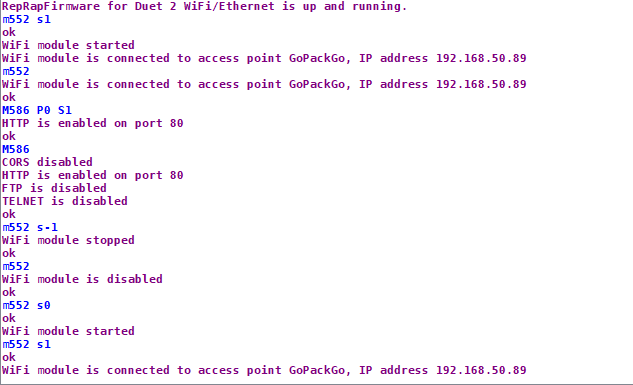

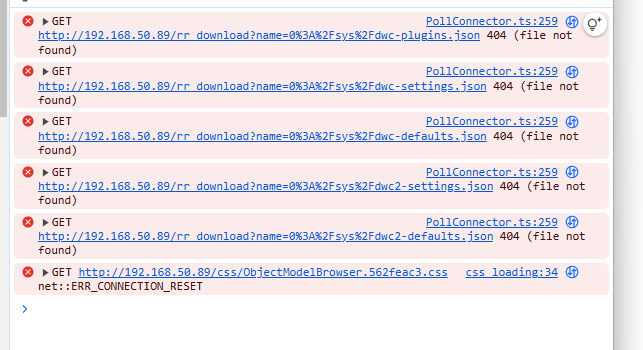

FWIW, I pulled the SD card out and checked it again, popped it in and it connected back to my GoPackGo network. I was able to navigate to the DWC with the provided IP, however it quickly disconnected me again.

So I did an M588 S"GoPackGo" to force it to switch to GoPackGoGuest.

And it did.

So I switched to GoPackGoGuest on my PC and navigated to the displayed IP and.... nothing. It just times out.

So here's my m122 now. I'm going to bed and I'll see if sleep helps.

