@phaedrux Ok, should I take the SD out and move this file into the /firmware folder I created?

@phaedrux Ok, should I take the SD out and move this file into the /firmware folder I created?

@phaedrux M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet WiFi 1.02 or later

Board ID: 08DGM-9T6BU-FG3SJ-6J9F2-3S06M-1AWHD

Used output buffers: 3 of 24 (10 max)

=== RTOS ===

Static ram: 23876

Dynamic ram: 74876 of which 0 recycled

Never used RAM 15664, free system stack 134 words

Tasks: NETWORK(ready,19.9%,143) HEAT(delaying,0.0%,330) Move(notifyWait,0.1%,305) MAIN(running,78.6%,441) IDLE(ready,1.4%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:01:07 ago, cause: software

Last software reset time unknown, reason: User, GCodes spinning, available RAM 15664, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x08

Aux0 errors 0,0,0

Step timer max interval 0

MCU temperature: min 23.0, current 24.1, max 24.3

Supply voltage: min 13.5, current 13.6, max 13.9, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 129859, standstill, SG min/max 0/377

Driver 1: position 129859, standstill, SG min/max 0/1023

Driver 2: position 129859, standstill, SG min/max 0/379

Driver 3: position 0, standstill, SG min/max not available

Driver 4: position 0, standstill, SG min/max not available

Driver 5: position 0

Driver 6: position 0

Driver 7: position 0

Driver 8: position 0

Driver 9: position 0

Driver 10: position 0

Driver 11: position 0

Date/time: 2021-08-09 18:47:50

Cache data hit count 2612550386

Slowest loop: 5.96ms; fastest: 0.17ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 2.8ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, maxWait 41048ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 8, completed moves 8, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 1510.93ms; fastest: 0.00ms

Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

Looks to be working now, thank you so much!

@phaedrux Download and load 3.2.2 onto the SD card? Then send the M997 S1 command? Or do 3.3 and send command?

So on my Rostock Max V4 I upgraded the firmware to RRF 3.2.2 with no problems, things were working fine. In my mind, I thought it would be completely fine to upgrade to 3.3. So I sent the M997 S3.3 command and it upgraded. The duet would no longer connect to my WiFi Network.

I've tried messing with starting, stopping, resetting, trying to reload 3.2.2, etc.

I am now stumped and out of ideas, I feel it can't be too complicated, when I send M115 I get a RRF3.3 and Duet Wifi 1.02.

I feel like it is an incompatible version of the wifi file with the new /firmware folder within 3.3 (different than /sys in 3.2.2), but I do not know.

Is there a way I can just go back to 3.0 clean slate? Then I'll upgrade to 3.2.2.

Let me know what would be the best course of action.

M122 Command:

M115 Command:

@fcwilt Ok, that's kind of what I was thinking. Here is my layout. Btw I have Duet 3 6ch MB and Duet 3Ch daughterboard with SBC Raspi 4.

I also am using E3D's toolchanger, therefore the C-Axis.

Mainboard:

Drive 0: X

Drive 1: Y

Drive 2,3,4: Triple Z

Drive 5: C axis (toolchanger)

Expansion Board:

1.Drive 0: E0

1.Drive1: E1

Does this clear things up? I think we were getting some wires crossed haha.

So would this be correct to correctly map what I have above?

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M569 P0.5 S1 ; physical drive 0.5 goes forwards

M569 P1.0 S1 ; physical drive 1.0 goes forwards

M569 P1.1 S1 ; physical drive 1.1 goes forwards

M584 X0.0 Y0.1 Z0.2 C0.5 E1.0:1.1 ; set drive mapping

@fcwilt said in Triple Z Ballscrew G32 Leveling Wrong Direction:

Your M584 has this: M584 X0 Y1 Z3:4:5 E4.

Let's assume that is correct - for now.

Then in the M671 the first X/Y values must refer to Z3.

Likewise the second X/Y values must refer to Z4 and the third X/Y values must refer to Z5.

And, of course, each stepper in Z3:4:5 must actually be connected to the stepper that is near those X/Y values.

And the G30 X/Y values in bed.g don't really seem to match up well with the values in M671.

If things are not in sync the process can make the bed less level.

Now back to your M584:

You have Z4 and E4 - one of them must be wrong.

Frederick

Can you explain to me what the E4 vs Z4 thing you are talking about is? Is E4 even needed, I am kinda confused.

@fcwilt @engikeneer @Nuramori works great now and levels great, thank you, stuff was massively screwed up. Thank you for your help I appreciate it.

@engikeneer that would make sense now wouldn't it. Thank you for pointing out my blindspot.

