@Blacksheep99 ohhh i like this idea

Posts made by PR1OR

-

RE: Printing issuesposted in 3D Printing General Chat

So i have a glue stick (very similar to pritstick) is that what you mean?

If so i will give it a go and feedback

-

Printing issuesposted in 3D Printing General Chat

Hi All,

I hope everyone is well,

Im hoping someone can help me with this. I seem to be having some issues with my printing and i have no idea why it keeps doing this.

So when i begin a print it starts well and i like to keep an eye on it for the first few layers. i then leave it for an hour to and hour and a half and i get this

https://youtu.be/LjgYvJZHnegive got a bl touch but i have also played with the leveling which seems pretty good

Anyone got any ideas? i really want to begin printing a new fan duct but this keeps happening.

Thank you

J -

Automated firmware updatesposted in Duet Web Control wishlist

Hi all,

Just wondering if there is a G code so i can get for updates software/firmware and it auto updates on start up of connecting to printer?

-

RE: DWC anywhere?posted in Duet Web Control

Ok thanks all, I feel alittle more clued up now and wont just password protect

I will have a look into my router and what is provided

thanks again

-

RE: DWC anywhere?posted in Duet Web Control

So I’ve been having a further think about this. A bit of blue sky thinking

, I’m not against the whole VPN thing but would rather do it for free which is why I’ve been thinking about it more. Is there not a way you could apply a password to the printers IP? therefore hacking would be heavily reduced no?

, I’m not against the whole VPN thing but would rather do it for free which is why I’ve been thinking about it more. Is there not a way you could apply a password to the printers IP? therefore hacking would be heavily reduced no? -

Help with what dual hot end to buy?posted in General Discussion

Hi there,

So I’m getting really frustrated with attempting to remove supports, especially on complex prints. I’ve read online there is dissolvable support filament now which I think would be great. I’m using an ender 3 so ideally i think I would want a 2 to 1 hot end (please correct me if this is a silly idea).

Has anyone use this functionality for the purpose I have set above and if so is it worth it over the hours of support structure removal time?

Thanks!

-

RE: DWC anywhere?posted in Duet Web Control

@Phaedrux said in DWC anywhere?:

anonymization servic

so if its on the router it will still allow me to see the DWC if im out of the house?

Also when you say they could mess with my printer. What do you mean? like turn it off or mess with the settings?

-

RE: DWC anywhere?posted in Duet Web Control

@Phaedrux (Y) thank you as always! I will have a think about it but I don’t really want to pay for a VPN. But great to know if I want to it is possible

-

DWC anywhere?posted in Duet Web Control

Hi there,

Is there a way to allow my duet2wifi be connected wherever I am I.e on my 4g?

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

@Phaedrux thanks i will try this on my next print, i have one going fairly well at the min so dont want to stop it haha

and the second point is the answer i was hoping for!! thanks again

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

@Phaedrux i think this is what you mean.

Start Code

; Ender 3 Custom Start G-code

G92 E0 ; Reset Extruder

G28 ; Home all axes

G1 Z2.0 F3000 ; Move Z Axis up little to prevent scratching of Heat Bed

G1 X0.1 Y20 Z0.3 F5000.0 ; Move to start position

G1 X0.1 Y200.0 Z0.3 F1500.0 E15 ; Draw the first line

G1 X0.4 Y200.0 Z0.3 F5000.0 ; Move to side a little

G1 X0.4 Y20 Z0.3 F1500.0 E30 ; Draw the second line

G92 E0 ; Reset Extruder

G1 Z2.0 F3000 ; Move Z Axis up little to prevent scratching of Heat Bed

G1 X5 Y20 Z0.3 F5000.0 ; Move over to prevent blob squishEnd Code

G91 ;Relative positioning

G1 E-2 F2700 ;Retract a bit

G1 E-2 Z0.2 F2400 ;Retract and raise Z

G1 X5 Y5 F3000 ;Wipe out

G1 Z10 ;Raise Z more

G90 ;Absolute positionningG1 X0 Y{machine_depth} ;Present print

M106 S0 ;Turn-off fan

M104 S0 ;Turn-off hotend

M140 S0 ;Turn-off bedM84 X Y E ;Disable all steppers but Z

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Wed Sep 16 2020 13:09:04 GMT-0600 (Central Standard Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-230.5 Y-235 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-230.5 Y-235 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X40.5 Y20 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioningConfig.g

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Wed Sep 16 2020 13:09:04 GMT-0600 (Central Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Jack's Printer" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ;a configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E93.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X600 Y600 Z600 E600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 S1 ;set axis minima NEW 22.09.2020

M208 X230 Y220 S0 ;set axis maxima NEW 22.09.2020

;M208 X-5.5 Y-10 Z0 S1 ; set axis minima

;M208 X220 Y220 Z250 S0 ; set axis maxima

;M208 X-5.5:220 Y-10:220 Z0:250 ; set axis minima and maxima NEW ADDED 22.09.2020; Endstops

M574 X1 S1 P"X Stop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"Y Stop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speedsG31 X-10 Y-20 Z0.5 ; set Z probe trigger value, offset and trigger height NEW 22.09.2020

M557 X30:215 Y0:200 P6 ; define mesh grid NEW 22.09.2020;G31 P500 X-31 Y20 Z0.5 ; set Z probe trigger value, offset and trigger height

;M557 X5:185 Y5:205 P6 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T98801 B4185 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T98801 B4185 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"Heatsink" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"PartCooling" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"Board Cooling" S1 ; set fan 2 name and value. Thermostatic control is turned on; Tools

M563 P0 S"Extruder 01" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first toolWhat do you mean by slicer start gcode section? as in Cura?

