@Phaedrux - Another note - I'll now do the Calibration for the PT1000 per:

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Temperature_connecting_thermistors_PT1000

Puterpro - Out. Be well my distant friend.

@Phaedrux - Another note - I'll now do the Calibration for the PT1000 per:

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Temperature_connecting_thermistors_PT1000

Puterpro - Out. Be well my distant friend.

@Phaedrux said in Extruder not showing Temps after upgrade:

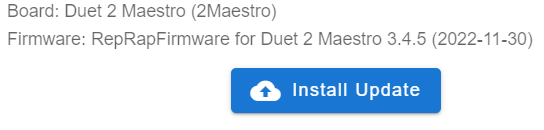

And just on the off chance that something went wacky with all the firmware updates, you can re-apply the firmware entirely by uploading the 3.4.5 zip file to the sys folder.

https://github.com/Duet3D/RepRapFirmware/releases/download/3.4.5/Duet2and3Firmware-3.4.5.zip

Upload the file itself, don't extract first.

That's what I started with, and I know to load the zip. I'll re-download just in case and try it if you haven't any thoughts about the heater test.

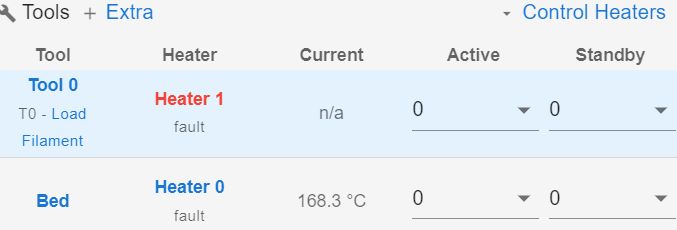

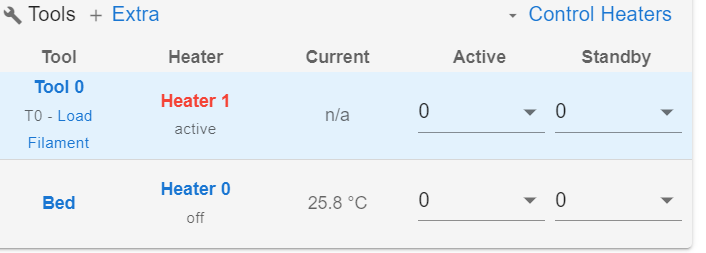

EDIT: I edited "e0temp" to "ctemp" and moved Thermistor to there, same message - HE is "Active" and Temp is "n/a". I'll try reloading the firmware as above and let you know.

BINGO! I suspected corrupted s/w but didn't question the Github download I'd done.

Came right up but temp was wrong so I guess I'd used a PT1000 so I changed "pt1000" B4092 and we have:

Yea!  I'll move it back to E0 so I don't go "Huh??!?" six months from now. Ha!

I'll move it back to E0 so I don't go "Huh??!?" six months from now. Ha!

Thanks so much, you're a Prince.

@Phaedrux Interesting thought! Wish I'd thought of it, LOL Here's the results (E0 disconnected)

@Phaedrux said in Extruder not showing Temps after upgrade:

If you're on firmware and DWC 3.4.5 just stay there. No need to jump around firmwares now.

Noted. Wanted to be sure I got a good load and json matched my changes for future uploads to Configurator.

If you copy and pasted the config sample for the heaters I posted, the config should be correct.

I agree. But it didn't work ...Also - Heater and Thermistor wired to either E0 or E1 makes no change.

Can you post your config.g as it currently is?

Sure:

; Configuration file for Duet Maestro (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.15 on Thu Jan 19 2023 09:20:10 GMT-0500 (Eastern Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"CR-10S DUET" ; set printer name

; Network

M552 P192.168.1.18 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.1.254 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z26.56 E419.80 ; set steps per mm

M566 X900.00 Y900.00 Z31.80 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z699.60 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y250.00 Z16.60 E166.00 ; set accelerations (mm/s^2)

M906 X1100 Y1100 Z1000 E900 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-5 Y-5 Z0 S1 ; set axis minima

M208 X295 Y305 Z320 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M950 S0 C"zprobe.mod" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6600 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X45 Y15 Z0.6 ; set Z probe trigger value, offset and trigger height

M557 X5:295 Y5:305 S20 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S110 ; set temperature limit for heater 0 to 110C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool

===========================================

Also please post the results of sending M122 and M98 P"config.g" in the gcode console.

