Hi everyone!

Some people may remember the SwissMak project from like 5 years ago. This is the culmination of that project.

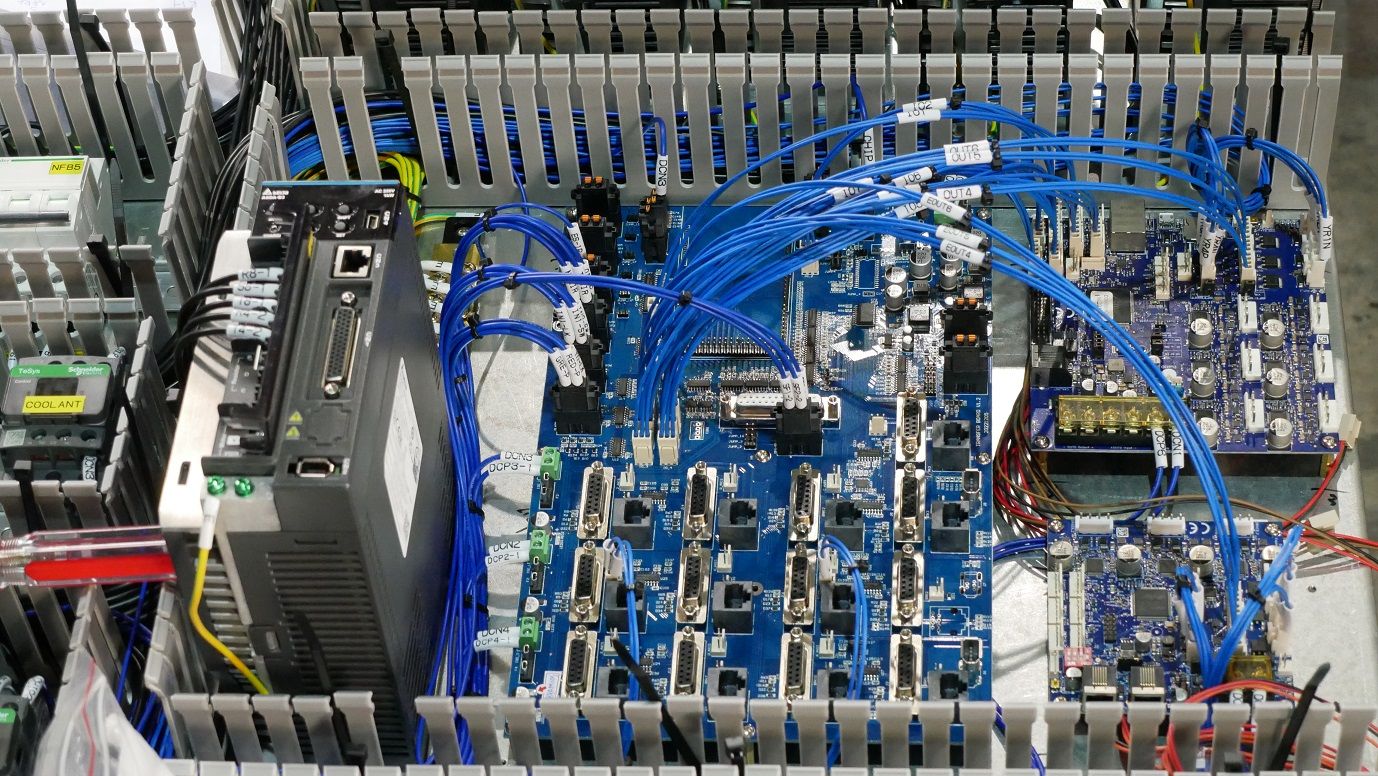

