Never mind. I got it working. The issue was with the time delays.

Chinese documentation:

M569 P41.0 S1 R1 T2.5:2.5:5:5

Reality:

M569 P41.0 S1 R1 T6:6:6:6

Never mind. I got it working. The issue was with the time delays.

Chinese documentation:

M569 P41.0 S1 R1 T2.5:2.5:5:5

Reality:

M569 P41.0 S1 R1 T6:6:6:6

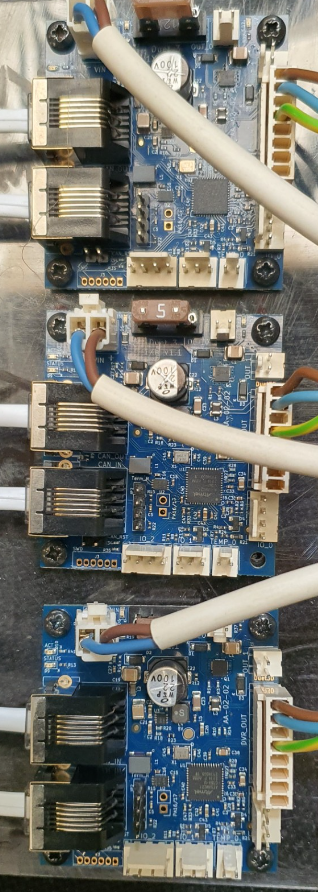

@droftarts At first, I intended to use the 6XD, but I received a pre-wired and configured 6HC bundled with an extruder, so I thought adding 3x 1XD would be faster and cheaper than switching to the 6XD.

Never mind. I got it working. The issue was with the time delays.

Chinese documentation:

M569 P41.0 S1 R1 T2.5:2.5:5:5

Reality:

M569 P41.0 S1 R1 T6:6:6:6

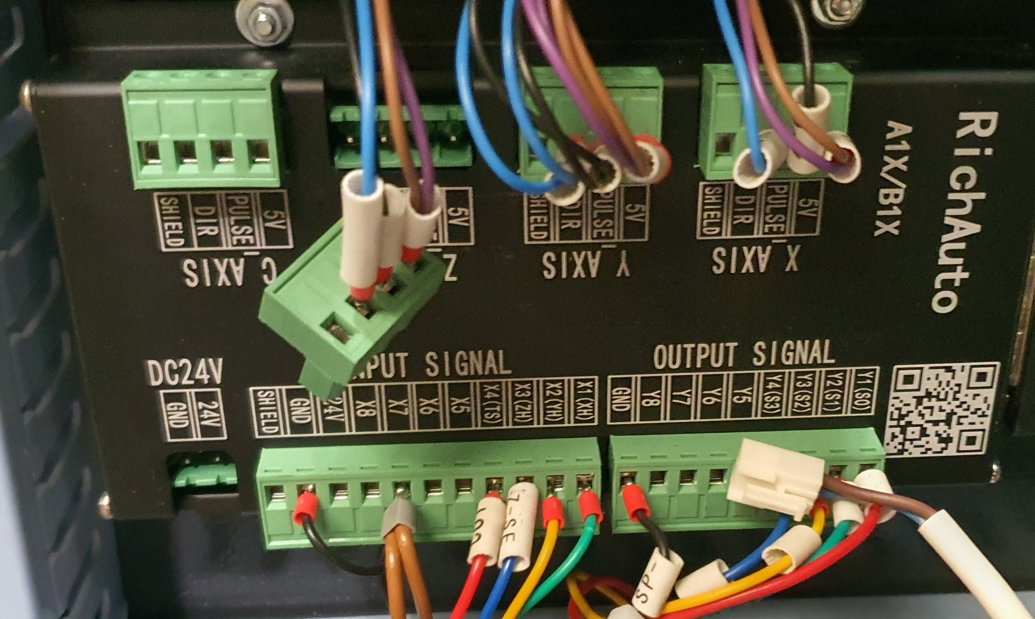

I am generally converting a CNC milling machine into a 3D printer. I want to replace the old motherboard (RichAuto A1X/B1X) with a Duet 6hc and 1xd modules.