1/20/2023, 7:56:04 AM M122

=== Diagnostics ===

RepRapFirmware for Duet 2 Maestro version 3.4.5 (2022-11-30 19:42:44) running on Duet Maestro 1.0

Board ID: 08D8M-9T8A2-MQNS0-7J9DD-3SS6S-9RT2X

Used output buffers: 1 of 26 (23 max)

=== RTOS ===

Static ram: 23620

Dynamic ram: 67020 of which 0 recycled

Never used RAM 23848, free system stack 218 words

Tasks: NETWORK(ready,24.7%,262) HEAT(notifyWait,0.1%,356) Move(notifyWait,0.0%,404) TMC(notifyWait,1.3%,117) MAIN(running,73.8%,492) IDLE(ready,0.0%,31), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:36:27 ago, cause: power up

Last software reset at 2023-01-19 09:24, reason: User, GCodes spinning, available RAM 23848, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Step timer max interval 1331

MCU temperature: min 28.4, current 36.0, max 36.5

Supply voltage: min 24.7, current 24.7, max 24.8, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, read errors 0, write errors 0, ifcnt 6, reads 36867, writes 6, timeouts 0, DMA errors 0, CC errors 0

Driver 1: standstill, read errors 0, write errors 0, ifcnt 6, reads 36867, writes 6, timeouts 0, DMA errors 0, CC errors 0

Driver 2: standstill, read errors 0, write errors 0, ifcnt 6, reads 36867, writes 6, timeouts 0, DMA errors 0, CC errors 0

Driver 3: standstill, read errors 0, write errors 0, ifcnt 6, reads 36867, writes 6, timeouts 0, DMA errors 0, CC errors 0

Driver 4: standstill, read errors 0, write errors 0, ifcnt 6, reads 36867, writes 6, timeouts 0, DMA errors 0, CC errors 0

Driver 5: not present

Driver 6: not present

Date/time: 2023-01-20 07:56:02

Slowest loop: 16.85ms; fastest: 0.17ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 15.0MBytes/sec

SD card longest read time 3.6ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1, chamber heaters -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== Network ===

Slowest loop: 30.29ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 1 of 8

Interface state active, link 100Mbps full duplex

========================================

1/20/2023, 7:57:37 AM M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

And finally, how bout a photo of the wiring on the board?

OK:

Can you check continuity of the thermistor cabling?

Mentioned twice above.  Digital Multimeter reads both heater and Thermistor at normal values. I also said I'd substituted a new, good, (knowing that's NOT the same thing LOL) Thermistor for testing, still gives "Active" and "n/a" for temp. Note: this machine has been running perfectly for months under 2.03, only change is the Firmware. Not dealing with some recent hardware change. FYI - I know you deal with lots of wiring & bad parts issues, but I'm an Electronics Tech for a looong time. Not bragging, just info. Wirings messy but functional. Thanks for your help with this!!

Digital Multimeter reads both heater and Thermistor at normal values. I also said I'd substituted a new, good, (knowing that's NOT the same thing LOL) Thermistor for testing, still gives "Active" and "n/a" for temp. Note: this machine has been running perfectly for months under 2.03, only change is the Firmware. Not dealing with some recent hardware change. FYI - I know you deal with lots of wiring & bad parts issues, but I'm an Electronics Tech for a looong time. Not bragging, just info. Wirings messy but functional. Thanks for your help with this!!  LOL

LOL

@Phaedrux Well Hello old Friend! Very long time since we spoke, hope all's well in your world.

No joy. I had moved to E1 for both heater and Thermistor, so for this code I moved them back to E0.

Same thing. I get "Active" and "n/a" as above. DMM reads both as normal values.

I grabbed a brand new Thermistor and tried it for a test, same thing.

I'm guessing corrupt software somehow.

I misunderstood in my 1st steps that Configurator would ALSO grab the latest files (Firmware and DWC) and include that in the zip, so I handled the config files & DWC as separate uploads from the Firmware. I get now that was wrong.

My upgrade path was: 2.04 / DWC Equally old > Backup sys to zip > Update DWC only to 3.1.1 > updated to 3.0 Firmware > load updated 3.0 zip from Configurator > Load 3.4.5 from Configurator zip for all.

BUT for the last step I unzipped the config.g from the zip, edited manually and verified line by line in Notepad++ 'Compare mode' to my old config.g, then replaced it back into the zip, THEN uploaded 3.4.5 to the Maestro.

