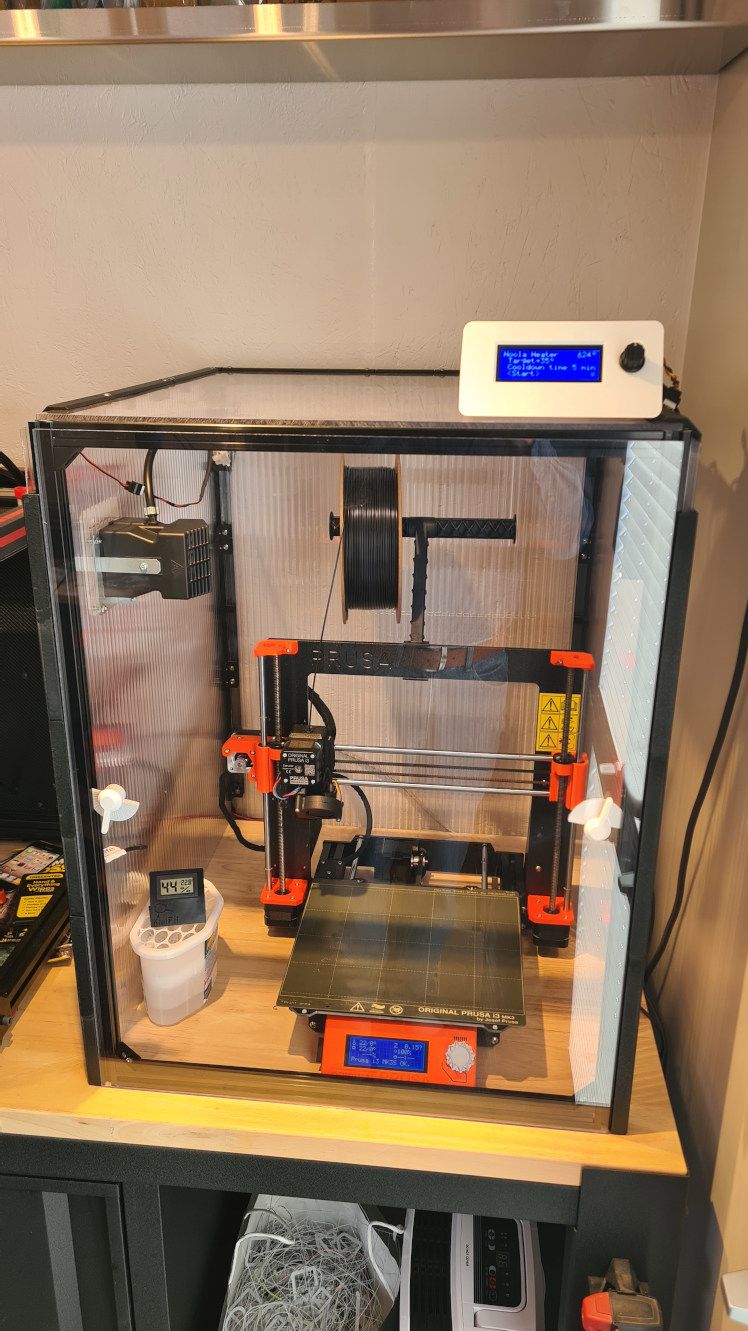

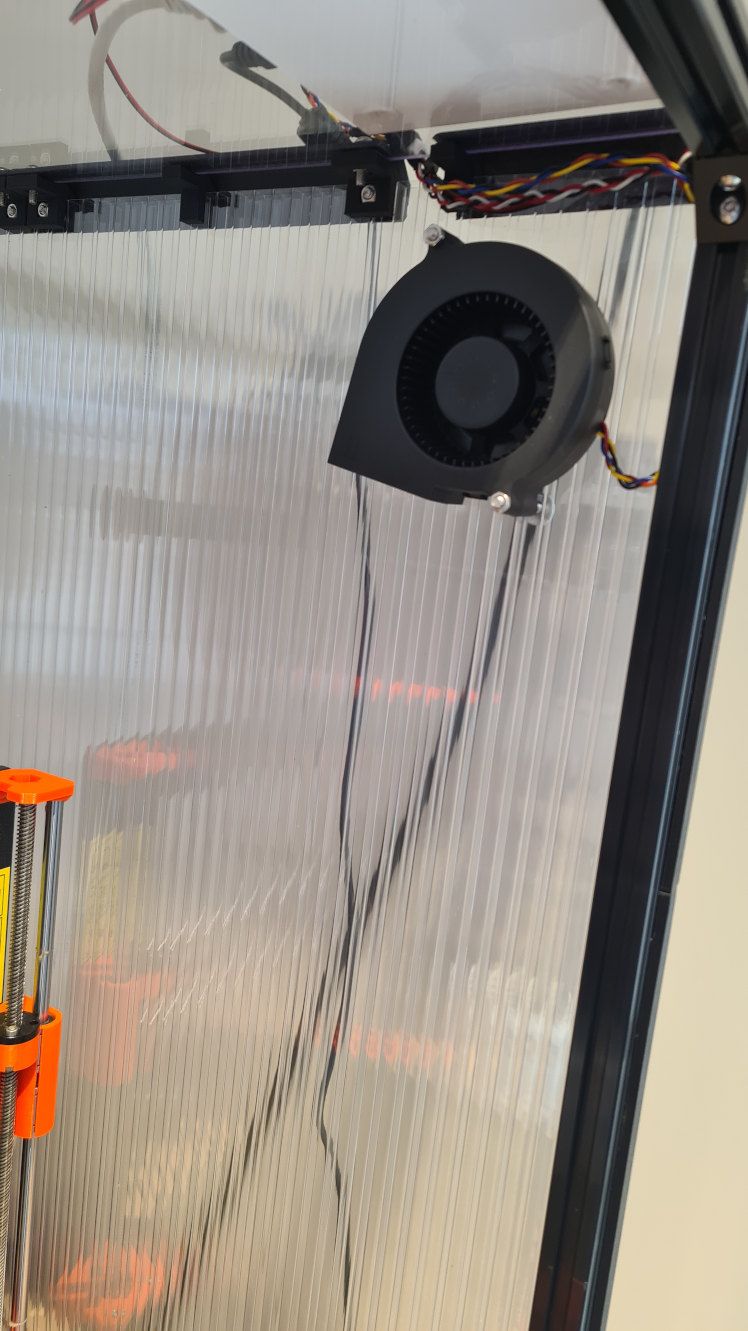

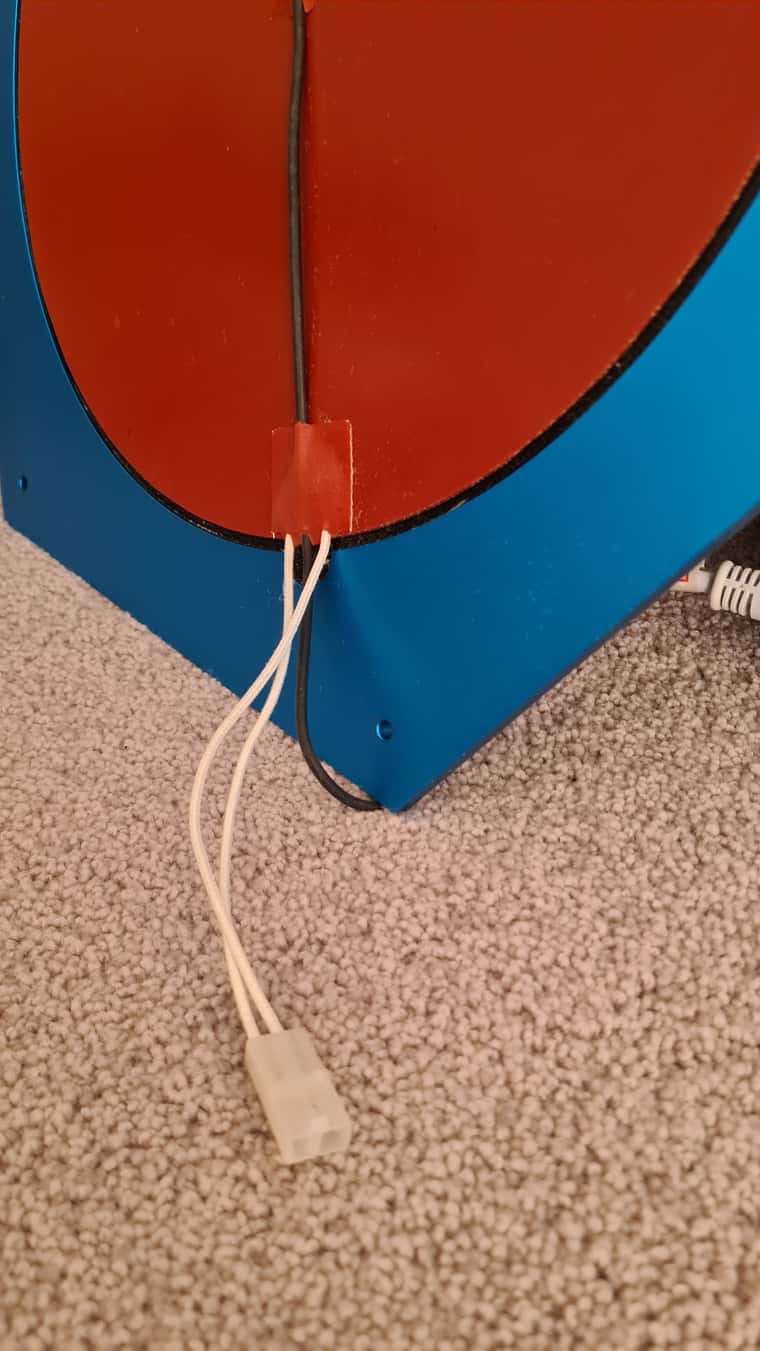

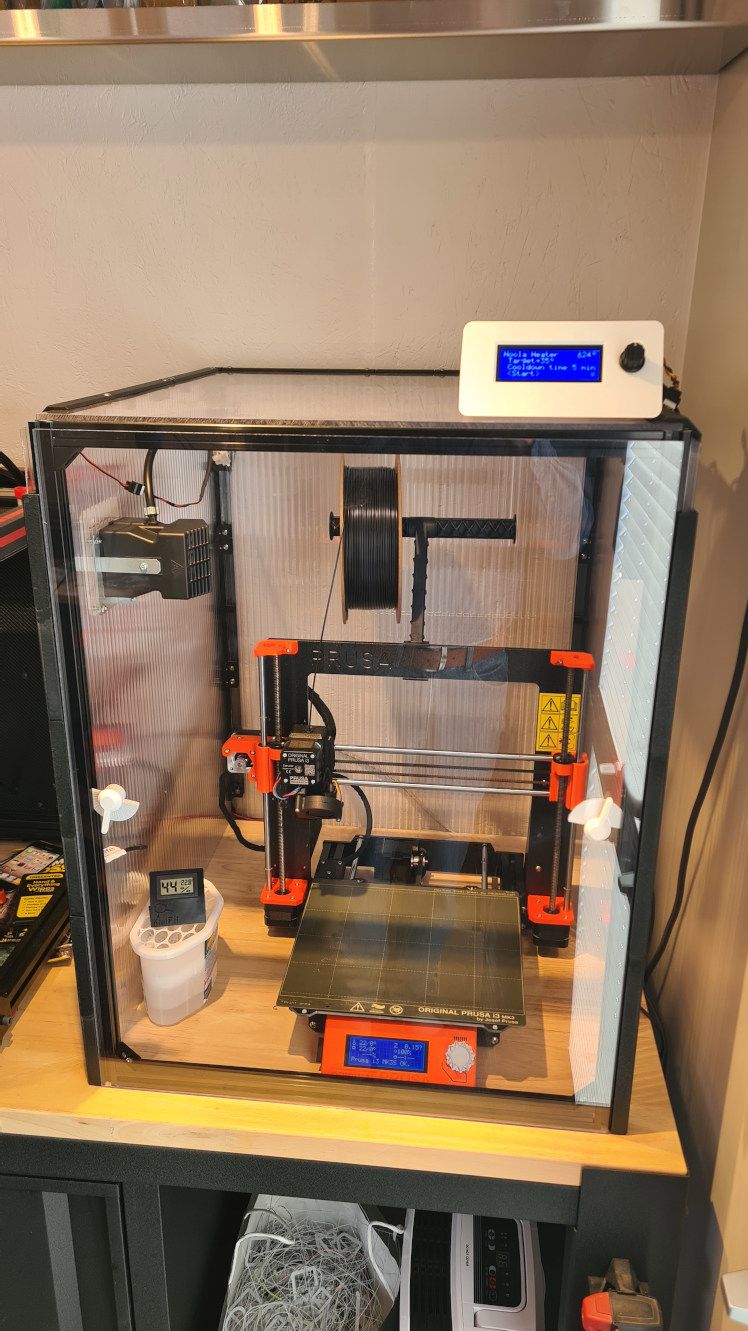

@T3P3Tony The heater is a combined 24V fan and 400W mains voltage heating element mounted towards the top on the left hand side of the enclosure. It