace and the wheels of the Z-axis carriage and I'm printing, but the current z-stop mount is a total hack (literally), so I'll have to design a more graceful solution that moves the z-stop to a different location.

As far as heat goes, I've only been running my steppers at 1.1-1.2 amps, and I haven't noticed heat to be much of a problem.

@JuKu yeah I've studied my now-former corduroy effect problem under a loupe and could see that it was a very fine difference in wall thickness that's so slight as to barely effect any dimensions, but on shiny and flat objects (where they lines align) be quite visually noticeable. I'm glad that's now a former problem.

@mrehorstdmd the idlers were 16t-sized. The original D-Bot uses a pair of stacked 623ZZ bearings (flanges outwards) to act as idler pulleys. When I swapped out my toothed idlers this weekend one of the corner braces got stacked 623ZZ bearings, the other one got actual smooth 16t-sized idlers that I happened to have. If I ever design or at least build a new printer I think I'd rather use 608-sized bearings or pulleys rather than these tighter-radius ones, or at least 20t-sized ones, for the larger radius.

-

RE: Motor noise and print qualityposted in Tuning and tweaking

@grizewald , I replaced all my toothed idlers with smooth ones, put the flip in the belt on the first run from the stepper on the "outside" runs of my CoreXY system so that the flat side of the belt is always bearing on the idler pulleys, and just finished my first print with it.

The flip made a ginormous difference in the surface quality, and utterly eliminated the "corduroy effect" I was seeing. I'm absolutely kicking myself that I didn't do this when I built the printer in the first place. It's unbelievable. Oh well, you live and learn.