@fcwilt Ok.... I followed @Phaedrux 's article he tagged and have my motors flipped, when I move with the G92 command I get my proper +Y to the back of the printer and +X to the right of the printer. Origin being at the front left corner of the build plate.

The next issue I had to deal with was flipping my pins for X&Y endstops, I have X working as it should, but no matter what I change, the Y-axis goes to the back of the printer (Ymax) and not to the front. I changed the M574 Y1 S1 and it still wants to move to the Ymax. So I am kind of at a loss here. Not sure what is happening, I am sure it is something simple I am missing.

Updated config.g:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Jul 10 2021 12:06:00 GMT-0400 (EDT)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 C0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 C16 E16:16 I1 ; configure microstepping with interpolation

M350 C16 I10 ; Configure microstepping without interpolation (toolchange motor)

M92 X80.00 Y80.00 Z800.00 C91.022 E145.51:145.51 ; set steps per mm

M566 X400.00 Y400.00 Z60.00 C2 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X20000 Y20000 Z4000 C8000 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X2000.00 Y2000.00 Z750.00 C500 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 C600 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 C-45 S1 ; set axis minima

M208 X400 Y400 Z440 C360 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y1 S1 P"io0.in" ; configure active-high endstop for low end on Y via pin io0.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

M574 C0 ; no C endstop

; Z-Probe

M558 P5 C"^io3.in" H15 F1200 T60000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:400 Y50:400 S50 ; define mesh grid

; Heaters

M308 S0 P"temp3" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp3

M950 H0 C"out3" T0 ; create bed heater output on out3 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin temp0

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S455 ; set temperature limit for heater 1 to 455C

M308 S2 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp1

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C

M308 S3 P"1.temp1" Y"thermistor" T10000 B1504 ; configure sensor 3 as thermistor on pin 1.temp1

M950 H3 C"1.out0" T3 ; create chamber heater output on 1.out0 and map it to sensor 3

M307 H3 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit

M141 H3 ; map chamber to heater 3

M143 H3 S90 ; set temperature limit for heater 3 to 90C

; Fans

M950 F0 C"!out4" Q25000 ; create fan 0 on pin !out4 and set its frequency

M106 P0 C"FRONT PANEL" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"!out5" Q25000 ; create fan 1 on pin !out5 and set its frequency

M106 P1 C"RAD 1 (TOP)" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"!out6" Q25000 ; create fan 2 on pin !out6 and set its frequency

M106 P2 C"RAD 2 (BOTTOM)" S1 H1 T45 ; set fan 2 name and value. Thermostatic control is turned on

M950 F3 C"1.out6" Q500 ; create fan 3 on pin 1.out6 and set its frequency

M106 P3 C"Water Pump" S1 H-1 ; set fan 3 name and value. Thermostatic control is turned off

M950 F4 C"out7" Q500 ; create fan 4 on pin out7 and set its frequency

M106 P4 C"E3D V6 Hotend" S0.5 H2 T45 ; set fan 4 name and value. Thermostatic control is turned on

; Tools

M563 P0 S"Mosquito Liquid" D0 H1 F-1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"E3D V6" D1 H2 F-1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings

M584 X0 Y1 Z3:4:5 E4 ; three Z motors connected to driver outputs 2, 5 and 6

M671 X-25.298:200.199:427.12 Y2.021:430.231:20.21 S10 ; ball screws at front left, back middle and front right

M308 S10 P"temp2" Y"thermistor" T10000 B3988 A"Coolant Cold" ; Configure coolant sensor cold side

M308 S11 P"1.temp2" Y"thermistor" T10000 B3988 A"Coolant Hot" ; Configure coolant sensor hot side on toolboard 1 temp2

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

@nuramori said in Triple Z Ballscrew G32 Leveling Wrong Direction:

@jordan_miller41 can you share your entire config.g file?

Where are your endstops located?

End stops are located left side for X and Front Left for Y. I do remember having the Y setup to where the homing is at the maximum and I think it was because it went the wrong way initially, I could be remembering wrong as this was 6+ months ago when I first started.

@fcwilt

Here is my current config.g:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Jul 10 2021 12:06:00 GMT-0400 (EDT)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 C0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 C16 E16:16 I1 ; configure microstepping with interpolation

M350 C16 I10 ; Configure microstepping without interpolation (toolchange motor)

M92 X80.00 Y80.00 Z800.00 C91.022 E145.51:145.51 ; set steps per mm

M566 X400.00 Y400.00 Z60.00 C2 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X20000 Y20000 Z4000 C8000 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X2000.00 Y2000.00 Z750.00 C500 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 C600 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 C-45 S1 ; set axis minima

M208 X400 Y400 Z440 C360 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin io1.in

M574 Y2 S1 P"io0.in" ; configure active-high endstop for high end on Y via pin io0.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

