@droftarts Thanks very much!

Posts made by kungpaoshizi

-

Repairs for out of warranty items?posted in Order discussion

Is there any repair service available? I assume we'll have to pay shipping, labor, cost of parts, but very much would love to have things repaired.

I've yet to pull the machine apart but getting ready to soon as I can't imagine life without it!Thanks very much!

-

RE: Pinpointing heater faultposted in General Discussion

@infiniteloop Thanks for the input! Again it's been operating forever just fine, well passed useful dates most likely, so the probability of the board finally giving out under such heavy use over the years is way more likely than the 2 wires breaking at the same time, or 2 separate crimps at the same time, etc.

Any other suggestions from others?

Hoping dc responds with a magic diag code... Though I'm afraid the graph spells it out

Replacing the psu would be so much easier.. -

RE: Pinpointing heater faultposted in General Discussion

@infiniteloop Actually you did just reinforce it's the board. The bed heater didn't show that hiccup and it's directly connected via offload relay to the psu.

The 2nd heater wasn't on, but clearly has some sort of hiccup of the relay.Again, you're trying to tell me that 2 different wires, have an issue all of a sudden at the same time, while all of the other 10-20 wires bundled with it don't have an issue, and I've taken great care to prevent long-term movement-breakage of these wires.

You realize the probability of that? It's not very realistic.

I'll have to tear it apart, but I'm afraid it's seen it's day

-

RE: Pinpointing heater faultposted in General Discussion

@jens55 I grouped all my wiring together, it's all tacked down, then leading to the carriage I used a multi-rubber band overhead crane setup, to guide the wiring taking great care to eliminate any sharp angles.

I've worked with pc's too long lol

But to have both fail around the same time, could be parts failing, but I haven't used extruder 1 for 80% of the time the machine has been up. So everything on that side should be pretty fresh on the MTBF timeline.

@dc42 is there a repair service if I pinpoint it to the board? It's a meanwell psu, which I may have taxed at the high end running a lot of prints at 120/245, but it's not out of the realm of possibility. My other psu is a generic 350 which wouldn't push that I don't think. Trying to recall what my upgraded bed wattage was, which indeed doesn't route through the board, I'll have to collect all the details.

Still hoping you might have a wonderful gcode tidbit that will give me some sort of 'power range from psu vs power range from individual outputs'.. -

RE: Pinpointing heater faultposted in General Discussion

@jens55 Two different sensors have faulty wiring at the same time?

I guess it's possible something could be pinched, I'll have to check it out.@dc42 Is there any diagnostic you can think of that might aid in this scenario? Since it's gone down I have felt an emptiness inside I've not felt in years!

-

RE: Pinpointing heater faultposted in General Discussion

@jens55 Right, you would think the heater would just cut out or runaway.

Though like I said, it's 2 thermistors, both all of a sudden started doing this on both of my extruders. With both firmware all the way back in the 1 versions up to the new 3's.

It was operating perfect for the last idk, 5 years?

So I'm afraid it's the board or psu. Both out of warranty too

Both the psu and the board never go above 36-38c as I have fans dedicated to each... -

RE: Pinpointing heater faultposted in General Discussion

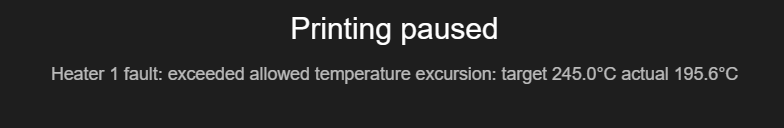

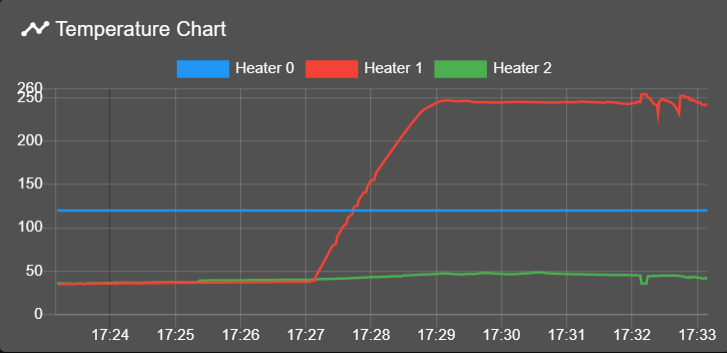

@dc42 Well now it successfully heated... I'll try a few more prints, iirc it was 'can't heat up to this temp'.. You can see the wobble in the graph

Otherwise it's not the firmware, I started having this issue on 1.21 or whatever it was. Was hoping it was a bug so new firmware looked promising...

