@phaedrux i had updated to firmware 3.4.1 and left my jerk at 120 and acceleration at 500

After having trouble removing support with from prints with pressure advance turned off I turned it on and the seams the print were extremely wide.

After that print took 13 hours I decided to set both jerk and acceleration to 1000 and the seam issue seemed to mostly disappear.

Unfortunately, It didn't seem to have any other effect on the problem.

I tried to further increase jerk and acceleration with no change in the print.

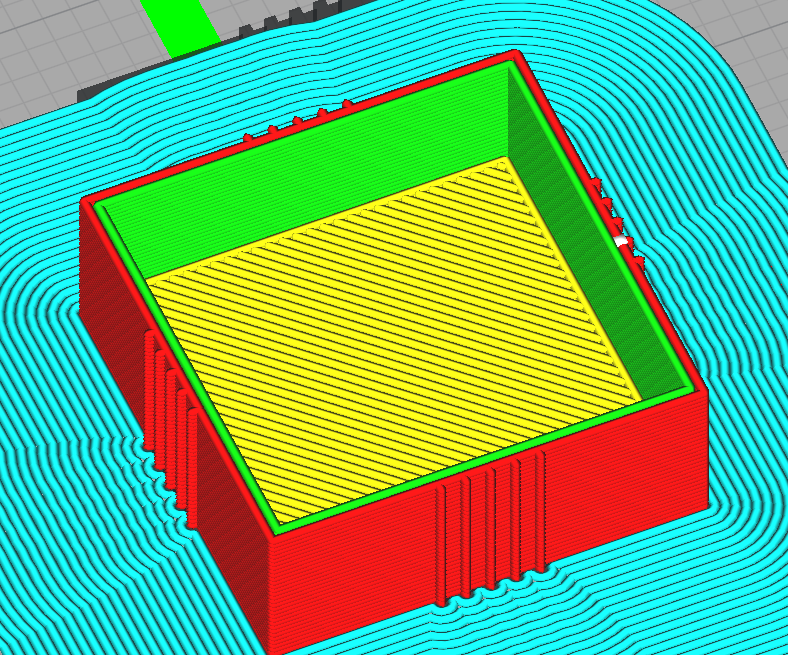

This image has one print with pressure advance off and the other one with it enabled. Both the exact same gcode.

Posts made by jim546

-

RE: Pressure advance causing reverse extrusionposted in Tuning and tweaking

-

RE: Pressure advance causing reverse extrusionposted in Tuning and tweaking

It seems that increasing (yes, increasing) the acceleration and jerk values reduces the problem for some reason.

-

RE: Pressure advance causing reverse extrusionposted in Tuning and tweaking

@phaedrux Just tested with firmware 3.3 with no change in how it prints this file.

Thanks for the suggestion

I think I'm going to try a full board reset to see if that fixes anything. If that doesn't work maybe I'll have to buy a new board. -

RE: Pressure advance causing reverse extrusionposted in Tuning and tweaking

Is it possible that something is wrong with my board? wiring? configuration?

is this problem repeatable for anyone else? -

RE: Pressure advance causing reverse extrusionposted in Tuning and tweaking

@deckingman The total / net extruder movement is negative 1mm of filament when printing testing 2.gcode.

A negative movement is expected when the printer slows down but it's also expected that when it speeds up there would be a positive extruder movement and the net movement of filament would be the same as without pressure advance. This is NOT what is happening.

The extruder is moving back as expected but is not moving back forwards when the extruder movement speeds up. This results in no filament being extruded or even net reverse extuder movement in this case.

The print works normally and has net positive filament feed when not using pressure advance.

The pressure advance of 1 was just random high value for testing to recreate the problem.

@Phaedrux I used the method here : (https://forum.duet3d.com/topic/6698/pressure-advance-calibration) to determine that .72 was the best pressure advance value. -

RE: Pressure advance causing reverse extrusionposted in Tuning and tweaking

I've revised the testing g code to get rid of the extruder priming moves and run it multiple times. Every time I run it with a pressure advance of 1 I get about a net negative 1mm of extruder movement. With no pressure advance I get a positive movement.

