Seeing now (not sure how I missed it) that there is already another thread on this.

Posts made by Jimborr

-

RE: 3.5.0rc1: Input shaping causes layer shifts!?posted in Beta Firmware

-

RE: 3.5.0rc1: Input shaping causes layer shifts!?posted in Beta Firmware

@oliof

Did you mean to add M376 H3 to bed.g (or config.g)?

If so, I did. No change, still layer shifting.config.g

; Axis and motor configuration M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes backwards M569 P4 S0 ; Drive 4 goes backwards ;M574 X2 Y2 Z2 P1 ; set endstop configuration (all endstops at high end, active high) M574 X2 S1 P"xstop" ; X min active high endstop switch M574 Y2 S1 P"ystop" ; Y min active high endstop switch M574 Z2 S1 P"zstop" ; Z min active high endstop switch ;M665 R175.50 L360.24 B140.0 H467.0 X0.00 Y0.00 Z0.00 ; set delta radius, diagonal rod length, printable radius, homed height and XY tower corrections ;M665 R168.00 L360.24 B140.0 H444.0; X0.00 Y0.00 Z0.00 ; set delta radius, diagonal rod length, printable radius, homed height and XY tower corrections M665 L360.240:360.240:360.240 R171.368 H445.000 B140.0 X0.331 Y-0.086 Z0.000 ;M666 X-0.27 Y0.52 Z-0.26 ; put your endstop adjustments here, or use auto calibration to find them all) M666 X0.00 Y0.00 Z0.00 M584 X0 Y1 Z2 E3 M92 X160.804 Y160.804 Z160.804 ; Set axis steps/mm (20 tooth pulleys, 0.9deg/step motors) M350 Z16 X16 Y16 E16 I1 ; Set 16x microstepping with interpolation ;M579 X1.005 Y1.005 X0.995 ;SCALE M579 X1.000 Y1.000 X1.000 ;SCALE M906 X1300 Y1300 Z1300 E600 I30 ; Set motor currents (mA) ;M201 X800 Y800 Z600 E1000 ; Set accelerations (mm/s^2) ;M203 X12000 Y12000 Z8000 E12000 ; Set maximum speeds (mm/min) ;M566 X700 Y700 Z1000 E1200 ; Maximum instant speed changes M201 X2000 Y2000 Z2000 E6000 ; Set accelerations (mm/s^2) M203 X14000 Y14000 Z10000 E6000 ; Set maximum speeds (mm/min) M566 X1000 Y1000 Z1000 E500 ; Maximum instant speed changes (jerk) G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Thermistors and heaters ;M305 S0 P"bed_temp" Y"thermistor" T100000 B3950 R4700 H0 L0 ; RRF3 Typical Chinese bed thermistor. Put your own H and/or L values here to set the bed thermistor ADC correction. ;M305 S1 P"e0_temp" Y"thermistor" T100000 B4388 R4700 H0 L0 ; RRF3 E3Dv6 hot end. Put your own H and/or L values here if necessary to set the first nozzle thermistor ADC correction. M308 S0 P"bed_temp" Y"thermistor" T100000 B5000 ; define bed temperature sensor ;M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.060000e-8 M308 S3 Y"mcu-temp" A"MCUTemp" ; configure sensor 3 as MCU Temperature M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 M140 H0 ; the bed heater is heater 0 ; Fans M950 F0 C"fan0" Q500 ; Print Fan M950 F1 C"fan1" Q500 ; Hotend Fan M950 F2 C"fan2" Q500 ; MCU FAN M106 P0 H-1 C"Print Fan" M106 P1 H1 S1 T60 C"Hotend Fan" ;S1 I0 F500 H2:2:1 T45 ; set fan 0 name, value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 H3 S0.4 T45:65 C"MCU FAN" ; set fan 1 name, value, PWM signal inversion and frequency. Thermostatic control is turned off M301 H0 P20 I0.5 D1000 T0.85 W150 B0 ; PID settings for the bed M301 H1 P10 I0.10 D100 T0.50 ; PID settings for extruder 0 M570 S200 H1 ; Allow extra heating time M143 S300 ; max hotend temp ;M307 H1 A343.1 C127.3 D 6.1 B0 ;From tuning H1 ( M307 H0 F20 M307 H1 R4.141 K0.448:0.326 D2.92 E1.35 S1.00 B0 V24.0 ; Tool definitions M563 P0 D0 H1 ; Define tool 0 G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ;M92 E450 ;old 475 ; Set extruder steps per mm for first and second extruders M92 E690 ; Set extruder steps per mm for first and second extruders ; CPU fan 60% ;M106 P1 H-1 ;M106 P1 S0.6 ;M106 P1 T45:65 H100:101:102 ; Z probe and compensation definition ;M558 P5 R0.4 F1000 T16000 ; Z probe is IR and is not used for homing any axes, Z probe dive height 3mm, probing speed 300mm/min, travel speed 12000mm/min ;M558 P5 C"e0stop" H5 F1000 T16000 ;G31 P100 X0 Y0 Z-0.12 ; Set the zprobe offset and threshold (put your own values here). For a delta, use zero X and Y offset. ;Duet3d Recommended M558 P8 C"zprobe.in+zprobe.mod" H4 F1000 T12000 R0.2 S0.02 A7 ;G31 X0 Y0 Z-0.12 P100 ; org - changed 201021-1627 ;G31 X0 Y0 Z-0.07 P100 ; s3d settings G31 X0 Y0 Z-0.0 P100 ; cura settings ;M572 D0 S0.12 ; set pressure advance M572 D0 S0.03 ; set pressure advance T0 ; select first print head ; Grid based M557 R130 S35 M501config-override.g

