@phaedrux

Thank you for your help!

The start.g attached to my first post is from a friend of mine. He owns the same printer. It is working for him. When I apply the following start.g (the "official" from caribou3d) the first layer is the same:

start.g

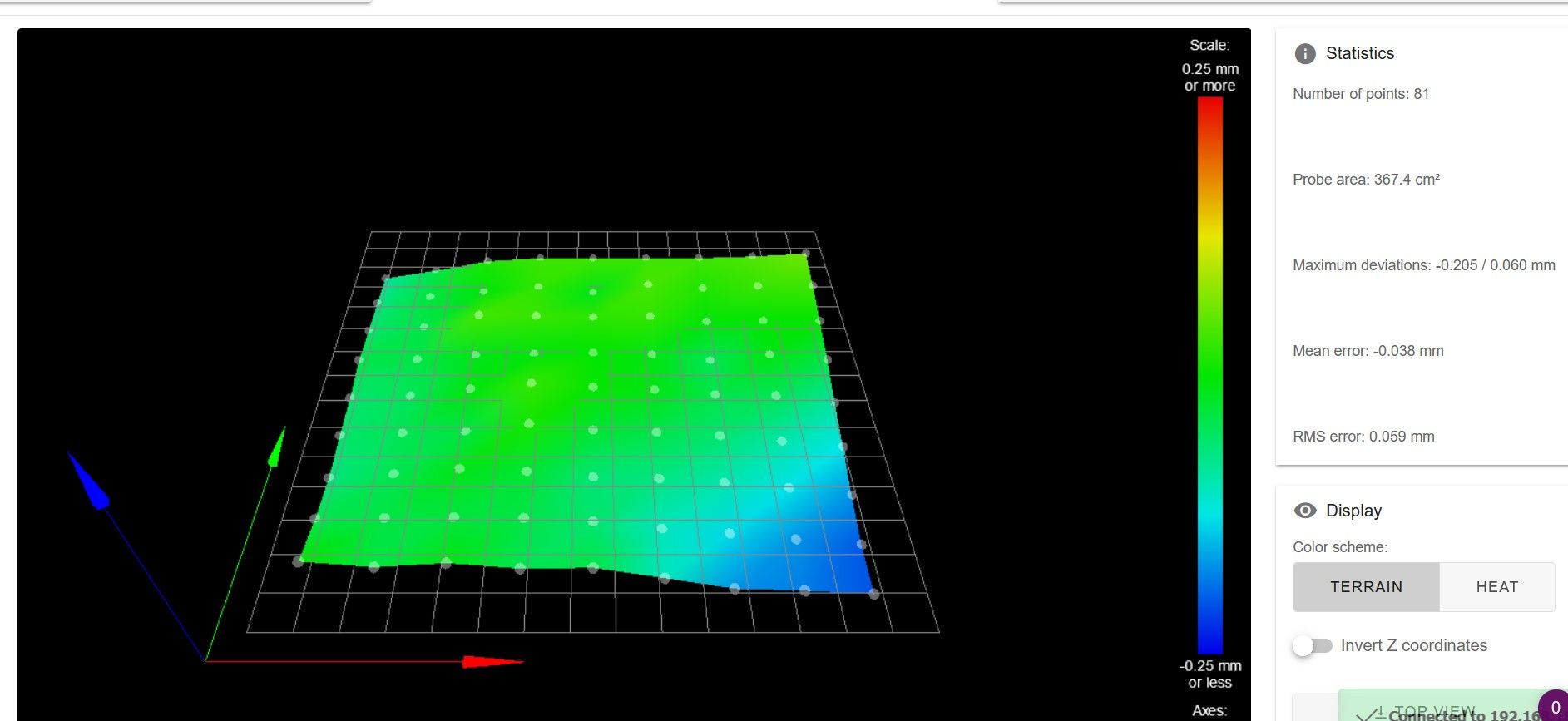

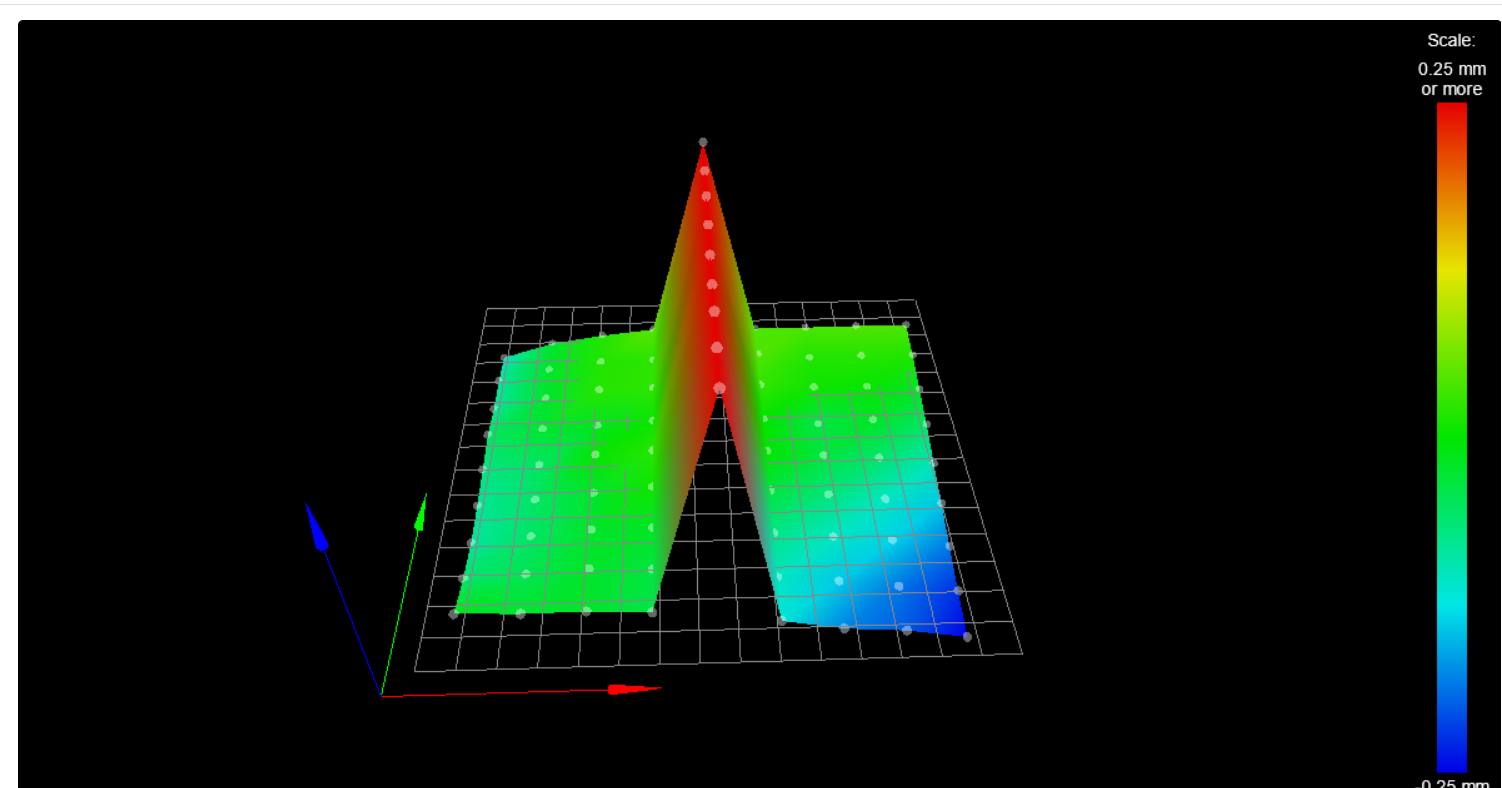

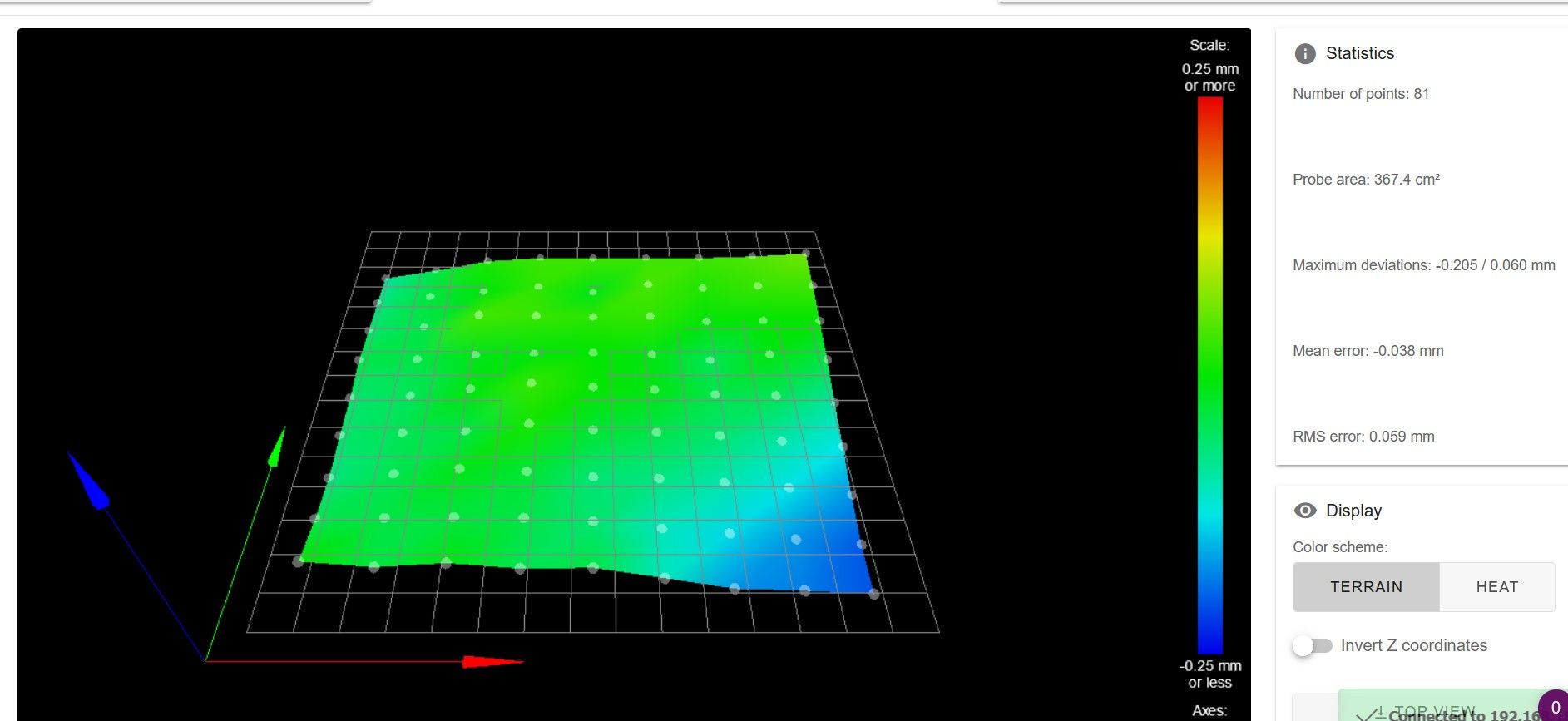

Picture of my heightmap.csv in the systemsfolder (9x9):

gcode-file I try to print (same result when I use prusa slicer 2.3):

; generated by PrusaSlicer 2.4.0+win64 on 2021-12-30 at 16:47:56 UTC

;

; external perimeters extrusion width = 0.60mm

; perimeters extrusion width = 0.50mm

; infill extrusion width = 0.50mm

; solid infill extrusion width = 0.50mm

; top infill extrusion width = 0.45mm

; first layer extrusion width = 0.42mm

M107

;TYPE:Custom

; =========================================================================================================

;

; start script for PrusaSlicer for CaribouDuet

;

; =========================================================================================================

;

G28 ; home all axis without mesh bed level

G0 X60 Y-3 Z80 ; move extruder above bed, keep extruder in front for cleaning and checking

