Hi together,

I have built my own IDEX printer based on a Duet Wifi 2 (RRF 3.4.4).

Everything is running fine except that all my circles printed in xy become ovals.

Parts are sliced in SuperSlicer and orientation doesn't matter.

Skew is already compensated and printed parts are all square.

I checked belttension multiple times.

There are only two things I am thinking of that could cause the problem but i am not sure about.

Maybe something with jerk and acceleration values ? But while printing everything looks fine and smooth.

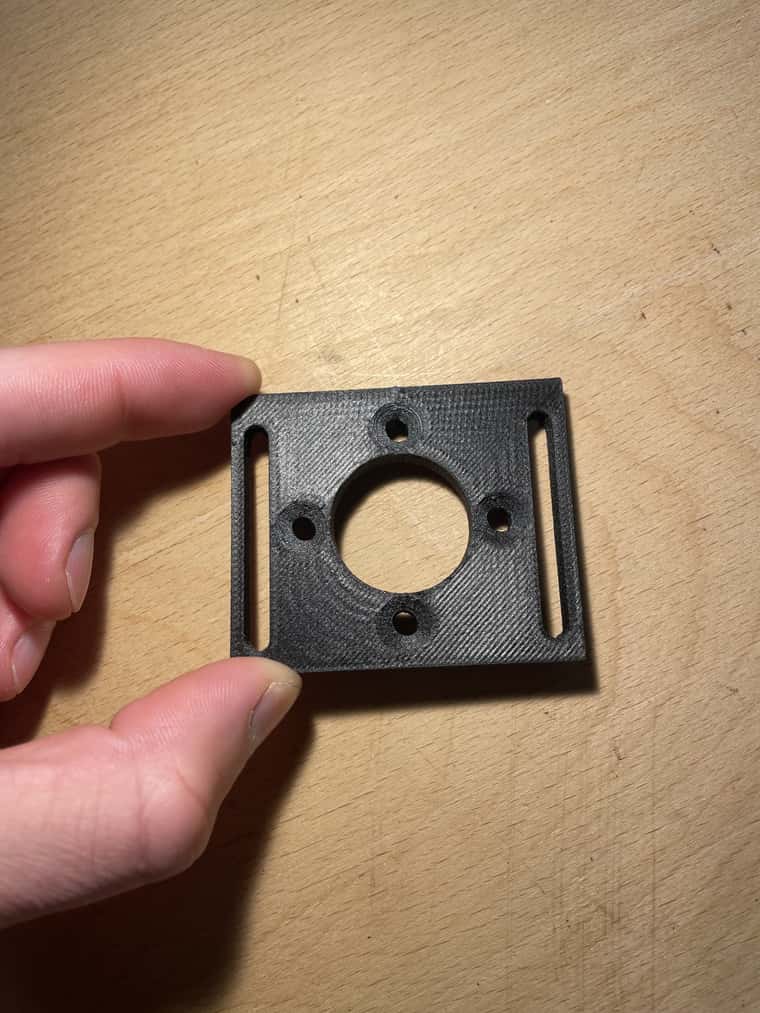

The other thing is, that i am running the x-axis on an external StepperOnline DM542T stepper driver.

link text

I already switched the axis to an onboard Duet Wifi driver with the same result.

I am very lost and would be very happy if somebody could help me.

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Machine m" ; set printer name

M669 K0 ; select Cartesian mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes backwards

M569 P4 S0 D2 ; physical drive 4 goes forwards

M569 P5 S0 R1 T2.5:2.5:5:0 ; drive 5 goes forwards

M569 P6 S0 R1 T2.5:2.5:5:0 ; drive 6 goes forwards

M569 P7 S0 R1 T2.5:2.5:5:0 ; drive 7 goes forwards

M569 P8 S0 R1 T5:5:10:0 ; physical drive 8 goes backwards aa:bb:cc a=Step pulse width/ b=