; config-override.g file generated in response to M500 at 2023-10-29 18:24 ; This is a system-generated file - do not edit ; Delta parameters M665 L367.003:367.003:367.003 R161.017 H444.611 B140.0 X0.450 Y-0.055 Z0.000 M666 X-2.732 Y1.370 Z1.362 A0.75 B1.27 ; Heater model parameters M307 H0 R0.129 K0.143:0.000 D10.00 E1.00 S1.00 B1 M301 H0 P20.0 I0.500 D1000.0 M307 H1 R4.141 K0.448:0.326 D2.92 E1.35 S1.00 B0 V24.0 M301 H1 P10.0 I0.100 D100.0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00bed.g

; Auto calibration routine for large delta printer with IR probe M561 ; clear any bed transform, otherwise homing may be at the wrong height ;G28 ; home the printer M376 H3 ; Probe the bed and do auto calibration G1 X0 Y0 Z10 F10000 ; go to just above the first probe point to speed up probing ; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 16 points, 6 factors, probing radius: 110, probe offset (0, 0) ; bed offset IRH param after () REMOVE added Z-start Zstart=+1.0 (0.5mm measure thickness + 1.0mm added for negative to work) ; (Bedoff+IR)-(0.5+1.38) lower value = nozzle closer to bed G30 P0 X0.00 Y110.00 Z-99999 ; H0.05 ; 2.27 - 1.73 G30 P1 X55.00 Y95.26 Z-99999 ; H0.10 ; 2.49 - 1.92 (org H0.1) G30 P2 X95.26 Y55.00 Z-99999 ; H0.10 ; 2.42 - 1.94 (org H0.02) G30 P3 X110.00 Y0.00 Z-99999 ;H0.15 ; 2.12 - 1.70 G30 P4 X95.26 Y-55.00 Z-99999 ; H-0.20 ; 1.75 - 1.41 G30 P5 X55.00 Y-95.26 Z-99999 ; H-0.20 ; 1.50 - 1.18 G30 P6 X0.00 Y-110.00 Z-99999 ; H0.05 ; 1.43 - 1.08 G30 P7 X-55.00 Y-95.26 Z-99999 ;H0.03 ; 1.49 - 1.06 G30 P8 X-95.26 Y-55.00 Z-99999 ; H0.05 ; 1.67 - 1.19 G30 P9 X-110.00 Y0.00 Z-99999 ; ;H0.08 ; 1.74 - 1.24 G30 P10 X-95.26 Y55.00 Z-99999 ; ;H0.00 ; 1.88 - 1.37 G30 P11 X-55.00 Y95.26 Z-99999 ; ;H0.00 ; 2.02 - 1.50 G30 P12 X0.00 Y55.00 Z-99999 ; ;H-0.45 ; 1.88 - 1.37 G30 P13 X47.63 Y-27.50 Z-99999 ; H-0.10 ; 1.69 - 1.33 G30 P14 X-47.63 Y-27.50 Z-99999 ; ;H-0.00 ; 1.66 - 1.25 G30 P15 X0 Y0 Z-99999 S9 ; 1.71 1.71 - 1.25 0.46 G1 X0 Y0 Z150 F15000 ; get the head out of the way of the bed -