;

M104 S160 T0 ; pre-heat extruder to 160°C

M140 S60 ; this will take the layer 1 temperature for bed 0

M190 S60 ; wait for bed temp

;

G29 ; mesh bed leveling using defined mesh grid

G0 X0 Y-3 Z0.6 ; go outside print area

;

M104 S215 ; set extruder temperature

M109 S215 ; wait for extruder temp

;

; =========================================================================================================

;

;

M98 P"0:/sys/primeLine.g" ; execute primeline macro

;

G92 E0.0 ; set extruder position

;

M572 D0 S0.07 ; set pressure advance

;

; =========================================================================================================

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; use relative distances for extrusion

M900 K0.05 ; Filament gcode LA 1.5

M900 K30 ; Filament gcode LA 1.0

M107

;LAYER_CHANGE

;Z:0.2

;HEIGHT:0.2

;BEFORE_LAYER_CHANGE

G92 E0.0

;0.2

G1 E-.4 F2100

G1 Z.4 F10800

;AFTER_LAYER_CHANGE

;0.2

G1 X4.516 Y7.168

G1 Z.2

G1 E.4 F2100

M204 P1000

;TYPE:Skirt/Brim

;WIDTH:0.42

G1 F1200

G1 X5.452 Y6.976 E.02998

G1 X245.296 Y6.928 E7.52013

G1 X246.603 Y7.32 E.04278

G1 X247.48 Y8.365 E.04278

G1 X247.673 Y9.305 E.03008

G1 X247.673 Y49.309 E1.25429

