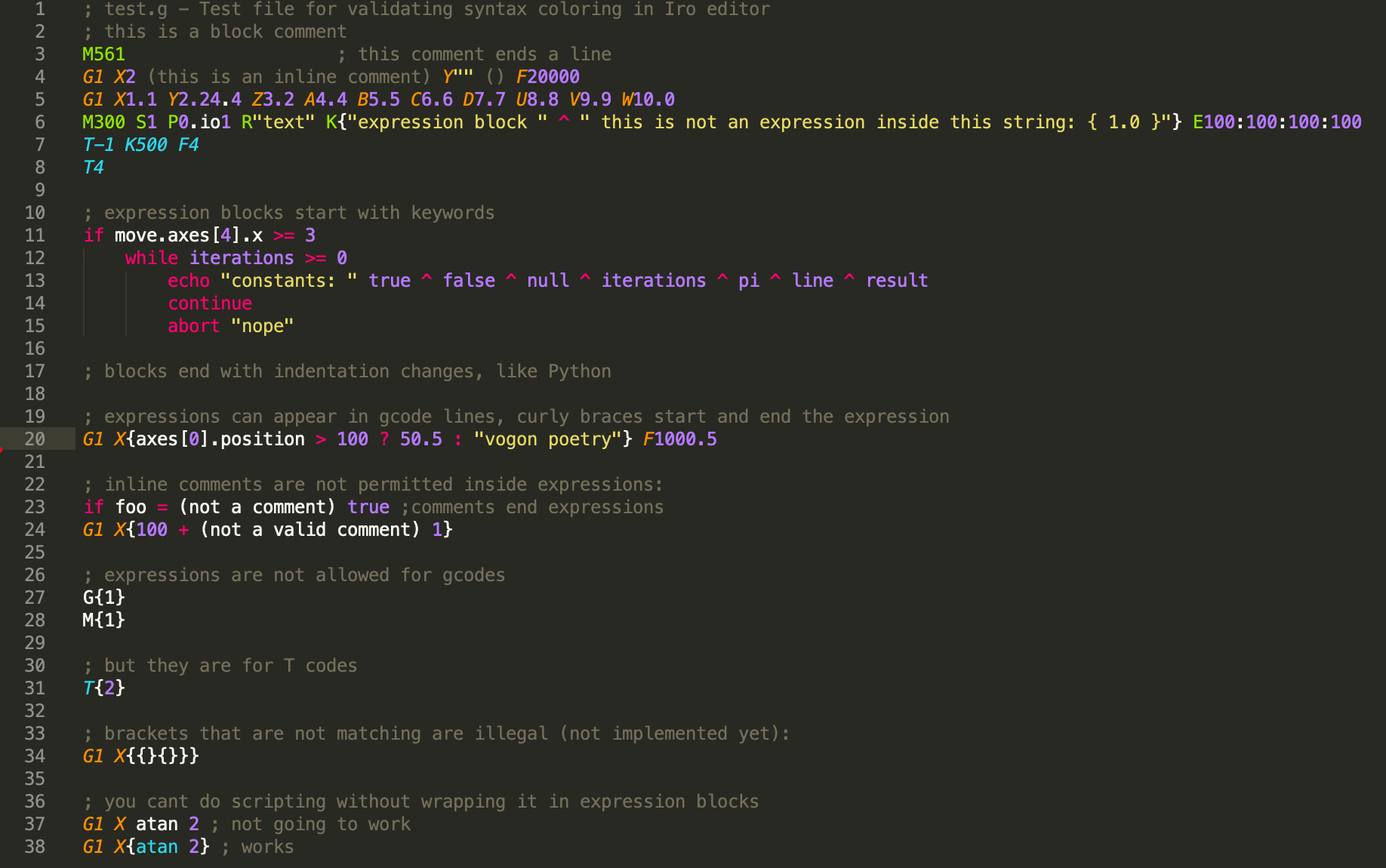

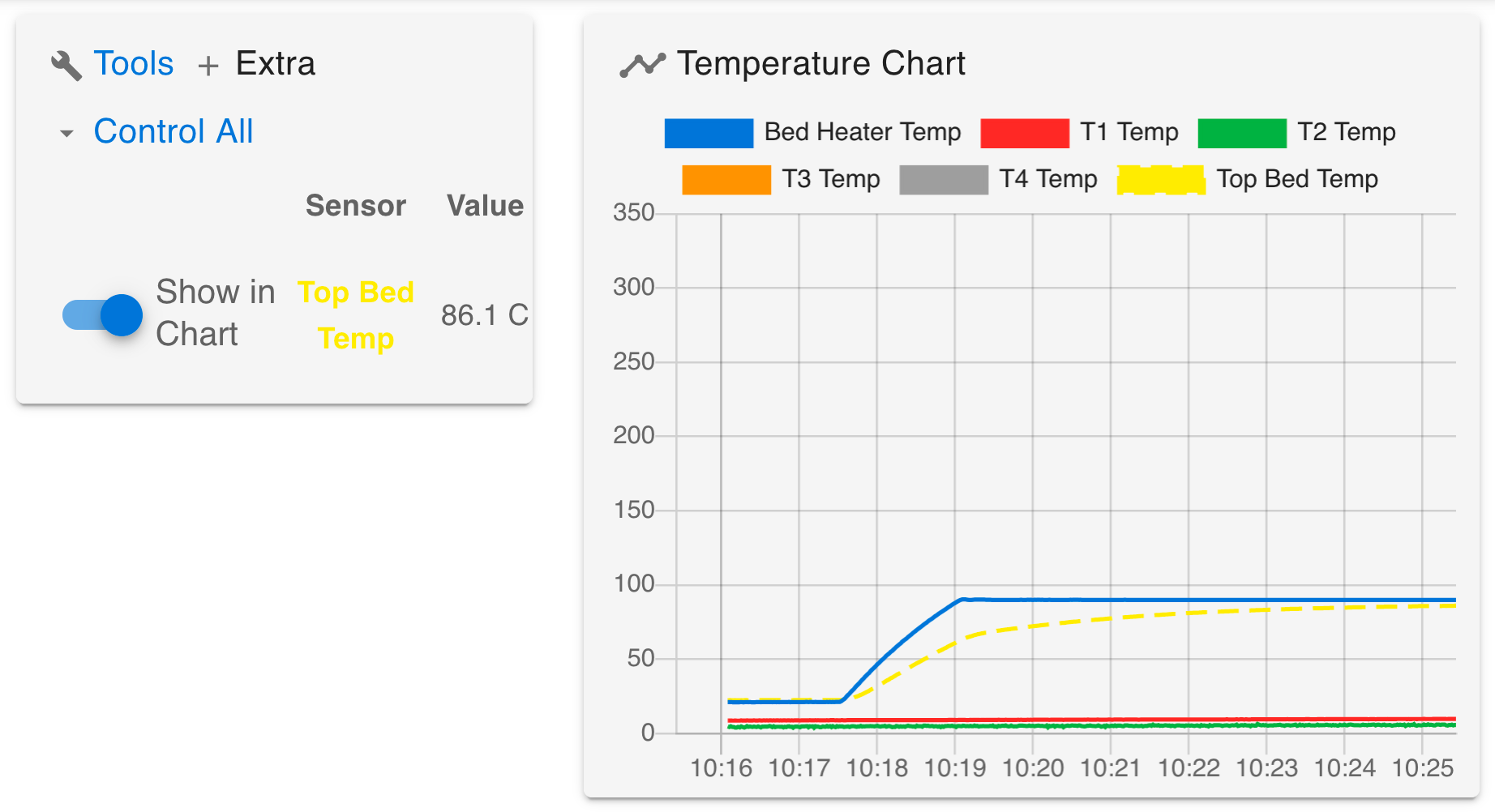

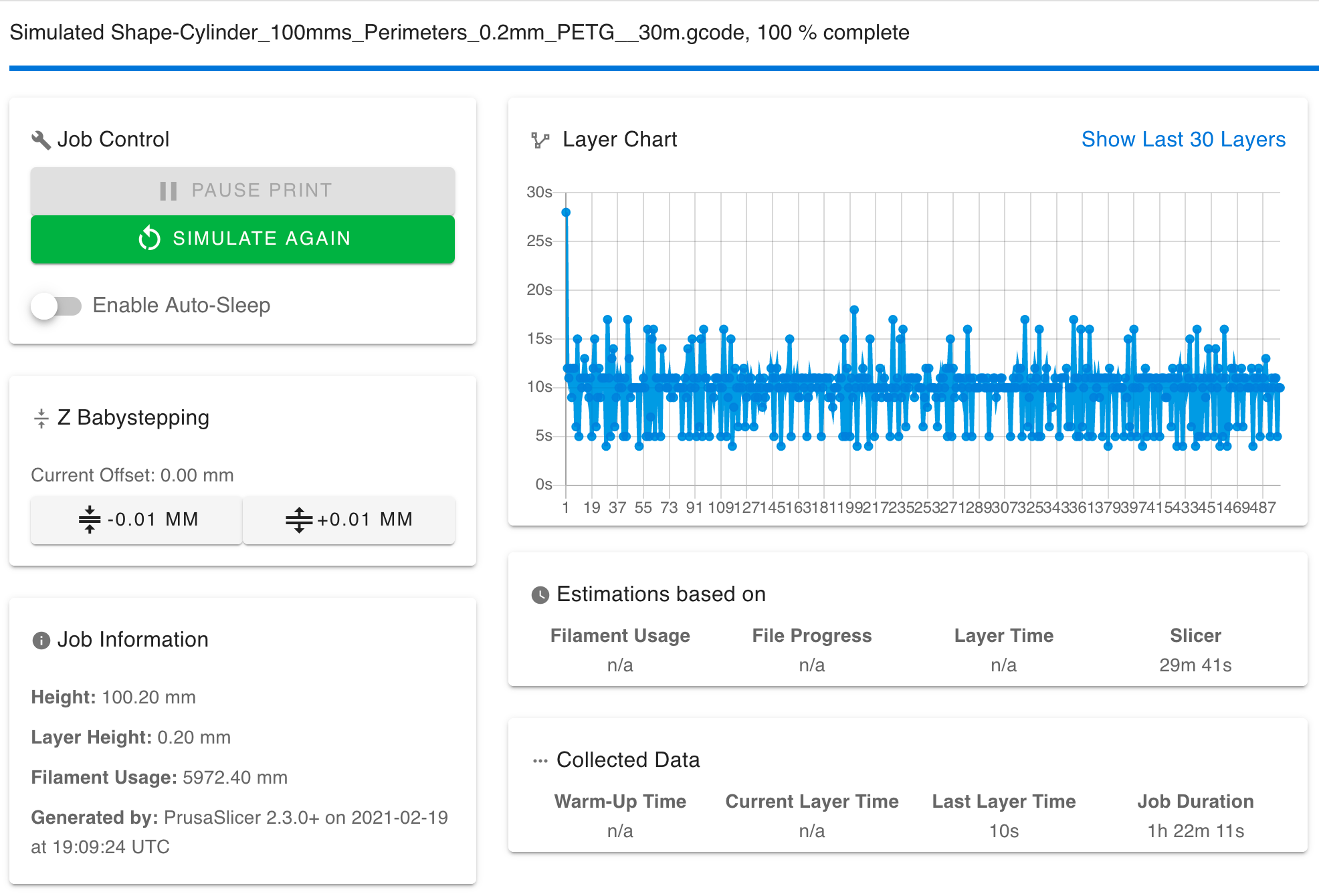

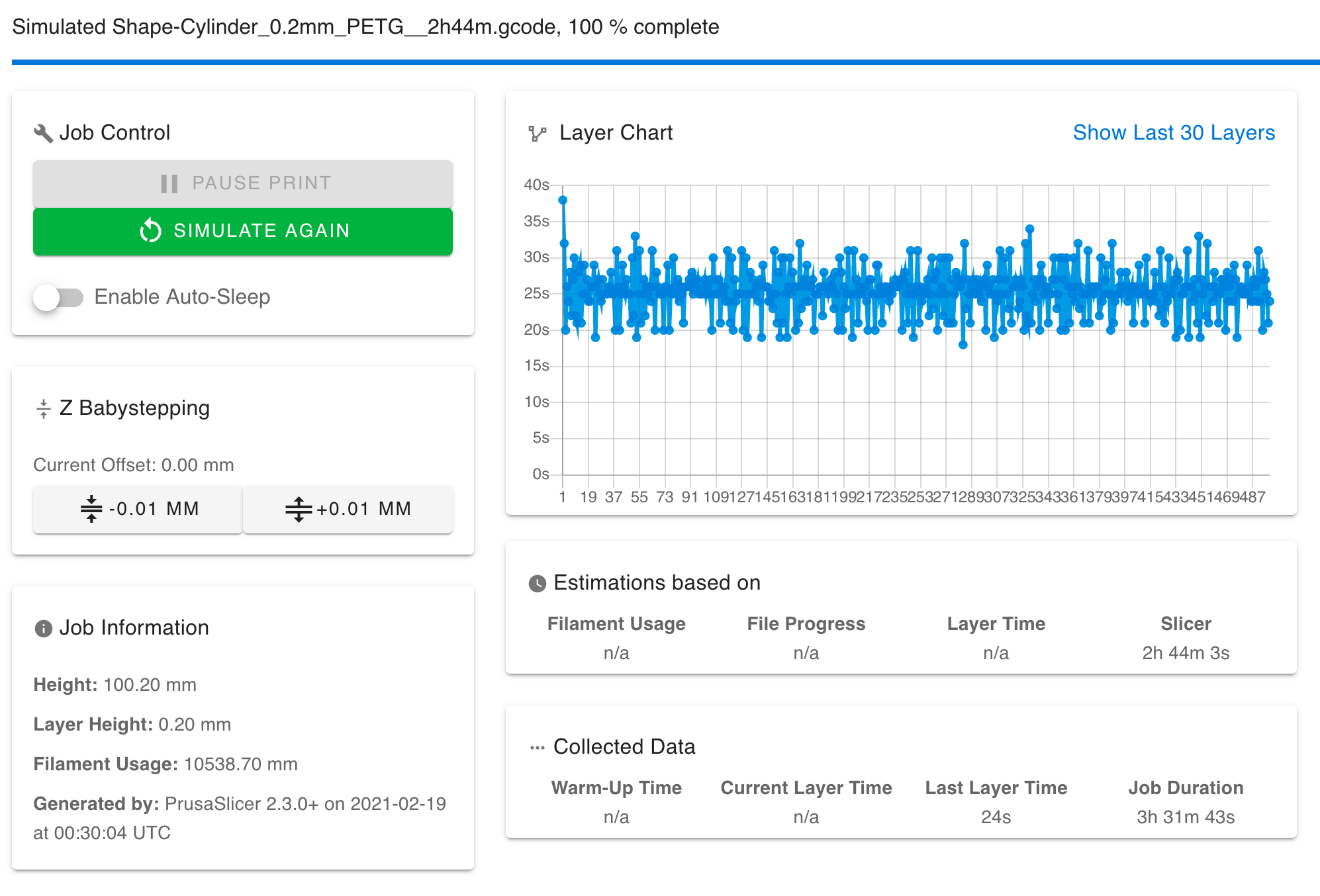

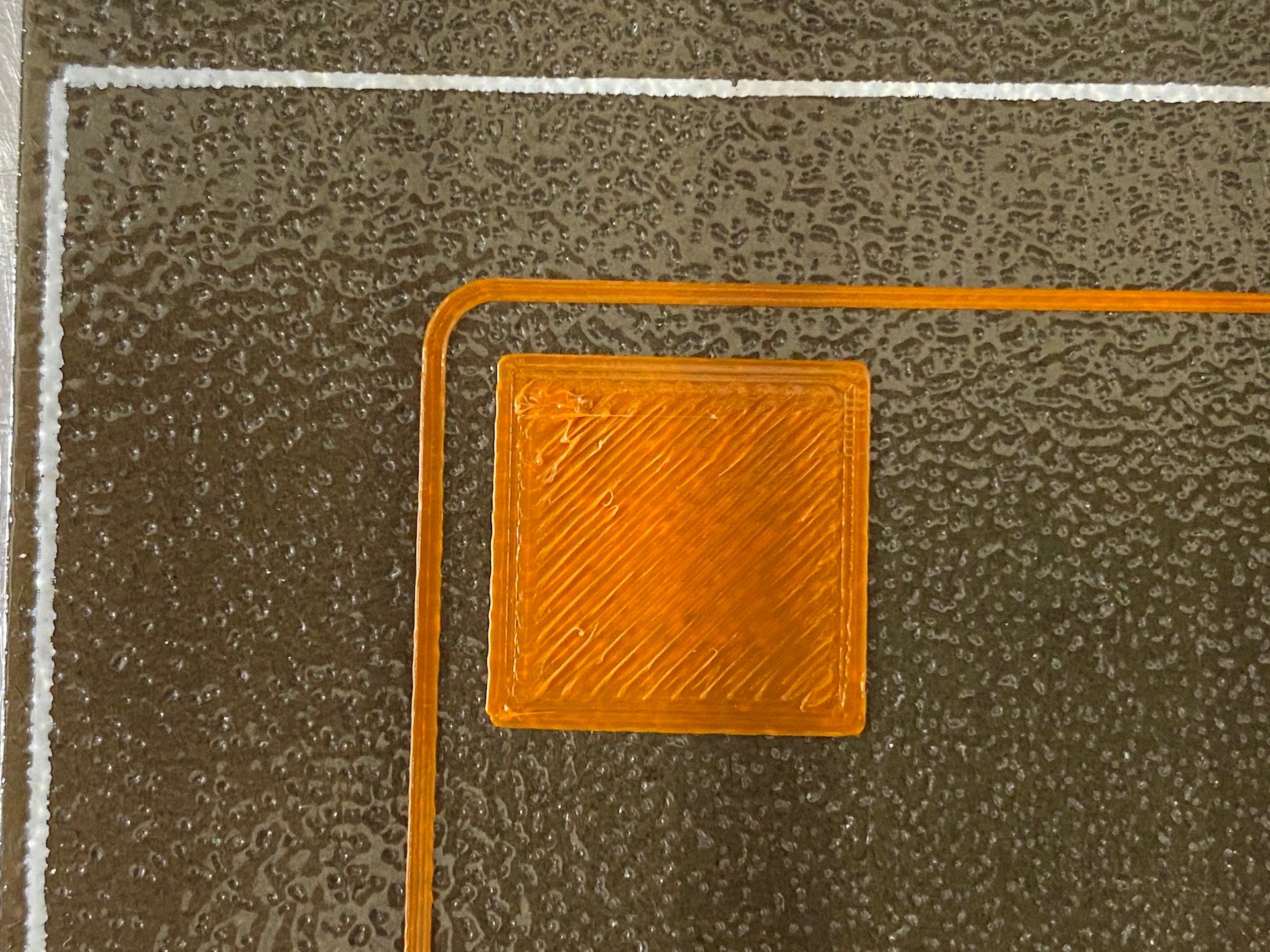

For my E3D Tool Changer I want to have a magnetic bed with swapable build plates. A somewhat surprising roadblock has been using an inductive probe on this bed with G29. With a high enough mesh density its inevitable that the probe samples the magnets and returns a false result:

With some GCode meta commands, execonmcode, an attached SBC and Python we can build an accurate heightmap from a set of probe points that miss all of the magnets:

Source Code

I've put everything into a project on github: rrf-mesh-level so you can do this too.