RE: 3.5.0rc1: Input shaping causes layer shifts!?posted in Beta Firmware

@NeoDue

I am using mesh bed leveling and am not using "fade height / taper M376" so the

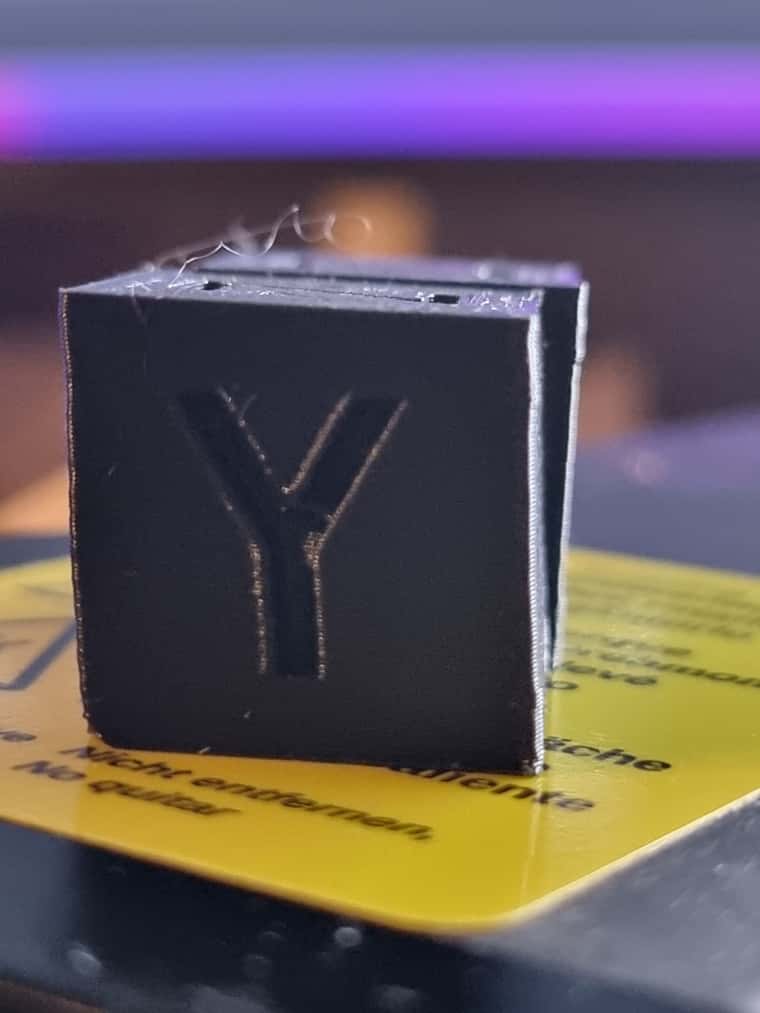

behaviour seems to be what @oliof wrote.Image is of 20mm cube (front is with 3.5.0rc1 and the one behind is 3.5.0b1), same config otherwise.

-

RE: 3.5.0rc1: Input shaping causes layer shifts!?posted in Beta Firmware

Explains the sudden layer shifting I got, going from 3.5.0 b1 to rc1 my prints started

shifting in the Y axis.

Reversing to beta1 solved the problem. -

RE: Mounting a radial fan on the Smart Effectorposted in Smart effector for delta printers

I've also create a mount/nozzle for a 5015 blower fan. Not the prettiest there is, function before form?!

You might loose some printarea depending on your setup though.https://i.imgur.com/YGceDSz.jpg?1

I haven't done any briding tests with it yet but it looks promising.

http://a360.co/2lfN2Qn mount

http://a360.co/2ChBnrn nozzle -

RE: Motedis 2020 i-type drop in t-nutsposted in General Discussion

These should work too, but the can be a pain sometimes since there is no spring on them

-

RE: Mounting a radial fan on the Smart Effectorposted in Smart effector for delta printers

The radial fan is far better in my opinion and I was considering myself to try and design something, but

I lack the time anytime soon.But If you find a solution that'd be great

-

RE: 40mm heatsink fan mount (when using part cooler)posted in Smart effector for delta printers

I've updated the thingiverse part, added a model where I removed about 2mm from the fan mount thickness.