G1 X247.426 Y201.94 E4.78564

G1 X247.032 Y203.246 E.04278

G1 X245.985 Y204.121 E.04278

G1 X245.051 Y204.313 E.0299

G1 X5.274 Y204.483 E7.51806

G1 X3.967 Y204.092 E.04278

G1 X3.09 Y203.046 E.04278

G1 X2.896 Y202.106 E.03008

G1 X3.076 Y9.35 E6.04373

G1 X3.469 Y8.044 E.04278

G1 X4.47 Y7.207 E.0409

; printing object Form-Kubus id:0 copy 3

for my taste (taste because I am a noob and have no knowledge  ) the g29 Sxx is applied a little to often. Is there any known interference?

) the g29 Sxx is applied a little to often. Is there any known interference?

I have often read that possibly the z-Motors don't get enough voltage for mesh compensation?

I have already checked that my extruder can travel along the gentry easily. A tilt of the gantry can be performed easily by turning one spindle.

I have not found any further (gcode-)commands where the used mesh can be visualised? Is there a way? Or is there a way to easily visualize the motor signals? So that one can see if there is a signal for the motor to turn?

...and again thank you for your much appreciated help in advance!

) the g29 Sxx is applied a little to often. Is there any known interference?

) the g29 Sxx is applied a little to often. Is there any known interference?