@dc42

Sorry to hijack this thread, but I don't want to create a new one for this.

I've heard somewhere in the wiki that the filament sensor needs to be on the same board than the extruder it's watching to.

Is it still the case with 3.3+?

I'm about to switch to Duet 3 with 1LC toolboard, my filament sensor is outside the carriage, on the main board.

Posts made by KipK

-

RE: Filament sensorposted in Filament Monitor

-

RE: PanelDue Firmware 3.3.0-rc2 releasedposted in PanelDue

@owend I was about to post the same issue. Happened yesterday, after a filament runout pause, the panel due was locked on screen saver. Couldn't wake it.

-

RE: Need help for few missing translation in fr, es and csposted in PanelDue

@mfs12

For french:Standby : En attente

Initializing: Initialisation -

RE: "waves" on rounded printsposted in General Discussion

I got this issue this week. Printer was like moving/extruding in wavy pattern around circles with unusual noise.

It was my extruder jerk/acc that was way too high.

Lowering it from 1000 to 300 srk and 2000 to 600 acc solved theproblem ( Orbiter ) -

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

That's what I use here, bondtech hobbed gear.

So after using the calibration factor + few change on the indirect casing, I now have this reported values :

measured min 93% avg 101% max 107% over 12365.3mm

Looks far better than what I ever achieved with direct reading.

I still have some false trigger because of the PTFE tube moving too fast with high acceleration, I will restrain it before the filament reader. -

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

@dc42 ho that's just perfect then.

-

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

I'm waking up this topic, ( deleted mine also ).

