@phaedrux yes we tried. I'm just reading through the M584 gcode in the Duet3d Docs. I think we applied the P parameter incorrectly. We'll have to take a closer look at that.

Thank you very much for your hint!

@phaedrux yes we tried. I'm just reading through the M584 gcode in the Duet3d Docs. I think we applied the P parameter incorrectly. We'll have to take a closer look at that.

Thank you very much for your hint!

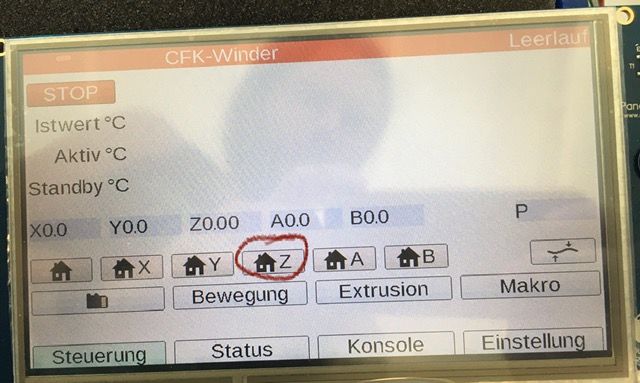

@Phaedrux So, the P4 can't solve our problem. The Z-axis is still on the PanelDue. Doesn't matter how we use the M584.

Finished!  We solved our Problem with the Homing. The Problem was the Wire of the Stepper. We had to shield them. Now the Homing does its Job as well!

We solved our Problem with the Homing. The Problem was the Wire of the Stepper. We had to shield them. Now the Homing does its Job as well!

Thanks for all your ideas and help!!

@phaedrux yes we tried. I'm just reading through the M584 gcode in the Duet3d Docs. I think we applied the P parameter incorrectly. We'll have to take a closer look at that.

Thank you very much for your hint!

@o_lampe Hm, well I din't think so. Cause the Y-axis Stepper also have a Gearbox. (the same) And there is no problem with the homing.

...here is a further problem with the Duet3D PanelDue 7i that we don't understand to solve:

https://forum.duet3d.com/topic/24040/delete-y-axis?_=1658297009772

Many thanks!!!

@spoonunit Yes, the Endstop of the B-axis is at a physical switch. Not really, the B-axis should only turn back and forth a few degrees during operation.

@3dpmicro Now, as you can see in the next picture, there isn't much torque on the B-axis for skipping a step. Of course, the stepper motor could also be defective. But we're not assuming that for now. Yes, the error repeats itself. First homing after restarting the machine works. If you press homing again, the axis moves by 3-4 degrees. And that every time you continue to press homing. Really strange...

Yes, we have already thought of another host, but unfortunately this project will be over for us at the end of July, so there is no time for a new host

The B axis can rotate a maximum of 340 degree. In operation it should (depending on the direction of travel of the x-axis) only ever move back and forth by a few degrees. It only controls that the filament is wound onto the cylinder (A axis) in a defined position.

Here's another picture with a caption. (in purple you can see the way of the filament)

Thank you for the reply

@dc42 Hi, we want to deactivate the Z-axis in the web control AND on the paneldue 7i. Cause we only use X, Y as linear and Y, B as rotatary. (CNC Mode)

As you can see in the config.g, we deactivate the z-axis with:

M18 Z

I don't know if this ist the right way, what did you mean?

config.g

Thank you for an answer!

Here is more info about our machine... (solved at 28.07.2022)

https://forum.duet3d.com/topic/29114/control-4-axis-cnc-machine

@3dpmicro Sorry for the late reply, something went wrong. My answer was not published a week ago and I was wondering why no email came about it.

So now again.

Thank you, yes that is really an exciting topic that we have here. I'll ask our professor if that's possible

We have another problem. The B-axis (a rotation axis, which the cfk-filament runs along to the cylinder) can only be homed once. With further homing, the axis is misaligned more and more. Homing only works as it should after a reset.

Any idea why that might be?

The B-axis gcode is the same as for the other axes where homing always works.

Furthermore, we would like to see in a live script on the duet paneldue (display) in which line of gcode the machine is currently working. Does anyone have a solution as to how or which gcode is used to solve this?

Thanks again for your answers

...I am attaching the gcodes here...

config.g

homea.g

homeb.g

homex.g

homey.g

homez.g

homeall.g

@3dpmicro Right, filament winding. Ah ok, so step/unit means it doesn't matter if I choose step/mm or step/degree!?

Well, the gcode is created by "x-winder design" software. But for the first, we have our own gcode to to adjust the config.g file for reprap 3.3.Once all settings are fine, we let "x-winder design" create the gcode for the winding.

Thx for your answering!