Each of the pads are 24V 300W

Posts made by Joaquin Suave

-

RE: Wiring multiable bed heaters as a single unit?posted in General Discussion

-

Wiring multiable bed heaters as a single unit?posted in General Discussion

For my "home built" printer (420mm cube) I bought a 450 mm silicone bed heater from China for the project. Well after waiting for over 8 weeks and receiving multiable LIES from the manufacture about why it had been not delivered, i demanded my money back and bough 4x 200mm silicone heaters on Amazon (they arrived in 2 days and less $$$ than my original purchase).

So now I want to wire them up as a single unit. Nothing fancy! just wanting to measure/ control the heated bed as a single unit! Do I wire the heaters & thermistors in parallel or in series?

Sorry for all the lame questions!

-

RE: NEMA 23 Dramaposted in General Discussion

So this is where I am at right now:

; Configuration file for Duet 3 (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Sat Mar 05 2022 11:18:10 GMT-0800 (Pacific Standard Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M584 X0.1 Y0.2 Z0.3 E0.0 ; set drive mapping

M350 X4 Y4 I0 ; configure microstepping without interpolation

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X154.50 Y154.50 Z262.00 E420.00 ; set steps per mm

M566 X1800.00 Y1800.00 Z1000.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z1000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z500.00 E250.00 ; set accelerations (mm/s^2)

M906 X4800 Y4800 Z1800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X416 Y416 Z400 S0 ; set axis maxima; Endstops

; WARNING: No endstops configured; Z-Probe

M558 P0 H5 F120 T12000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S300 ; set temperature limit for heater 1 to 300C; Fans

M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out7" Q500 ; create fan 1 on pin out7 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

RE: NEMA 23 Dramaposted in General Discussion

Hello: My name is Joaquin Suave and I am a .... BONEHEAD!!!!

Being the lazy old curmudgeon that I am, I have been doing all my code modifications in the RRF config tool. Being around machine controls for longer than most of you "pups" have been alive, I "assumed" that when the control was unplugged that it would do a reboot and the upload from the config tool would change my settings... OOPS!

This morning I opened the config.g file and it looked NOTHING like the edits I have been trying for the last 3 weeks! I manually entered my original mm/ step and droftarts suggestions (thanks again!) and the motor shaft turned!

I put the belt back on the reduction drive: WORKED FINE!

Reattached the X motor/drive to the X carriage: AND IT MOVES LIKE A CHARM!!!"Bolted" the Y drive back together: AND ROCK & ROLL BABY!!!

My problem is solved! Thank you all again for you patience & help!!!

-

RE: NEMA 23 Dramaposted in General Discussion

Thanks for the recent advice Guys,

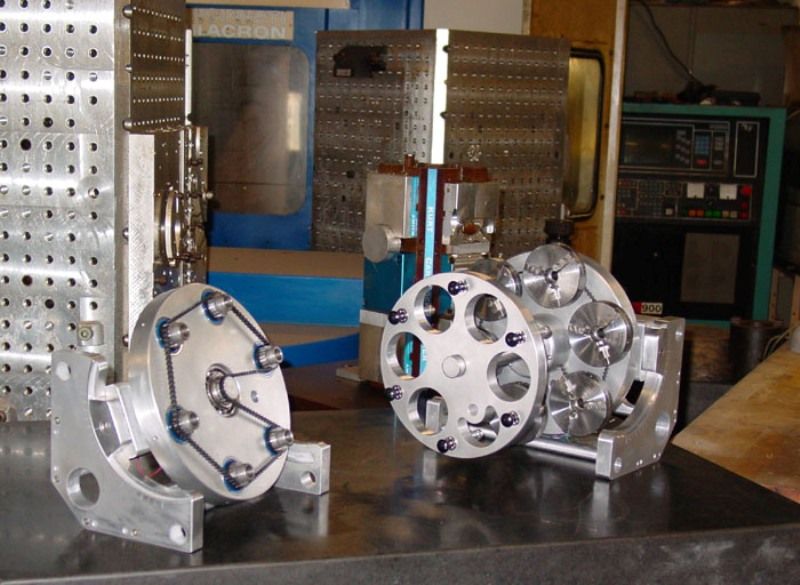

I grounded the metal table that device is being developed on the power cord ground and to the giant mill behind it in the pictures.