I realize now that was a lot of unneeded work and the Comparator handles it all. Duh. (OCD creeps out LOL)

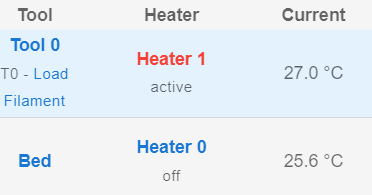

Here's current:

You think I should run Configurator directly from the json in sys and try again with a new load? EDIT: Did "edit via config tool" and re-ran Configurator, fixed a few values (matching current config.g above except a few minor things). I chose "Semitec 104NT" and SET values using it's defaults. No change. END EDIT

Or go back to 3.3? Or wipe and try again?

Note I went 2.04 > 3.0 > 3.4.5 not 2.04 > 3.0 > 3.3 > 3.4.5.

I'm in your worthy hands.

@dc42 Yes Sir! BTW - I moved the Heater and the Thermistor back to E1 as it's been fine there for years. ALSO - I realized I had the old config-override.g with the old values so I renamed it config-override.g.old in case it was the culprit. No joy.

; Configuration file for Duet Maestro (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.15 on Wed Jan 18 2023 09:54:15 GMT-0500 (Eastern Standard Time)

; MODIFIED by Bob M to transfer settings from 2.x

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"CR-10S DUET" ; set printer name

; Network

M552 P192.168.1.18 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.1.254 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z1593.48 E419.80 ; set steps per mm Chng Z: 400 to 1600 (2mm Lead Acme Screw upgrade)11-18-21 Chg Z from 1600 to 1593.48 (measured)

M566 X900.00 Y900.00 Z31.80 E120.00 ; set maximum instantaneous speed changes (mm/min)Chng Z: 12 to 32 (2mm Lead Acme Screw upgrade)

M203 X12000.00 Y12000.00 Z700.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y250.00 Z16.60 E166.00 ; set accelerations (mm/s^2)

M906 X1100 Y1100 Z1000 E900 I30 ; set motor currents (mA) and motor idle factor in per cent CHGED Z 900 TO 1000 (2mm Lead Acme Screw upgrade)

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-5 Y-5 Z0 S1 ; set axis minima

M208 X295 Y305 Z320 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M950 S0 C"zprobe.mod" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X45 Y15 Z0.6 ; set Z probe trigger value, offset and trigger height ORIG .4 Nozzle = Z0.6

M557 X5:295 Y5:305 S20 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4388 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as Semitec 104NT on pin e1temp (E3D Gold)

M950 H1 C"e1heat" T1 ; create nozzle heater output on e1heat and map it to sensor 1

M307 H1 B0 S1 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S310 ; set temperature limit for heater 1 to 310C

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool

EDIT: Here's the Heaters:

@jay_s_uk Found it:

M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Error: Heater 2 not found

@jay_s_uk K doing it ...

Where's it put the output? I entered in console and nothing happened I could see

Long time user of Maestro, finally decided to get off 2.03.

Ran through RRF configurator, mapped my values, created a zip and did a side by side update of my config.g to map in all values and fix errors. Saved changed file back into the RRF zip.

Read tons of guides and after 1 false start managed to get from 2.03 to 3.0 to 3.4.5, including DWC up to 3.4.5 as well. I killed all the little bugs and typos and all's well except the Extruder.

I've a CR-10S (highly modded) running a E3D Gold HE with a genuine E3D Semitec 104NT. All was working fine under 2.03

It was attached as E1 heater and Themistor connected to Themistor 2 (E1). During Configuration I accidentally specified a pt1000 (had it on a Dragon HE which died). Realized my mistake and manually reconfig'd to the Semitec 104NT.

Doesn't read temps. Heater shows Active and will select temps (doesn't heat of course) Temp shows "Current - n/a"

Checked thermistor with a DMM, reads 101KΩ. Tried moving them both to E0 but same results!

HALP! What the heck am I missing??

Here's my config.g heater section:

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4388 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as Semitec 104NT on pin e1temp (E3D Gold)

M950 H1 C"e0heat" T1 ; create nozzle heater output on e1heat and map it to sensor 1

M307 H1 B0 S1 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S310 ; set temperature limit for heater 1 to 310C

EDIT: I forgot to mention I have a dual Z with the second motor on Drive 4 E1 Motor just as info ...

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z1593.48 E419.80 ; set steps per mm Chng Z: 400 to 1600 (2mm Lead Acme Screw upgrade)11-18-21 Chg Z from 1600 to 1593.48 (measured)

M566 X900.00 Y900.00 Z31.80 E120.00 ; set maximum instantaneous speed changes (mm/min)Chng Z: 12 to 32 (2mm Lead Acme Screw upgrade)

M203 X12000.00 Y12000.00 Z700.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y250.00 Z16.60 E166.00 ; set accelerations (mm/s^2)

M906 X1100 Y1100 Z1000 E900 I30 ; set motor currents (mA) and motor idle factor in per cent CHGED Z 900 TO 1000 (2mm Lead Acme Screw upgrade)

M84 S30 ; Set idle timeout

That did the trick! Thx! So much to absorb ...