Seems after going down that path it's still presenting randomly. This is after a pid tune as well. I've got an enclosure with all fans off, so it's not some random wind.

I'll follow up later, thanks so much DC42! Been awhile since I've been on the site I hope all is well!! -

Pinpointing heater faultposted in General Discussion

Just wondering, I'm on latest firmware now, hoping there's some sort of diagnostics for heater relay funcitonality or the psu power levels?

I was operating on extruder2, heater faults cropped up, changed thermistors from extruder1 to extruder2, then still got heater faults.

Wiring from board to psu is all mounted and screwed down.Any input would be appreciated, I'm thinking it's either the board or the psu, I've already changed out the surge protector, I could try another outlet I guess in case it's a power dip on the outlet, but otherwise in thinking about the psu/board, really hoping there's some diags to pinpoint this

-

RE: Duet 2 upgrade from RRF 1.21posted in Firmware installation

@Phaedrux Hey there, just found this post as I too have been operating on 1.21 for a bit longer than I would like to admit!

I'm trying to get up to speed and reading what I can, but is it necessary for Duet 2's to upgrade to firmware 3? Or does 3 focus more on the Duet 3?

Thanks very much!!! -

M584 command when Z is in series?posted in General Discussion

Perhaps I'm misunderstanding this, and I think I might have a guess why, but what would the following Z parameters be for these two ports in a M584?

M584 X0 Y1 ZZA:ZB? -

Way to change result message from Dual Z sync?posted in Tuning and tweaking

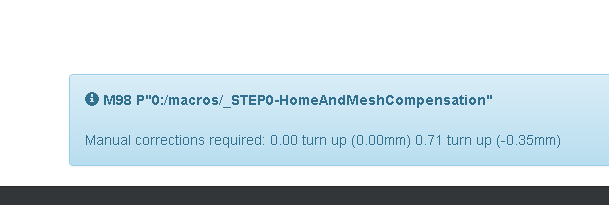

So for the life of me every time I look at this, I can never remember which is which at a glance. Is there a place to change the verbiage on this?

Also, in the pic, the left side is always 0. But if the right side is .71 higher, shouldn't the adjustment be closer to .71 vs half of the figure(.35) as the left side is near-solid as it's screwed in? It's not like we're adjusting a floating plane which reacts on both sides to the degree if center was 0 and each side was + or - ? (if center was 0 then yes, you would adjust down on the right .35 and up on the left .35, if the difference between the 2 is .71, at least iirc, been forever since school )But yes, I would love to change the verbiage. I think it's always the turn up (positive movement) a negative number.

-

RE: Installing BLTouch V2 on Duet WiFiposted in General Discussion

@brian_k Looks good, though I would warn you, if all lights don't come on right away and it seems that 12v lights up but 3.3 and 5 are off or dim, turn it off right away. I would switch the expansion port connectors to a 8 pin for better stability on the pins.

-

RE: Crimping tool?posted in Duet Hardware and wiring

Raise your hand if it took you half a day because you took great care in every single connector as you did it by hand.

-

Leveling vs mbcposted in General Discussion

If the bed is fairly flat, but stationary, is there limitations to mesh bed compensation? Or can one just go with it and never have to level the bed again?

-

RE: Best bed levelling system?posted in General Discussion

@mrehorstdmd nice, i guess ive been brainwashed by the cheap printers these days

-

RE: Best bed levelling system?posted in General Discussion

@deckingman said in Best bed levelling system?:

@claustro said in Best bed levelling system?:

.................. I am afraid about aluminum bed for 3 reasons cost, availability and thermal reaction.................

Aluminium tooling plate is the best solution because the bed needs to be flat, and it needs to be stiff enough, and it needs to have good thermal conductivity. This question gets raised with monotonous regularity.

Aluminum doesnt remain flat though. Glass is preferable.