Im running it with stock proximity sensors and it works perfect.

No issues what so ever once the connection setup was sorted out to get separate 5v 3,3 wont work. The 5v I took from the expansion slot and sensor signal commes from the normal XY sensor pins.

Its actually were easy once you understand how to do it… 5v is the key here.

Posts made by Loffy770

-

RE: Tevo black widow compatibilityposted in Duet Hardware and wiring

-

RE: Are you using a filament sensor with your duet?posted in General Discussion

I'm using a simple microswitch, similar to this: https://www.thingiverse.com/thing:2010235

With this in my config.g: [c]M581 E1 T1 S0 C1 ; Filament run-out sensor triggers a pause[/c]

And this in my start gcode: [c]M582 T1 ; check if filament is present[/c]So, if I would start a print without filament, it directly goes to pause. If the filament runs out during a print, it also pauses.

Simple and easy solution

-

RE: Are you using a filament sensor with your duet?posted in General Discussion

We are going ahead with the manufacture of a small batch of laser filament monitors for resale, and we are in discussions with a third party about further development of the rotating magnet sensor.

David Im up for a pre order of a few laser sensors if possible.

//Roger

-

RE: Are you using a filament sensor with your duet?posted in General Discussion

No one with a filament monitor setup?

-

Are you using a filament sensor with your duet?posted in General Discussion

Good morning!

I thought I ask here in the forum about peoples experience and solution to filament monitor because last night I ran out of filament on a long print and realise that its time to look in to a filament monitor..Please share your experience and the solution you implemented on your Duet.

Happy eastern

Roger -

RE: Backlash compensationposted in Tuning and tweaking

Why not use either anti-backlash nuts, or a finer pitch on the Z leadscrews so that the backlash is tiny, or a less fine pitch so that gravity does the work? Bed compensation already adds a lot of wear to the Z leadscrews, and doing backlash compensation will increase the wear further. Even better, use a flat bed.

I agree with you David to use better screws and anti backlash nuts. I did upgrade mine from supplied stock but as you understand it does cost a bit to do so. (About 200 USD) But its a bit off topic..

For me backlash comp are a valuable function to have regardless of my specific case here. And I understand your prioirities for more pressing needs. My question was simply to find out if it ever was implemented.

Regards

Roger -

RE: Backlash compensationposted in Tuning and tweaking

@vp:

..

All the mechanical "solutions" doesn´t work perfectly and have their own issues (e.g. more wear, less netto torque…).

On my 3D-printer i stopped using the auto mesh bed leveling, because even < 0.05 mm backlash is too much to make it better with auto bed mesh leveling than without. Loading the nuts so heavily, that there is no backlash, just wears them off unnecessarily (i don´t do that just for the 1st layer) ....

If hysteresis at least in z could be compensated, i would use auto bed leveling again.

People also could use cheaper hardware, because the software would compensate it, one reason more to buy a Duet - or not to buy it.At least for auto bed leveling we need it also in 3D printing.

I think this is what I need to do, turn of bed leveling as it will just amplify the problem of backlash when using screws without anti backlash nuts. This machine that Im working on is for my father, I got the same machine with one differance, mine has new screws with anti backlash nuts which works great in terms of the backlash.

On my dads machine the first layer gets screwed up and it drags the nose on spots when printing 0.10 mm first layer as it cant compensate for the uneven surface detected during bed leveling.

I have still one 10 station VMC but have had a another bunch of "professional" CNC machines and backlash comp is a must on those.

-

RE: Printer Running Very Slowposted in Firmware installation

I did tune my steps at the same time as I did the upgrade and did put my decimals in the wrong position.. maybe not what you did but if you tweaked your steps you might wanna doubble check that.

-

RE: Backlash compensationposted in Tuning and tweaking

Ok thanks for the reply.

Why its needed is because on a Z with dual screws one one belt with non anti backlash nuts you can have a hang and fall situation.Sitting in a Cartesian semi rigid Z carrage the scrws might not apply equal contact with both screws, one might be high and one might be low and if the play inte nuts are great it will cause a backlash no matter the gravity force.

Of course you use and dail in the screw contact with a dail indicator and adjust the pulleys, but a backlash compensation have more use than most realize especialy when you control very precise requirements.

Thanks for reading

Roger -

RE: Backlash compensationposted in Tuning and tweaking

Hi and thank you for the reply.

1: Yes it does

2: Nothing wrong with my DRO or scales, Been using them for years.Anyway, my question was about firmware support for backlash compensation and if I was implemented at some point from 1.18 that David mentioned to be on the list a year ago.

Just want to know if it made it to implemented.

Thanks for reading.

Roger -

Backlash compensationposted in Tuning and tweaking

Hi, I did hook up my lathe dro and a scale to test my Z lead screws. As it turns out a have a bit of backlash.. And yes the gravity should take care of it but it does not.

I did read a Comment from David that it was to come a backlash comp after 1.18, I cant find it so was it ever implemented?

Thanks for read

Roger -

RE: PT100 or Thermocouple Kposted in Duet Hardware and wiring

Thanks for the replies, seems like PT100 four wire is the prefered choice among you.

What would be the argument to run a Thermocouple K over a PT100, Im asking because Duet offers both and if PT100 if prefered whats the argument for Thermocouple K?I just what to learn the pros & cons…

-

PT100 or Thermocouple Kposted in Duet Hardware and wiring

Hi,

I have both set of PT100 and Thermocouple K on my desk ready for use.

I the past I tested the ThermoC K but due to the interference problems I had at the time of test I gave up on it.My setup runs all cables in a cable chain, all my cables are unshielded at this point.

Since I have both PT100 and ThermoC K at hand I like to give it a new shoot…

PT100 & ThermoC K daughterboards are the original boards for Duet.

PT100 & ThermoC K cartridge original E3D (wire)Questions;

Pros and cons PT100 vs Thermocouple K?

What does each solution require to perform as exspected?

Do I need to change to shielded wires on all my cables or only for sensors..

Can I run a 28awg shielded two led wire to the thermocouple K and have that on a short led and still get accurate readings?

Can I move out the daughterboard to the extruder and run normal wires between the main board and the daughterboard and thus avoid interference?Thanks for reading

Roger -

RE: PT100 - 3 or 4 wire?posted in Duet Hardware and wiring

David, I have interest in this too as I did in the past try the PT100 with my Duet but due to the spiking to 2000 degree I went back to a termistor. My PT100 and board came with my Duet from you guys so its know parts.

So if I understand you correct I could use the same PT100 cartridge if I basically solder on two leads on the original leads? And the join again at the PT100 board..? 2 to 4 to 2 again..

Should I run the four leads from close to the extruder, through the cable chain all the way up to the board to avoid interference from the cables in the chain?

Can I use a regular awg28 flat ribbon leads to add the extra two leads or do I need a specific cable like the original PT100 cable?

Just trying to understand what it takes to get the PT100 to work correctly.

-

RE: Wiring for a PWM Noctua.posted in Duet Hardware and wiring

Thank you David, I appriciate the support

-

RE: Wiring for a PWM Noctua.posted in Duet Hardware and wiring

Thank you David

Regarding the RPM if you could look for it I like to try it out… Its a very cool feature even if the use is somewhat limited.

Common ground, I guess it means that I cant run the ground through the step down converter or does that counts as common ground? Just thinking that the step down does something to it...

-

RE: Wiring for a PWM Noctua.posted in Duet Hardware and wiring

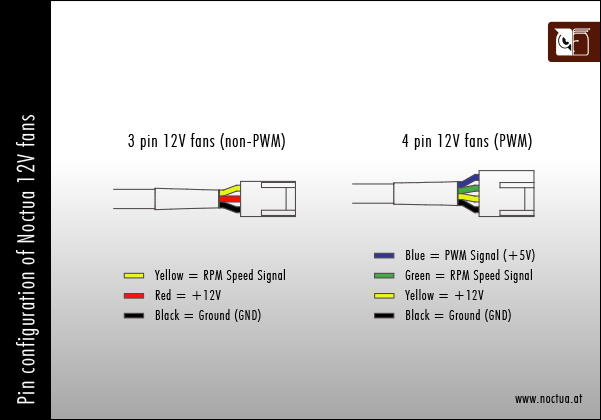

I also have a step down converter that I can use assuming that I need to take power from 24v in via step down to 12v. So plus and minus to stepdown from main 24v. 12v plus and minus from stepdown to fans. So where does the signal cables go is I like to have speed control… ? I hope the image below display correctly.. Its the official Noctua pinout.

-

Wiring for a PWM Noctua.posted in Duet Hardware and wiring

Hi,

I need to connect a few new fans to my Duet.

1: Noctua NF-S12A (PWM fan) four wire

2: Nuctua NF-A6x25 (not PWM) three wireIt would be great if someone could point me to how I connect these as the board has only two pin connectors…

Anyway I thought I ask first for a change? -

RE: Add MCU temp in DWCposted in Duet Web Control wishlist

Nope that does not work, that only ads it to the chart. I want it to be displayed to the table left of the chart.

-

Add MCU temp in DWCposted in Duet Web Control wishlist

Hi,

I added the MCU temp in DWC and now I would like it to be shown under the bed and hot end temp. As of now I can only see it separately from bed and hot end.

How can I get all 3 to be shown at the same time?