No Luck!

I played around a bit with the EMF calculator. I added the spec's of the motor, tried max travel as low as 60 mm a second with nothing connected to the motor shaft and am still stalling the motor.

An advice on the "ball park" values I'm looking for would be greatly appreciated!

So at this time I am going to keep trying different configurations, but more importantly I am going to GUT my X and Y drive systems then design and build belt drive replacements ( It helps to have a 5 axis CNC shop at one's disposal).

So a couple of quick questions about belt drives for 3D printers:

What is the "typical" mm/step travel (@ 1x, @ 16x )? I'll do the math from there to get the pulley size.

Are there "off the shelf" belt clamps (I'll be using GT3 3/mm belts)?

I have designed and built A BUNCH of belt driven devices but have always been the "mechanical guy" and worked with the "electronic people" of the companies/ DOD to integrate my devices into their equipment. The only previous experience I have had was with CNC4pc motion controller and it was child's play.

-

RE: NEMA 23 Dramaposted in General Discussion

Holding Torque: 2.39 oz-in (169 N-cm)

Phase Current: 2400 ma

Leads: 4

Phase resistance: 1.5 Ohms

Phase Inductance: 5.4 mH

Detent Torque 9.7 oz-in (6.9 N_cm)

Rotor Inertia: .0065 oz-in-sec2 (.46 kg-cm2)

Length: 2.99" (7.6 cm)

Weight: 35.3 oz (1 kg)Thanks again for your help!

Here are a couple of more pictures:

-

RE: NEMA 23 Dramaposted in General Discussion

Well I spoke too quickly!

I did one test run @ 16x : 150 steps/ sec. : 15 change: 200mm/ sec. : 500 Accl :

5000 current... And the motor shaft rotated without stalling.Since then I have done +/- 60 tests WITH NO LUCK (in every imaginable configuration).

I disconnected the motor from the board and wired it up to a simple driver i have and it works just fine!?!?

Can anyone give a starting point to configure the drives for these motors?

Intelligent Motion Systems M-2231-2.4S (nema 23)

And I desire to achieve this travel:

79.8mm = 1 rotation of the pinion on the rack / the timing belt gear reduction of 3.75:1 = 21.28mm for 1 revolution of the motor shaft.Or at 1X (200 steps) = 9.398 steps/ mm.

Or at 16X (3200 steps) = 150.368 steps/ mm.Could there be a possibility that i am just asking too much from the drivers?

Could there be a possibility that i "fried" the drivers?

Could there be a possibility that i can wire in "add-on" drivers?In the worst case scenario, I could tear the machine apart and replace the rack/ pinion w/reduction to a regular belt drive. If so, what is a "comfortable" mm to shaft ratio?

I am not trying to break any "speed records", but rather trying to repurpose a really nicely made (expensive) piece of hardware, learn about controls, 3D printing.

I can't say that I have been very successful so far!

-

RE: NEMA 23 Dramaposted in General Discussion

I GOT IT!!!!!

I didn't have enough current for the motors! Now I will start fine tuning!

Thank all you SO MUCH!

-

RE: NEMA 23 Dramaposted in General Discussion

@joaquin_suave said in NEMA 23 Drama:

M584 X0.1 Y0.2 Z0.3 E0.0 ; set drive mapping

M350 X1 I0 ; configure microstepping without interpolation

M350 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X200.00 Y1.50 Z266.00 E100.00 ; set steps per mm

M566 X6000.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X2000 Y800 Z800 E800 ; set motor currents (mA)

M84 S0 ; Disable motor idle current reductionI am only trying to configure X for right now (the X & Y motors are identical).

Z is a nema 17 with a leadscrew and is moving correctly as for as I can tell ( without using a test indicator), E is a nema 17 and moves the filament close to the correct length.