brings in air from outside the enclosure, and, while it's not easily visible, the rear of the enclosure hangs over the back of the work bench, so the cooler air lower in the enclosure air exits at that point. I debated for a long time whether to just recycle (reheat) the air in the enclosure, but I hadn't worked with this kind of heater before and didn't know how hot the 'input' air could safely be, so I went for the safe option, and heat room temperature air. It looks like the heater is designed to be mounted on the outside of an enclosure, but I couldn't find any more guidance on the data sheet. This work space is not occupied, so I have no problems with potentially harmful ASA and other particles from engineering filament being blown into the room.

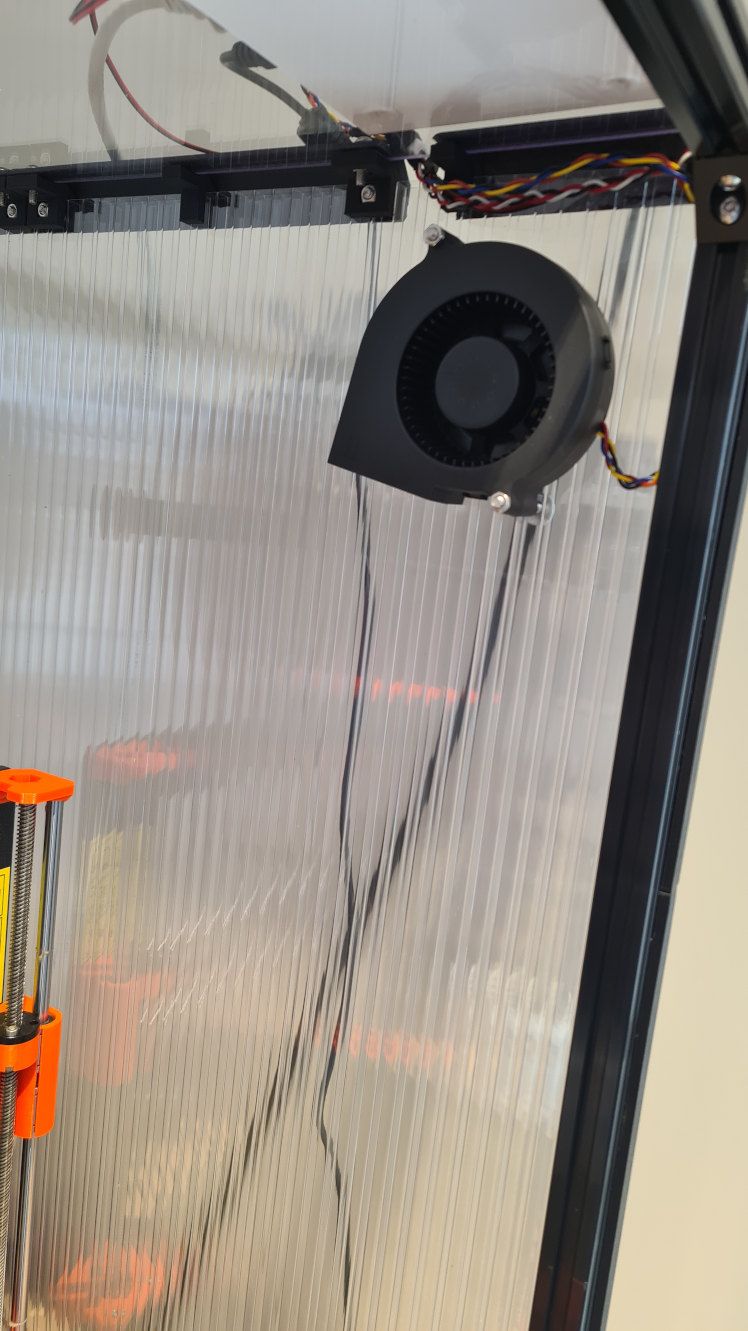

There is a blower fan that is used for the initial stage of heating in order to mix the air thoroughly throughout the enclosure.

