Yes its same board.

Posts made by Maciek

-

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

Ok I know at least it's a D3m board issue. I borrowed duet mini from a friend. I plugged everything in and powered it up - it works as it should :/.

So for sure something with the board

-

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

@Phaedrux

I tried that at very begining. Even before writing here.I ran many tests tonight.

I unplugged everything from the board and plugged it in one by one - I didn't notice that anything had an effect.

I see that the motors sometimes respond. Sometimes. They don't move in the correct way - for example, they just whirl. But a piece move by jumping.

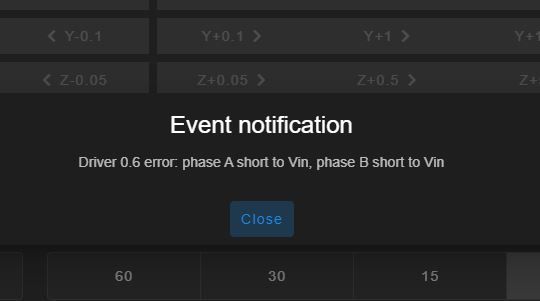

I could not find the correlation. I unplugged and tried to check each one individually - on each it happens - either it does not work at all or works completely incorrectly.Occasionally, from time to time, there is a message about a driver short circuit. But not every time. Happens with different drives.

-

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

The printer was working, printing. During one of the printouts suddenly the drives stopped working. At the time I did nothing about it because it was nearing the time of moving and I did not want to start it. Then everything slipped, and now that I finally have time I set about getting it up and running.

That is, there was a failure, the printer in such a state stood protected for a good few months.

After starting it up, basically after checking a few obvious things - whether there was a short somewhere, whether there was power, whether the fuse blew - I immediately wrote here.If it is a UART issue then what is the prognosis?