The results are repeatable and slowing down the acceleration or jerk does not seem to change them.

both extruders behave exactly the same.

testing 2.gcode -

RE: Pressure advance causing reverse extrusionposted in Tuning and tweaking

@dc42

This gcode recreates the problem.

new 1.gcode -

RE: Pressure advance causing reverse extrusionposted in Tuning and tweaking

@dc42

Board: Duet 2 Maestro (2Maestro)

Firmware: RepRapFirmware for Duet 2 Maestro 3.4.0 (2022-03-15) -

Pressure advance causing reverse extrusionposted in Tuning and tweaking

When using pressure advance on a model with multiple small surface details the filament retracts instead of extrudes.

disabling pressure advance solves the issue but has the expected issue of running a bowden setup with no pressure advance

I've tried lowering jerk to 50mm/m but it made no difference to the extruder movement.

the pressure advance is set to 0.72

no steps seem to be skipped as I can slow the print down to 1 percent speed and watch it slowly retract as it should be printing the small surface details.

I've been trying on and off to fix this issue for over a month so any help will be very appreciated.

Thanks

config(1).g -

RE: Occasional underextrusionposted in General Discussion

@phaedrux

I took the extruder off of the motor and reassembled it. The gear spins freely within the bearings when under load.

I've switched to the other extruder and haven't noticed it yet but I haven't had time to tried to try and cause it yet. -

RE: Occasional underextrusionposted in General Discussion

@phaedrux What am I looking for in the bearings? The gear seems to be solidly mounted with no way for the teeth to skip or for the gear to move around.

I'm going to try to print the model on the second extruder to see if it does the same thing.

-

RE: Occasional underextrusionposted in General Discussion

I've created a model that recreates the issue

When the extruder goes over the small surface details the filament retracts more than it extrudes. When I first saw this I thought it was a cut and dry case of skipping steps. I lowered the jerk and acceleration more and more until I could watch it accelerate slowly but it was still doing the same thing.

video link here.

extrusion_Trim.mp4

The ptfe tube is separated from the top of the extruder so I could more easily see how far its retracting.

I checked the gcode to make sure there were no problems there and printed the model with pressure advance disabled. I also reset the acceleration and jerk. The model printed normally but with the expected problems from no pressure advance. -

RE: Occasional underextrusionposted in General Discussion

@jumpedwithbothfeet

It does do it with different filaments. I'll need to see if I can recreate it intentionally. and see if its consistent is some spots or random.

thanks -

Occasional underextrusionposted in General Discussion

This seems to happen mostly around more detailed areas and I suspected that it might have to do with the acceleration due to pressure advance. I lowered the extruder's acceleration and jerk with no change. I have also increased the amperage of the extruder motors from 800 to 1000 to 1400mA with the problem still seeming to appear at the same rate.

The extruder is an E3D titan in a flying extruder configuration with an ~180mm bowden tube to an E3D chimera with a .35mm nozzle.

This problem causes significant issue with the strength of functional parts.

Here is the config.g: config.g

Thanks -

RE: intermittent connection with LIS3DH accelerometerposted in Duet Hardware and wiring

I re wired the connector using the twisted pairs as if I was using a usb3 cable and it seems to be working so far.

I probably should document that the the first half of the cable is cat 6a and the second half is cat 7.

Thanks for the help. -

intermittent connection with LIS3DH accelerometerposted in Duet Hardware and wiring

I've connected an LIS3DH to a duet Maestro running RepRapFirmware for Duet 2 Maestro version 3.3 (2021-06-15 21:47:01). When M955 P0 C"twd0+twck0" is sent about a quarter of the time it responds: Error: M955: Accelerometer not found on specified port.

Most of the time it sends:

M955 P0 C"twd0+twck0"

Accelerometer 0 with orientation 20 samples at 1344Hz with 10-bit resolution

After the accelerometer is connected, about half the time when an m956 command is run the printer soft resets.

I checked the wiring for the int pin with a multi meter to verify it was connected to the proper location and had a stable connection.

The wire is about 2.5 meters of cat 6 connected with DuPont connectors.

m122.txt