@dc42 Thank you very much it works, I had to reread the Documentation to remember to use two double quotes to add a double quote to a string, to set globals in a datetime format.

Best posts made by modl

-

RE: Questions regarding various job timeposted in Gcode meta commands

Latest posts made by modl

-

RE: Help understanding the "new" reusrrect.gposted in Tuning and tweaking

@dc42 I ended up removing M596 and M486 instructions indeed, they were causing issues in my case, where i was restarting the print with T1 instead of T0. Thank you for your replies

-

RE: Help understanding the "new" reusrrect.gposted in Tuning and tweaking

@dc42 OK I think i understand. It looks like it's not relevant for my setup as the motion system is the same for both extruders as they share the same tool head ? But I don't necessarily need to remove one sequence or the other as they are, at worst, harmless ?

-

RE: Help understanding the "new" reusrrect.gposted in Tuning and tweaking

@dc42 Thank you for your reply !

I guess i could either delete or ignore M204

There is indeed a P parameter after the first M26 call, that makes sense. But the second call only gets an S parameter

My question is , why is this sequence repeated twice with slightly different parameters?M83 G94 G17 M26 xxxxxx G1 P0 M204 G21 M596I guess there is no command i need to delete as they won't get in the way or are default from config.g (M596 M486 G54 G21 G94 G17) but the repetition of G1 instructions to the same point seems odd

-

Help understanding the "new" reusrrect.gposted in Tuning and tweaking

Hi everyone

A one week print failed 80% in because of a "G2 out of bound" error. i'm not sure how it happened considering a whole support has been printing at the exact same spot for the whole duration of the print. Anyway, it didn't generate a resurrect.g but i have safeguards and can pinpoint accurately enough where the print failed (layer number global, and last reported position registered by daemon.g). So i will try to resurrect this print by editing the resurrect.g template which i did in the past when I was on 3.4.6. I'll add an M564 S0 and see where it goes. But things have changed a lot with 3.5.x and I'm seeing a whole lot of gcode command sequences that seem to be repeating and some that are more CNC oriented.

-My machine is a rather simple corexy dual extruder 3D printer.

-->What parts could I get rid of after resurrect-prologue have been called ?

-->What are the X and Y arguments for in the first M26 call ? couldn't find them in the reprap gcode reference.

--> M204 P50000 T50000 is extremely far from my settings in config.g (see at the end of the post for reference)Thank you very much in advance