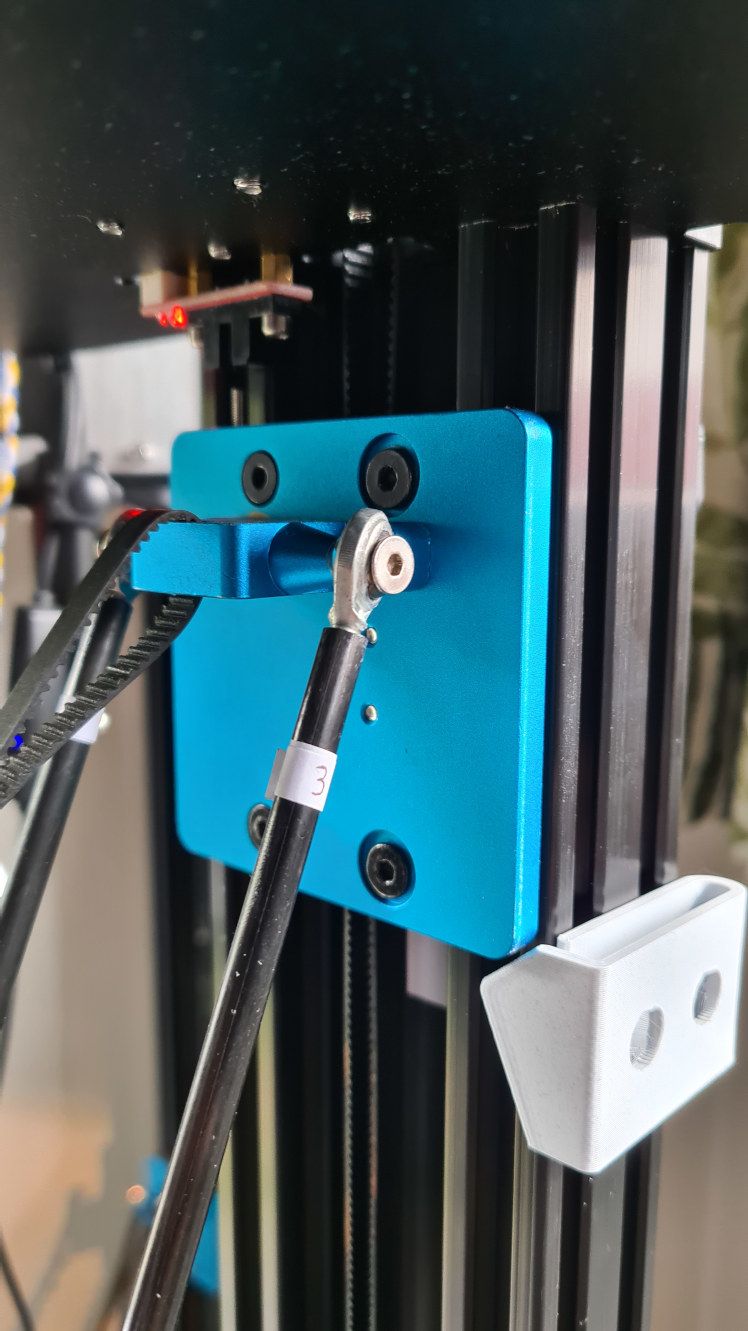

I have a single DS18B20 temperature sensor.