M574 C0 ; no C endstop

; Z-Probe

M558 P5 C"^io3.in" H15 F1200 T60000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:400 Y50:400 S50 ; define mesh grid

; Heaters

M308 S0 P"temp3" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp3

M950 H0 C"out3" T0 ; create bed heater output on out3 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin temp0

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S455 ; set temperature limit for heater 1 to 455C

M308 S2 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp1

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C

M308 S3 P"1.temp1" Y"thermistor" T10000 B1504 ; configure sensor 3 as thermistor on pin 1.temp1

M950 H3 C"1.out0" T3 ; create chamber heater output on 1.out0 and map it to sensor 3

M307 H3 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit

M141 H3 ; map chamber to heater 3

M143 H3 S90 ; set temperature limit for heater 3 to 90C

; Fans

M950 F0 C"!out4" Q25000 ; create fan 0 on pin !out4 and set its frequency

M106 P0 C"FRONT PANEL" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"!out5" Q25000 ; create fan 1 on pin !out5 and set its frequency

M106 P1 C"RAD 1 (TOP)" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"!out6" Q25000 ; create fan 2 on pin !out6 and set its frequency

M106 P2 C"RAD 2 (BOTTOM)" S1 H1 T45 ; set fan 2 name and value. Thermostatic control is turned on

M950 F3 C"1.out6" Q500 ; create fan 3 on pin 1.out6 and set its frequency

M106 P3 C"Water Pump" S1 H-1 ; set fan 3 name and value. Thermostatic control is turned off

M950 F4 C"out7" Q500 ; create fan 4 on pin out7 and set its frequency

M106 P4 C"E3D V6 Hotend" S0.5 H2 T45 ; set fan 4 name and value. Thermostatic control is turned on

; Tools

M563 P0 S"Mosquito Liquid" D0 H1 F-1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"E3D V6" D1 H2 F-1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings

M584 X0 Y1 Z3:4:5 E4 ; three Z motors connected to driver outputs 2, 5 and 6

M671 X-25.298:200.199:427.12 Y2.021:430.231:20.21 S10 ; ball screws at front left, back middle and front right

M308 S10 P"temp2" Y"thermistor" T10000 B3988 A"Coolant Cold" ; Configure coolant sensor cold side

M308 S11 P"1.temp2" Y"thermistor" T10000 B3988 A"Coolant Hot" ; Configure coolant sensor hot side on toolboard 1 temp2

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

Thank you for your help, I will start to implement your suggestions here in an hour or so.

@fcwilt Ok I will work on changing/verifying those things.

On a bit of a side note, how do you "switch" can axis?

Right now my X minimum is on my left side, and my Y maximum is at the very front of the printer, Y minimum is at the back. See picture.

How can I switch my Y-Axis direction to be Y0 at the front?

Thanks.

So the triple Z leveling seems to act a bit wonky. When the build plate is angled towards the front of the printer (video angle is from the left side) and I run a G32 command it ends up angling more. (Video)

It levels well left to right (looking at front of the printer). So I am a bit confused.

Hopefully, it is something simple I am missing.