m122

=== Diagnostics ===

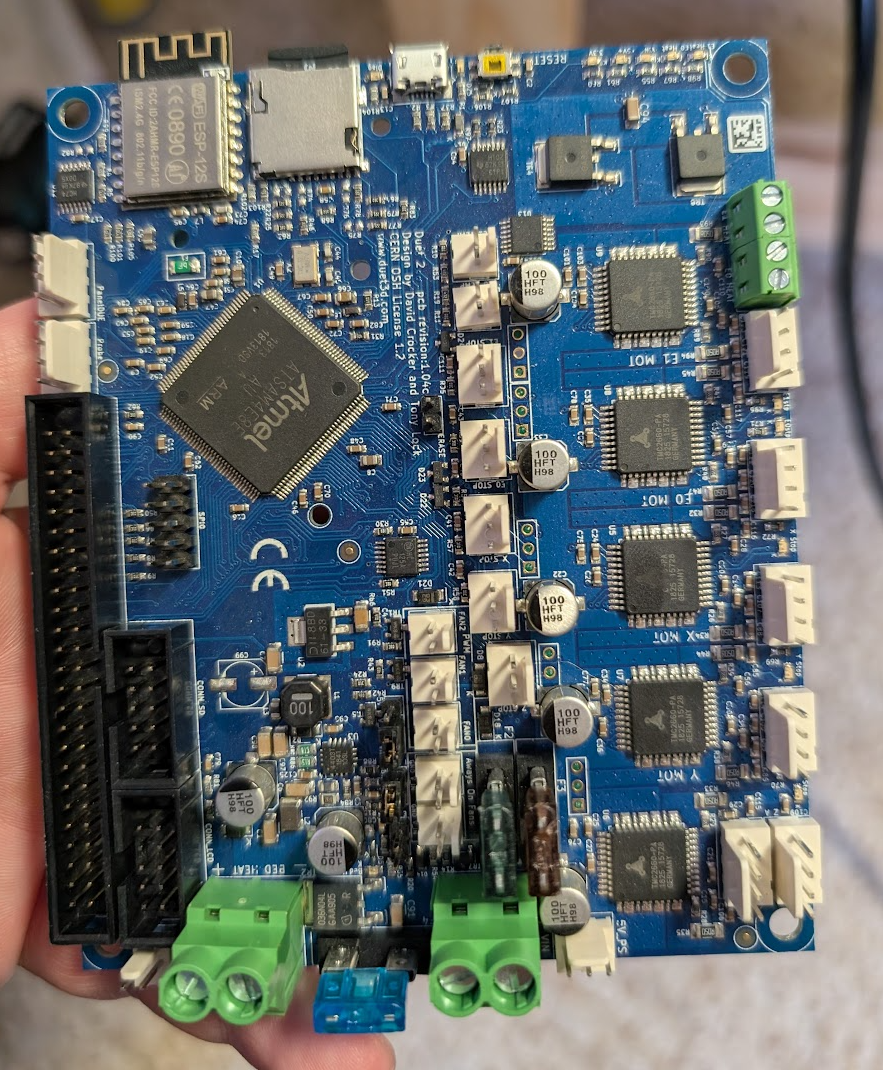

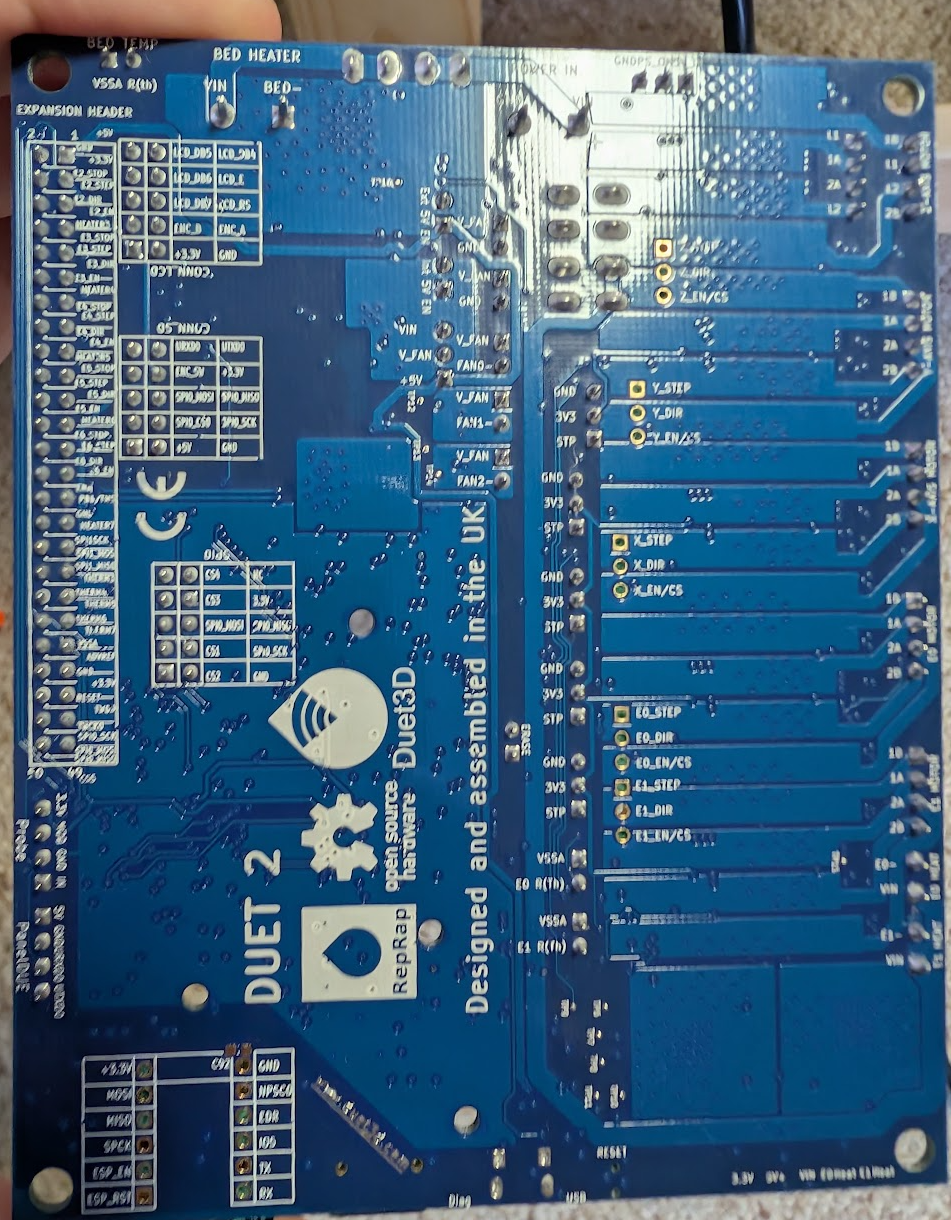

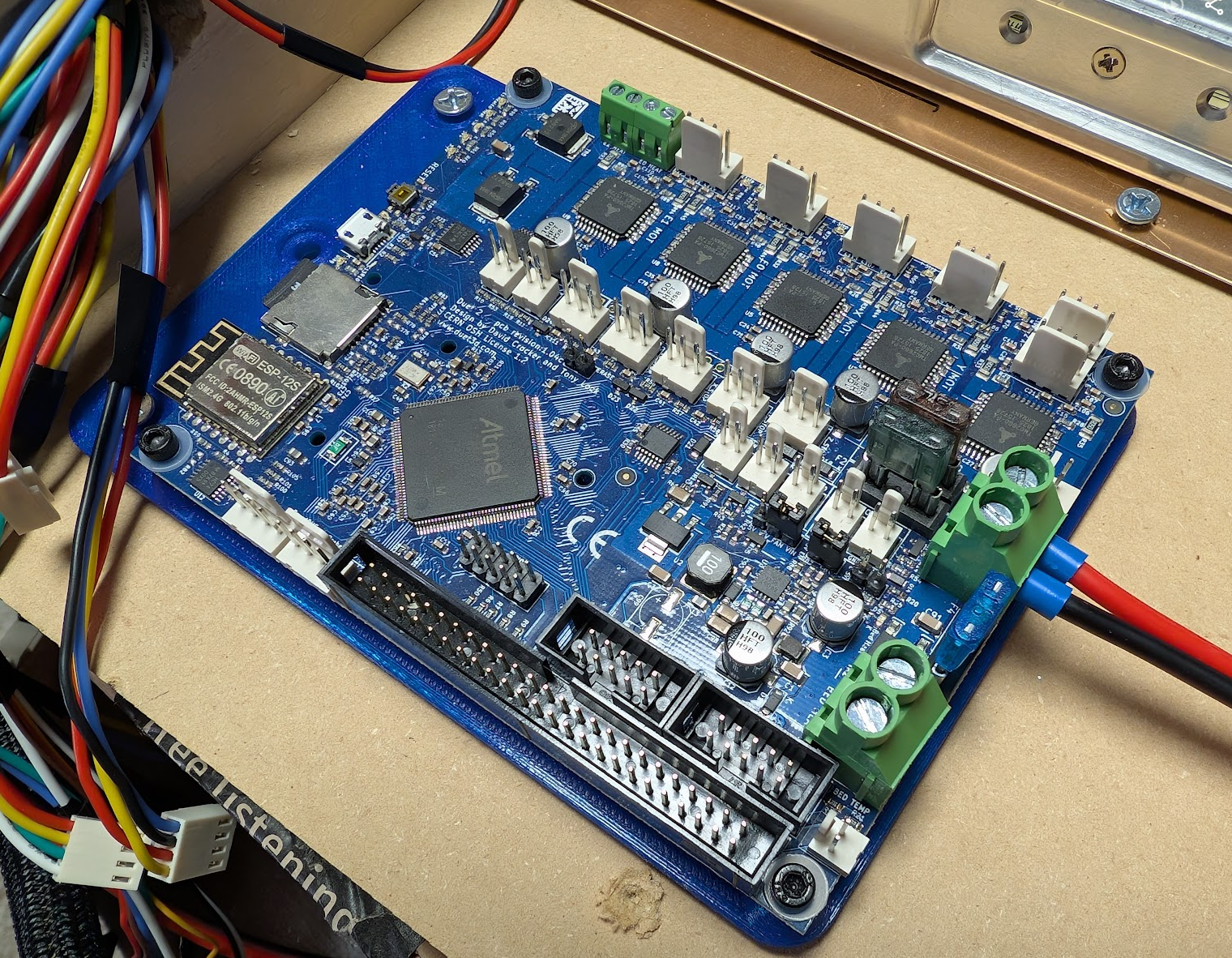

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.5.4 (2024-11-24 10:43:42) running on Duet WiFi 1.02 or later

Board ID: 08DGM-917NK-F2MS4-7JTDJ-3SD6M-KDT8F

Used output buffers: 1 of 26 (14 max)