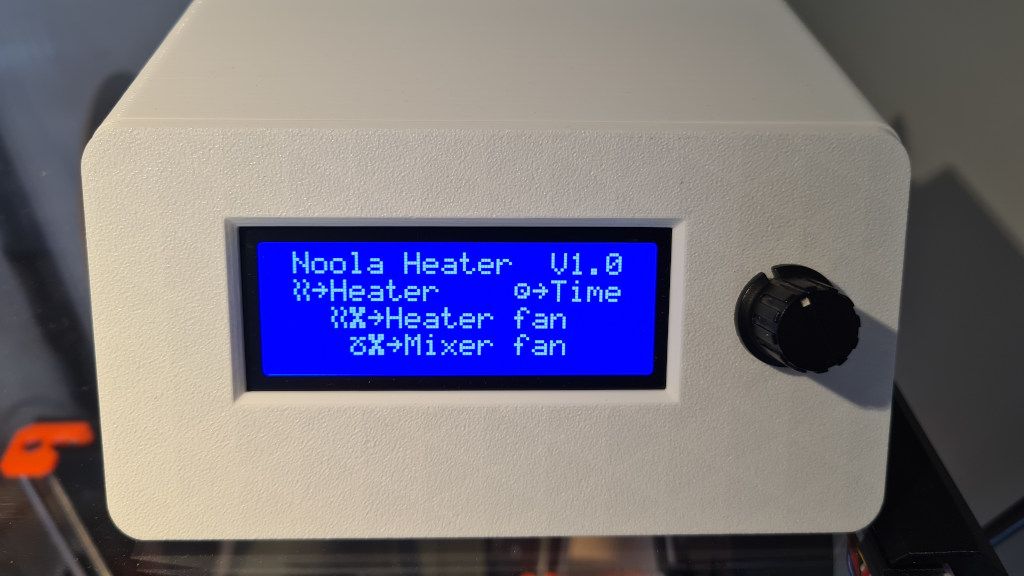

I'm using a simple heating thermostat algorithm (bang bang) to turn the heating element on and off. I found the location of the temperature sensor is critical and sensitive. At one extreme, if the sensor is in the hot air stream the heater will of course turn off far too early. At the other extreme, say if the sensor is tucked away in the enclosure frame tubing, the air in the enclosure gets far too hot before the heater will turn off. What I have found is that it's best where it is in the photo. I think it's best to have a sensor that reacts a little on the fast side, and just let the whole setup stabilise for a while, than risk wild temperature swings of a too slow sensor response. Yes, I could implement a PID system, but that would be more work.

The heater unit spec is as follows.

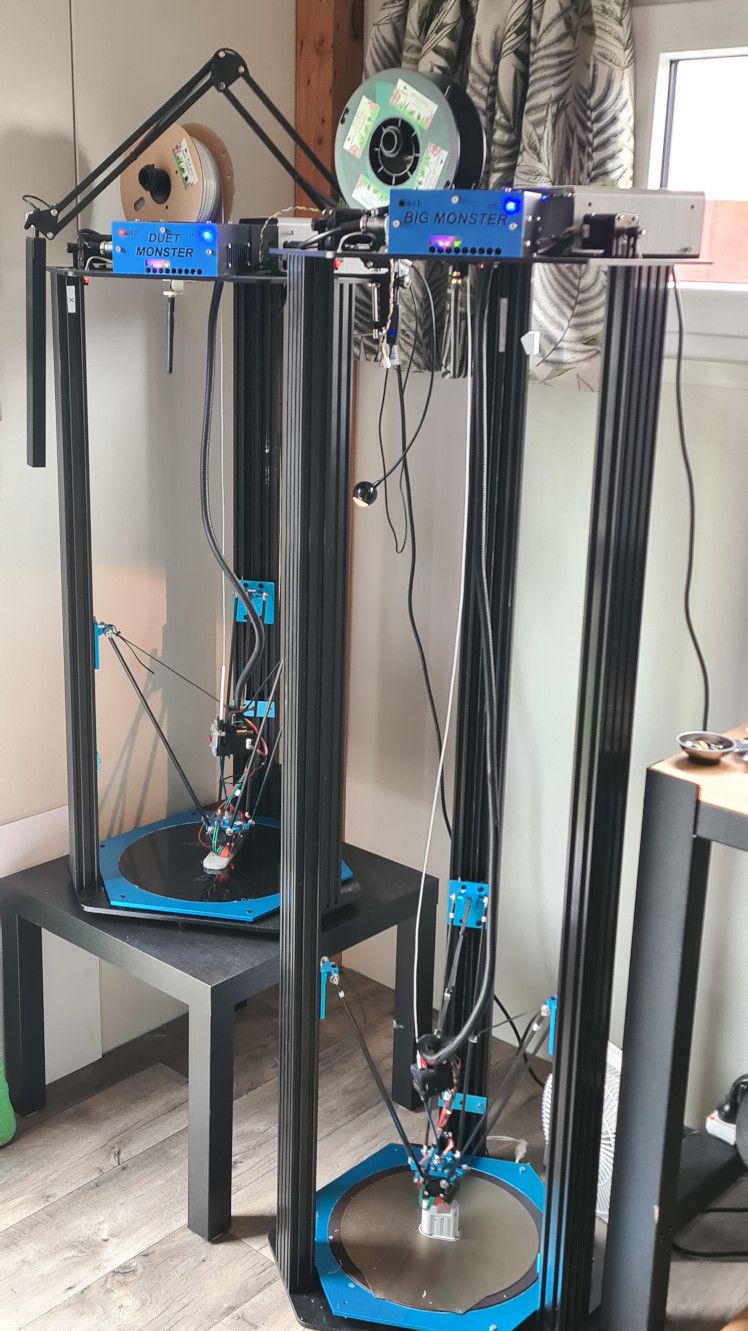

As I say, this is not hooked up to a Duet, but the controller does have a serial interface that I designed to work with my Duet equipped machines. I'm hoping that one day I'll have an enclosure ready for those, and can do something similar.