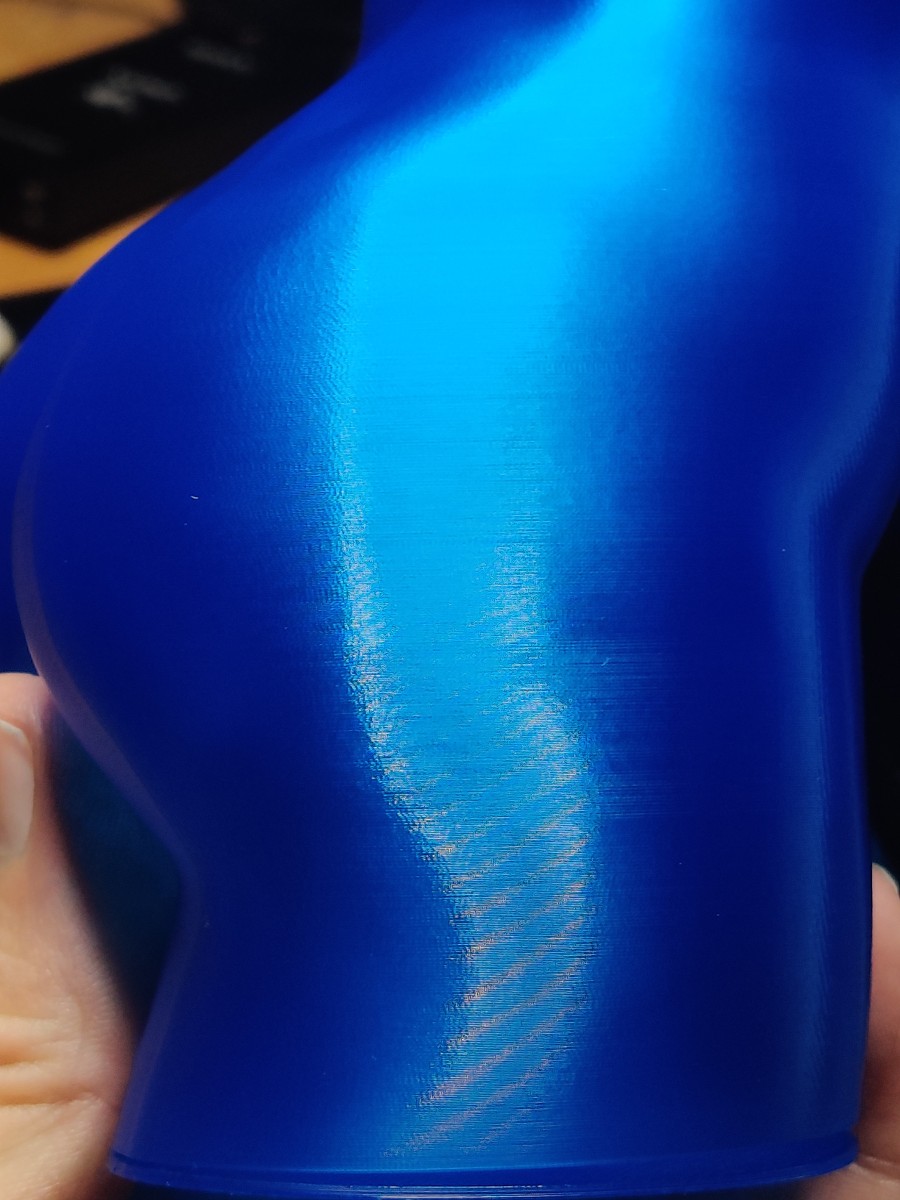

Here are two photos of a relatively innocuous portion of a particular figure. The blue one is the new print with the flipped belts and smooth idlers, the clear one is with the belts not flipped and the teeth rolling over toothed idlers.

As you can see, in the photo of the blue print all of that corduroy effect is completely gone. That corduroy effect has afflicted every print I've ever made on this printer until now. On highly detailed models with no or few flat or relatively flat surfaces, or with filament that doesn't reflect light that much, it wasn't really noticeable. On shiny flat surfaces it was always highly obvious. I almost can't even believe how much of a difference it's made.

-

RE: Motor noise and print qualityposted in Tuning and tweaking

@phaedrux said in Motor noise and print quality:

@sethipus The DBot isn't a very good candidate for enclosure. It's way more work than it's worth IMO. I've made do with a plastic shroud that can hang around the entire printer on it's stand. It's like a loose curtain. At the top is an exhaust duct. It works fairly well with ASA, etc, both with chamber temp and fume exhaust, but it's not perfect. 40c at best.

A design like the Voron2 or RailCore II that are designed from the ground up for enclosure would be perfect... if you want another new printer.

I totally hear ya. I do want to move my power supply out of the build area, and I could design a new Duet Wifi controller box that hangs off the side rather than being centered within the left-side frame. I think I could get the bottom enclosed, the sides, front, and rear without too much trouble. The top might be "well enough" enclosed with a little plastic bag-like tent that is tall enough not to disturb the bowden tube. You're 100% right that it's not optimal at all, but I think it could be done. I've got parts (including parts on my printer) that are from ASA, but I've struggled a lot with it warping. My attempts at PC blends almost all ended in warped parts. I even had PC-blend parts that stuck to the bed throughout the print, were annealed in place by placing a cardboard box over the completed print and allowed to heat-soak on the build plate for a couple hours, cool down slowly, and then literally warped after I removed them from the build plate. Other than nylon, I've all but given up the other filaments other than PLA and PETG until I can get my printer enclosed.

I'll have to look at those other designs and decide if I need to have another printer project in my future.

-

RE: Motor noise and print qualityposted in Tuning and tweaking

@grizewald said in Motor noise and print quality:

@sethipus said in Motor noise and print quality:

I don't recall what printer you're using @grizewald, but is it using gt2 belts to drive the X/Y access? And if so, are there places where your toothed belts are running around idler pulleys, whether smooth or toothed?

My printer is the V-Core from RatRig. They've just released version 2, so the pictures for version 1 are no longer present on the site, but it's big Core-XY based on OpenBuilds parts with a nominal 300 x 300 x 300mm build volume.