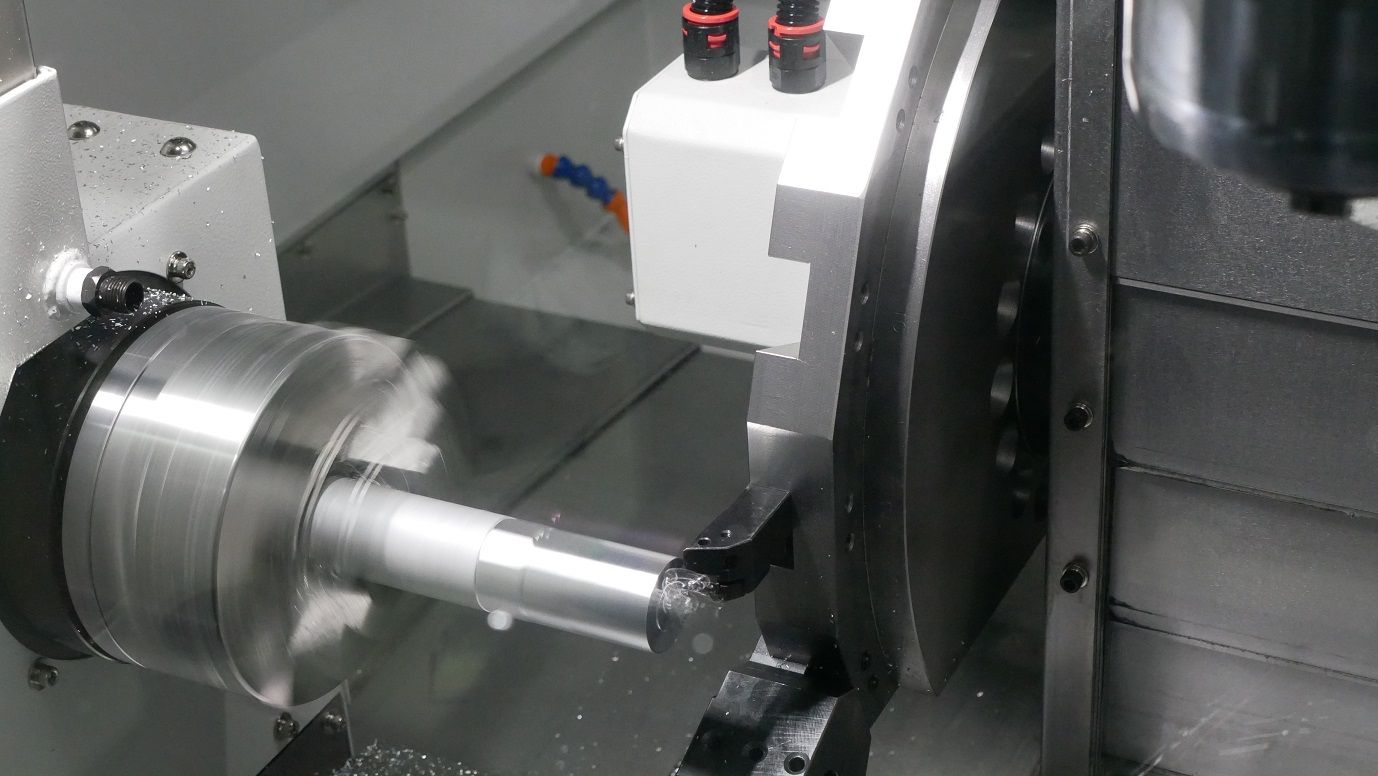

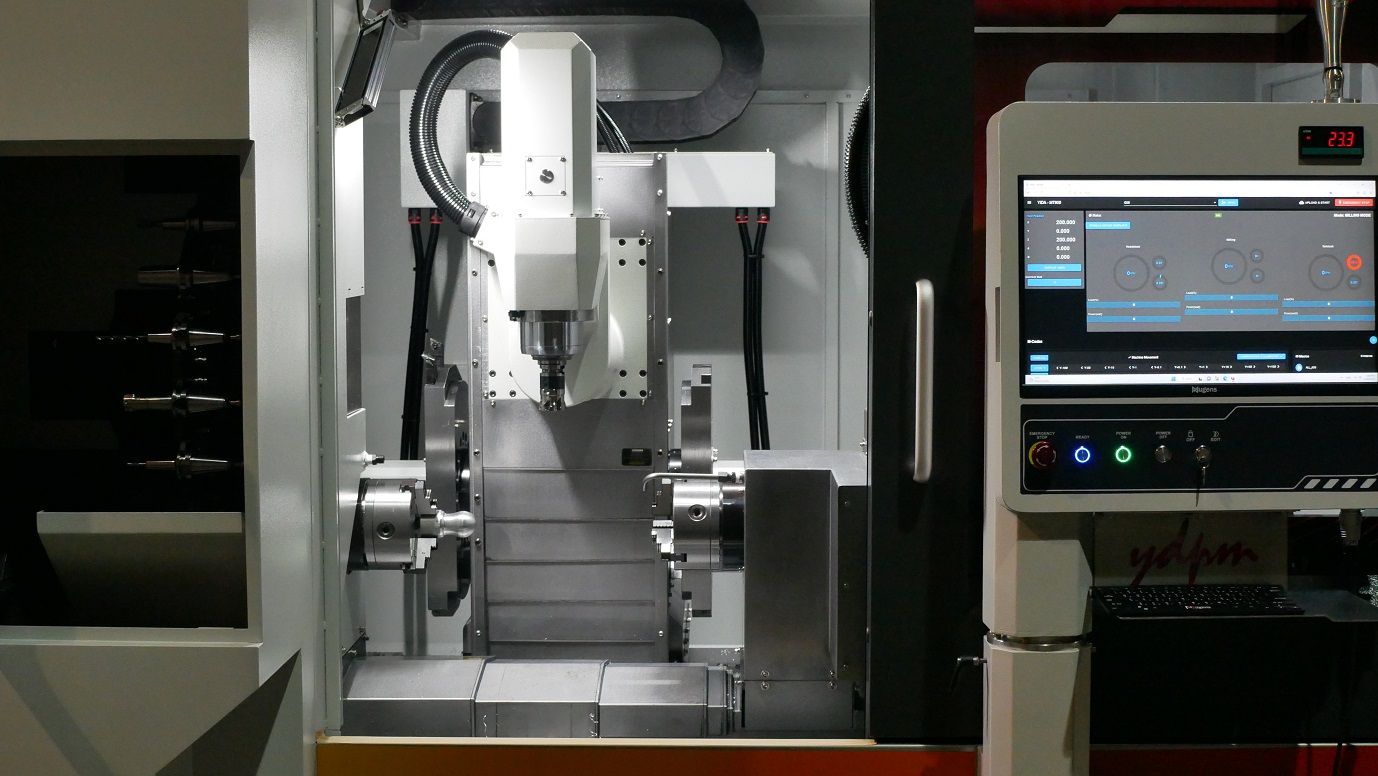

It's a 12 servo, 8 axis mill turn machining center that runs on the Duet 3 with an expansion board and a custom transfer board we made that allows the Duet to control full sized industrial AC servos.