Wiring:

A2: Green

A1: Green/ White

B2: Red

B1: Red/ White -

RE: NEMA 23 Dramaposted in General Discussion

Oops My bad!

I am only testing the motor (nema 23) with the X drive and have set it so that when I manually move 1 mm it should turn the shaft 1 revolution. I figured that once i have achieved that I can tune the X & Y drives correctly.

Z and E are nema 17's and I don't seem to have any issues with them.

Any test setting you guys can suggest will be GREATLY appreciated!!!!

-

RE: NEMA 23 Dramaposted in General Discussion

Here is my latest test and still no luck:

; Configuration file for Duet 3 (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Fri Mar 18 2022 10:57:30 GMT-0700 (Pacific Daylight Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M584 X0.1 Y0.2 Z0.3 E0.0 ; set drive mapping

M350 X1 I0 ; configure microstepping without interpolation

M350 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X200.00 Y1.50 Z266.00 E100.00 ; set steps per mm

M566 X6000.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X2000 Y800 Z800 E800 ; set motor currents (mA)

M84 S0 ; Disable motor idle current reduction; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X416 Y416 Z400 S0 ; set axis maxima; Endstops

M574 X1 S1 P"null" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin null

M574 Y1 S1 P"null" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin null; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out7" Q500 ; create fan 1 on pin out7 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

RE: NEMA 23 Dramaposted in General Discussion

m203

Max speeds (mm/min): X: 12000.0, Y: 12000.0, Z: 180.0, E: 1200.0, min. speed 30.00

3/17/2022, 2:52:11 PM m106

3/17/2022, 1:58:43 PM m98 p

Error: M98: non-empty string expected=========

When i am trying to make changes, i go into the RRF config tool and create a new zip file the download it in "my printer". It goes through the process then tells me that only one file has changed... I presumed that it was the config.g, but don't know for sure.Am I missing something... I'm starting to feel really dumb here!

-

RE: NEMA 23 Dramaposted in General Discussion

Here is my M122 info:

m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.3 (2021-06-15 21:45:47) running on Duet 3 MB6HC v1.01 or later (standalone mode)

Board ID: 08DJM-9P63L-DJ3S0-7JTD0-3S46L-TUKZ8

Used output buffers: 3 of 40 (12 max)

=== RTOS ===

Static ram: 150904

Dynamic ram: 91692 of which 0 recycled

Never used RAM 111596, free system stack 193 words

Tasks: NETWORK(ready,30.3%,270) ETHERNET(notifyWait,0.1%,117) HEAT(notifyWait,0.0%,325) Move(notifyWait,0.0%,284) CanReceiv(notifyWait,0.0%,944) CanSender(notifyWait,0.0%,374) CanClock(delaying,0.0%,333) TMC(notifyWait,7.7%,59) MAIN(running,61.8%,1096) IDLE(ready,0.0%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:09:16 ago, cause: software

Last software reset at 2022-03-17 13:47, reason: User, GCodes spinning, available RAM 111596, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Step timer max interval 148

MCU temperature: min 34.0, current 36.9, max 36.9

Supply voltage: min 36.0, current 36.0, max 36.1, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.1, max 12.2, under voltage events: 0

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 730913, standstill, reads 19469, writes 14 timeouts 0, SG min/max 0/0

Driver 1: position 0, standstill, reads 19456, writes 27 timeouts 0, SG min/max 0/179

Driver 2: position 0, standstill, reads 19469, writes 14 timeouts 0, SG min/max 0/0

Driver 3: position 0, standstill, reads 19469, writes 14 timeouts 0, SG min/max 0/0

Driver 4: position 0, standstill, reads 19472, writes 11 timeouts 0, SG min/max 0/0

Driver 5: position 0, standstill, reads 19473, writes 11 timeouts 0, SG min/max 0/0

Date/time: 2022-03-17 13:56:29

Slowest loop: 6.84ms; fastest: 0.05ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 2.1ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, maxWait 219077ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 21, completed moves 21, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 21], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== CAN ===