It looks like this:

It does use GT2 belts and apart from the pulleys, the belts go around OpenBuilds smooth idlers. It would be very difficult to arrange twists in the belts so that every idler had a smooth belt side running around it.

I had a close look at my D-Bot's setup and a single twist (per belt) immediately after the stepper itself, on the outer belt run (ie: not the one that must remain parallel) will ensure that the back side of my belt runs against the idlers for the rest of the run. When I first tried addressing the corduroy effect, I swapped out the smooth idlers for toothed ones, but it didn't really help. There is this microscopic jump in the X and Y motion as each tooth engages (or each ridge on the belt hits a smooth idler) that results in very slight extrusion rate differences on a printed straight line, and that's what's causing this effect.

Anyhow, CoreXY is CoreXY and I'd be surprised if your printer's belt runs are really any different than mine in this regard. Is there really no way to introduce a twist in the outer belt run away from each stepper, to get smooth belt backside against the idlers?

ETA: I really wish I'd built my D-Bot to the 300x300x300 version. I built mine to the 200x300x300 version. In theory it wouldn't be too hard to change mine, just four lengths of v-slot rail and a new build platform, but I just can't bring myself to do it. What concerns me more than that extra 100mm of Y axis is getting my printer enclosed. I've tried printing PC and nylon and ASA and whatnot without an enclosure without a lot of success (well, had more success with the nylon than the other two). My biggest thing is that I've got things that would be inside the enclosure if I just put a large box over it that I don't really want heated, like the power supply, Duet Wifi controller, and steppers, plus the bowden tube is sticking up from the extruder, which is mounted to the top rear frame rail. One of my next big upgrade projects will be to move everything that might be heat sensitive out of the build volume area, and figure out some attachment points or whatever for some materials that can enclose the build volume itself.

-

RE: Motor noise and print qualityposted in Tuning and tweaking

It looks like you're getting a much finer and more closely spaced vertical artifact, and then a much wider spaced and broader artifact, that looks very much like the "corduroy effect" I talked about with my prints, that has an ~2mm wavelength and thus is almost certainly connected with the gt2 belts. I don't recall what printer you're using @grizewald, but is it using gt2 belts to drive the X/Y access? And if so, are there places where your toothed belts are running around idler pulleys, whether smooth or toothed?

I've just reprinted the corner braces for my (massively customized) D-Bot, and I'm going to install the smooth pulleys in those braces, and tonight rebuild the top end of the printer with the smooth pulleys, and install new belts with a twist in them so that toothed belt is never wrapping around smooth idlers (ie: the flat back side of the belts will wrap around the idlers). Phaedrux reported that he'd been seeing the same corduroy effect as I do, and that when he stopped toothed belt from wrapping around his idlers on the 2mm-pitch toothed side this corduroy effect went away. I should be in a position to confirm or deny that with my printer something either tonight or at least sometime this weekend.

That corduroy effect obviously is all lined up like in your photo on flat surfaces like boxes and whatnot, but on curved surfaces it still shows up in very distracting patterns, as in this little snippet from another vase-mode print. It's this I'm hoping goes away after my work on the belts and pulleys this weekend.

-

RE: Motor noise and print qualityposted in Tuning and tweaking

@grizewald said in Motor noise and print quality:

@sethipus Thanks, I might be needing that luck!

I feel there is going to be some Dremel assisted violence visited upon the pulley today. I can't see any way to defend the stepper's bearings against the use of a hammer to slot the set screw, so cutting a slot through the pulley and into the set screw with a cutting disc would appear to be my only option. If slotting it fails, I'll just cut straight down along the flat part of the stepper's spindle and hope the cut misses the broken ball end. I don't much rate a cutting disc's chances against tool steel, even if it's cheap and nasty tool steel.

I rate the chances pretty highly actually. If you're going slow even if you hit the ball head your cutting disc should go through it just fine.