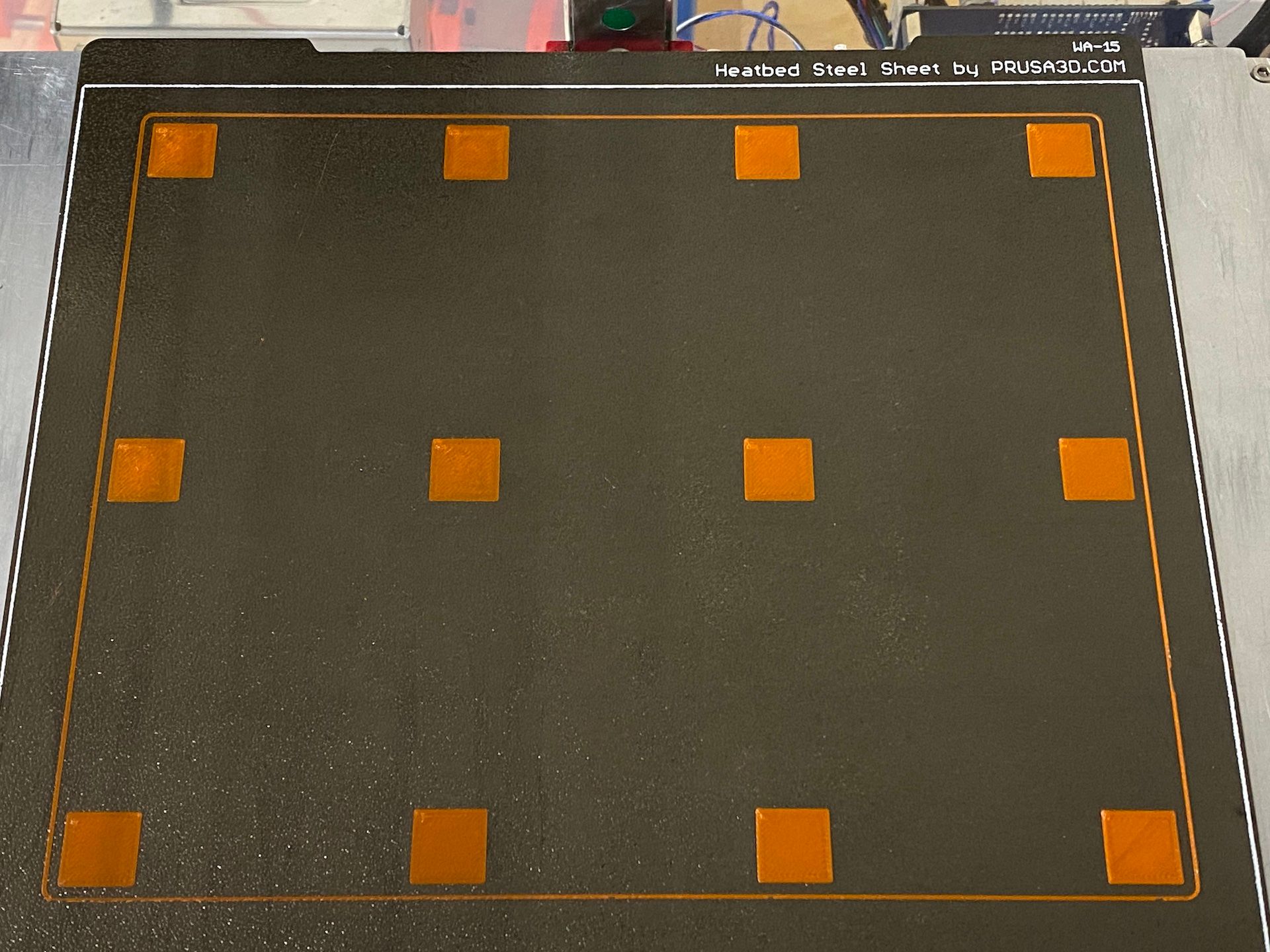

Results

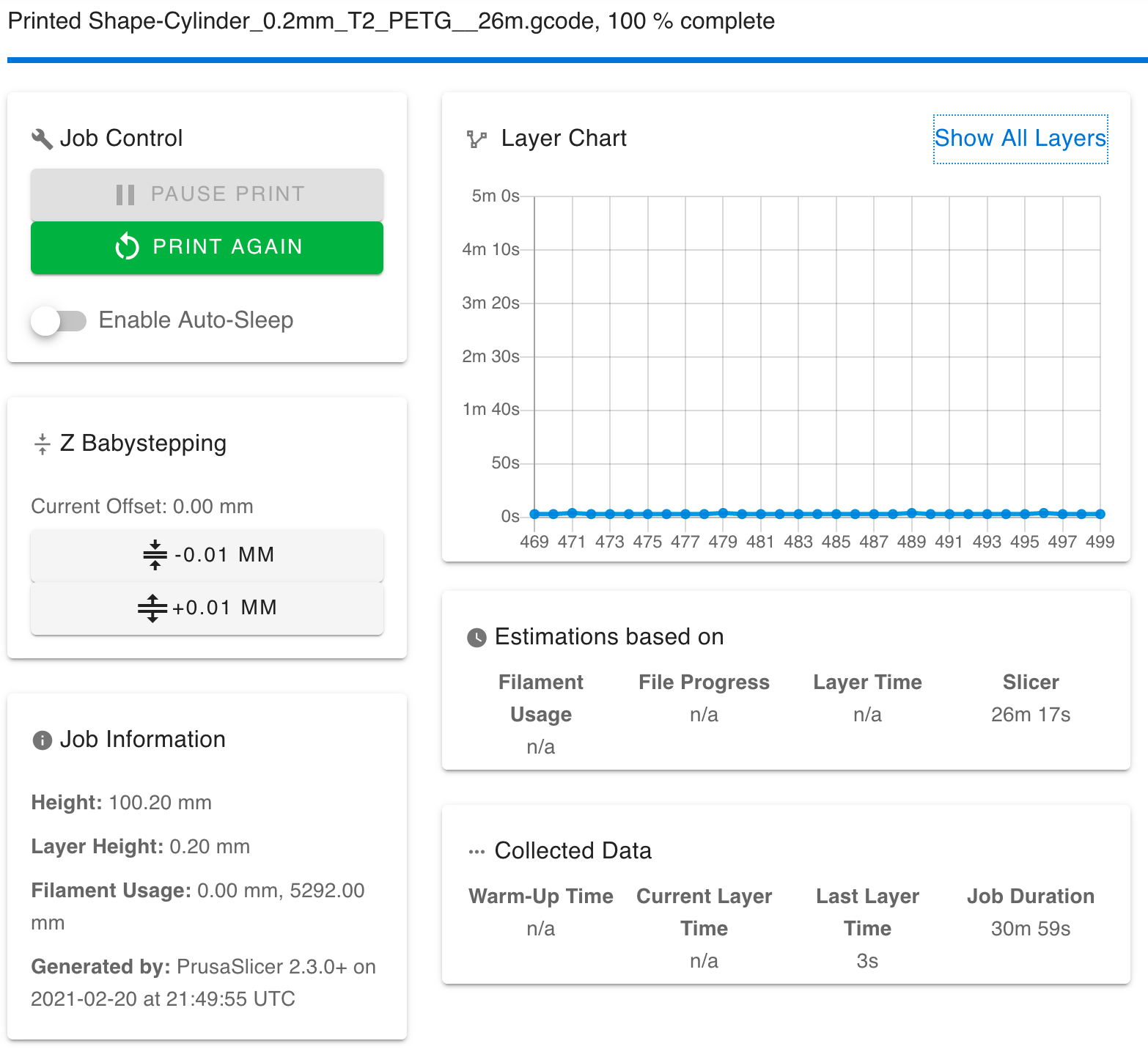

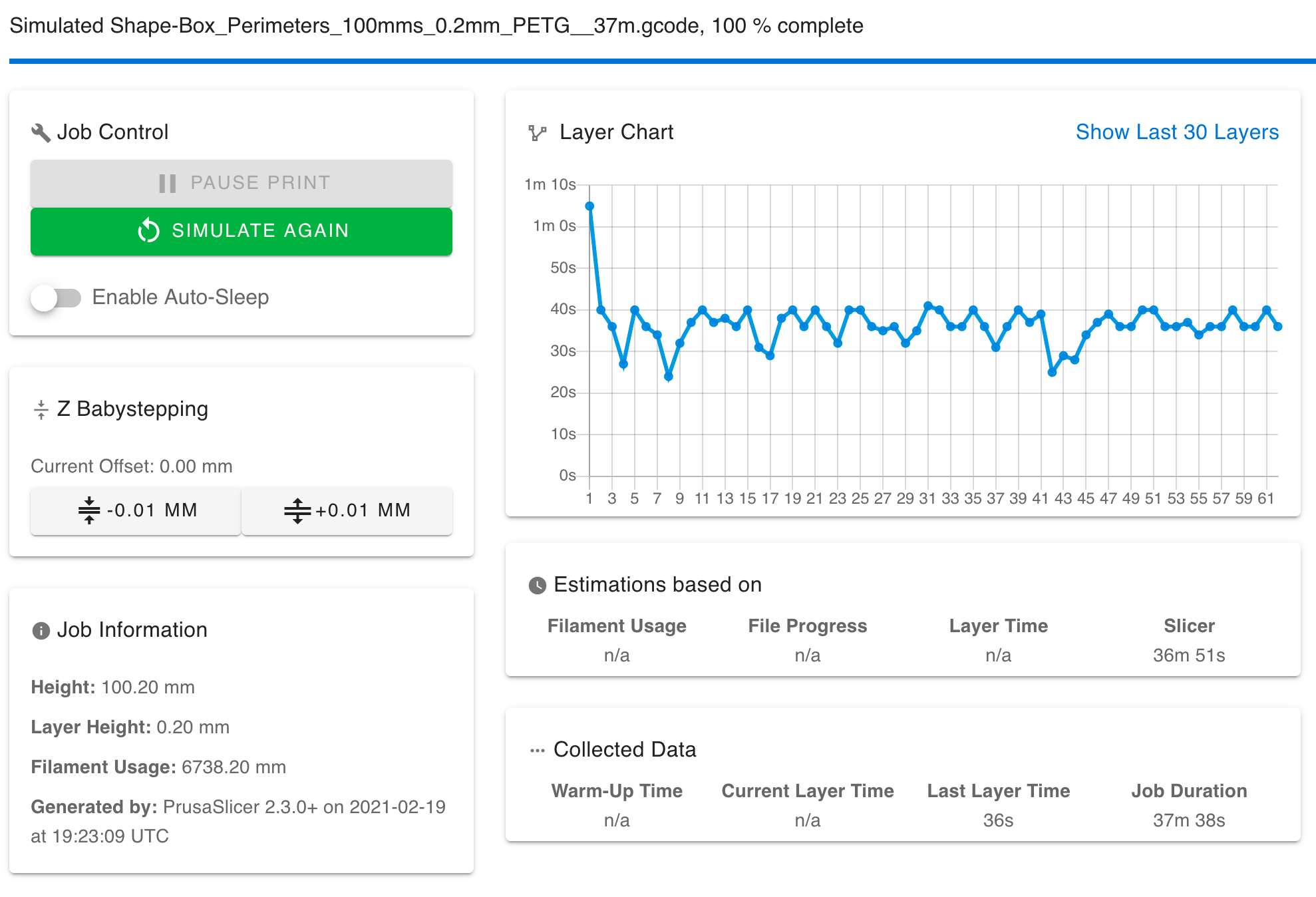