M584 X8 Y1:2 Z5:6:7 U0 E3:4 ; set drive mapping

M350 U16 Y16:16 Z16:16:16 E16:16 I1 ; configure microstepping with interpolation

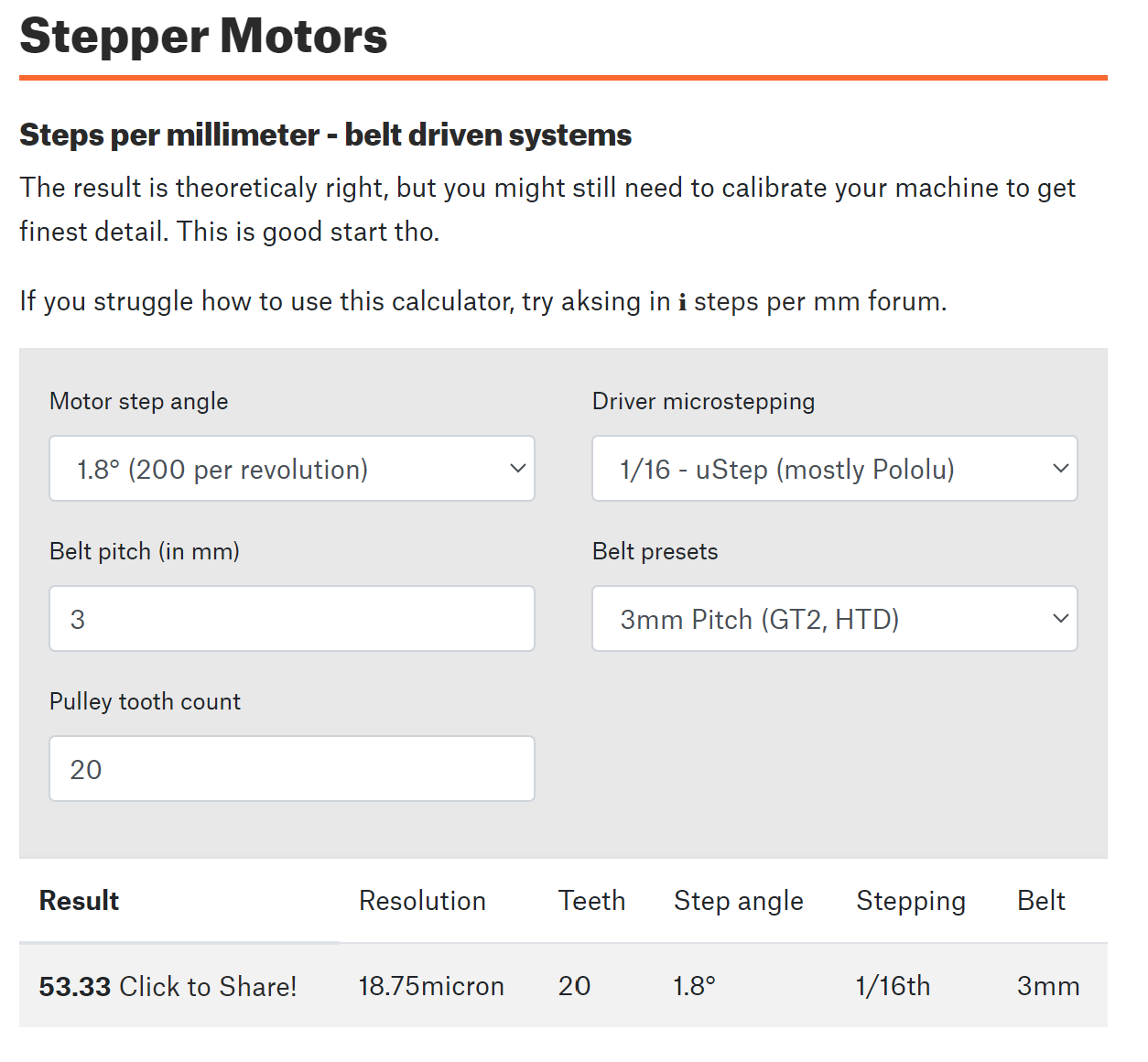

M92 X40.00 U80.00 Y53.33 Z640.00 E396.00:396.00 ; set steps per mm (E old 390)

M566 X400.00 U400.00 Y400.00 Z300.00 E3000.00 ; set maximum instantaneous speed changes (mm/min) 900