I printed a tall sculpture over the last couple of days and noticed a mechanical problem which I need to look at. When the printer was performing a 100mm/s travel move in the +X direction, the print head would clip the support layer it was travelling over with a loud 'snap'. If it wasn't for the fact I'd anchored the sculpture with a brim, I'm pretty sure the collisions would have knocked the print over. Even though that didn't happen, the resulting wobble lead to increasingly poor finish as the print got taller.

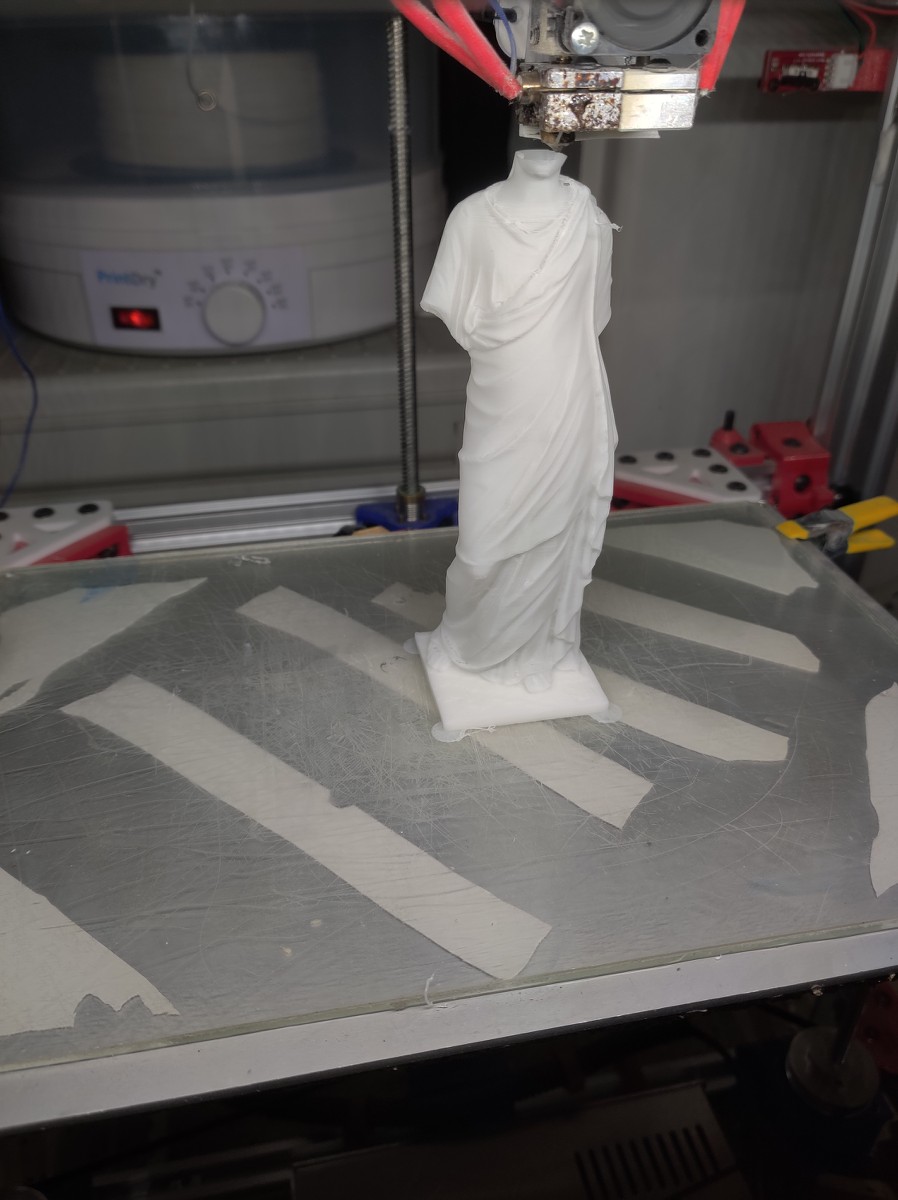

I've had that happen before. It's not always mechanical. It's possible the support structure is just curling up a little. Had that sort of thing happen many times. In fact, between reading your post and replying to it I heard a noise I didn't like the sound of. I'm printing a Greek statue in vase mode, and in a particularly tight fold of the woman's robe the head was making a very sharp turn, and apparently part of a line curled up just enough that it was starting to hit and get worse with each go around. I had to pause it twice and, with a little knife, cut a shaving of plastic off that was sticking up. As the fold continued up the statue it was happening again after a couple go arounds, and I ended up just very gently putting my fingers around the statue and holding it just enough to resist the gentle bump by the nozzle, and after several go arounds it got past that point and the problem was averted. I'll probably have some tiny little quality hiccup at that spot if I look at it carefully, but I did save the print. (so far, it's not finished yet, and I worry about the top of the head)

I found the Bondtech BMG remarkably immune to non-linear extrusion effects when I tested it. It was only when I got to 5mm/s extrusion that the amount of filament extruded would start to differ from what was commanded, so I've left that uncorrected for the moment.

I admit I set my non-linear extrusion parameters using my previous extruder, which was a belted, single-drive extruder. The values obtained were very small, and I haven't changed them, and they don't seem to be hurting me. I think I'll go through the tests again this weekend with the BMG clone and see how much different results I get. I don't think they'll change much until I get up to 6mm/s or so, because I believe a lot of the reduction I was seeing in feedrate at higher speeds was due to backpressure in the melt chamber, which hasn't changed, and didn't slip until the 5-6mm/s range.

-

RE: Motor noise and print qualityposted in Tuning and tweaking

