Nevermind this, was wrong again, but you got me in the right direction. Thanks for that^^

Best posts made by Nordle

-

RE: Triple Z G28/G32 homing errorposted in Firmware installation

-

RE: Single Axis multiple stepper with different steps/mm possible?posted in Firmware installation

Thanks for all the helpful replies.

@o_lampe I would like to stay away from ball screws, as they tend to be rather expensive or a cheap hit/miss. And I'm already very impressed by the results of the belted Z. I did consider other gearing solutions like a worm gear but it is the same pita as acquiring quality ball screws, and a mediocre solution would probably give me more headache than my current counterweights.

I didn't think about the gearing ratio to much, went a little crazy probably should choose less ratio.

How is your ball screw setup geared? belt and pulleys?

I could probably do a 1/10 belted space wise.@jay_s_uk special thanks for the clarifications

@dc42 I didn't. something like this first I could find on aliexpress? Are they in holding position when no power is applied?

Latest posts made by Nordle

-

What does the accelerometer plugin do?posted in Duet Web Control

For input shaping there's a ''external plugin'' for dwc.

But there is also a ''integrated plugin'' Accelerometer. What does it do? -

RE: True bed leveling but in reverse?posted in Firmware installation

Works like it should, thanks for the clarifications

-

RE: True bed leveling but in reverse?posted in Firmware installation

@Nordle said in True bed leveling but in reverse?:

Should this work to move to Z max?

G91 G1 H1 Z420 F600 G1 Z-3 G90I think I need different H parameter. but I am not sure exactly

-

RE: True bed leveling but in reverse?posted in Firmware installation

@Phaedrux

Should this work to move to Z max?G91 G1 H1 Z420 F600 G1 Z-3 G90@oliof thanks, I'll keep that in mind for a future upgrade

@deckingman I appreciate the explanation as a non native english speaker.

Would mesh bed compensation take care of that? -

True bed leveling but in reverse?posted in Firmware installation

Hello,

my printer is set up to use 3 independent Z motors, I recently added individual end stops for each motor on it's maximum position. I use touch probe as minimum limit.my config:

M584 X0 Y1 Z7:8:9 E3 ; Endstops M574 X1 S1 P"xstop" M574 Y1 S1 P"ystop" M574 Z1 S2 M574 Z2 S1 P"exp.e4stop+exp.e5stop+exp.e6stop"when I power down my machine the bed tilts so much that I can't run true bed leveling anymore. that's a problem because I like to start it remotely.

Is it possible to create a macro which moves the individual Z drives (simultaneously!) until they hit their assigned end stop?

Then I could run true bed leveling again. -

RE: retracts over Firmare or PrusaSlicer?posted in General Discussion

What happens if I set up firmware retraction and use different retraction settings in a slicer?

-

RE: Expansion Header Ex_STOP pinsposted in Duet Hardware and wiring

@Phaedrux Currently it is a coreXY with triple Z, might want to add something like automatic toolchange or ERCF(MMU) in the future, so the endstops will be handy. The printer currently runs with some crappy dupont connections and I'm cleaning up some wiring right now

-

RE: Optical Endstopsposted in Duet Hardware and wiring

wouldn't it work to just run the sensor from any spare 5V pin on the baord?

-

RE: Expansion Header Ex_STOP pinsposted in Duet Hardware and wiring

@alankilian Thanks again for the detailed answer.

I have currently wired drives 5 to 9 form the expansion header to a Ramps1.6 board. It would be very convenient for me to also wire the endstops to the same.

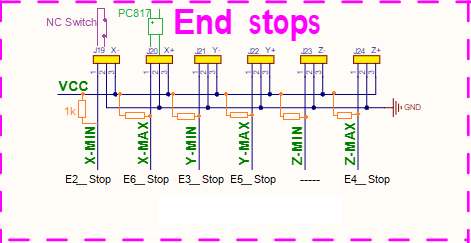

If I take the simple approach without LEDs, I could just solder the required resistor to the underside of the endstop pins of the ramps like this:

Am I missing something or could this work? -

RE: Expansion Header Ex_STOP pinsposted in Duet Hardware and wiring

@alankilian Thanks.

What would be the simplest way to wire those up?

Could I wire a normally closed switch with +3.3V from Expansion Header also?