Just trying to setup new config for upgrade to 3.0 prior to 3.1, and I started fresh, no JSON loaded.

When I get to the Endstops page, "Unmodulated or Smart IR Probe" is selected and BLTouch is greyed out.

I'm configuring a Maestro, Cartesian.

I checked I/O Mapping and it says under Z-Probe:

Input Pin = zprobe.in

Modulation Pin = zprobe.mod

PWM Control Channel (BLTouch only) = (not assigned) <-- This does not allow another choice, the drop down opens but won't accept a click on zprobe.mod (or inverted).

I can set it up manually after I'm done, but what's up with it not allowing a BLTouch??

@RGV250 said in A total minefield for a newbie:

so I can have a beer while looking

Just make sure it's A beer ... LOL!

Glad to hear you're chasing the axis first. I always advise people make sure the mechanicals are right before messing with the settings. Can't believe how many times I've seen someone wrestling with settings when the problem is a loose widget ... You obviously get it. I guess having that many printers will do that!

Have fun!

@deckingman

Thx! @Phaedrux was quicker on the keys! Appreciate the help, as usual my friend.

2mm here I come. now to find some that they don't want $50 USD for a pair.

I have to deal with WAF.

I think I found someone on AliExpress that will cut down a 550mm to 515 and appears to have nice quality, I just have to wait until Thanksgiving or so ... LOL.

@Phaedrux said in Advice on upgrading from 8mm Lead to 2mm Lead T8 screws:

And I doubt anyone is going to want to use 0.2875mm layer heights.

HA! You don't know what I'm planning! {Insert evil chuckle}

That's about what I came away with from my research. My 310x310mm bed isn't that heavy, especially with the load on two motors. Thx.

A total minefield for a newbie

I LOL'd at this one. I setup mine almost two years ago and thought that. After a lot of work and mind numbing reading of posts and articles (and a HEALTHY dose of help on here!) I finally mastered the beast.

Here we are, a while down the road, and I made some upgrades to my machine and the house of cards came down. The old adage "If you don't use it you lose it" kicked in and again I found myself banging my head on the desk as I struggled relearn AND to grasp the changes that occurred since last time!

I'm now back in it (mostly) and it occurs to me that I might try my hand at writing a beginners guide aimed at the total noob. I'm fairly good at explaining things once I grasp them, my biggest hurtle is that I tend to long winded. Nature of the beast {SIGH}.

There are lots of guides out there, many of them excellent, but I'm thinking sorta a "Guide to the Guides" with some simple explanation of the major terms thrown in since that's often the main sticking point when starting a new field of learning.

The guides don't always define their terms up front, so the beginner gets lost in the terms rather than the concepts being explained. The old "Well, I'm at the end of the page and I'm more confused then when I started" thing.

I'm sure I'd be asking a lot of Q's of the old hands if I do it to ensure I don't send someone off a cliff, LOL! (I can hear the groans now  )

)

Hang in Bob, it'll start coming together. Good luck!

@deckingman said in Advice on upgrading from 8mm Lead to 2mm Lead T8 screws:

@PuterPro I published my own thoughts .... https://somei3deas.wordpress.com/2017/01/31/z-axis-lead-screws/

Thx, I'll read that.

I use 1mm lead screws (single start, 1mm pitch) but 2mm would also be fine. I bought mine from China via Amazon.

Read it. Nice post, I knew most from my research (like 1 start vs 4) but you made some points clearer. BTW - I forgot the name of your blog, but as I was reading I grabbed my COLD coffee then started laughing.

So, 2mm vs 1mm. Any real difference in choice? Obviously the 1mm give a touch more accuracy. I've been looking for 2mm lead but I'm open here.

I'm running the little motors Creality used, but being there's two of 'em I imagine I'll have no trouble driving either rod choice. I'm currently limiting them to 900ma. here's my motors section:

M350 X16 Y16 Z16:16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E412.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y250.00 Z16.60 E166.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

And for reference, here's the (VERY hard to find) motor info:

Brand: Creality 3D

Item name: RepRap 42 Stepper Motor

Item number: 42-34

Step angle: 1.8 degrees

Nominal Voltage: 4.83V

Current Rating: 1.5 (A)

Rated speed: 1-1000 (rpm)

Rated torque: 0.4 (NM)

Ambient Temperatuar: -20℃~+50℃

Length: 34mm

Application: 3D printer

Resistance: 9.6Ohm

Inductance: 7.6mHy@1kHz (frequency used in datasheets)

JK42HS34-0844YA-03F - Offered by Tiny Machines as direct replacement for Z

So I'm running about 60%. I am running the Maestro right around 27v .