Doh! that sucks about the ball head breaking off in the set screw. Good luck getting that off. I've made a lot of progress on my end. I've reprinted new versions of my upper frame corner braces that will make maintenance and adjustment far easier, and also got new genuine Gates belt. I'm going back from toothed idlers to the smooth stacked-bearing configuration, and will add a twist to the belts to keep the flat sides against the idlers. Combined with the move to the 0.9-degree steppers, and getting my config.g sorted out so I'm now running with 16x + 16x interpolation on all axes, my printer is quieter and should be delivering the best quality I've ever seen. Oh, over the last couple weeks I also got pressure advance and non-linear extrusion sorted out too, which contribute to that.

-

RE: Help me understand my M350/M92 commands (steps/microstepping)posted in Tuning and tweaking

@Phaedrux Btw just got my gt2 Gates belt, and I've reprinted the left and right rear corner braces where the pulleys go with a remixed version that allows the pulleys to be replaced without having to disassemble the whole top of the frame. Doh! Can't believe the original design has the lower pulley screws facing down. For good measure I also printed out versions of the stepper mounts that allow the belts to be tightened at the stepper motor, rather than at the print carriage. Either tonight, or latest this weekend, I'll pull the whole top end apart and rebuild it, replacing the four corner pieces, and using the original smooth bearings in place of the toothed pulleys I've got in there now, and using the twist of the belt to keep the flat belt backs against the flat bearing/pulleys. Assuming this was always the source of my "corduroy" pattern artifacts, my prints should come out better than ever.

I've never used M122 before. I'll have to add it to my ending scripts and get that output as default from now on. Sounds like a useful diagnostic.

-

RE: Help me understand my M350/M92 commands (steps/microstepping)posted in Tuning and tweaking

@phaedrux said in Help me understand my M350/M92 commands (steps/microstepping):

X16 with interpolation is definitely quieter and sounds smoother than using other microstepping values. At least on my machine.

As you're playing around with microstepping keep an eye on the hiccup count in the M122 report. If you're getting a few hiccups reported it would indicate you're exceeding the step rate limit.

I've got a print running right now where I just set X and Y to 16x with interpolation, and it does indeed sound a little quieter. It was pretty quiet before, but it's definitely a little quieter.