Messages queued 5011, received 0, lost 0, longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 49 (min 49), ts 2785/0/0

Tx timeouts 0,0,2784,0,0,2225 last cancelled message type 30 dest 127=== Network ===

Slowest loop: 4.60ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions

HTTP sessions: 1 of 8- Ethernet -

State: active

Error counts: 0 0 1 0 0

Socket states: 5 2 2 2 2 0 0 0

========

Help me guys! I am more confused than ever! - Ethernet -

-

RE: NEMA 23 Dramaposted in General Discussion

I have checked all the motors for paired windings by checking resistance and by shorting them and spinning the shaft. I am 100% sure that the wiring is correct.

The 2 motors I plan on using are Intelligent Motion Systems M-2231-2.4S

And... No luck!I also tried an Oriental Motors C0145-9212K... No luck!

And an Oriental Motors PK268-E2.0A... No luck!All these motors work correctly with an external drive.

I have to run out and meet with a client for few hours. When i get back to the shop I'll share the setting that I have tried in the RRF Config tool.

Thanks again to all of you for "pitching in"!

-

RE: NEMA 23 Dramaposted in General Discussion

Yes both the motors work fine with a simple drive powered by a 24V 4a PSU.

-

RE: NEMA 23 Dramaposted in General Discussion

I have checked the wiring of both the motors per the Duet documentation and A+/- & B+/- are paired correctly and I am using the drivers on the Duet3 HC board.

The new PSU is ordered and should be here Thursday!

-

RE: NEMA 23 Dramaposted in General Discussion

Thank you guys SO MUCH!

I am sure the PSU is set to 110V and the tried my other PSU (@ 4A) and had the same results.

To give you a little back round about the device, It was originally intended to be used in an "all-terrain" environment, all weather, and any of the axis able to take "hit". That is why I designed the drives to be rack & pinion with a 3.75:1 reduction by belt drive. If the axis gets hit it can skip a tooth then quickly "homed" and reset with minimal damage to the hardware.

I am going to order the suggested PSU right now the go dig through my notes then post steps/mm and the other configurations later today.

BTW: I am turning it into a 3D printer with a 400mm cube and eventually fully enclosed.

Thank you all again for your input!

-

RE: NEMA 23 Dramaposted in General Discussion

I tested the motors several times with a multitude of different configurations (steps/ mm, microstepping, and current) an the only results I got was a "studering" of the spindle (like 1/20 of a rotation) regardless of my desired manual travel request (1mm, 10mm, 50mm).

Due to my lack of confidence in my skills... I tried some of the same tests with a Nema 17 motor and it performed exactly like it should.

I admit I am a total NOOB when it comes to the configuration of control systems and invested in this project as a learning experience. I guess this is a classic case of "be careful of what you wish for"!

Here is my device with my 8 pallet mill in the backround:

-

NEMA 23 Dramaposted in General Discussion

Howdy Folks,

Let me first apologize for my lack of working knowledge when it comes to electronics and firmware with regards to NC systems.

NC? That was what this sh*t was called back in 1983 when I bought my first NC milling machine ( why yes! you are correct! I am a DINOSAUR!). AKA: Numerical Control... Before Computer Numerical Control was even a "twinkle" in your mom's or dad's eye!

So let's fast forward.. To NOW! I am trying to "rap" my brain around re-proposing a device I built about 10 years ago to ***** (sorry bound my NDA'S).

My problem is that I can not get Nema 23 motors to BEHAVE at all! Nema 17's not problem.

I have hooked my X & Y motors up to a simple drive powered by a 24VDC 4A and they spin like a charm! I then reread the Duet doc's and see that a higher voltage power supply is suggested, I turned up my current power supply (24VAC 20A) to 28.4VAC... And still no luck!

I then started looking for 32VAC 20A power supplies and haven't had any luck other than buying direct from China...( I will NEVER do that again).

Can anyone direct me to a good US source for my necessary power supply?