Hey Ian,

thank you for your very detailed response. This answers quite a few questions I had in mind.

I tried using M204 recently but didn't get any noticable acceleration / braking, but only hard starts and stops. Now with your info, this obviously doesn't work because I am on a cnc-configuration, where there are no extrusions. So basically everything is a travel move.

M566 / jerk also isn't what I am looking for, since i am not looking for anything specific to segments or how it handles the transition from one move to another in specific, but rather accelerating and slowing down within a single move.

So my takeaway is, that M201 is what I am looking for.

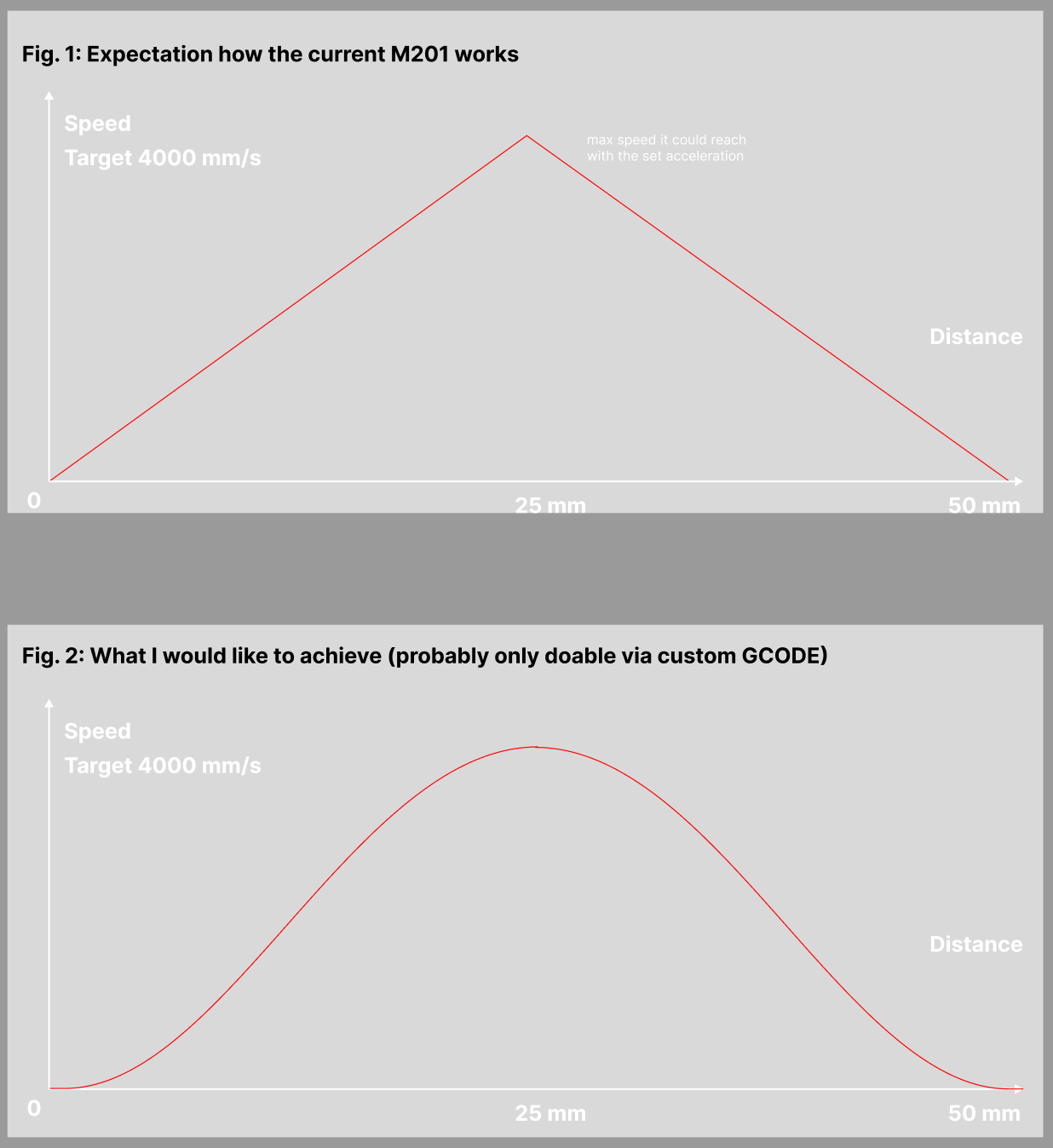

My understanding is that with an acceleration (M201) of 1000 mm/s^2, it takes the machine 1 second to reach the full speed on a G1 F1000 move in a linear way and it will also start slowing down 1 second before reaching the end of this specific move. Is that correct?

If the move in question is too short to reach this speed at all, will it start slowing down after half the distance and smoothly come to a stop, or will it try to reach the max speed until the end of the line and then do a full stop at whatever speed it reached at this point?

I am trying to smooth out a fast back and forth motion over a 50 mm distance. I am currently running with 4000 mm/s max speed and an acceleration of 4000 mm/s^2. Obviously, it won't reach it's full speed at this short distance (it would after 4000 mm), but i fill like I should atleast notice a starting acceleration or a slow-down.

M566 X2000.00 Y2000.00 Z2000.00

M203 X4000.00 Y4000.00 Z4000.00

M201 X4000.00 Y4000.00 Z4000.00