M203 X20000.00 U20000.00 Y20000.00 Z2100.00 E3600.00 ; set maximum speeds (mm/min)

M201 X2000.00 U2000.00 Y2000.00 Z400.00 E4000.00 ; set accelerations (mm/s^2) 4000

M204 P4000 T5000 ; Set print and travel accelrations [mm/s^2]

M906 U1000 Y1800:1800 E1000:1000 I30 ; set motor currents (mA) and motor idle factor in per cent

;M671 X390:-10:-10 Y200:5:390 S100 F1 ; Leadscrew at rear front, back middle and rear front

M671 X390:-10:-10 Y200:5:390 ; Leadscrew at rear front, back middle and rear front

M84 S30

; Axis Limits

M208 X-47 U25.5 Y-36 Z0 S1 ; set axis minima

M208 X360 U436.7 Y417 Z300 S0 ; set axis maxima

M564 H0 ; Allow axis movement before homing

; Endstops

M574 X1 S1 P"e1stop" ; set active high endstops for X-axis

M574 U2 S1 P"xstop" ; set active high endstops for U-axis

M574 Y1 S1 P"ystop+e0stop" ; set active high endstops for Y-axis; 2 enstops used

;M574 Y1 S1 P"e0stop"

M574 Z2 S2 ; set endstops controlled by probe

; Z-Probe

;M558 C"!zprobe.mod" P5 R0.4 H1.5 F800:600 T12000 A2 I1 S0.1 ; set Z probe type to effector and the dive height + speeds

M558 C"!zprobe.mod" P5 R0.4 H4 F800:600 T12000 A2 I1 S0.1 ; set Z probe type to effector and the dive height + speeds

G31 X-0.5 Y-26.352 Z1.45 S20 H0 ; set Z probe trigger value, offset and trigger height 1.58

;M557 X15:400 Y0:370 S40 ; define mesh grid

M557 X5:350 Y0:400 P7:7 ; define mesh grid

; Heaters

; Bed

M140 H0

M308 S0 P"bedtemp" Y"thermistor" A"Bed Temperature" T100000 B3950 C7.06e-8 R4700

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B1 S1

;Extruder E0 Hotend (E3D Hemera)

M308 S1 P"e0temp" Y"thermistor" A"Extruder 1 temp." T100000 B4725 C7.06e-8 R4700

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S285 ; set temperature limit for heater 1 to 285C

M307 H1 B0 A346.2 C189.8 D4.3 S1.0 ; Set heating process parameters, Heater1 (H1),Gain (A), time constant (C), Dead time (D), Max PWM 100% (S1.0)

M302 P1 ; Allow cold extrusion

M572 D0 S0.025 ; Preassure Advance

;Extruder E1 Hotend (E3D Hemera)

M308 S2 P"e1temp" Y"thermistor" A"Extruder 2 temp." T100000 B4725 C7.06e-8 R4700

M950 H2 C"e1heat" T2 ; create nozzle heater output on e0heat and map it to sensor 2

M143 H2 S285 ; set temperature limit for heater 2 to 285C

M307 H2 B0 A346.2 C189.8 D4.3 S1.0 ; Set heating process parameters, Heater2 (H2),Gain (A), time constant (C), Dead time (D), Max PWM 100% (S1.0)

M302 P1 ; Allow cold extrusion

M572 D0 S0.03 ; Preassure Advance

; Fans

M950 F0 C"fan0"

M950 F1 C"fan1"

M106 P0 S0 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S0 H-1 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Tools

M563 P0 S"ExtruderE0" D0 H1 F0 X0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"ExtruderE1" D1 H2 F1 X3 ; define tool 1

G10 P1 U0.5 Y14.8 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

T0

; Accelerometer

M955 P0 I54 C"spi.cs4+spi.cs3" ; Accelerometer Configuration

M593 P"mzv" F36 ;Input shaping at 33Hz; Damping: 0

; Custom settings are not defined

M305 P2 S"Heizbett oben" T100000 B3950 C7.06e-8 R4700

; Miscellaneous

M556 S100 X-1.058 Skew factor

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss