Installed 2.02 today. Download and install of .zip was insanely easy. No issues here on a kossel mini with smarteffector. Homing et.al. worked as expected.

Thanks again for your hard work @dc42

Installed 2.02 today. Download and install of .zip was insanely easy. No issues here on a kossel mini with smarteffector. Homing et.al. worked as expected.

Thanks again for your hard work @dc42

Not used here and works well without. Printer sits next to my computer and I can also connect on mobile device like tablet or phone if required.

@deckingman @Phaedrux Thank you both for reply and insights. I will have to tinker around a bit with your input. I am considering also a zesty-nimble for the smarteffector. I see it mentioned on the forum and it has its own adapter published on thingiverse, but am a bit conserned if calibration will work well for it.

@jpwheless To run script, would I just copy it into new textfile, rename as .gcode and run? Would this work  I realise post is a while ago and also wondered if you have considered change to script since in regards to the latest updates?

I realise post is a while ago and also wondered if you have considered change to script since in regards to the latest updates?

Thanks for quick reply @dc42 . I was aware of ground loops and have been connecting to the Duet with laptop powered by battery alone which was suggested a safe option. I also think the new doku is very very good, so thank you very much for this

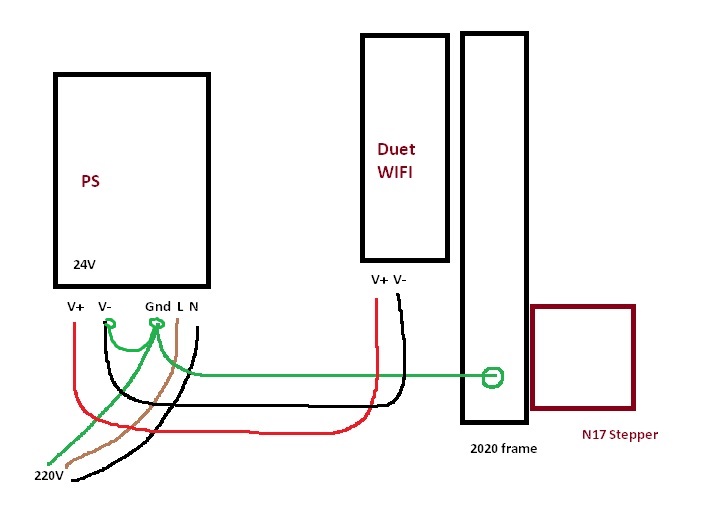

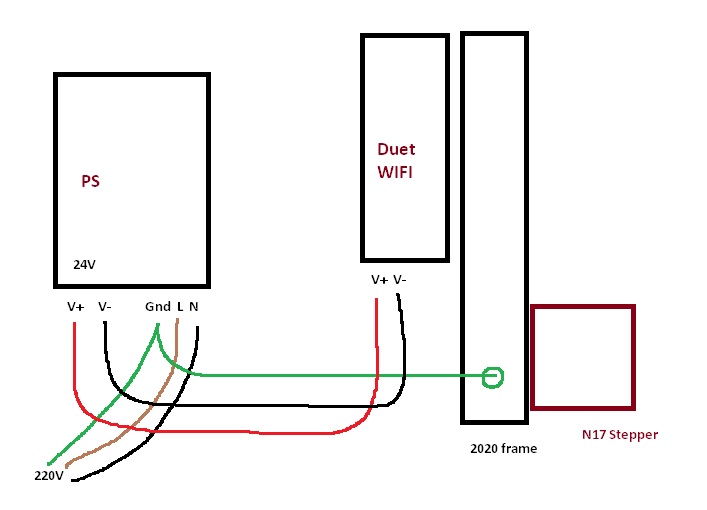

I updated the drawing as suggested and will wire up the rest of printer again shortly. I have also updated my steppers to 0.9 17HM19-2004S as suggested earlier in your blogpost. Practically my kossel mini came together by reading your blog, so thank you so much again

Hi all,

I have have been having random head-crashes of my kossel mini between 2 - 4 hours into prints. I have been able to isolate it to one stepper motor that has now eventually failed, but was reading up in the doku when I came across paragraph to ground stepper :

"Note: it is highly recommended that the stepper motor casings be grounded, especially in belt-driven printers. Otherwise, motion of the belts causes static charge to build up, which eventually arcs over to the windings. If the motors are screwed to a metal frame, grounding the frame is sufficient."

There was anorther post on here to suggest to do it by attaching ground to frame which in turn is attached to the stepper through metal vertex of the kossel. My question is if I can ground it to mains ground as seen in quick illustration as attached.

Thank you all for great suggestions. Sorry for late reply, but was on short holiday  I will give it a try later on today. I use S3D, but was wondering if there a way to adjust the settings "live" while printing?

I will give it a try later on today. I use S3D, but was wondering if there a way to adjust the settings "live" while printing?

Hi all,

I have been quite happy running my duet wifi on my homebuild kossel mini for a few months now (just casually running it during weekends here and there, so no pro by all means)

I am perhaps running a few fw versions behind at:

Firmware Name: RepRapFirmware for Duet WiFi

Firmware Electronics: Duet WiFi 1.0

Firmware Version: 1.20beta8+1 (2017-11-18)

WiFi Server Version: 1.20b9

Web Interface Version: 1.19.3

Generally I am very happy with dimentional accuracy of my print for practical stuff, but I have been having start/end blob issues to my moves and I have started to experiment with pressure advance settings as I would like to print a few more aestetic figures and not just my current mounting brackets and hooks

However, I am not having much luck with my current troubleshooting, so I thought I would post my settings here for you to critique if anyone have the time to look through.

Some background, .. Firstly, my printer is a mini kossel with a capricorn bowden. I have a e3d v6 hotend and a duetwifi + smarteffector setup (calibrating to 0.007 which I am quite happy ). I am on 24V.

From config (sorry about my obvious comments, but I am quite new to this..)

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X100 Y100 Z100 E815 ; Set steps per mm (Extruder steps mm) 837 corrected from wiki > 815 (5.02.2018)

;For 256microstepp from 100 -> 1600

M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X1300 Y1300 Z1300 E900 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

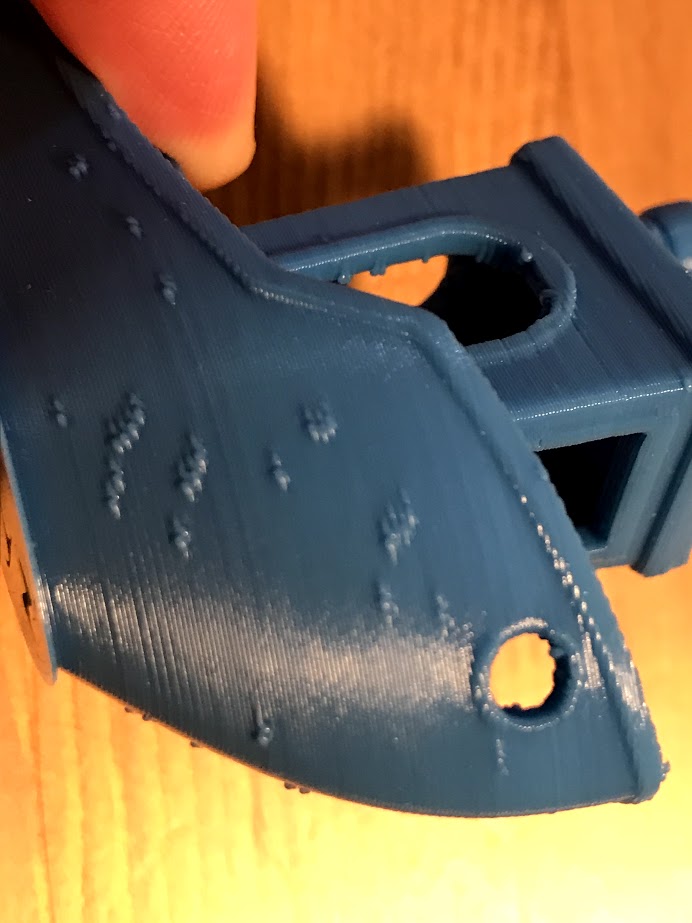

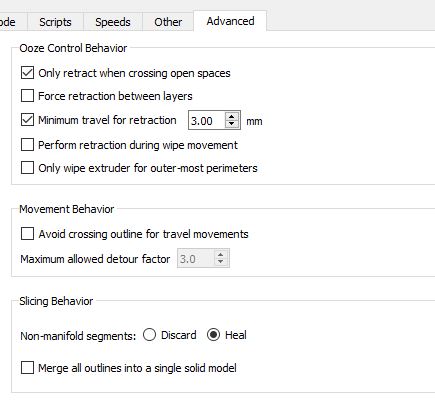

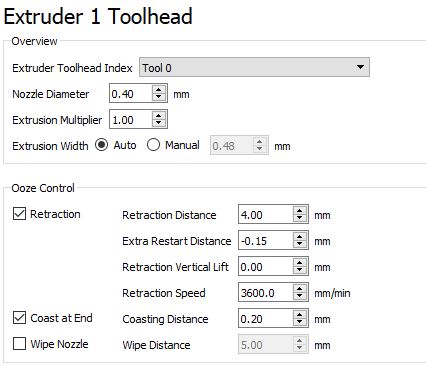

I am uploading a couple of pictures for reference.

The blobs come at both start and end of move. For the benchy they are at the same spots for the different settings I have tried for the pressure advance:

M572 D0 S0.05 and up, but when I go over 0.2 my extruder seems to start grinding away at my filament. I did not try lower.

I used S3D and have following settings:

and

and

Clearly the devil is in the relationship between my retraction, speed and jerk, however... after a good while of blind guessing and reading through posts, I am still not getting it right. Simply I am not "getting" it

I am sure some of you could instantly spot my err and I would be very grateful to any pointers to further try out.

On a more positive sidenote:

I had a small session about 3d printing and coding to 50 young boys in a school here in Dublin today. It is very cool to see them inspired by this technology and the kossel makes for a very interesting object to watch as it makes wonderful movements. Next month I will be showing the minikossel on a stand at Dublin Maker 2018, so if anyone is in town, do hook up for a light chat and a Guinness

Here is a picture of it in action, but only showing without the kids  So much fun.

So much fun.

Pps: New forum looks/works great!

We are taking to E3D about a lightweight version of the Aero that would be suitable for a delta printer with a smart effector. It's likely to take some time though.

Sign me up on waiting list

Thank you Justine for superquick answer and checkpoints… I took extruder apart again, reassembled it flush and doublechecked it all while testing it with a bit of load.. works as butter again

Thank you Justine for superquick answer and checkpoints… I took extruder apart again, reassembled it flush and doublechecked it all while testing it with a bit of load.. works as butter again

I have been thinking of moving my titan extruder when I noticed the mount had a crack. I took it off and fixed it with superglue and put it back together. While getting it ready to print spare part, I noticed that the wheel of the extruder got stuck and so I dismounted and adjusted it and put it back together. After testing it, the wheel was free to move and I started up to print again. It seems to be extruding well, but in some parts of printing I now get vibration type sounds from the stepper(possibly skipping). It seems to not hold much power when I put my finger to the wheel and will stop easily, however will rotate as needed if I just help a little.

The extruder is of pancake type and I am running 24v on my kossel. I wonder if I 1. have ruined the driver on the duet-wifi by accidently plugging it in while on… not sure if I did this by accident, 2. do not have enough current on the motor, or the motor itself perhaps is perhaps damaged.. What are my options and how should I be testing further to check? Extruder is currently on 1A, but when checking google some people use much more current on the same pancake motor.

My setup worked just great before this, so appreciate any assist I can get. Currently the file is printing, but seems to be underextruding as motor skips and so I will not be using print. From checking now on the print itself, extrusion per layer is very variable and very ugly...

Hi Vlad,

I can only share from my experience. From setup, I went to this site, clicked on Documentation and searched for wifi. First link provides step by step for what firmware is needed which was not difficult for me. I understand the board to be rather good, perhaps expensive for some, however there is no language barrier to asking questions on forum when I got stuck, which was with operations of the printer, not the setup/firmware part. Perhaps it is just my logic that is in harmony with what is being provided. Again, please provide links to products and documentation that you felt was excellent and point out the features you liked. Perhaps this can improve and help for next users of similar background to yourself. I would like to help out.

Hi Vlad, I have a very non-technical artist-background speaking as an illustrator. For me, I found it quite easy to set up with a delta printer of own built. Provided, I did take good time to read through the documentation a couple of times as this was my first 3d printer project.

I can understand how different people have background and experience that change perception of what is expected from the documentation in order to set these things up, so to this point Vlad, perhaps you can share some constructive feedback of how you expect the documentation to read. How could it be more helpful to you? Would it be better with more visual input or videos showing setup? For instance, I noticed the newer setup by E3D to document their hotends with schematics and a step by step pictures/videos which I thought was pretty good. Provide some links to what you like and try to explain why you like them.

For my part, people here have been friendly and helpful when asking for help. With a bit of effort and constructive feedback I am sure it can only become better.

L

I finally decided on a 24v silicon 300w heater from ebay > http://www.ebay.ie/itm/3D-Printer-Round-Silicone-Heated-Bed-12v-24v-heat-plates-Dia-180mm-260mm-/192070208772?var=&hash=item728ace1000

My 24 PSU from E3D should hopefully be able to power it with the duet wifi and steppers.

In order to complete it, I will need to find supplier for the aluminium and glass plate before I can hook it up on my 2020 mini kossel type 3d printer.

Do anyone have any tips for setting it up in terms of config files etc. I will be using S3D to generate Gcode, but as you can probably tell I am all new to this

Hm, its gone and also with the sticky posts… seems several of Calvinx posts are deleted which is a shame - so good

Hi all,

@CaLviNx Be nice  ..and super thanks for link, I understand the smart-effector to be a very new product and I have not seen much else out there like this. If all my customers read all links available for product, I would be out of a job, by the way. Often for new people like me there is so much information that it is super easy to be confused in lingo and all possible configurations.. hence wonderful to be able to go to a great forum like this and ask to get pointers in right direction, but also to get in touch with friendly community.

..and super thanks for link, I understand the smart-effector to be a very new product and I have not seen much else out there like this. If all my customers read all links available for product, I would be out of a job, by the way. Often for new people like me there is so much information that it is super easy to be confused in lingo and all possible configurations.. hence wonderful to be able to go to a great forum like this and ask to get pointers in right direction, but also to get in touch with friendly community.

I warn you in advance Calvinx, I will have many "stupid" questions for you, heh  Cheers

Cheers

Thanks number40fan and DjDemonD for help  I will look into it and update with results later.

I will look into it and update with results later.

Thanks DjDemonD, I found this link and wonder if it would be suitable for Kossel Mini size, 200mm was smallest diameter I could find for the Keenovo - https://www.aliexpress.com/item/Dia-200mm-300W-220V-w-3M-PSA-NTC-100K-Thermistor-Keenovo-Round-Silicone-Heater-Pad-Delta/32575792674.html?spm=2114.search0302.4.84.yuPMrs In addition I would need a SSR to controll it, any suggestions (again for UK/Ireland/Eu type availability?).

If I understand this correctly, the kapton heaters might not be so safe, but for 24V and a small heater, just starting out perhaps it is good enough? In which case should I try to find heater for Anycubic kossel mini perhaps, or what is my best bet?  Again, thank you for help

Again, thank you for help

Hi first post here,

I will be in same position as you but am looking for a 24V bed for a mini-kossel type with 2020 frame. Basically have no idea of what I am doing and learningcurve is steep

I am wondering what is a good established source to order from in europe as I am located in Dublin, Ireland

Leif