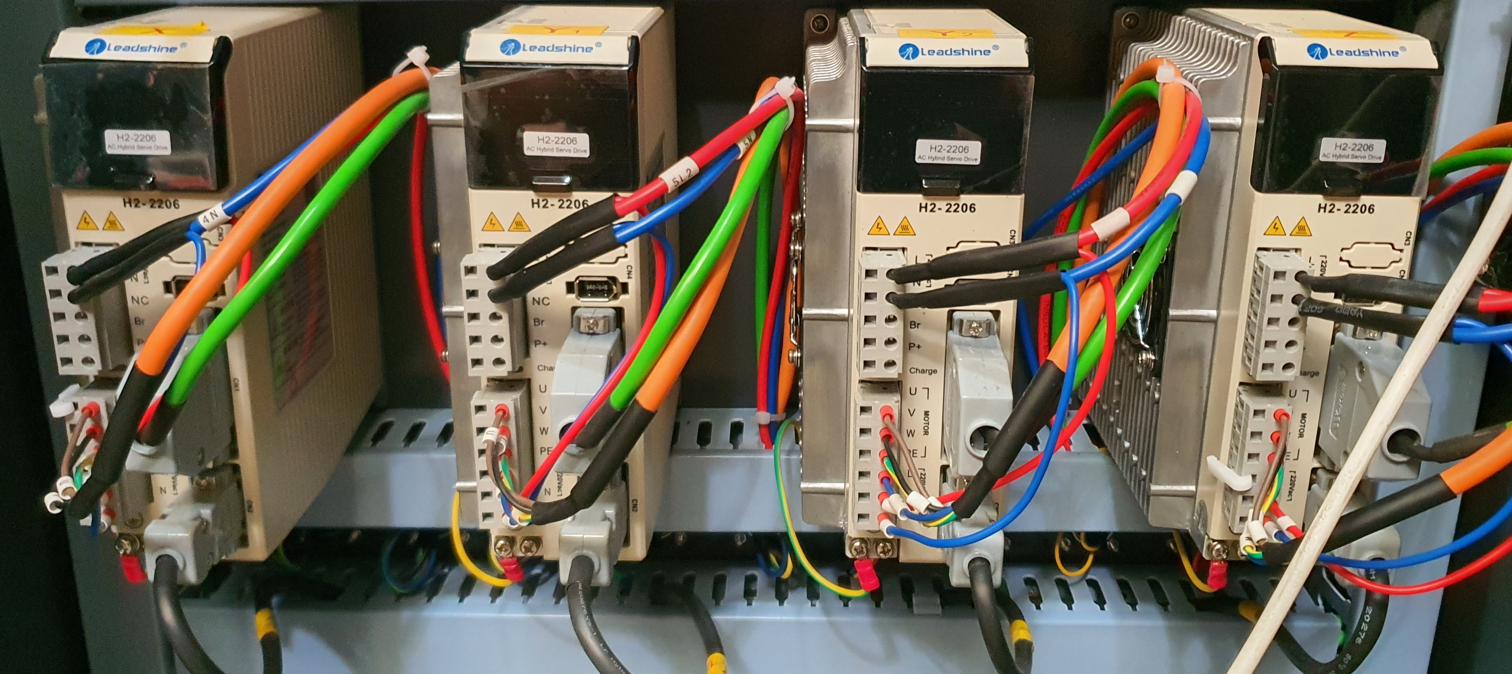

The motor drivers are H2-2206, and the servo motors are 863HSM100H. The documentation includes information about pulse times, and they are set in the firmware as follows:

M569 P41.0 S1 R1 T2.5:2.5:5:5

Regarding the connections, +5V is connected to 5V, STEP- to PULSE-, and DIR- to DIR-. The drivers do not have EN inputs.