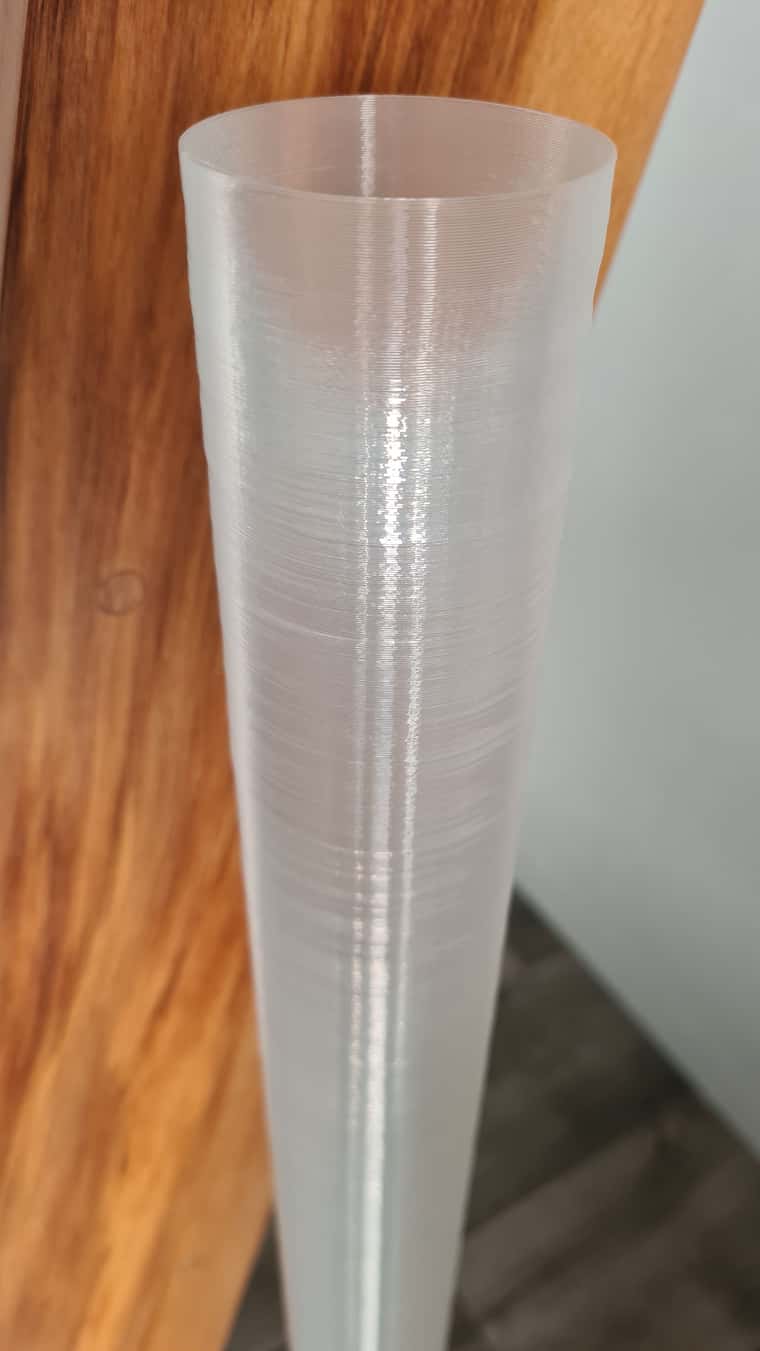

Incidentally the enclosure is made from 8mm twin wall polycarbonate (roofing material), which is cheap, and for the parts where I want to see in it's made from 4mm Lexan (polycarbonate). This was about the best bang for the buck I could manage here in New Zealand, but it still cost a few hundred NZ dollars (maybe USD$200). The panels are joined together using brackets printed from eSun ABS-MAX which is UL94V0 rated filament. There is also a smoke detector nearby and a second one that is wired to an occupied area.

Regards,

-Martin