Not printed it yet, but should work fine.

-

RE: 40mm heatsink fan mount (when using part cooler)posted in Smart effector for delta printers

I could probably make it a 1mm shorter before the angle and shave of a millimeter or two from the fan mount side..

It sticks out about 1-2mm more than the part cooler, measured on the "long side".

-

RE: Main website reverted to pre-launch?posted in General Discussion

Seems also the Order site is reverted to the old main site.

-

Main website reverted to pre-launch?posted in General Discussion

Is it my computer that's a bit strange today or did the main website revert back to a pre-duetwifi launch state?

-

40mm heatsink fan mount (when using part cooler)posted in Smart effector for delta printers

I couldn't find any 40mm heatsink fan mount that worked when using the part cooler.

30mm fans are too loud for my taste.I'm currently remixing one now. I have a working one running on the printer now but

I'm not too pleased with the fiting, it's a bit loose. Mostly doing this by trial and error

since designing parts isn't my best skill.Both models below require the spacer between pcb and heatsink, however I've made it only 2mm thick which

seems to work nicely.Current iteration that I'm printing for testing right now.

http://a360.co/2xFPFyhCurrently mounted and working, but not near perfect.

http://a360.co/2kOg2kmIf there is a working solution for this I'd be very happy to see it.

-

RE: PanelDue Flashing on and offposted in Duet Hardware and wiring

I still suspect the cable.

I'll check it when I'm rebuilding/re-cabling when my PCB Effector kit arrives

Don't have the cash for a new screen atm anyways

-

RE: PanelDue Flashing on and offposted in Duet Hardware and wiring

Starting to suspect the inverter then. Read that there would be a buzzing sound when it's broken, which sometimes comes from the LCD panel when this is happening.

New 5" needs to be ordered then..

Thanks for the help David, always a pleasure to get your insight!

-

RE: PanelDue Flashing on and offposted in Duet Hardware and wiring

If the voltage on the 4-pin PanelDue connector is fluctuating, that points to a problem either on the Duet or more likely in the cable connecting the PanelDue to the Duet. Probably a bad crimp connection.

I will take a look at the duet side tonight if I get the time.

But it only happens when the PanelDue is connected to the LCD. If I disconnect the PanelDue from the LCD is stops and just gives a nice stable 4.8-ish voltage.Thinking that perhaps the LCD is bad and messing with the voltage from its side.

-

RE: PanelDue Flashing on and offposted in Duet Hardware and wiring

Please don't mind my shaky morning hands.

This is when everything is connected, except USB.

-

RE: PanelDue Flashing on and offposted in Duet Hardware and wiring

Tested the following now.

Cable from Duet: 4.87v steady

Cable from Duet only Paneldue:- Pin directly: 4.87v

Please clarify: were those voltages measured with the LCD connected and flashing (no USB power supplied), or not? And were BOTH of them steady?

Both above, steady, voltages were without LCD connected.

I just tried checking the pins on the connector on the paneldue (where the cable is directly connected) when connected to the LCD (no USB) and it fluctuates, however it's a more

slow up and down between ca 3.5V and 4.7v. I recorded this and will link it as soon as I'm able to. -

RE: PanelDue Flashing on and offposted in Duet Hardware and wiring

Tested the following now.

Cable from Duet: 4.87v steady

Cable from Duet only Paneldue:- Pin directly: 4.87v

- 5v pin on the pins going to the LCD (LCD not connected): 4.5v

Same 5v pin above when connected to LCD: jumping between ca 3v and 4.5v (flickering)

LCD when power only from USB3.0: ca 4.3v on above pin (not flickering)

LCD when power from both duet cable and USB: 4.3 (not flickering)So something has all of the sudden started screwing with the voltage when it comes from the duet cable only.

My electronics skills are not good enough to say where though.. I see no damaged parts on the LCD.ideas? besides scrap the LCD..

m38cKecNc9nTnsZvvf6qREg

m38cKecNc9nTnsZvvf6qREg