You see any issues here?

And you can hold that weight with zero motor holding current, whereas the weight of a heavy bed acting on the steep helix angle of a 4 start thread might cause the bed to drop when the motors are deactivated.

This has always been a problem for the CR-10S series. Something I liked about the Duet is easily telling it to hold idle to reduce this. Not currently a problem for me but nice that it lessens the drop potential.

For those who have upgraded to 2mm Lead screws, have you seen much difference and what was your source for the screws?

I've got what started life as a CR-10S running on a Maestro. I've read about this upgrade in several places including this one from @Phaedrux :

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+5:+Upgrades/54?lang=en#s208

The one thing that strikes me is that with 2mm lead it's evenly divisible for any layer height, no more being restricted to certain layer settings.

My rods are the stock Creality and they were both slightly bent and pretty rough. I've cleaned them up and straightened to "pretty good" but still would like to dump 'em.

How much impact have those who have this noticed or is this just another hole for money?

One problem I face is the rods on my CR-10S are 515mm, an odd size. Although I can cut down larger and re-bevel it's a pain.

I've found two local sources on Amazon, one after contacting the manufacturer on AliExpress, and a bunch of other on Ali too, of varying quality.

Here's the Amazon ones for anyone else doing this:

https://smile.amazon.com/dp/B07QFL6D46 <- Expensive but looks good quality (close up pics on AliExpress, here: https://www.aliexpress.com/item/32921211173.html)

EDIT:

Other Amazon source: https://smile.amazon.com/dp/B0851F5P7Q <- This is HALF the price, but no reviews so ... Of course in this day of fake reviews, that may be a blessing! Also they would have to be cut 550mm not 515). <- This is confusingly described and is actually a 8mm Lead.

Like anyone doing upgrades I'd love to get polished, straight rods for $2 each ... LOL. But I have found paying for quality usually pays off. Still if anyone has a good source for quality rods for little outlay, I'd love it.

Thoughts and advice welcome!

@bot said in Baby Stepping.. can it, or can it not be permanent?:

@PuterPro My dude, tone is difficult even in real life. Sorry if I come across as belligerent sometimes. I'm only intending on being a tiny bit belligerent.

Especially for Engineer / Tech types who tend towards awkwardness in all social situations! LOL

Peace out!

We do need to put a fork in this whole thing, a few comments for clarity -

@deckingman said in Baby Stepping.. can it, or can it not be permanent?:

Woah, hold on my friend. There is a world of difference between adding something that makes life slightly easier than editing one line of gcode, and restoring basic printer functionality to the firmware, which are the things that I'd like to see implemented.

I could not agree more! I absolutely agree that the things you're pushing for should have priority over such a silly thing as Baby steps being optionally persistent. I was just commenting on it being dismissed out of hand by someone who doesn't use it, and offering a case scenario where I could see it's validity ... if you get my drift. (And I AM drifty ... LOL!)

@bot said in Baby Stepping.. can it, or can it not be permanent?:

This request, beaten to death, is already achievable with the current behaviour .... add a line at the end of your config.g that runs a macro with M98 .... Done. It will save your magic sequence of babystepping settings to load every time you boot.

Thank you for getting I wasn't berating you, it's sometimes hard with just text and an emoji or two ...

THAT's a simple way to accomplish this, thanks for that, now we have a couple solutions. Personally I rarely use Baby Steps but I have found it handy at times.

@OwenD Hilarious!! Love it.  And thanks for the solutions, I confess to a misread of your earlier posts ALSO being in humor. Working on my halo ...

And thanks for the solutions, I confess to a misread of your earlier posts ALSO being in humor. Working on my halo ...

@DeltaCon said in Baby Stepping.. can it, or can it not be permanent?:

It is certainly no dealbreaker for me. I did not invent the subject.

@ ALL - This sums up my involvement as well. I apologize for extending this so long when obviously there are multiple ways to solve this without changing the firmware. Many thanks to all that participated!!

@Phaedrux said in Its safe to move a Duet v2 to firmware 3.x:

for the average person.

HEY! WHO ARE YOU CALLING AVERAGE??!?

I've been lightly stroking my finger on the trigger, but assuming {AHEM} RC12 is the last ...

I guess I'll wait for the final release since I'm running fine now thanks to all the kind people here.