Best; Resume printing file "0:/gcodes/PIECE 1/PIECE 1 SLICED bed1.gcode" after print paused at 2025-02-17 21:14 M140 P0 S50.0 G29 S1 M568 P0 A2 S215 R215 M568 P1 A1 S215 R215 G21 M98 P"resurrect-prologue.g" X201.622 Y71.138 Z130.470 M290 R0 X0.000 Y0.000 Z-0.080 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 M596 P0 M486 S-1 T0 G54 M106 S0.00 M116 G92 E0.00000 M83 G94 G17 M23 "0:/gcodes/PIECE 1/PIECE 1 SLICED bed1.gcode" M26 S407214168 P0.688 X190.489 Y68.203 G90 G0 F6000 X191.622 Y71.138 G1 F3600.0 P0 M204 P50000.0 T50000.0 G21 M596 P1 M486 S-1 G54 M106 S0.00 M116 G92 E0.00000 M83 G94 G17 M26 S407214168 G1 F3600.0 P0 M204 P50000.0 T50000.0 G21 M596 P0 M106 P1 S0.00 M106 P3 S0.10 M106 P4 S0.00 M106 P5 S0.10 M106 P6 S0.00 M302 P0 M24; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Mon Jan 09 2023 14:50:13 GMT+0100 (Central European Standard Time) ; General preferences G4 S1 ; give time for expansion board communication G90 ; absolute coordinates... M83 ; ...but relative extruder moves M550 P"CBMP" ; set printer name ; Network M552 P192.168.1.14 S1 ; enable http, disable Telnet M586 P1 S1 ; enable ftp if !exists(global.oneYearPrint) global oneYearPrint = 0 else set global.oneYearPrint = 0 ; for Z, define global probing speed to make it uniform across Z homing macros and bed mesh probing, for better accuracy. I recommend something around 100 if !exists(global.probingSpeed) global probingSpeed = 90 else set global.probingSpeed = 90 ; for X and Y, defines fine homing speed global if !exists(global.homingSpeed) global homingSpeed = 360 else set global.homingSpeed = 360 ; Drives M569 P0.2 S0 M569 P0.3 S1 ; physical drive 0.2 goes forwards M569 P0.4 S1 ; physical drive 0.3 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes backwards M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S0 M569 P123.0 S1 ; physical drive 0.1 goes forwards M584 X123.0 Y0.3:0.4 Z0.2:0.5 E0.0:0.1 ; set drive mapping M350 X16 Y16:16 Z16:16 E16:16 I1 ; configure microstepping with interpolation M92 X64.32 Y64.00 Z1600.00 E415.00:415.00 ; set steps per mm X modified from 64 to 64.32 after measurements with precision tool M566 X1200 Y1200 Z300 E1500:1500 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z330.00 E3600.00:3600.00 ; set maximum speeds (mm/min) M201 X1500 Y1500 Z240 E6000:6000 ; set accelerations (mm/s^2) M906 X2400 Y2400 Z2300:2300 E600:600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X357 Y990 Z354.67 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in M574 Y1 S1 P"io1.in+io3.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in M574 Z2 S1 P"io2.in" ; Z-Probe M950 S0 C"io4.out" ; create servo pin 0 for BLTouch M558 P9 C"io4.in" H5 F{global.probingSpeed} T12000 R0.3 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X0 Y22.7 Z4.55 ; set Z probe trigger value, offset and trigger height M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M557 X15:335 Y25:985 S40 ; define mesh grid ;M557 X20:320 Y25:925 S300 ; rough mesh grid M376 H100 ; Heaters M308 S0 P"temp2" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp2 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.591 K0.132:0.000 D6.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R3.233 K0.345:0.000 D5.82 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin temp1 M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2 M307 H2 R3.233 K0.345:0.000 D5.82 E1.35 S1.00 B0 V23.8 M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"out3" Q0 ; create fan 0 on pin out9 and set its frequency M106 P0 C"Pompe" S1 H1:2 T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"out7" Q0 M106 P1 C"Tools Fan" S0 X0.7 H-1 M106 P1 F0 ;M950 F2 C"out8" Q0 ;M106 P2 C"T2 fan" S0 H-1 ;M106 P2 F0 ;LED strip M950 F3 C"0.out4" Q500 M106 P3 C"White" S0.05 M950 F4 C"0.out5" Q500 M106 P4 C"Red" S0 M950 F5 C"0.out6" Q500 M106 P5 C"Green" S0.05 M950 F6 C"0.out9" Q500 M106 P6 C"Blue" S0 ; Tools ; set mixing ratios for tool 2 M563 P0 S"Right Extruder" D0 H1 F1 ; define tool 0 G10 P0 X-10 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"Left Extruder" D1 H2 F1 ; define tool 1 G10 P1 X10 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M572 D1 S0.05 ; configure pressure advance M572 D0 S0.05 ;filament run-out sensor M591 D0 P4 C"io6.in" L25.8 S1 E5 M591 D1 P4 C"io5.in" L25.59 S1 E5 ; Z screws positions for Z motors adjustments M671 X180:180 Y-180:50 ; Custom settings are not defined ;M955 P0 C"spi.cs3+spi.cs2" I50 S1344 R10 ; Miscellaneous M911 S22 R23 P"M913 X0 Y0 Z0 M98" "; set voltage thresholds and actions to run on power loss M929 P"eventlog.txt" S1 ; start logging to file eventlog.txt M501 -

RE: Duet 3 MB6HC 3.5.2 in standalone mode: trouble connecting to DWCposted in Using Duet Controllers

Hi, I'm having the same problem, except I'm stuck in a reconnecting / /connected / disconnected loop. Refreshing or closing firefox , and deleting all sites data , doesn't work.

It happens after a somehow long operating time (~ 2 weeks)Irecently upgraded everything to 3.5.3

-

[3.4.6][possible bug?]babystepping offset in resurrect.gposted in DSF Development

Hello everyone

In resurrect.g generated after a power failure something looks weird with the way z height is handled.

Example from a few hours back (but happened a few times before): powerloss during a print at Z22.380 while babystepping is -0.10.

Resurrect.g has G92 Z22.380 in the beginning , then sets babystepping back to -.10, then goes to last print move at 22.280 .Last time i had a hint about this happening, different print, babystepping was set to .30 when power failure occured, I didn't take a look at the details in resurrect this time but the resuming layer was exactly .3 too high and i had to set babystepping back to 0 to compensate.

Let me know if you need more info

Best

-

RE: Handling powerloss while G4 in a macro, during a printposted in Gcode meta commands

@chrishamm Thank you very much I'll stick with the G4 in the macro then. Will report if the event occurs

-

Handling powerloss while G4 in a macro, during a printposted in Gcode meta commands

Hi everyone,

I have a question : for my specific porject, I have a macro on every layer change that calculates a dwell timing for the print to take a specific time to complete. I was thinking of a scenario: what happens if the printer is shut down (either accidentally or intentionaly) during the G4 command executed from a macro, called from the print ? Will the frimware be able to generate a proper resurrect.g with the correct parameters ?