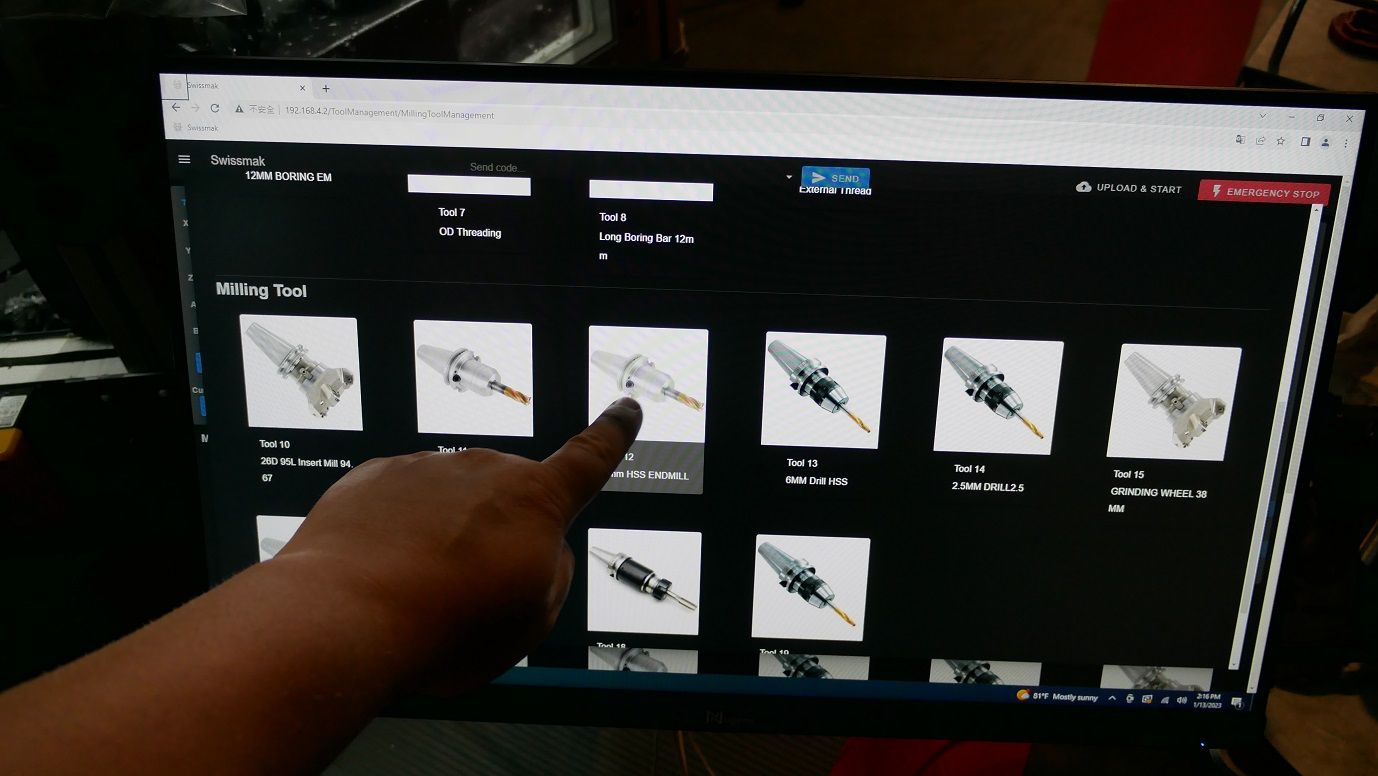

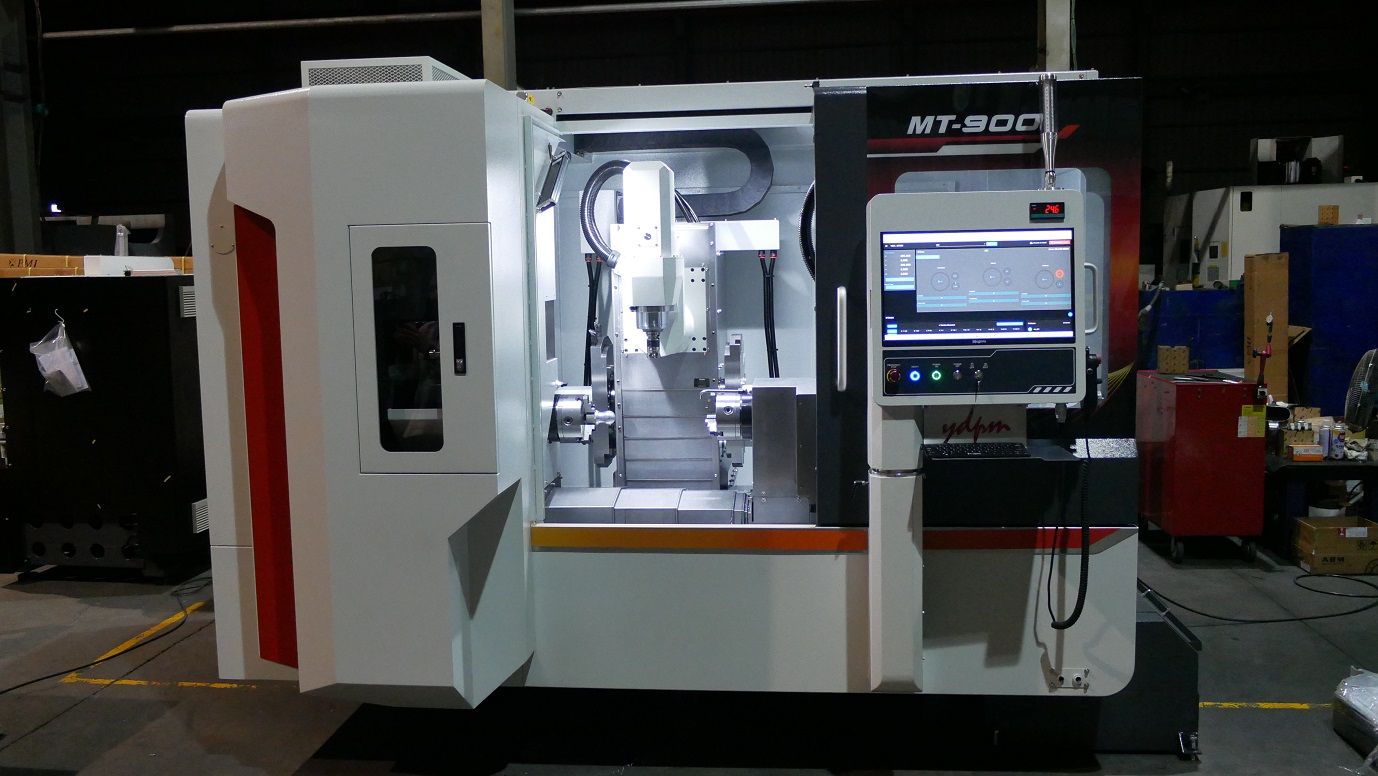

I have a lot of photos and videos but the file size limit of 4 mb here prevents the cool GIFs from being uploaded. I'll be posting content to YouTube and my website in the future. I'm not trying to advertise this machine here because it's prohibitively expensive for hobbyists and 3d printer people. My original goal of building super low cost machines never panned out, rather than producing a 4-5 thousand dollar mill turn for hobby level machining with stepper motors, we ended up building a $25,000 machine for job shops and companies that do prototyping which we call the MT-210, and the photos above are of the newest model, the MT-900. Both the MT-210 and MT-900 run on the Duet 3 board with an expansion board (they need like 10-12 servos!). We have heavily modified the RepRap firmware and the DWC to run Gcode from CAM software intended for CNC machines. I would like to contribute to the open source side by merging our additional G-codes and M-codes and the system we designed that allows the DWC to take feedback from the servo drivers and display it on the DWC menu in real time. We also need to update to 3.5 firmware because the 3.3 firmware has some bugs that negatively affect us. Our attempt at branching the RepRap/DWC code bases have been messy and inefficient, but we do have a working, functional system.

We built two of these for the TIMTOS machine tool trade show which is coming up on March 6-11 of 2023. We have entered this in a competition for most innovative machine, and the big thing we're emphasizing is the Duet 3 control based system. Since the CNC manufacturers aren't used to seeing 3d printer controllers running full sizes CNC machines, we should stand out a bit. I'll post here with the results after next week, hopefully we win!

I think this is probably the most complex and expensive machine to be built with the Duet boards. My biggest long running concern is that every time we update the RepRap firmware, we have to re-integrate all our custom CNC code and debug. 3.5 firmware is very different so we are going to have to spend a ton of time redoing it. We really need some of the new features, especially things that make 5 axis programs run better, and other CNC specific processes that we haven't programmed yet.