-

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

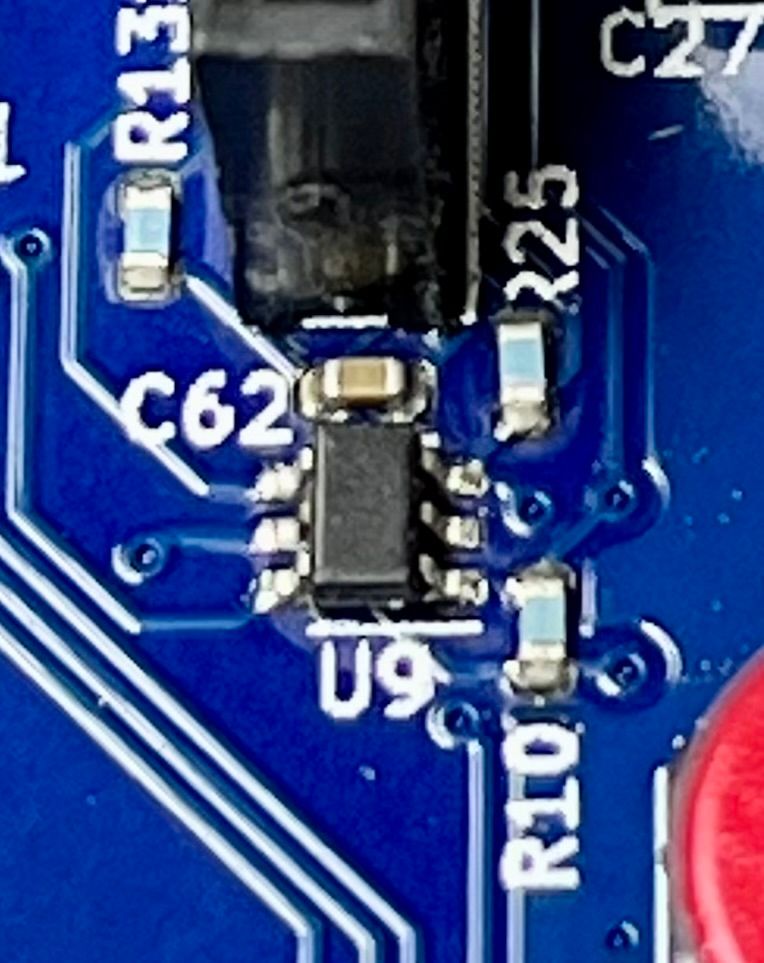

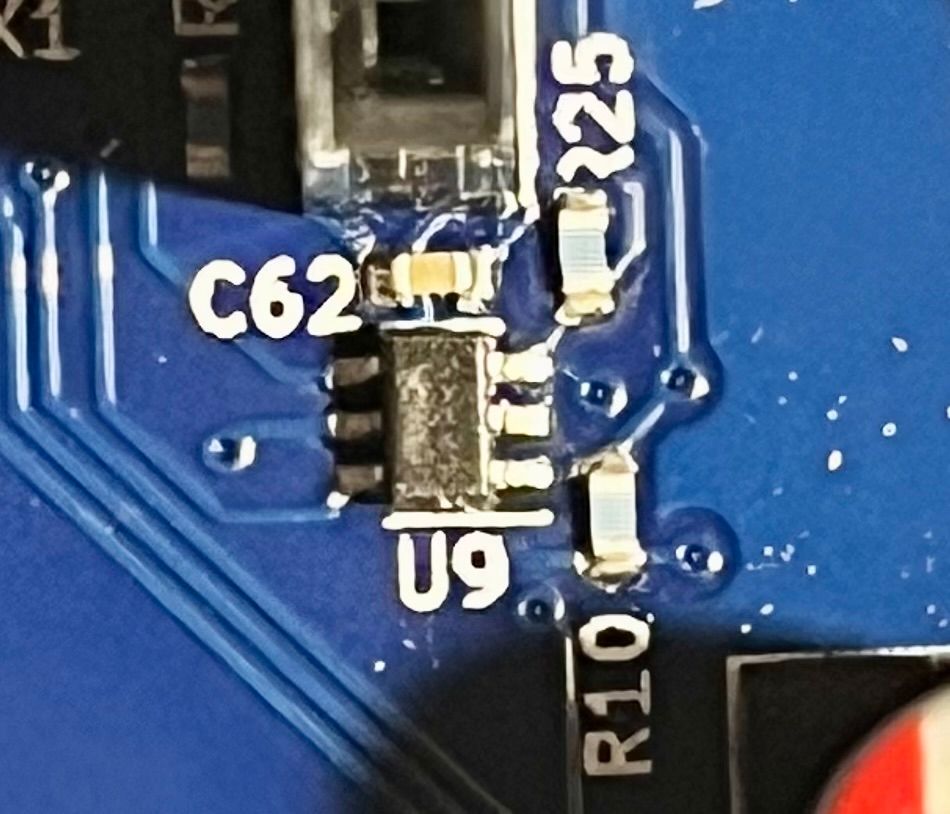

Are these pictures good enough? Do you need higher magnification or sharpness? If you say which part, I can try to do a macro.

-

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

@Maciek

I have the impression - but I'll check it when I have access to the printer - that one of the indicator LEDs - specifically the blue one glows weaker than the other three.

The voltage on the power supply is within the normal 24V.

Are there any measurement points on the board where I can check if everything is OK? -

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

I disconnected the daughter-board, started the printer - it did not change anything. I tried to move the Z-axis - (I did fake homing M92 Z) but it did not help.

To answer your question - the daughter board was mounted correctly - using standoffs.

In general, the printer is decently wired, without any tangles, the wires poised, used terminals, ferrules, etc.I did update to 3.4.5 - nothing changed.

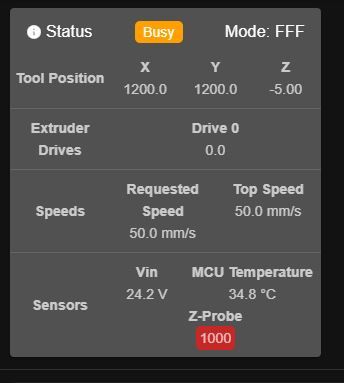

For me personally, it is interesting that if I move , it appears to me as if the axis is moving - there is a set speed, there is a top, even the position of the axis according to dwc changes.

(now Z is -5 because i did G0 z-999999 just to make a screenshot)

Any more ideas?

Is there anything else I can check to determine what might have happened and how to fix it?

I would like to determine if something can be done or look around for a new board. -

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

@DIY-O-Sphere

nothing interesting

; config-override.g file generated in response to M500 at 2021-10-04 21:45 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R0.756 C301.148:301.148 D2.76 S0.60 V23.6 B0 I0 M307 H1 R1.835 C219.900:173.600 D7.75 S1.00 V24.1 B0 I0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 -

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

@Phaedrux

It was working like a charm on that firmware. Now its dead.

Im waiting for more suggestions. -

RE: Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

@jay_s_uk

The board was purchased in mid 2021 at FilaFarm and has already been replaced once under warranty.

Unfortunately, due to moving house, the printer was unused for a year and the warranty flew

I checked fuse 10 and 15 and both are ok.

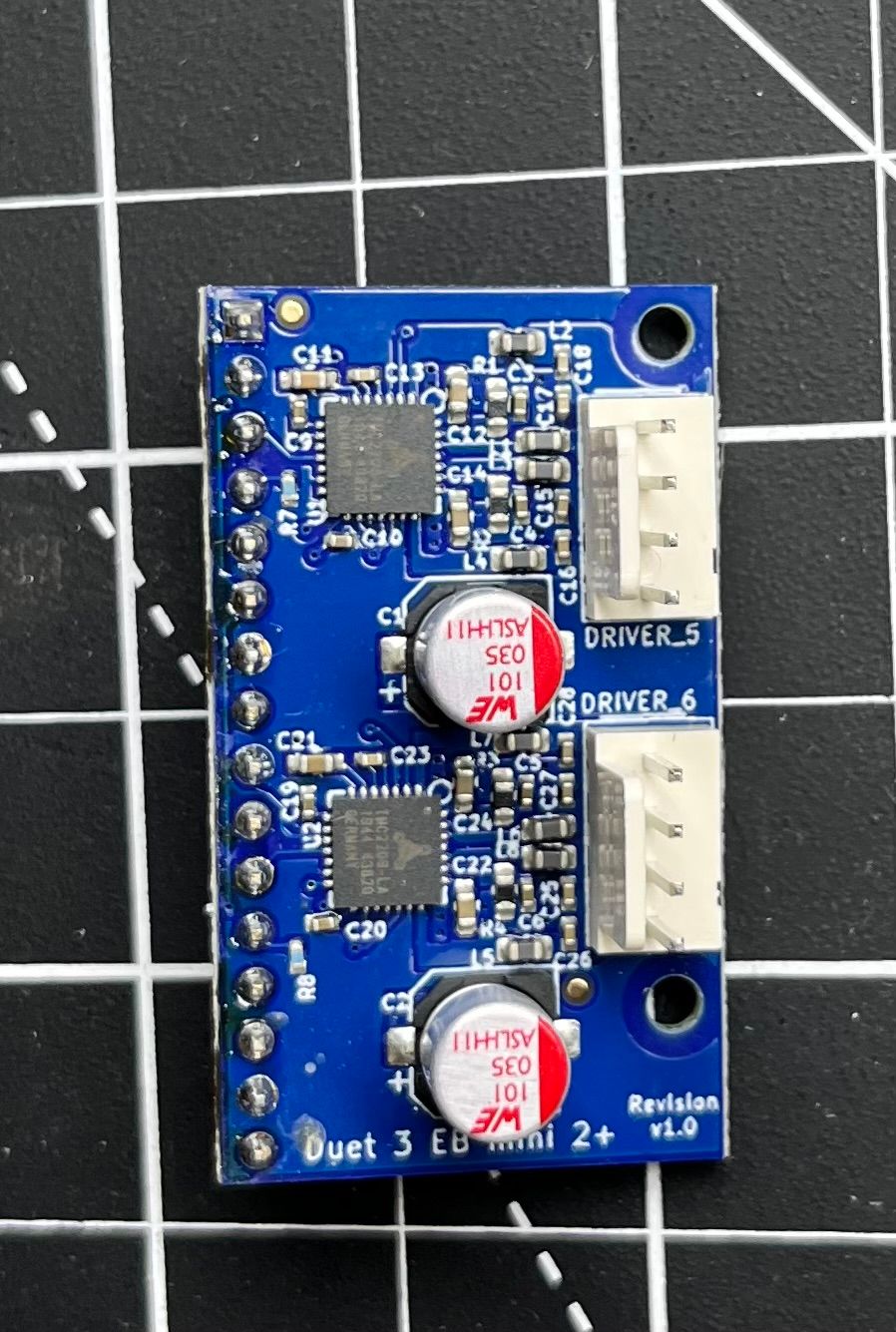

By expansion board I mean this small board for 2 steppers - not to be confused with LC1.

I didn't try to unplug it because I didn't see any reason to check it

I have a feeling that this is some kind of communication problem - I can't imagine a situation where 7 motor controllers go down at once. -

Problem with all axis/motors (D3Mini+extension board)posted in Duet Hardware and wiring

Hello.

I have a problem with axis/motor movements in the printer.

I can't do homing, I can't move anything.

All axes are not working. The printer is V2.4.

Other than that, everything works

Hotend heats up, table the same, temp readings are normal.

My first thought is that there is a problem with the voltage, with the fuses - but it looks like they are ok.I attach what the printer told me:

m122 b0 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.3 (2021-06-15 21:46:11) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: 384NZ-P096U-D65J0-40KM4-N113Z-7TJN1 Used output buffers: 3 of 40 (25 max) === RTOS === Static ram: 102724 Dynamic ram: 106832 of which 0 recycled Never used RAM 31292, free system stack 130 words Tasks: NETWORK(ready,15.2%,255) HEAT(notifyWait,0.0%,366) Move(notifyWait,0.1%,305) CanReceiv(notifyWait,0.0%,941) CanSender(notifyWait,0.0%,371) CanClock(delaying,0.0%,340) TMC(notifyWait,0.3%,115) MAIN(running,83.6%,426) IDLE(ready,0.0%,29) AIN(delaying,0.9%,273), total 100.0% Owned mutexes: WiFi(NETWORK) HTTP(MAIN) === Platform === Last reset 00:01:45 ago, cause: software Last software reset at 2023-04-01 21:33, reason: User, GCodes spinning, available RAM 31292, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 106112, completed 106110, timed out 0, errs 0 Step timer max interval 752 MCU temperature: min 32.6, current 33.5, max 33.5 Supply voltage: min 24.1, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/3, heap memory allocated/used/recyclable 2048/38/0, gc cycles 0 Driver 0: position 192000, assumed not present Driver 1: position 0, assumed not present Driver 2: position 4000, assumed not present Driver 3: position 0, assumed not present Driver 4: position 0, assumed not present Driver 5: position 0, assumed not present Driver 6: position 0, assumed not present Date/time: 2023-04-01 21:34:50 Cache data hit count 190966865 Slowest loop: 5.73ms; fastest: 0.11ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 3.4ms, write time 0.0ms, max retries 0 === Move === DMs created 83, maxWait 38866ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 4, completed moves 4, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1, chamberHeaters = -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is ready with "m122 b0" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === CAN === Messages queued 821, received 0, lost 0, longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 17 (min 17), ts 456/0/0 Tx timeouts 0,0,456,0,0,365 last cancelled message type 30 dest 127 === Network === Slowest loop: 199.55ms; fastest: 0.06ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 1 WiFi firmware version 1.26 WiFi MAC address f0:08:d1:02:ef:49 WiFi Vcc 3.35, reset reason Power up WiFi flash size 2097152, free heap 25312 WiFi IP address 192.168.0.17 WiFi signal strength -53dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0And my config file:

; Configuration file for Duet3 Mini5+ with Mini2+ expansion (firmware version 3.3 or newer) ; executed by the firmware on start-up ; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M669 K1 ; Select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed ;M918 P2 R6 C30 E-4 F200000 ; Fysetc 12864 display ; Network M550 PVoron V2.471 ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP (for DWC) M586 P1 S1 ; Enable FTP (for remote backups) M586 P2 S0 ; Disable Telnet ; --- Z Drive map --- ; _______ ; | 1 | 2 | ; | ----- | ; | 0 | 3 | ; ------- ; front ; ; (looking at the printer from the top) ; Drive directions M569 P0 S0 ; Z0 M569 P1 S1 ; Z1 M569 P2 S0 ; Z2 M569 P3 S1 ; Z3 M569 P4 S0 ; Extruder M569 P5 S1 ; A M569 P6 S0 ; B TODO I wired one of them backwards of course :( ; Motor mapping and steps per mm M584 X5 Y6 Z3:2:1:0 E4 M350 X16 Y16 Z16 E16 I1 ; Use 1/16 microstepping with interpolation everywhere M92 X80 Y80 Z400 ; Set XYZ steps per mm (1.8deg motors) ;M92 X160 Y160 Z800 ; Set XYZ steps per mm (0.9deg motors) M92 E406 ; Set Extruder steps per mm ; Drive currents M906 X1000 Y1000 Z1000 E600 ; XYZ and E current M906 I30 ; Idle current percentage M84 S120 ; Idle timeout ; Accelerations and speed M98 P"/macros/print_scripts/setup_printing.g" ; Axis travel limits M208 X0 Y0 Z-5 S1 ; Set axis minima M208 X298 Y303 Z250 S0 ; Set axis maxima ; Endstops M574 X2 S1 P"io5.in" ; Xmax endstop on hall effect board M574 Y2 S1 P"io6.in" ; Ymax endstop on hall effect board M574 Z0 P"nil" ; No Z endstop ;klicky probe M558 K0 P8 C"io1.in" I1 H10 F600:300 T18000 A6 S0.0075 R0.2 ; set Z probe type to switch and the dive height + speeds G31 K0 P500 X0 Y19.0 Z7.375 ; set Z probe trigger value, offset and trigger height / wiecej = niżej, mniej = wyżej. Zero = roznica wysokosci miedzy dysza a clicky ; Bed leveling M671 X-53:-53:351:351 Y0:370:370:0 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right) M557 X25:275 Y25:275 S25 ; Define bed mesh grid (inductive probe, positions include the Y offset!) ; Bed heater (dual thermistor setup) M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed Heater" ; configure sensor 0 as thermistor on pin temp0 (heater sensor) M950 H0 C"out0" T0 Q10 ; create bed heater output on out0 and map it to sensor 2 (mic6 sensor). Set PWM frequency to 10Hz M140 P0 H0 ; Mark heater H0 as bed heater (for DWC) M143 H0 P1 T0 A2 S115 C0 ; Regulate (A2) bed heater (H0) to have pad sensor (T0) below 115°C. Use Heater monitor 1 for it M143 H0 P2 T0 A1 S125 C0 ; Shut off (A1) bed heater (H0) if pad sensor (T0) exceeds 125°C. Use Heater monitor 2 for it <-- to jest chyba w ogole nie potrzebne ?? M143 H0 S115 ; Set bed heater max temperature to 110°C, use implict monitor 0 which is implicitly configured for heater fault M307 H0 B0 S0.6 ; disable bang-bang mode and set PWM to 60% to avoid warping ; Hotend heater M308 S1 A"Hotend" P"temp1" Y"PT1000" ; Hotend is 2-wire PT1000 on pin temp2 M950 H1 C"out1" T1 ; Hotend heater is connected to out1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S290 ; Set temperature limit for heater 1 to 350C ; Chamber M308 S2 P"temp2" Y"thermistor" T100000 B3950 A"Chamber" ; Todo: Chamber temperature sensor via io port (needs RRF3.3b1+) ;M308 S10 P"io4.out+io4.in" Y"dht21" A"Chamber Temp[C]" ; Set DHT21 for chamber temp ; Fans M950 F0 C"out5" Q250 ; Create fan 0 (hotend) on pin out3 and set its frequency M106 P0 S1 H1 T50 C"Hotend" ; Configure fan 0: Thermostatic control is turned on, based on sensor #1 M950 F1 C"out3" Q20 ; Create fan 1 (cooling) on pin out4 and set its frequency M106 P1 S0 H-1 C"Cooling" ; Configure fan 1: Thermostatic control is turned off M950 F2 C"out4" Q250 ; Create fan 2 (electronics bay) on pin out5 and set its frequency M106 P2 S255 H1 T50 C"Bay" ; Run the fans at 25% if the hotend is over 50C M950 F3 C"out6" Q30 ; Create fan 3 (chamber) on pin out6 and set its frequency M106 P3 S1 H0 T30 C"Chamber" ; Configure fan 3: Thermostatic control is turned on, based on sensor #2 (mic6 temp) ; Licznik M950 F4 C"out2" Q250 ; Create fan 0 (hotend) on pin out3 and set its frequency M106 P4 S1 H1 T150 C"Counter" ; Tools M563 P0 D0 H1 F1 ; Define tool 0 using fan 1 for M106 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Misc ;M572 D0 S0.075 ; Pressure Advance ;M572 D0 S0.01 ; Pressure Advance M592 D0 A0.015 B0.0012 L0.2 ; Non-linear extrusion M376 H10 ; Fade mesh out compensation over 10mm Z ;M912 P0 S-8.5 ; MCU temp calibration ;INPUT SHAPER ; DAA tuning (you will need to change this for your slicer) ;M593 F26.6 ; Cura 4.5 stock profile @ 40mm/s outer printing speed ;M593 F42.5 ; PrusaSlicer @ 40mm/s outer perimeter ;M80 ; turn on PSU & mains voltage ; panel due M575 P1 S1 B57600 ; Stallgaurd Sensitivy (maybe use to pause print after crash) M915 X S2 F0 H200 R0 ; Set X axis Sensitivity 1.8 motors M915 Y S2 F0 H200 R0 ; Set y axis Sensitivity 1.8 motors M501 ; load config-override.g T0 ; select tool 0 ; Prepare global vars for print macros global bed_temp = 0 global hotend_temp = 0 global box_temp = 0 -

RE: Duet3mini5+ problem with sd cardposted in Duet Hardware and wiring

@dc42 said in Duet3mini5+ problem with sd card:

@maciek I am sorry your Duet has developed a fault. We will replace it. Please email warranty@duet3d.com and cc Filafarm. You will receive a reply with a link to a form to fill in.

Its no problem. I like duet because of your support.

Im just worried that if I will have replacement from vendor, from the same batch, I will have same issue.

-

Duet3mini5+ problem with sd cardposted in Duet Hardware and wiring

Hi,

2 days after wiring and configuring duet3mini I have:Your Duet rejected the HTTP request: page not found

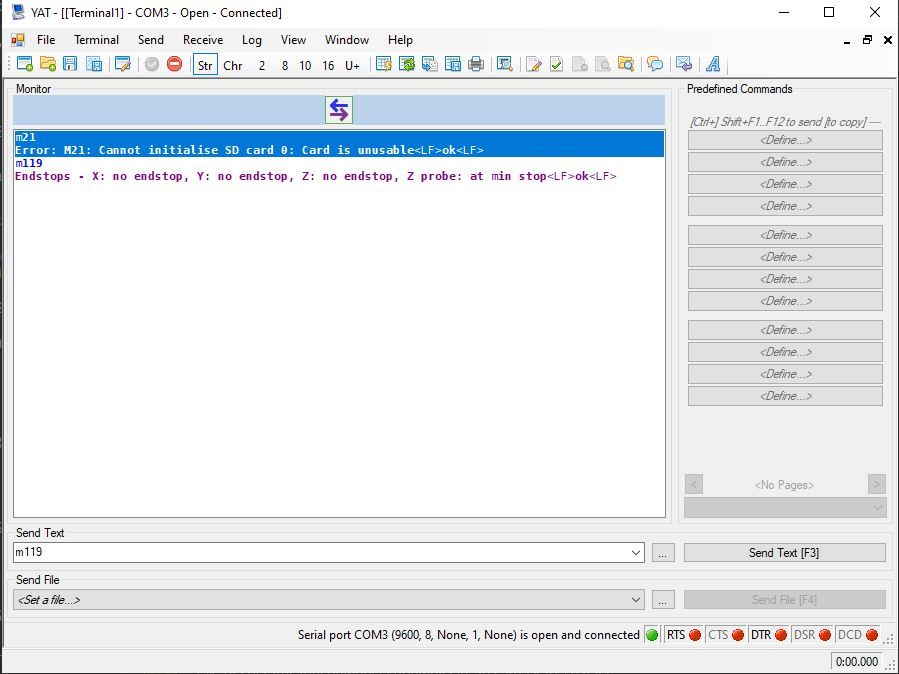

Check that the SD card is mounted and has the correct files in its /www folderI connected with Yat and did M21 command:

I connect sd card to pc, and it looks normal.

Can you tell me what I should do now?

I bought my duet from filafarm. -

RE: CoreXY Hevo Sensorless homing problem with Y.posted in Tuning and tweaking

Big thanks for reply David.

I tried higher S in the M915 to reduce sensivity. '4' is limit for my ears. And even with that sometimes homing fails.

Temperature in my opinion is not the issue. Both motors have same temperature and only Yaxis fails.

Moreover, I tested it on cold motors. My test print gcode is so short that motors cannot get even warm.

Im printing quite fast (100-150mm/s, 400mm/s travel, 5k acc), so current reduction is someting im afraid of.I start to think its something maybe with slicer start and end gcode.

Starting:

G28;

G1 Z10;Ending:

G4 ; wait

M221 S100

M104 S0 ; turn off temperature

M140 S0 ; turn off heatbed

M107 ; turn off fan

{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+20, max_print_height)}{endif} ; Move print head up

G1 X0 Y200; home X axis

M84 ; disable motorsFor now I just edited ending gcode to go to home position after print. It works, but its not how it should be.

-

RE: CoreXY Hevo Sensorless homing problem with Y.posted in Tuning and tweaking

I did some tests. I made very fast printable gcode (about 1sec print) just to make printer start and stop. I repeated it over and over. About 10% of homings before print was failure - after X was homed, Y wasnt.

I tried higher value of sensivity - with no luck.

I tried higher homing speed - same.

Same with motor current.Any idea?

Here is my config.g:

0_1539641962022_config_backup.gHere is newly edited homeall.g:

M400 ; make sure everything has stopped before we make changes

M913 X40 Y40 ; XY motors to xx% current

M915 H400 X Y S2 R0 F0 ; set X and Y to sensitivity 3, do nothing when stall, unfiltered

M574 X1 Y1 S3 ; set endstops to use motor stallG91 ; use relative positioning

G1 S2 Z10 F1200 ; lift ZG1 S1 X-300 F6000 ; move right/back 325mm, stopping at the endstop

G4 P500 ; wait 500msec

G1 X5 ; move away from home

G4 P500 ; wait 500msecM913 X40 Y40 ; XY motors to xx% current

M915 H400 X Y S2 R0 F0 ; set X and Y to sensitivity 3, do nothing when stall, unfiltered

M574 X1 Y1 S3 ; set endstops to use motor stallG1 S1 Y-300 F6000 ; move beyond axis minimum

G4 P500 ; wait 500msec

G1 Y5 ; move away from home

G4 P500G1 S1 Z-255 F1800 ; move Z down until the endstop is triggered

G92 Z0 ; set Z position to axis minimum (you may want to adjust this)G1 Z-10 F1200 ; lower Z

M400 ; make sure everything has stopped

M913 X100 Y100 ; XY motors to 100% current

G90 ; back to absolute positioning

M574 X1 Y1 S1 ; define active low microswitches -

CoreXY Hevo Sensorless homing problem with Y.posted in Tuning and tweaking

Hello.

All previous topics are closed thats why I make new one.

Sometimes Y axis is not homing properly. After X homing, it moves a bit and finish homing in wrong posiotion.

It happens when print finish and carriage go to parking position. After that, when I upload file to print homing Y axis will be like I said.

If before print Ill manually use homeall scrips it will go OK.Here is my homeall.g

0_1539634869422_homeall.gM400 ; make sure everything has stopped before we make changes

M913 X40 Y40 ; XY motors to 65% current

M915 H400 X Y S2 R0 F0 ; set X and Y to sensitivity 3, do nothing when stall, unfiltered

M574 X1 Y1 S3 ; set endstops to use motor stallG91 ; use relative positioning

G1 S2 Z10 F1200 ; lift ZG1 S1 X-300 F3000 ; move right/back 325mm, stopping at the endstop

G4 P500 ; wait 500msec

G1 X5 ; move away from home

G4 P500 ; wait 500msecM913 X40 Y40 ; XY motors to 65% current

M915 H400 X Y S2 R0 F0 ; set X and Y to sensitivity 3, do nothing when stall, unfiltered

M574 X1 Y1 S3 ; set endstops to use motor stallG91 ; use relative positioning

; lift Z

; make sure everything has stopped before we make changes

; X is homed at this point, now home the other axis

G1 S1 Y-300 F3000 ; move beyond axis minimum

G4 P500 ; wait 500msec

G1 Y5 ; move away from home;G1 Z5 F6000 S2 ; lift Z relative to current position

G1 S1 Z-255 F1800 ; move Z down until the endstop is triggered

G92 Z0 ; set Z position to axis minimum (you may want to adjust this)G1 Z-10 F1200 ; lower Z

M400 ; make sure everything has stopped

M913 X100 Y100 ; XY motors to 100% current

G90 ; back to absolute positioning

M574 X1 Y1 S1 ; define active low microswitchesSorry for the mess, Im new with Duet

cheers