Btw, there was an error in my previous post. My Z steps for default needed to be 1500, not 256. Doh! I figured it out midway through the second layer of course. I've got multiples of the current print to make, so I'll set everything else to 16x with interpolation after this one and have some basis for comparison. I'm also happy inside that my config.g is a little more rigorous and sensible, even though it previously worked.

-

RE: PEI coated flex-plate systemposted in 3D Printing General Chat

@klcjr89 is it possible to order sizes other than what you have in your dropdown menu?

I ask because my D-Bot was built with the nominally 200x300 option, and my actual current heatbed is 215x335. I'd almost certainly order the PEI plate and magnet sheet if I could cover that. Given I'm currently using clips to hold down the glass/PEI sheet I currently print on I can't use the whole surface, but not having to use clips to hold the sheet down I'd love to be able to print out almost to the bitter ends of the plate.

A future upgrade for my printer will expand my heated bed to 230x350 (already have the aluminum plate for it), so it's possible I would order ones sized for that when the time comes.

-

RE: Help me understand my M350/M92 commands (steps/microstepping)posted in Tuning and tweaking

@deckingman, this was awesome, thanks!

I recognized "belt and braces" as a figure of speech, but didn't directly understand it, though from context I understood its meaning to be to be doubly sure. Being the curious type I looked it up, and it's a figure of speech in the UK referring to the use of both a belt and braces to hold up one's trousers, ie: make doubly sure they won't fall down. The sticking point linguistically for me was that we refer to braces in the US as "suspenders." Interesting tidbit. I interpret your caution here to mean that you don't want to just assume that M92 will calculate its values based on a 16x default (who knows, future drivers may change that) so you set everything to 16x in M350 prior to the M92 to ensure that that in fact is the basis for the setting, and then follow it within another M350 in order to set whatever microsteps/interpolation that you wish to actually use. Seems prudent to me, and I shall copy the practice myself.

When the current print is done I'll change my config.g as follows:

M350 X16 Y16 Z16 E16:16 ; confirm 16x defaults

M92 X200 Y200 Z256 E415:415 ; set steps according to 16x defaults

M350 X128 Y128 Z32 E64:64 I1 ; set steps to actually use, system will automagically recalculate stepsSubsequent to that I can feel free to change M350 values to alter axes' microsteps to my heart's content, with no need to manually recalculate M92. If there's no drawback it's possible I'll just set all axes to 16x and let interpolation happen with them, but it's likely I'll do that in stages so I can see the effects on individual axes as I make the changes. I'm actually curious whether little surface texture artifacts that I see will change with the extruder going from 64x microstepping to 16x with 16x interpolation.

Again, thanks for the help!

-

Help me understand my M350/M92 commands (steps/microstepping)posted in Tuning and tweaking

OK, so from my config.g I have:

M350 X128 Y128 Z32 E64 I1 ; Set microstepping with interpolation

M92 X1600 Y1600 Z3000 ; Set axis steps/mm. This is for the 0.9 degree steppersI should say that this is all working just fine. There's no problem here, but I want to re-arrange these in accordance with what I read yesterday in the docs, as referred to in another post here.

My understanding of what's in my config.g file is that with the M350 command first, I'm having to specify the M92 with the correctly calculated steps/mm, whereas if I put the M92 command in first using just the non-microstepping steps/mm, the M350 command will automatically recalculate the steps based on whatever microstepping I specify in the M350 command.

Since my printer is working properly, I can conclude that my M92 values are currently correct.

I also learned yesterday through reading threads here and in the docs that my I1 is having no effect (Duet Wifi here) because interpolation only takes effect with microstepping set to 16x, and all of my axes are currently at values higher than that.

Since my printer is working fine, and is pretty quiet (though not totally silent especially on fast travel moves) I should in theory leave well enough alone. Being a tinkerer, however, I just can't do that.

So I'd like to move my M92 command in front of the M350 command, and then be free to set different values in M350 for the various axes to try out different microstepping levels, maybe go 16x and let 256x interpolation work to see what difference that makes, etc. without having to recalculate M92 each time.