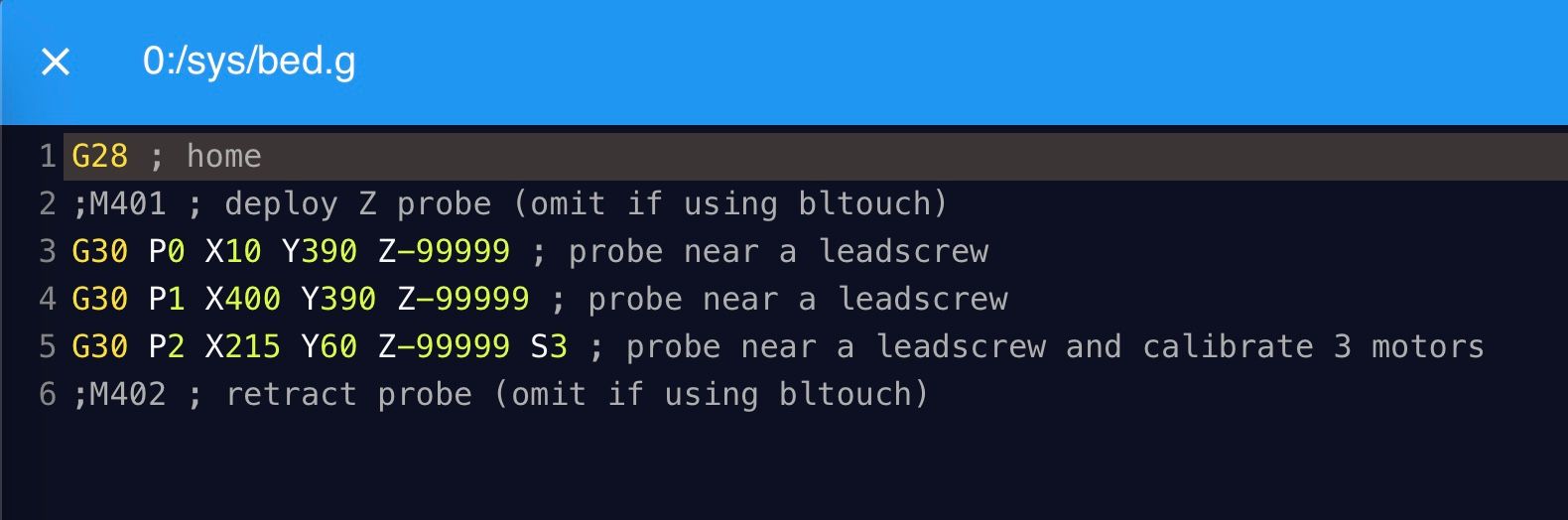

Attached are the Config.g and bed.g screenshots of what I have.

@phaedrux understood, so for an enclosure heater, is there a way to adjust the "watchdog" parameters? I don't know how long it will take to heat my enclosure and I don't want it to time out.

@alex-cr ok what if it is for bang-bang mode? So I have to tune the bed before it will heat all the way up?

@dc42 So got the thermisters remapped, the SSR kicks on and started heating the bed up, then it just faulted again after heating the bed from 18C to 30C. Only stays on for about 30-45 seconds. Thoughts?

@dc42 thank you, that clears it up!

@alex-cr Ahhhhh that makes sense, I will do that in the morning. I think that would have to be it, didn't even think of that. I'll report back tomorrow with hopefully good results!

@alex-cr I think your on to something, this makes sens sensor #0 and 3 not being configured, I was too ignoring them

What do I need to do to fix it?

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Apr 19 2021 17:15:29 GMT-0400 (EDT)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E145.51:145.51 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X400 Y400 Z440 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin io1.in

M574 Y2 S1 P"io0.in" ; configure active-high endstop for high end on Y via pin io0.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M558 P5 C"^io3.in" H15 F1200 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:400 Y50:400 S50 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"1.out1" T0 ; create bed heater output on 1.out1 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp2" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin temp2

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S455 ; set temperature limit for heater 1 to 455C

M308 S2 P"temp3" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp3

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C

M308 S3 P"temp1" Y"thermistor" T10000 B4723 C1.19622e-7 ; configure sensor 3 as thermistor on pin temp1

M950 H3 C"1.out0" T3 ; create chamber heater output on 1.out0 and map it to sensor 3

M307 H3 B1 S1.00 ; enable bang-bang mode for the chamber heater and set PWM limit

M141 H3 ; map chamber to heater 3

M143 H3 S90 ; set temperature limit for heater 3 to 90C

; Fans

M950 F0 C"!out4" Q25000 ; create fan 0 on pin !out4 and set its frequency

M106 P0 C"FRONT PANEL" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"!out5" Q25000 ; create fan 1 on pin !out5 and set its frequency

M106 P1 C"RAD 1 (TOP)" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"!out6" Q25000 ; create fan 2 on pin !out6 and set its frequency

M106 P2 C"RAD 2 (BOTTOM)" S1 H1 T45 ; set fan 2 name and value. Thermostatic control is turned on

M950 F3 C"1.out6" Q500 ; create fan 3 on pin 1.out6 and set its frequency

M106 P3 C"Water Pump" S1 H-1 ; set fan 3 name and value. Thermostatic control is turned on

M950 F4 C"out7" Q500 ; create fan 4 on pin out7 and set its frequency

M106 P4 C"E3D V6 Hotend" S0.5 H2 T45 ; set fan 4 name and value. Thermostatic control is turned on

; Tools

M563 P0 S"Mosquito Liquid" D0 H1 F-1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"E3D V6" D1 H2 F-1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings

M584 X0 Y1 Z3:4:5 E4 ; three Z motors connected to driver outputs 2, 5 and 6

M671 X-25.298:200.199:427.12 Y2.021:430.231:20.21 S0.5 ; ball screws at front left, back middle and front right

M308 S10 P"1.temp0" Y"thermistor" T10000 B3988 A"Coolant Cold" ; Configure coolant sensor cold side

M308 S11 P"1.temp1" Y"thermistor" T10000 B3988 A"Coolant Hot" ; Configure coolant sensor hot side

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

@alex-cr It faults right away. The temp it gives is 22.5C. Just double-checked again, it does not turn the light on.