If no: I was thinking of three things to mitigate this:

-add a dwell right after the macro call in the print file. Tricky, I have a file currently being printed that will go on for one year, i.e. I can't modifiy the original file. Do we have a way to "dynamically" add gcode to the file being printed ?

-call the dwell from deamon.g using a global, we would be out of a macro, would that pause the print ? Or just the deamon? (can't test right now, printer has been shut off and I won't be able to run such tests confortably as i'll be handling it remotely)

-call M27 and M114 from the macro so I can make a custom reusrrect.g . Will their output get written in the eventlog ? If not can I write the output to a file ?Thank you all in advance

Best -

RE: Gap in printing concentric circles-(CW side)posted in General Discussion

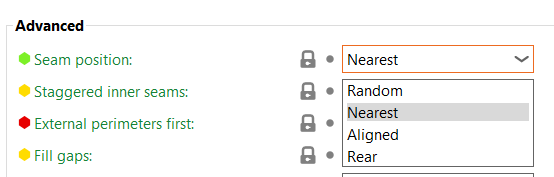

@JayT In most slicer you can choose where the seam is located. The seam is where an external perimeter starts and end, it usually creates an irregularity at that point

Prusaslicer

-

RE: Dual extruder - Preheat nozzle before tool changeposted in Gcode meta commands

Hi eveyone here is an update on this. So I'm stil lnot able to have Prusa's macro to work, in the meantime I did two things , one is working the second remains to be tested. I needed to implement the first solution in deamon.g to accomodate an ongoing long print (2weeks) that didn't have a single macro called on tool changes.

This assumes that succesive layer times have little variations (successive tool work times are approximately similar) which is the case for me with variations from layer to layer being a couple tens of seceonds at max . The thing is, every tool is going to be preheated regardless of their future usage, which is OK in my case as both tools are used until the last layers

Here is what i have in deamon.g

if state.status == "processing" if exists(global.previousTool) if state.currentTool != global.previousTool ; executes right after tool change G10 P{abs(state.currentTool - 1)} R160 if exists(global.newToolchangeTime) ; intitialize previous tool change time with last know tool change time if !exists(global.previousToolchangeTime) global previousToolchangeTime = global.newToolchangeTime else set global.previousToolchangeTime = global.newToolchangeTime if !exists(global.newToolchangeTime) ; update tool change time global newToolchangeTime = state.time else set global.newToolchangeTime = state.time echo "Last Toolchange time was :", global.previousToolchangeTime ; see if it works as intended echo "New Toolchange time is :", global.newToolchangeTime if exists(global.newToolchangeTime) && exists(global.previousToolchangeTime) echo "Calculating time between last tool changes..." if state.currentTool == 0 if !exists(global.lasttoolworkduration0) global lasttoolworkduration1 = global.newToolchangeTime - global.previousToolchangeTime else set global.lasttoolworkduration1 = global.newToolchangeTime - global.previousToolchangeTime if state.currentTool == 1 if !exists(global.lasttoolworkduration1) global lasttoolworkduration0 = global.newToolchangeTime - global.previousToolchangeTime else set global.lasttoolworkduration0 = global.newToolchangeTime - global.previousToolchangeTime if exists(global.lasttoolworkduration0) echo "It took", global.lasttoolworkduration1, "s between two tool changes from 1 to 0" else echo "Not enough tool changes were sampled" if exists(global.lasttoolworkduration1) echo "It took", global.lasttoolworkduration0, "s between two tool changes from 0 to 1" else echo "Not enough tool changes were sampled" if !exists(global.previousTool) global previousTool = state.currentTool else set global.previousTool = state.currentTool if !exists(global.preheatingoffset) global preheatingoffset = 40 else set global.preheatingoffset = 40 ; start heating up 60 seconds before next layer if exists(global.previousLayerTime) && exists(global.lasttoolworkduration0) && exists(global.lasttoolworkduration1) if state.currentTool == 1 && state.time >= global.newToolchangeTime + global.lasttoolworkduration1 - global.preheatingoffset echo "Preheating extruder ", abs(state.currentTool - 1), "..." G10 P{abs(state.currentTool - 1)} R{heat.heaters[abs(state.currentTool -1) + 1].active} ;G10 P{state.currentTool} R150 elif state.currentTool == 0 && state.time >= global.newToolchangeTime + global.lasttoolworkduration0 - global.preheatingoffset echo "Preheating extruder ", abs(state.currentTool - 1), "..." G10 P{abs(state.currentTool - 1)} R{heat.heaters[abs(state.currentTool -1) + 1].active} ;G10 P{state.currentTool} R150Now the goal, and second solution will be to execute a macro called preheatextruders.g in prusaslicer tool change custom gcode that will handle the Time globals

and let deamon.g do the regular checksIt's DIY and has a rather narrow scope i know but I hope it can help others in similar situations