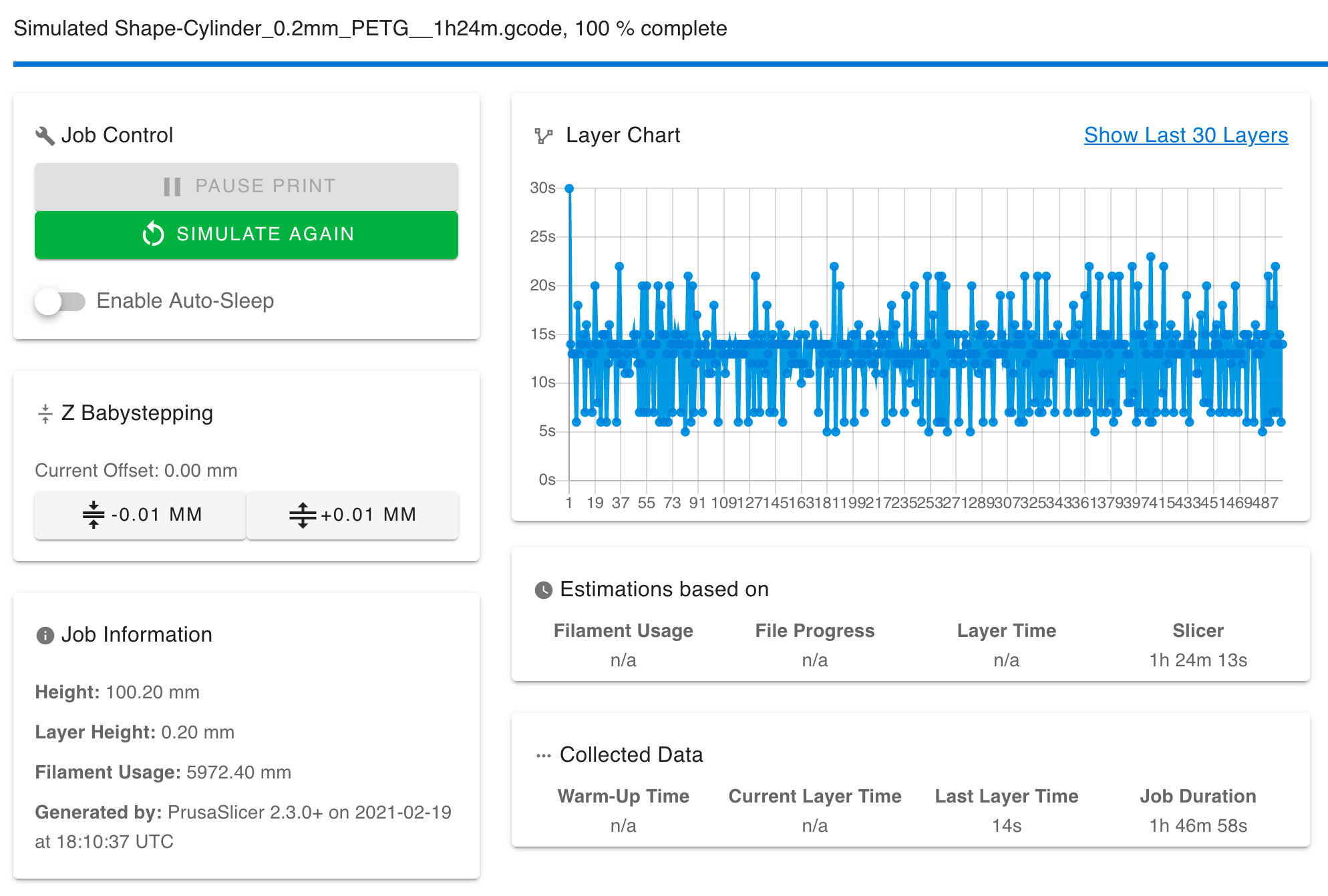

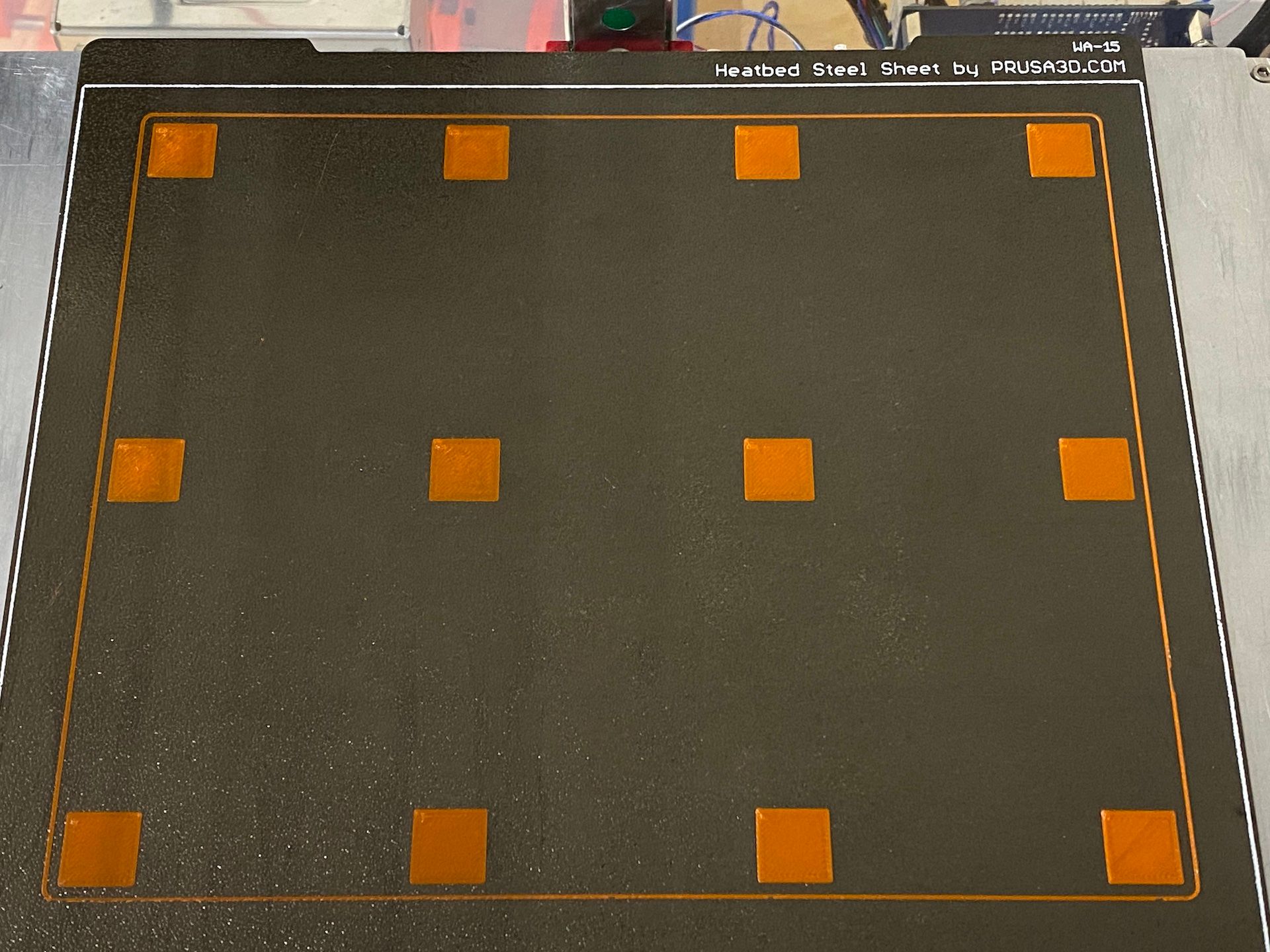

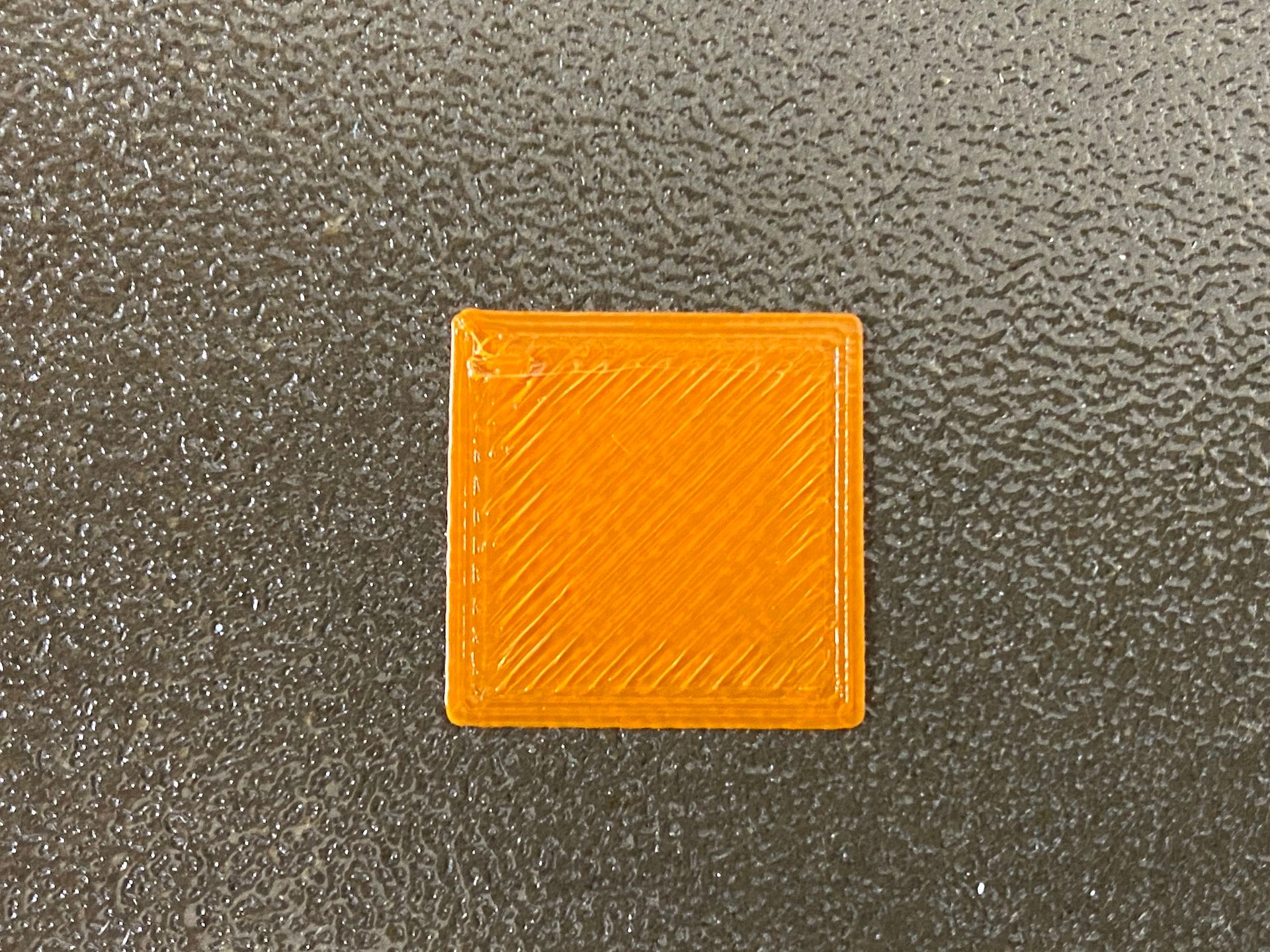

Before I talk about how its done lets see how it prints. The best build plate that I have is the Prusa textured sheet so that's what I'm testing on:

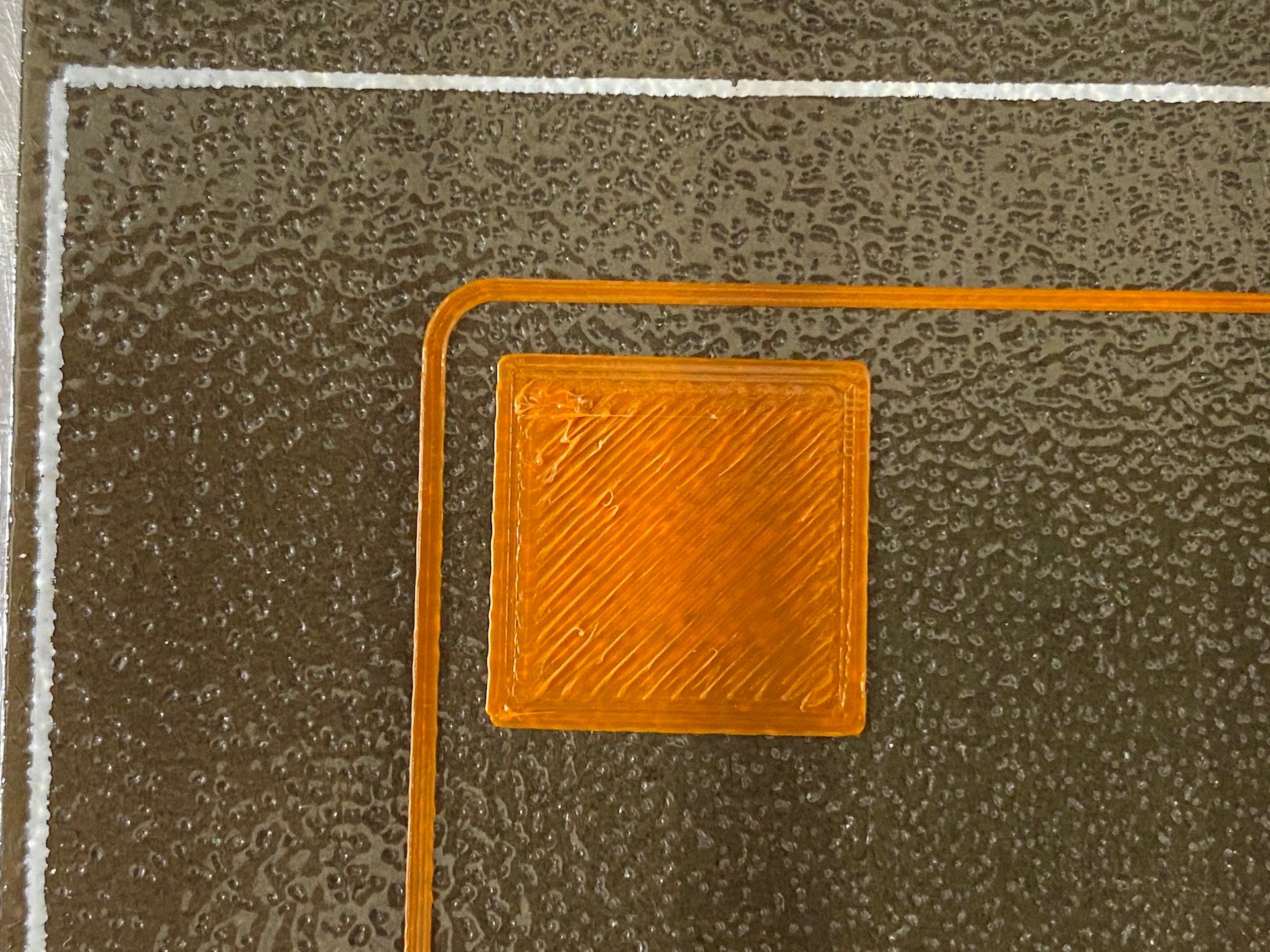

The lowest square (some over extrusion is present):

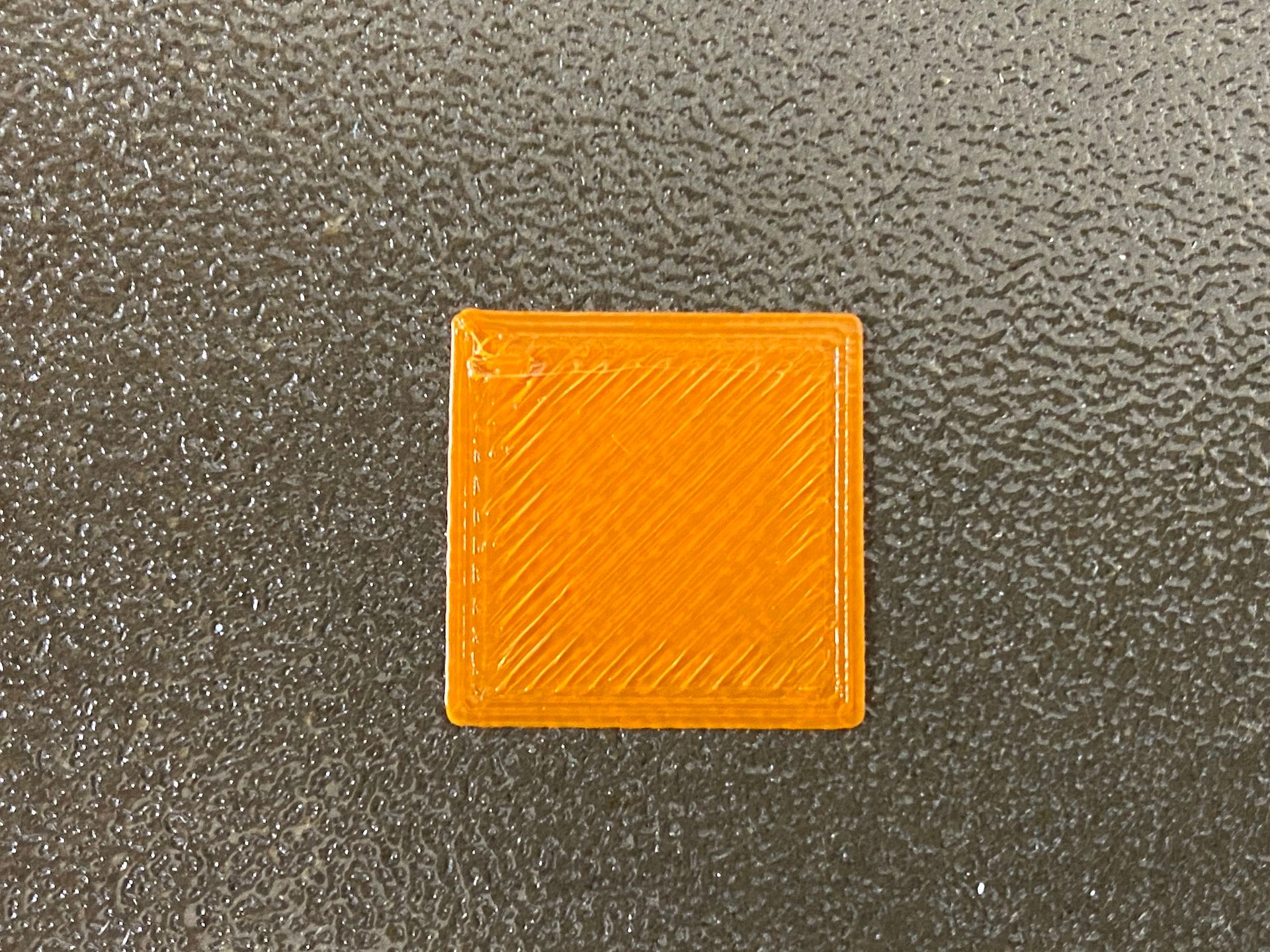

An average square:

The highest square (some under extrusion is present):

I could nitpick but I think you see the technique works.