=== RTOS ===

Static ram: 23488

Dynamic ram: 70940 of which 0 recycled

Never used RAM 19048, free system stack 186 words

Tasks: NETWORK(1,ready,26.8%,239) HEAT(3,nWait 5,0.0%,378) Move(4,nWait 5,0.0%,361) MAIN(1,running,73.2%,501) IDLE(0,ready,0.0%,29), total 100.0%

Owned mutexes: USB(MAIN)

=== Platform ===

Last reset 00:09:18 ago, cause: power up

Last software reset details not available

Error status: 0x00

MCU temperature: min 26.9, current 29.7, max 30.2

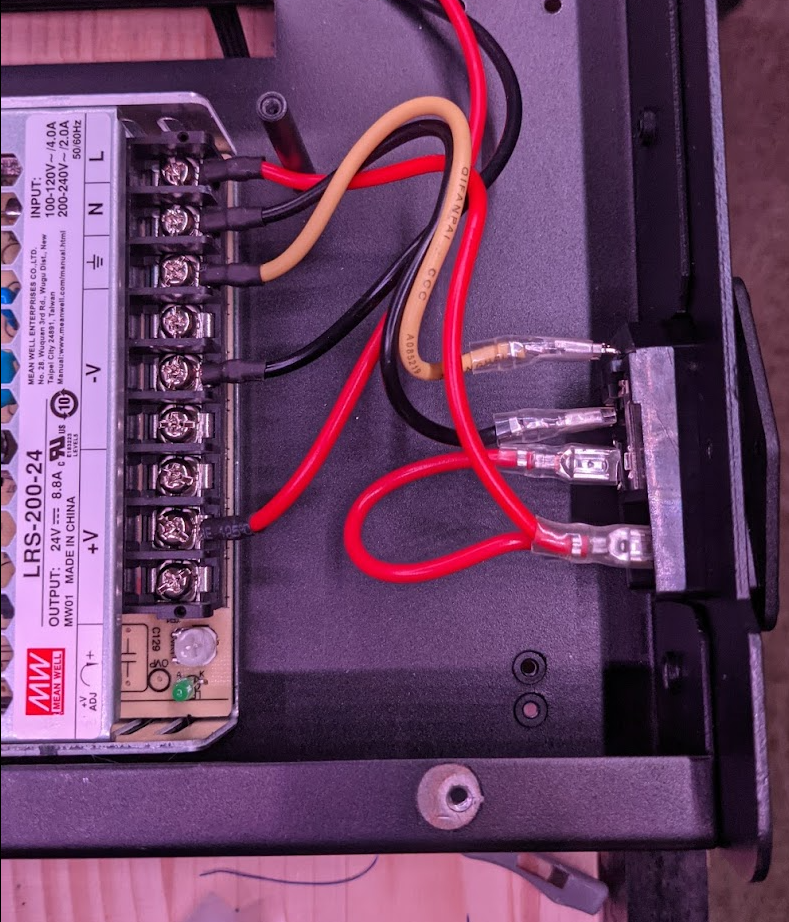

Supply voltage: min 1.6, current 1.7, max 1.8, under voltage events: 0, over voltage events: 0, power good: no

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: ok, SG min n/a

Driver 1: ok, SG min n/a

Driver 2: ok, SG min n/a

Driver 3: ok, SG min n/a

Driver 4: ok, SG min n/a

Driver 5:

Driver 6:

Driver 7:

Driver 8:

Driver 9:

Driver 10:

Driver 11:

Date/time: 2025-02-06 22:21:18

Cache data hit count 4294967295

Slowest loop: 99.26ms; fastest: 0.14ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 3.8ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00

no step interrupt scheduled

Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0

=== DDARing 0 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Movement locks held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is ready with "m122" in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Q0 segments left 0

Code queue 0 is empty

=== Network ===

Slowest loop: 17.02ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 0 of 8

=== WiFi ===

Interface state: active

Module is connected to access point

Failed messages: pending 0, notrdy 0, noresp 0

Firmware version 2.2.0

MAC address 60:01:94:2e:9a:74

Module reset reason: Turned on by main processor, Vcc 3.43, flash size 4194304, free heap 46064

WiFi IP address 192.168.101.88

Signal strength -48dBm, channel 5, mode 802.11n, reconnections 0

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

ok