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

@Veti said in unusual/unnerving noises + error codes:

G28 and G29 m

So i dont believe im using a G28 code. Should i be?

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

@Phaedrux said in unusual/unnerving noises + error codes:

220

Thank you for this!! i now am not getting that message. I have sorted the parameters and i think i have as bigger printing area as i can get.

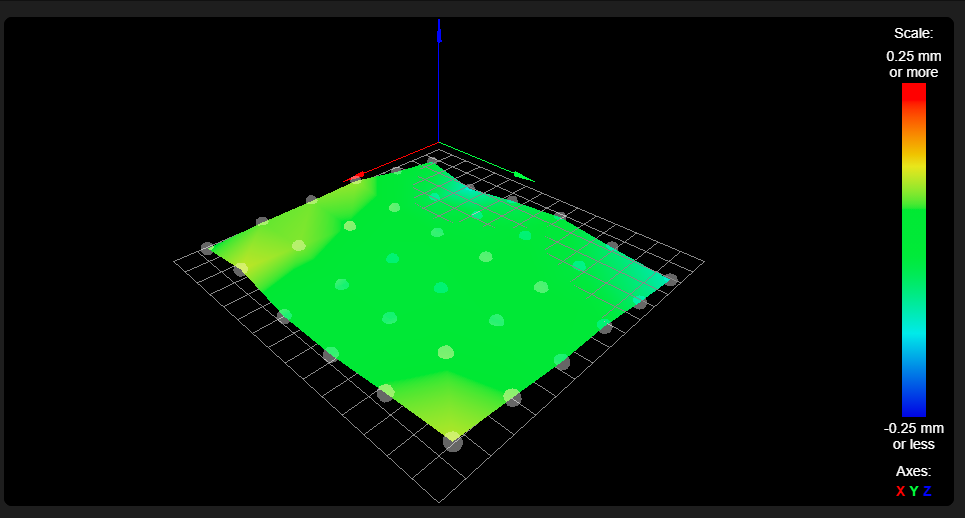

However i am now getting this

Warning: the height map has a substantial Z offset. Suggest use Z-probe to establish Z=0 datum, then re-probe the mesh.

36 points probed, min error -1.793, max error -0.002, mean -0.966, deviation 0.483I have tried to recalibrate the BL touch using this

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

As i read that, that maybe the issue, but it keeps coming up now

Any ideas? also as a side point (pardon my ignorance) should the BL touch auto adjust the Z axis depending on the height or do i still have to manually have to adjust using the height map?

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

also are you able to break down that code so i can start understanding the structure and meaning? I think it will help for the future (rofl)

I would on SAP and code regularly so i think if i started understanding what everything means i maybe able to start fault finding alittle better

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

@Phaedrux Ahh ok fine thats ok then ill just hide one of them

in regard to the M557 X5:185 Y5:205 P6 i have updated this.

and am now getting this

G32Warning: Skipping grid point (5.0, 5.0) because Z probe cannot reach it

Warning: Skipping grid point (41.0, 5.0) because Z probe cannot reach it

Warning: Skipping grid point (77.0, 5.0) because Z probe cannot reach it

Warning: Skipping grid point (113.0, 5.0) because Z probe cannot reach it

Warning: Skipping grid point (149.0, 5.0) because Z probe cannot reach it

Warning: Skipping grid point (185.0, 5.0) because Z probe cannot reach it -

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

@Phaedrux perfect i think i have this right.

I think i only have two things left wooohooo

-

I have two fan bars on the DWC but they only seem to move together and not individually. How would i make them independant?

-

When doing the true bed leveling i keep getting this response. But i can see where to amend either G32 or G29

Warning: Skipping grid point (190.0, 60.0) because Z probe cannot reach it

Warning: Skipping grid point (210.0, 60.0) because Z probe cannot reach it

Warning: Skipping grid point (210.0, 80.0) because Z probe cannot reach it

Warning: Skipping grid point (190.0, 80.0) because Z probe cannot reach it

19/09/2020, 11:36:03 G29

Warning: Skipping grid point (190.0, 20.0) because Z probe cannot reach it

Warning: Skipping grid point (210.0, 20.0) because Z probe cannot reach it

Warning: Skipping grid point (210.0, 40.0) because Z probe cannot reach it

Warning: Skipping grid point (190.0, 40.0) because Z probe cannot reach it

-

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

@Phaedrux said in unusual/unnerving noises + error codes:

simplify 3d

yeah using the your one.

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Wed Sep 16 2020 13:09:04 GMT-0600 (Central Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet2Wifi" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ;a configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E93.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X600 Y600 Z600 E600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-5.5 Y-10 Z0 S1 ; set axis minima

M208 X220 Y220 Z250 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-31 Y0 Z0.6 ; set Z probe trigger value, offset and trigger height

M557 X9.5:220 Y5:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T98801 B4185 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T98801 B4185 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"Heatsink" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"PartCooling" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F1 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P1 C"ExtruderCooling" S1 H1 T45 ; set fan 2 name and value. Thermostatic control is turned on; Tools

M563 P0 S"Extruder 01" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first toolSo i didnt use a slicer there was a gcode on the interface for the benchy so i thought id try that. Im just downloading cura now so will try again and see what happens

-

RE: unusual/unnerving noises + error codesposted in Duet Hardware and wiring

So it seems to be working ok now which is good. but when going for a test print i reserve this

Error: Fan number 2 not found

Error: Invalid tool number

Warning: Tool 0 was not driven because its heater temperatures were not high enough or it has a heater faultthe Fan i think can probably wait til a little later but the tool i feel is an issue