How?

The process goes like this:

- Probe the bed and log the probed points to the SD card

- Use execonmcode to invoke mesh-level.py with the log file and bed shape

- mesh-level.py uses Python/SciPy to processes the probe data with some cool math and produce a heightmap.csv file

- Profit!

Step 1 - Probing

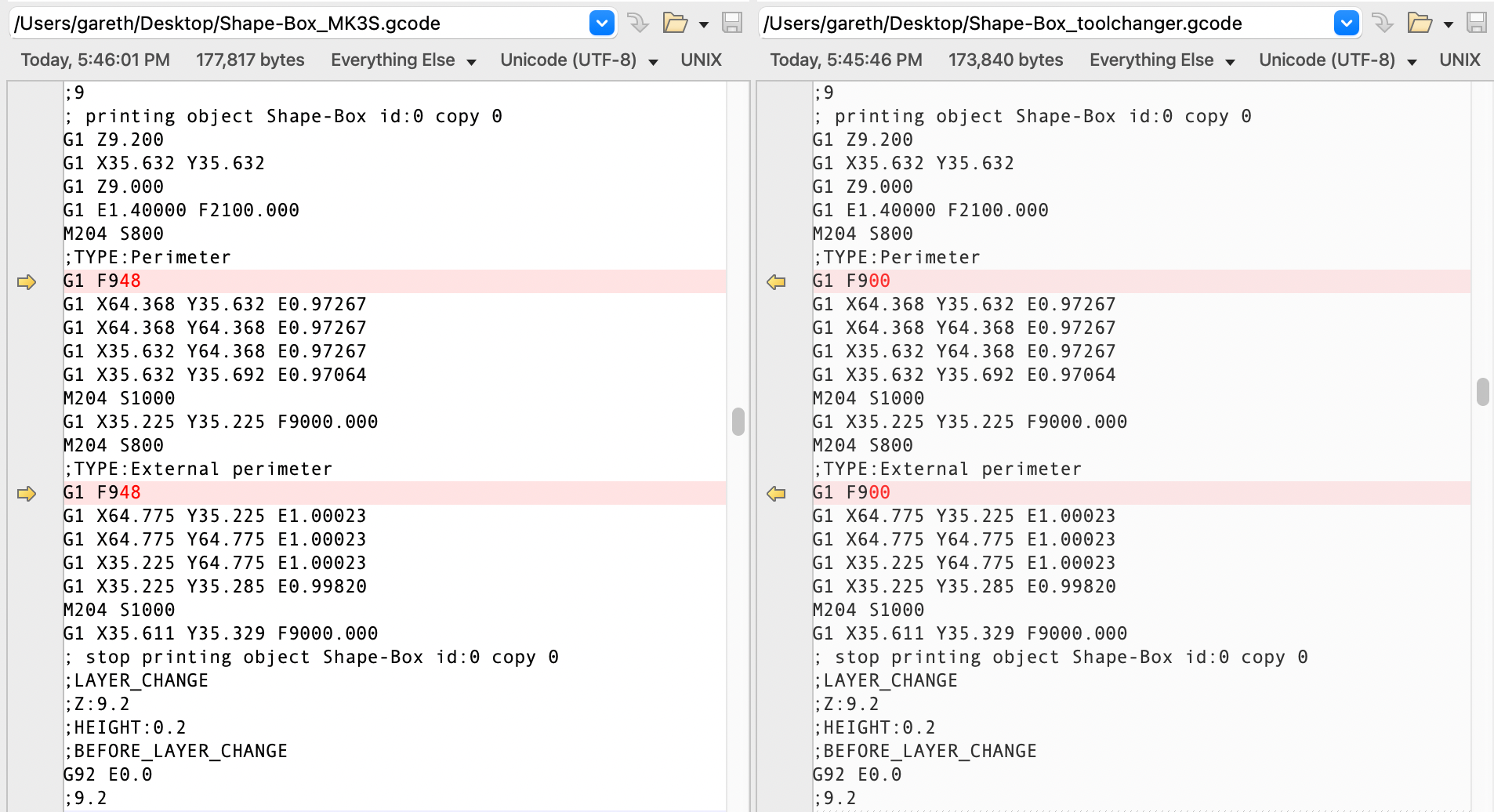

You will need to work out what X/Y points you want to probe your bed at. I used a CAD model of my bed to measure X/Y probing locations from machine 0,0. Then I used a Python script to generate the GCode for probing each point. This takes the sensor offset and sensor travel speed into account. My bed.g file contains all the probe points that were generated. This is the truncated version:

; delete any previous log file so previously probed points don't get sampled

M30 "/sys/meshbedprobe.log"

; start INFO logging to the SD card

M929 S2 P"/sys/meshbedprobe.log"

; probe bed points by moving to each X/Y coordinate and then calling the point probe script

; Probing row #1, Direction: ->

G1 X{32.353 - sensors.probes[0].offsets[0]} Y{-11.0 - sensors.probes[0].offsets[1]} F{sensors.probes[0].travelSpeed * 60}

M98 P"/sys/probe-point.g"

; ... many, many more points get probed

; stop logging

M929 S0

The probe-point.g macro is where the actual probing of individual points happens. It uses a loop and G30 S-1 to probe the location and M118 to write the results of each probing to the open log file. You don't have to copy this, any macro that writes the same Mesh Point: Xn Yn Zn format will work with the python script. The resulting log file looks like this:

2021-01-24 12:26:58 Mesh Point: X32.355 Y-11.000 Z-0.254

2021-01-24 12:26:59 Mesh Point: X32.355 Y-11.000 Z-0.254

2021-01-24 12:26:59 Mesh Point: X67.030 Y-11.000 Z-0.313

2021-01-24 12:27:00 Mesh Point: X67.030 Y-11.000 Z-0.314

Step 2: Calling Python with execonmcode

Using the excellent execonmcode utility we invoke the mesh-level.py script using a custom MCode M7029 from inside bed.g:

; call the custom MCode to create the heightmap.csv file, all params must be passed as strings

M7029 X"0:300" Y"0:200"

The parameters here are the same as X, Y from M557

The script supports a lot more parameters besides these, the file names, point spacing etc. can be customized if desired.

Building the heightmap.csv

mesh-level.py uses something called Radial Basis Functions (RBF) to compute an interpolated surface from your probe point data. The surface is a high quality representation of the bed shape where the surface passes through all of your probe points (no smoothing is performed). The more points your probe, the better that representation is going to be.

RBF has some characteristics that make it very useful in this application:

- It can work with scattered X/Y input points, they don't need to be in anything like a regular pattern

- It can extrapolate beyond the bounds (convex hull) of the probed points. This solves the problem of not being able to probe right at the edge of the bed and allows the final heightmap to cover the entire printable area

- It can be up-sampled. The final heightmap point density can be higher than the sample density! This leaves the liner interpolation code in RRF with less guessing to do and better encodes curves in the bed surface. The script automatically tries to use up as much of the 441 points that RRF allows.