; Configuration file for Duet 3 (firmware version 3.5.1)

; executed by the firmware on start-up

;

; SBC Config

M291 P"Applying persistent configuration options" R"Please wait" S1 T60 ; show that persistent settings are being configured

while exists(sbc) && plugins.DuetPiManagementPlugin.pid < 0 && iterations < 30

G4 S2 ; wait for DuetPiManagementPlugin to become available

G4 S2 ; wait another moment

M929 S2 ; start logging events to the SD Card

M550 P"MD" ; set persistent hostname for printer

;M551 P"mdrapid" ; set password

M586 P0 S1 C"*" ; configure HTTP & enable CORS

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

M292 ; hide message box again upon completion

; General Preferences

G21 ; Work in millimetres

G90 ; absolute coordinates

M83 ; relative extruder moves

; Drives

M569 P41.0 S1 R1 T2.5:2.5:5:5 ; physical drive 0.0 goes forwards with active high enable config pulses intervals (x)

M569 P42.0 S1 R1 T2.5:2.5:5:5 ; physical drive 0.0 goes forwards with active high enable config pulses intervals (y)

M569 P43.0 S1 R1 T2.5:2.5:5:5 ; physical drive 0.0 goes forwards with active high enable config pulses intervals (z)

M584 X41.0 Y42.0 Z43.0 ; set drive mapping

M92 X83.50 Y83.50 Z320.00 ; set steps per mm

M566 X600.00 Y600.00 Z60.00 ; set maximum instantaneous speed changes (mm/min)

M203 X3000.00 Y3000.00 Z1800.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 ; set accelerations (mm/s^2)

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X2000 Y4000 Z320 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io2.in

M574 Y1 S1 P"io3.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io3.in

; Z-Probe

M558 P5 C"io5.in" H10 F900 T3000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z8 ; set Z probe trigger value, offset and trigger height

M557 X0:1250 Y0:2400 S200 ; define mesh grid

; PE320 Extruder

M569 P40.0 S1 R1 T0:0:0:0 ; external drive CAN address 40 goes forward, active high enable

M584 E40.0 ; set drive mapping - map extruder to CAN address 40

M350 E1 I0 ; configure extruder with NO microstepping

M92 E301.6485 ; set steps per mm - extruder E-steps/mm (resolution of 1:48) or 166.7 steps/rev

M566 E3000 ; set maximum instantaneous speed changes (mm/min)

M203 E3000 ; set maximum speeds (mm/min)

M201 E20000 ; set accelerations (mm/s^2)

; Temp sensor parameters

M308 S0 P"2.spi.cs0" Y"rtd-max31865" A"Top"

M308 S1 P"2.spi.cs1" Y"rtd-max31865" A"Middle"

M308 S2 P"2.spi.cs2" Y"rtd-max31865" A"Bottom"

M308 S3 P"2.spi.cs3" Y"rtd-max31865" A"Nozzle"

; Create heaters

M950 H0 C"out0" T0 ; create Top heater output on out0 and map it to sensor 0

M950 H1 C"out1" T1 ; create Middle heater output on out1 and map it to sensor 1

M950 H2 C"out2" T2 ; create Bottom heater output on out2 and map it to sensor 2

M950 H3 C"out3" T3 ; create Nozzle heater output on out3 and map it to sensor 3

; Set PID heater parameters

M307 H0 R1.319 K0.319:0.000 D25.28 E1.35 S1.00 B0

M307 H1 R0.650 K0.120:0.000 D35.30 E1.35 S1.00 B0

M307 H2 R0.636 K0.188:0.000 D41.46 E1.35 S1.00 B0

M307 H3 R0.500 K0.137:0.000 D21.29 E1.35 S1.00 B0

; Maximum extruder heater temperature

M143 H0 S400 ; set temperature limit for heater 0 to 400C

M143 H1 S400 ; set temperature limit for heater 0 to 400C

M143 H2 S400 ; set temperature limit for heater 0 to 400C

M143 H3 S400 ; set temperature limit for heater 0 to 400C

; Extruder heater fault detection

M570 H0 P60 T30 ; An anomaly on heaters 0 must persist for 60 seconds, and must be greater or less than 30C from the setpoint, to raise a heater fault.

M570 H1 P60 T30 ; An anomaly on heaters 1 must persist for 60 seconds, and must be greater or less than 30C from the setpoint, to raise a heater fault.

