Here is a short video.

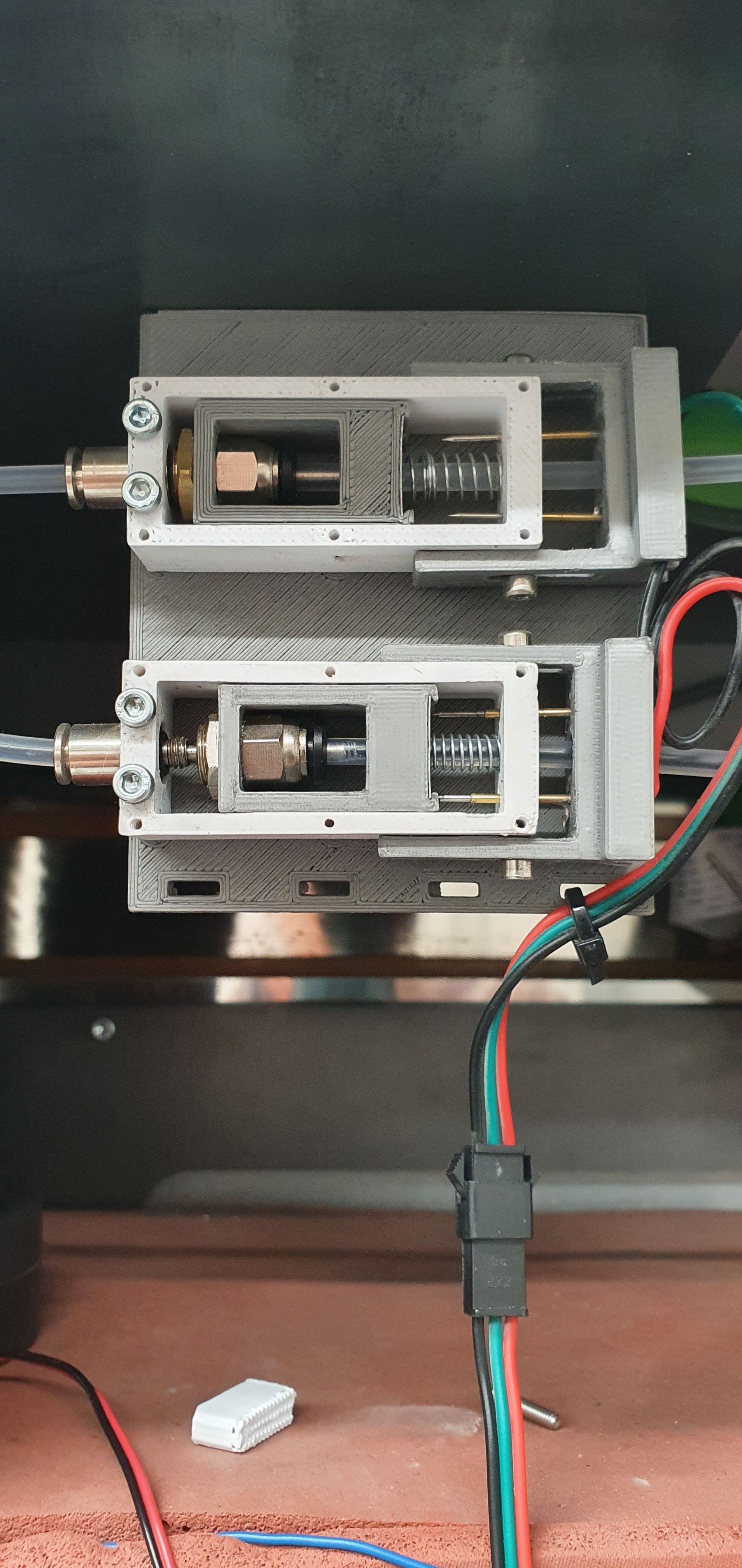

Key principle is:

1: The PTFE tube held by the shuttle wants to move away from the pressure of the fed filament when there is a blockage at the other end (i.e. there is no filament extruding)

2: When there is no blockage at the other end (i.e. filament is being extruded) pressure is released.

Use a fine capillary tube (2.5mm OD - 2mm ID) and drill out the end of the PTFE tube so that it slides easily. Using this method Filament will not get jammed when a new roll of filament is fed behind the old (as there is no way for it to get around the outside of the pushed filament)