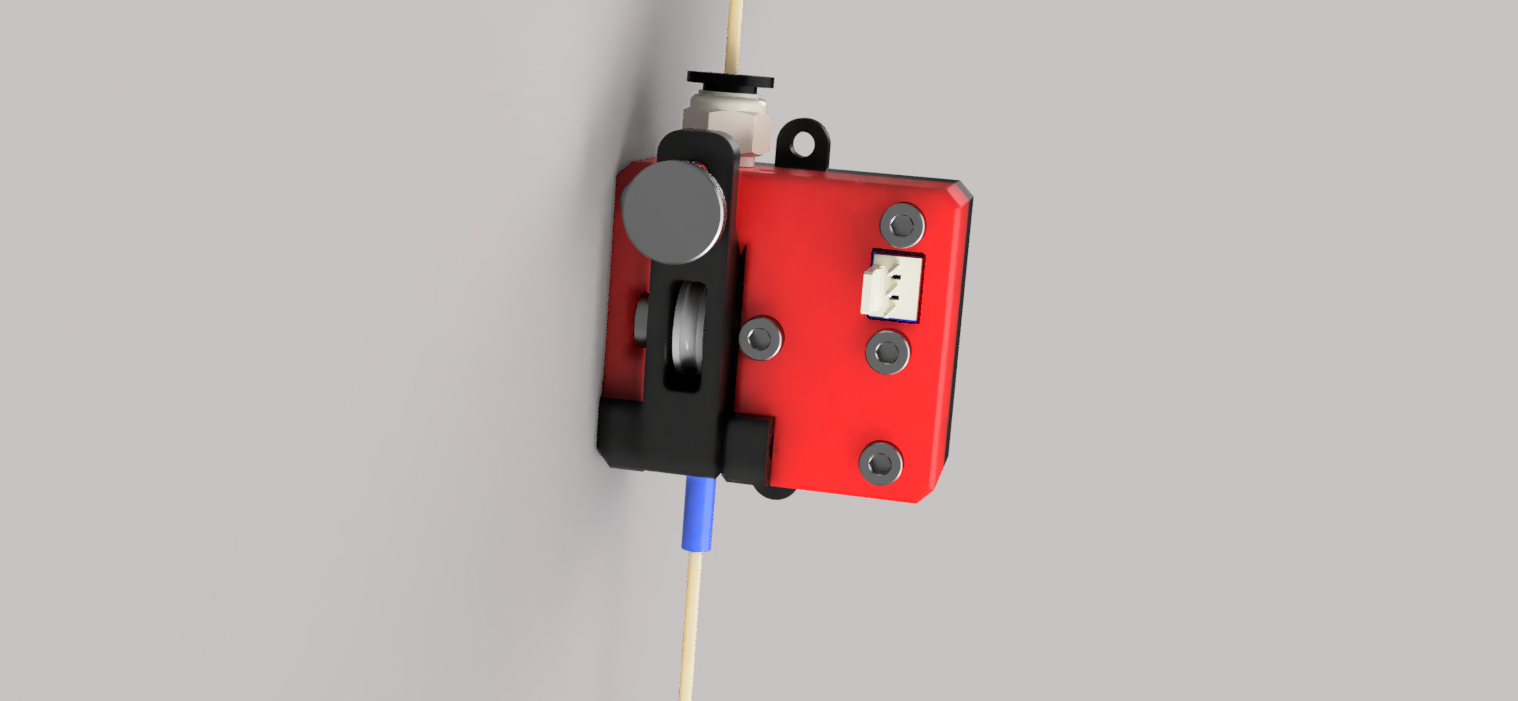

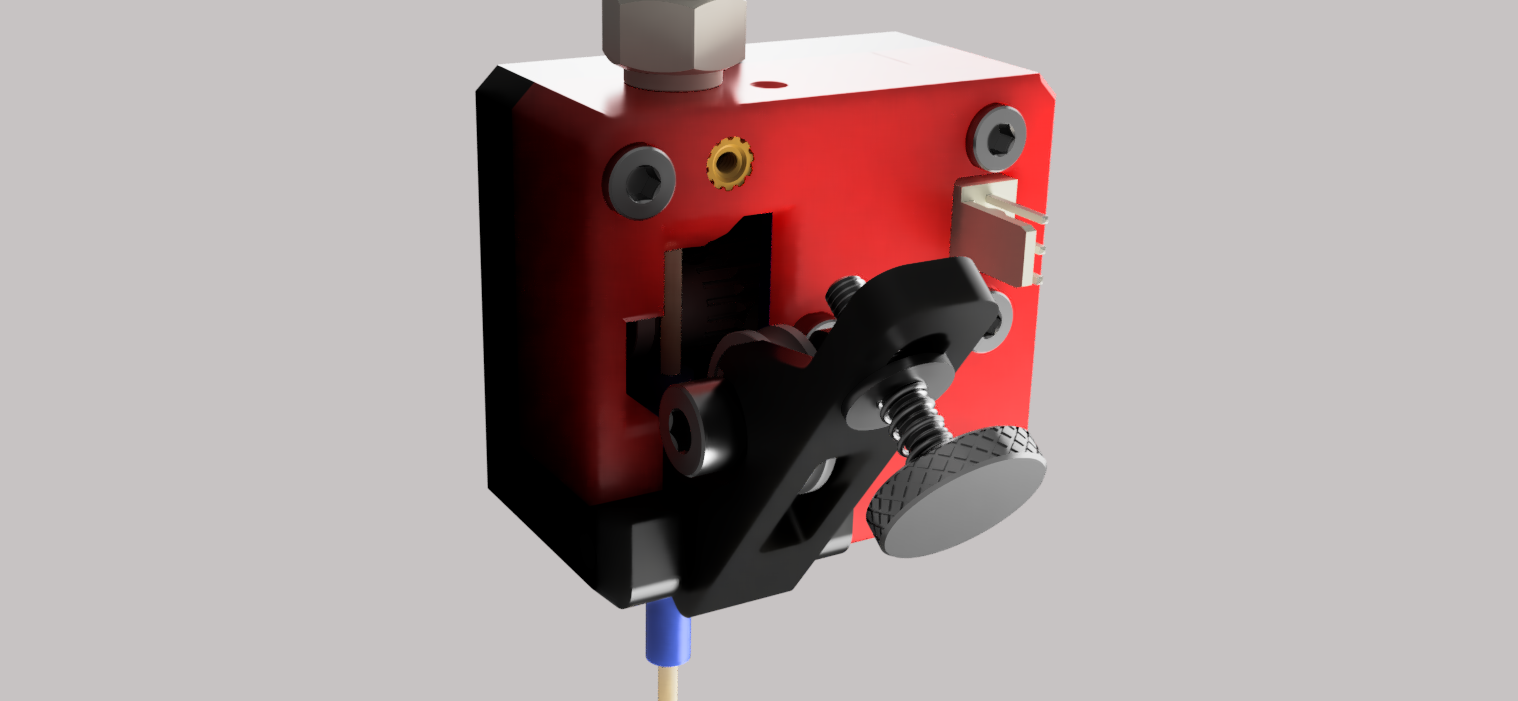

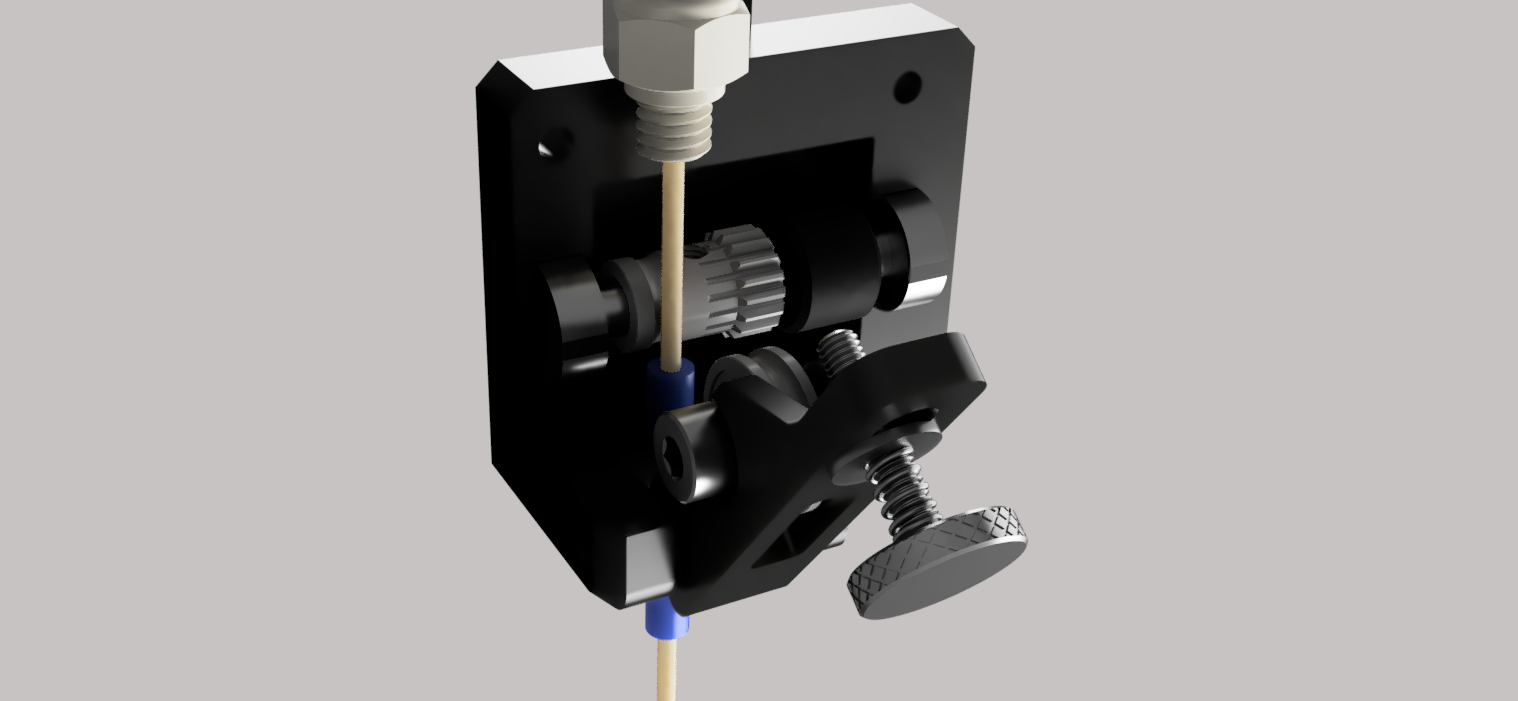

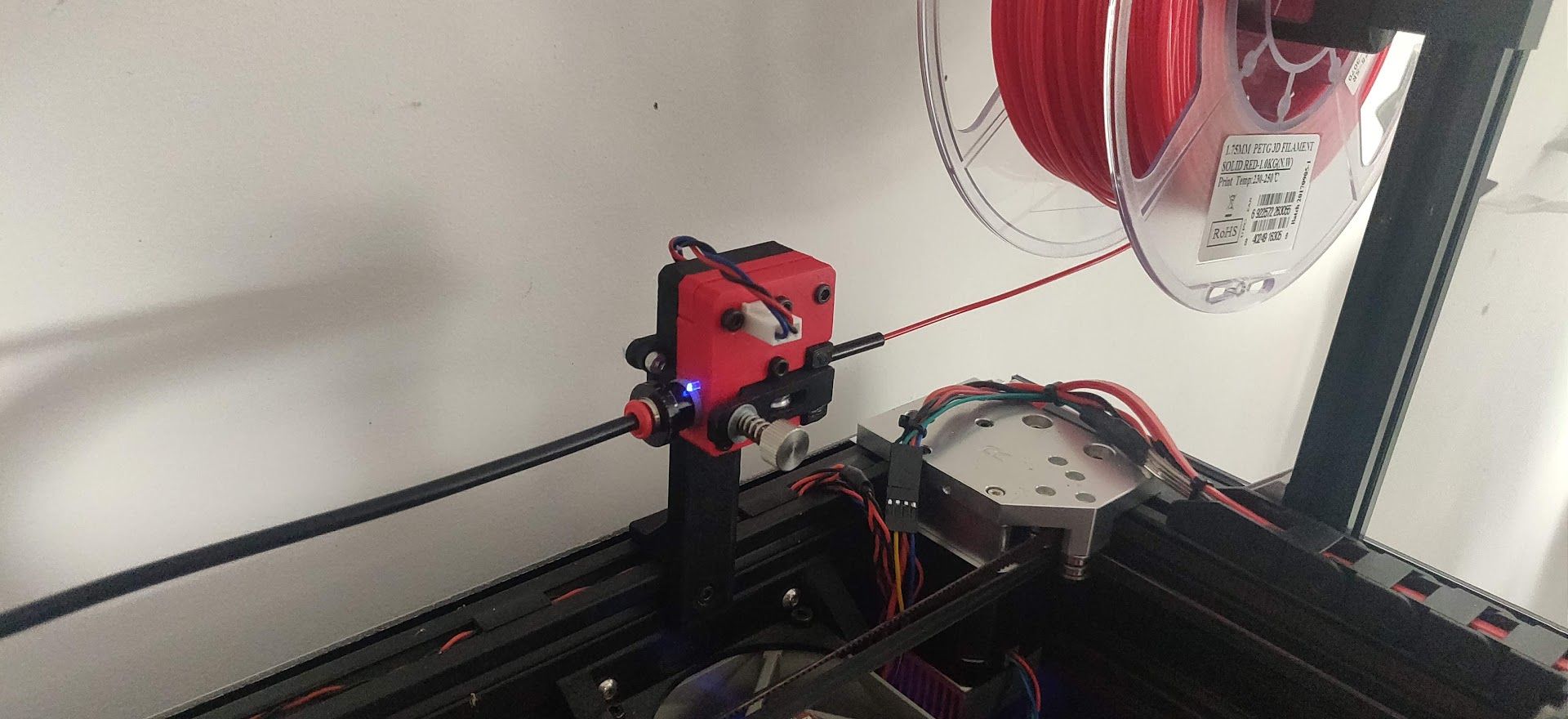

Here is my version of indirect filament reading, inspired by your ideas here.

It uses an 5mm shaft hobbed gear from Bondtech and U shape bearing on the latch.

Tensionning can be adjusted from the latch.I use it outside of my DD carriage, don't have any problem with retractions ( considering I have 0.6mm retracts this prollyt explains why ).

https://www.thingiverse.com/thing:4882602

I get readings from 188% to 266% , average 230%. Is it acceptable or should I try to read around the 100% ? I think I can tweak it by adjusting the printed wheel diameter.

-

RE: Live changing Z probe parameters without deleting pinposted in Tuning and tweaking

@dc42 said in Live changing Z probe parameters without deleting pin:

ut P or C parameters to change dive height, probing speed, travel speed etc. of the existing configured probe.

Thanks. Wondering why I haven't tried that

-

Live changing Z probe parameters without deleting pinposted in Tuning and tweaking

Hi

I'd like to change my dive height once my 3 point auto bed leveling as been done. By security, I keep the dive height to 15mm in case the bed is tilted before auto level.

Then I'd like after leveling to change the probe dive heightbut I can't call M558 without freeing the zprobe pin first.

Is there an easy way to achieve this ? -

RE: Announcement: Duet 3 Toolboard revision v1.1posted in Duet Hardware and wiring

So I need a Toolboard to finish a current build now. Which reseller in EU is supposed to receive 1.1 stock shortly?

-

RE: Sticking magnetic surface to Borosilicate glass?posted in 3D Printing General Chat

I use some thermal pads under the glass when I need it. It sticks well to the magnetic surface.

-

RE: RepRapFirmware 3.2beta4.1 now availableposted in Beta Firmware

Got a problem updating to latest beta.

After upgrade printer doesn't connect to wifi anymore.When doing M587 I get an error saying another SPI transfer is pending.

Tryed rebooting but it's still stuck, any tip ?

Thanks

Edit: I solved it by manually flashing again the wifi module. Wondering what did happened

-

RE: Paneldue , erase firmware from softwareposted in PanelDue

@wilriker

thanks for this, will get the panel unmounting thing of the past

thanks for this, will get the panel unmounting thing of the past -

Paneldue , erase firmware from softwareposted in PanelDue

Hi.

I'd like to ease up my paneldue upgrade process. It's mounted in such a way that accessing the usb ports and buttons need a pain disassembly of my printer front panel.

I have an extension connector of the paneldue serial port, I'd like to flash the paneldue from uart instead of usb

However, I still need to push the erase button that is not accessible.Is there not a software way of erasing the firmware from a serial command?

-

RE: PanelDue Upgrade Firmware 3.2-RC3 Screen distortionposted in Duet Hardware and wiring

Have you not got makerbase paneldue 7?

If yes, it needs paneldue5 firmware instead of 7. -

RE: PanelDueFirmware 3.2-RC2 releasedposted in PanelDue

@wilriker , sure

I only have one extruder.

I was about to get 97%. Then got back in the web panel and saw it was still 100%.

Than saw the error in panel console.

I could eproduce it at each try then.I'll investigate further.

here is config.g

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"BLV MGN cube" ; set printer name M669 K1 ; select CoreXY mode M575 P1 B57600 S0 ; set serial port fur paneldue ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S1 ; enable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P4 S0 ; physical drive 2 goes backward M569 P6 S1 ; physical drive 3 goes forward M569 P7 S1 M569 P8 S1 ;M584 X1 Y0 Z6:8:7 E4; three Z motors connected to driver outputs 6, 8, 7 M584 X1 Y0 Z6:7:8 U7 V8 P3 E4; three Z motors connected to driver outputs 6, 8, 7 M350 X16 Y16 Z16 U16 V16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z1600.00 U1600 V1600 E416.62 ; set steps per mm M566 X600.00 Y600.00 Z50.00 U50 V50 E2000.00 ; set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y15000.00 Z400.00 U400 V400 E3600.00 ; set maximum speeds (mm/min) M201 X1200.00 Y1200.00 Z200.00 U200 V200 E2000.00 ; set accelerations (mm/s^2) M906 X1500 Y1500 Z1200 U1200 V1200 E700 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-173 Y-157 Z0 U0 V0 S1 ; set axis minima M208 X173 Y174 Z343.88 U343.88 V343.88 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop ;M574 Z2 S1 P"duex.e2stop+duex.e6stop+duex.e5stop" ; configure active-low endstop for high end on Z via pin zstop M574 Z2 S1 P"duex.e2stop"; set endstops for Z M574 U2 S1 P"duex.e6stop"; set endstops for U M574 V2 S1 P"duex.e5stop"; set endstops for V ; Z-Probe M558 P9 C"^zprobe.in" H15 F200 T25000 R0.4 A4 S0.03 B1 ; set Z probe type to bltouch and the dive height + speeds M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch G31 P25 X36.47 Y-4 Z1.95 ; set Z probe trigger value, offset and trigger height M557 X-135:135 Y-135:135 P5:5 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S130 ; set temperature limit for heater 0 to 130C ;M308 S1 P"e1temp" Y"thermistor" T4606017 B5848 C5.548428e-8 H0 L0 ; configure sensor 1 as thermistor on pin e0temp M308 S1 P"spi.cs1" Y"rtd-max31865" R380 ; create sensor number 1 as a PT100 sensor in the first position on the Duet 2 daughter board connector M950 H1 C"e1heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 0 to 130C ; Fans M950 F0 C"fan1" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"duex.fan5" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 H1 T45 S1 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"duex.fan7" Q500 M106 P2 S115 H-1 M950 F3 C"duex.fan6" Q500 M106 P3 S115 H-1 ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Leadscrews M671 X-214:214:214 Y0:118:-121 S20 ; leadscrews at middle left, front right, and rear right ; Miscellaneous T0 ; select first tool M81 ; trick to enable ATX button on web interface ;M572 D0 S0.035 ; enable pressure advance ( ABS ) M572 D0 S0.028 ; enable pressure advance ( PLA ) M593 F27.84 ; dynamic acceleration ( cancel ringing at 53.33hz) M911 S21.0 R23.0 P"M913 X0 Y0 G91 M83 G1 Z5 E-1 F1000" ; pause print when power fail M80 ; power on 24v M376 H10 ; tapper mesh bed leveling to 10mm M950 J2 C"!^duex.e3stop"; ; set e3stop trigger M581 P2 T2 S1 C0 ; trigger T2 when duex.e3stop is rising M501 ; load saved parameters from non-volatile memory