M570 H2 P60 T30 ; An anomaly on heaters 2 must persist for 60 seconds, and must be greater or less than 30C from the setpoint, to raise a heater fault.

M570 H3 P60 T30 ; An anomaly on heaters 3 must persist for 60 seconds, and must be greater or less than 30C from the setpoint, to raise a heater fault.

; Define Heaters as Tools

M563 P0 H0 S"Top"

M563 P1 H1 S"Middle"

M563 P2 H2 S"Bottom"

M563 P3 D0 H3 S"Nozzle"

; Heater Cooling Fans

M950 F0 C"2.out0+io1.in" Q100 A"Heat Break Fan" ; Heat Break Fan -- 4-wire PWM 12V fan so invert it, 100Hz PWM, NO tacho

M950 F1 C"!2.out3+out3.tach" Q100 A"Top Fan" ; Top Fan -- 4-wire PWM 12V fan so invert it, 100Hz PWM, tacho connected

M950 F2 C"!2.out4+out4.tach" Q100 A"Middle Fan" ; Middle Fan -- 4-wire 12V PWM fan so invert it, 100Hz PWM, tacho connected

M950 F3 C"!2.out5+out5.tach" Q100 A"Bottom Fan" ; Bottom Fan -- 4-wire 12V PWM fan so invert it, 100Hz PWM, tacho connected

M106 P0 S1 T40 H0:1:2:3 ; Turn on Heat Break Fans when heaters 0-3 are above 40 deg

M106 P1 S0.5 ; Run at 20% speed at 2200rpm (max 11000rpm)

M106 P2 S0.5 ; Run at 20% speed at 2200rpm (max 11000rpm)

M106 P3 S0.5 ; Run at 20% speed at 2200rpm (max 11000rpm)

; Bed Heaters

;M308 S4 P"1.temp0" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed thermistor at 1.temp0

;M308 S5 P"1.temp1" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed thermistor at 1.temp1

;M308 S6 P"1.temp2" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed thermistor at 1.temp2

;M308 S7 P"temp0" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed thermistor at temp0

;M950 H4 C"1.out0" T4 Q10 ; create bed heater output on 1.out0 and map it to temp sensor 4

;M950 H5 C"1.out1" T5 Q10 ; create bed heater output on 1.out1 and map it to temp sensor 5

;M950 H6 C"1.out2" T6 Q10 ; create bed heater output on 1.out2 and map it to temp sensor 6

;M950 H7 C"1.out3" T7 Q10 ; create bed heater output on 1.out3 and map it to temp sensor 7

;M307 H4 R0.421 K0.321:0.000 D5.73 E1.35 S1.00 B0 ; Bed PID tuning parameters

;M140 P0 H4 ; map heater 4 to heated bed 0

;M140 P1 H5 ; map heater 5 to heated bed 1

;M140 P2 H6 ; map heater 6 to heated bed 2

;M140 P3 H7 ; map heater 7 to heated bed 3

;M143 H4 S120 ; max temp -- 120 deg C

;M143 H5 S120 ; max temp -- 120 deg C

;M143 H6 S120 ; max temp -- 120 deg C

;M143 H7 S120 ; max temp -- 120 deg C

;M570 H4 P60 T15 ; An anomaly on heaters 4 must persist for 60 seconds, and must be greater or less than 15C from the setpoint, to raise a heater fault.

;M570 H5 P60 T15 ; An anomaly on heaters 4 must persist for 60 seconds, and must be greater or less than 15C from the setpoint, to raise a heater fault.

;M570 H6 P60 T15 ; An anomaly on heaters 4 must persist for 60 seconds, and must be greater or less than 15C from the setpoint, to raise a heater fault.

;M570 H7 P60 T15 ; An anomaly on heaters 4 must persist for 60 seconds, and must be greater or less than 15C from the setpoint, to raise a heater fault.