Here's what's bugging me: to set M92 before M350 I need to know what the non-microstepping steps are, and I am unsure if I'm understanding these values correctly. My first read is that I should simply divide the current M92 values by whatever level of microstepping I have set up in my current M350 command, but that leaves some pretty small values. For instance, X and Y axes have X128 Y128 set in M350, and X1600 Y1600 set in M350. Dividing the two would give me M92 X12.5 Y12.5, which seem very low. The printer is a D-Bot (CoreXY) with the standard 16-tooth pulleys on the X/Y steppers, which as of last week are 0.9-degree/step steppers (my E-stepper and Z-stepper are both still 1.8-degree steppers, and both have gear or belt reduction).

My e-steps are currently set in a separate line, which is:

M92 E1660:1660 ; esteps for 64x microstepping and the fake Bondtech BMG extrudersIf my understanding is correct, then my M92 command placed before the M350 command would be:

M92 X12.5 Y12.5 Z93.75

M92 E25.9375:25.9375Those values look wonky to me, especially the e-step value. 1660 doesn't look like it should make sense, but when extruding into thin air (not pushing into the hotend) I get as close to 100mm of filament out my bowden tube for a 100mm extrusion command as I can measure it with a ruler, so that's what's in there. I suppose I could extrude 500mm instead and cut the error margin down further with a more exact value, but haven't done that.

So firstly: am I understanding this correctly?

I just noticed that I've only specified one extruder in my M350 command, but two extruders in my M92 command, since I've got two extruders. Since I've still never used the second extruder the printer's been working fine, but I recognize that the M350 should be changed to E64:64 to be correct.

If I'm understanding this all correctly then I should change all this to:

M92 X12.5 Y12.5 Z93.75

M92 E25.9375:25.9375

M350 X128 Y128 Z32 E64:64 I1Knowing that the I1 isn't actually meaningful with those settings, which would have to change some axis to 16x microstepping in order for interpolation to occur.

I could just try this right now (not literally right now since I'm in the middle of a print), but I'd like to avoid sending my print gantry crashing into the frame if I'm wrong, and I'd like to ensure that I'm actually understanding this correctly, not just going on trial and error.

I'm thinking once these values are correctly set I may experiment with M350 X16 Y16 first to let interpolation go into effect and see if it makes any difference. As my Z and E are both reduced (4:1 I believe in the case of the extruder and I forget what pulleys I used in my Z, but it could be 3:1, I'd have to count the pulley teeth). With the gear reductions in Z and E I think the current values are already very fine, so not sure what real advantage would accrue with 16x + interpolation to 256 with those, though I'd probably give them a try.

Anyhow, am I on the right track?

-

RE: Where can I get a new 3D printer with Duet3d already installed?posted in General Discussion

Whether he's wrong or not I couldn't possibly know, but you do show an overly aggressive "bedside manner" that makes me think he's right that no vendor would really want to deal with you.

I don't know if this is meant to be your second printer or if you had more than one already, but I think CalvinX is right about mucking about with printers; there's some things people simply won't learn without doing it. If you've extensively modded, repaired, upgraded, etc. a printer before then maybe you really are well on your way. If you haven't, then I think CalvinX is right.

How much is a Duet Wifi right now? $179 or so? Why not just buy a cheap-enough printer whose features you want and in approximately the price range you want and upgrade it to a Duet Wifi yourself? It's only a very small fraction of the time and effort of building a whole printer. If you look at the printers available it should be possible to find one whose existing components, with little to no further modification, should be compatible. Unhook some wires, hook up the Duet Wifi, print out a case to hold it, and be on your way. I got my original Wanhao printer up and running with Duet Wifi in one evening, and built my D-Bot with another Duet Wifi from the ground up, skipping the RAMPS completely that was specced in the design. It wasn't rocket science, and it didn't take much time. If you can't spare one weekend to do this yourself then good luck when your printer requires some other maintenance.