; Define Bed Heaters as Tools

;M563 P4 H4 S"Bed 0"

;M563 P5 H5 S"Bed 1"

;M563 P6 H6 S"Bed 2"

;M563 P7 H7 S"Bed 3"

; Define Inputs

M950 J0 C"io0.in" ; Relay 12 - Estop

M950 J1 C"io1.in" ; Relay 13 - Reset

;M950 J2 C"io2.in" ; Relay 14 - X-Endstop

;M950 J3 C"io3.in" ; Relay 15 - Y-Endstop

;M950 J4 C"io4.in" ; Relay 16 - Z-Endstop

;M950 J5 C"io5.in" ; Relay 17 - Z-Probe

M950 J6 C"io6.in" ; Relay 18 - FREE

M950 J7 C"io7.in" ; Relay 19 - FREE

M950 J8 C"io8.in" ; Relay 20 - FREE

M950 J9 C"1.io0.in" ; Relay 21 - FREE

M950 J10 C"1.io1.in" ; Relay 22 - FREE

M950 J11 C"2.io0.in" ; Smart Wiring Loom - Material sensor LEFT

M950 J12 C"2.io2.in" ; Smart Wiring Loom - Material sensor RIGHT

M950 J13 C"40.io0.in" ; 1XD board - Servo Drive Fault

; Configure Input Triggers

M581 P1 T2 S1 R0 ; Relay 13 - trigger 2 (Reset) activates on falling edge when Estop button is pressed

M581 P13 T3 S1 R0 ; Trigger 3 (Servo Drive Fault) activates on falling edge when servo fault detected

; Define Ouputs

M950 P0 C"out4" ; Relay 1 - Pellet Material Feed Solenoid

M950 P1 C"out5" ; Relay 2 - Part Cooling Solenoid

M950 P2 C"out6" ; Relay 3 - FREE

M950 P3 C"out7" ; Relay 4 - FREE

M950 P4 C"out8" ; Relay 5 - FREE

M950 P5 C"out9" ; Relay 6 - FREE

M950 P6 C"1.out1" ; Relay 7 - FREE

M950 P7 C"1.out2" ; Relay 8 - FREE

M950 P8 C"1.out3" ; Relay 9 - FREE

M950 P9 C"1.out4" ; Relay 10 - FREE

M950 P10 C"1.out5" ; Relay 11 - FREE

M950 P11 C"40.io0.out" ; 1XD board - Clear Servo Drive Faults

; Set Outputs

M42 P0 S0 ; Output OFF

M42 P1 S0 ; Output OFF

M42 P2 S0 ; Output OFF

M42 P3 S0 ; Output OFF

M42 P4 S0 ; Output OFF

M42 P5 S0 ; Output OFF

M42 P6 S0 ; Output OFF

M42 P7 S0 ; Output OFF

M42 P8 S0 ; Output OFF

M42 P9 S0 ; Output OFF

M42 P10 S0 ; Output OFF

M42 P11 S0 ; Output OFF

; Select Tool

T3 ; select nozzle heater with PE320 extruder

M568 P3 A0 ; set nozzle heater to off

; Custom settings

https://www.control-drive.com/Documents/Manuals/CN/H2-2206_manual_cn.pdf

https://www.scribd.com/document/717854727/H2-2206-manual-cn

https://forsuncnc.com/wp-content/uploads/2021/11/DSP-A11-User’s-Manual.pdf

This is the second milling machine I am converting into a 3D printer. The previous one was very similar, and it works correctly. The motor drivers there were H2-758. I also connected only 5V, Step-, and Dir- there. I used Duet 6xd there. When I measure the step signal during movement there, it shows 0.5V, which is more than on 1xd.

Hi,

I am connecting a stepper motor driver via the Duet 1XD module to the driver out outputs: +5V, step-, and dir-. When I click on the +50 or -50 shift on the panel, nothing happens.

After measuring the voltages with a multimeter on +5V and dir-, it shows 5V, and after changing the direction of movement, it shows 0V (which is correct).

When measuring the voltage between +5V and step-, it shows 0V, and when I click on the +50 or -50 shift on the panel, the voltage changes briefly to 0.05V (while it should change to 5V). What could be the cause?