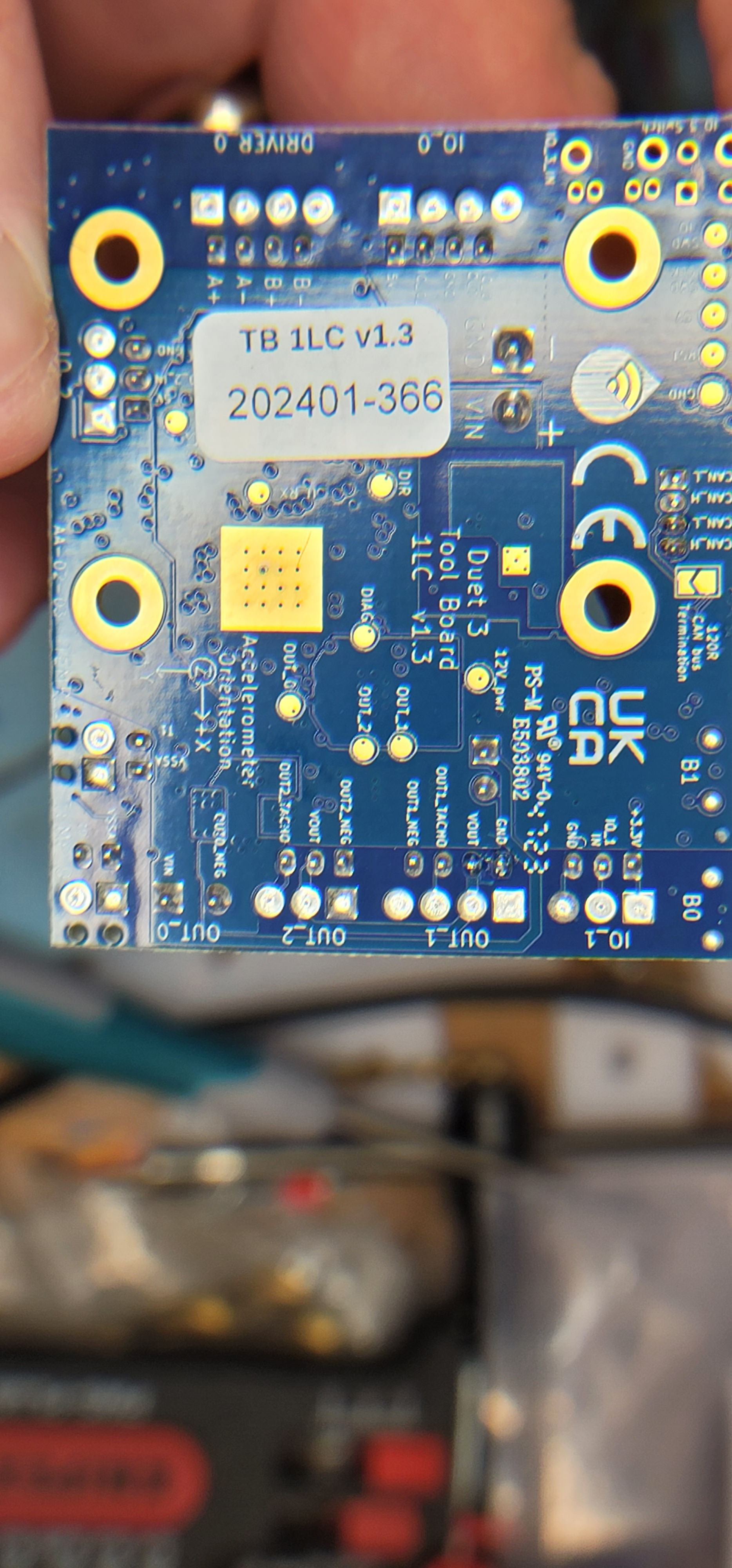

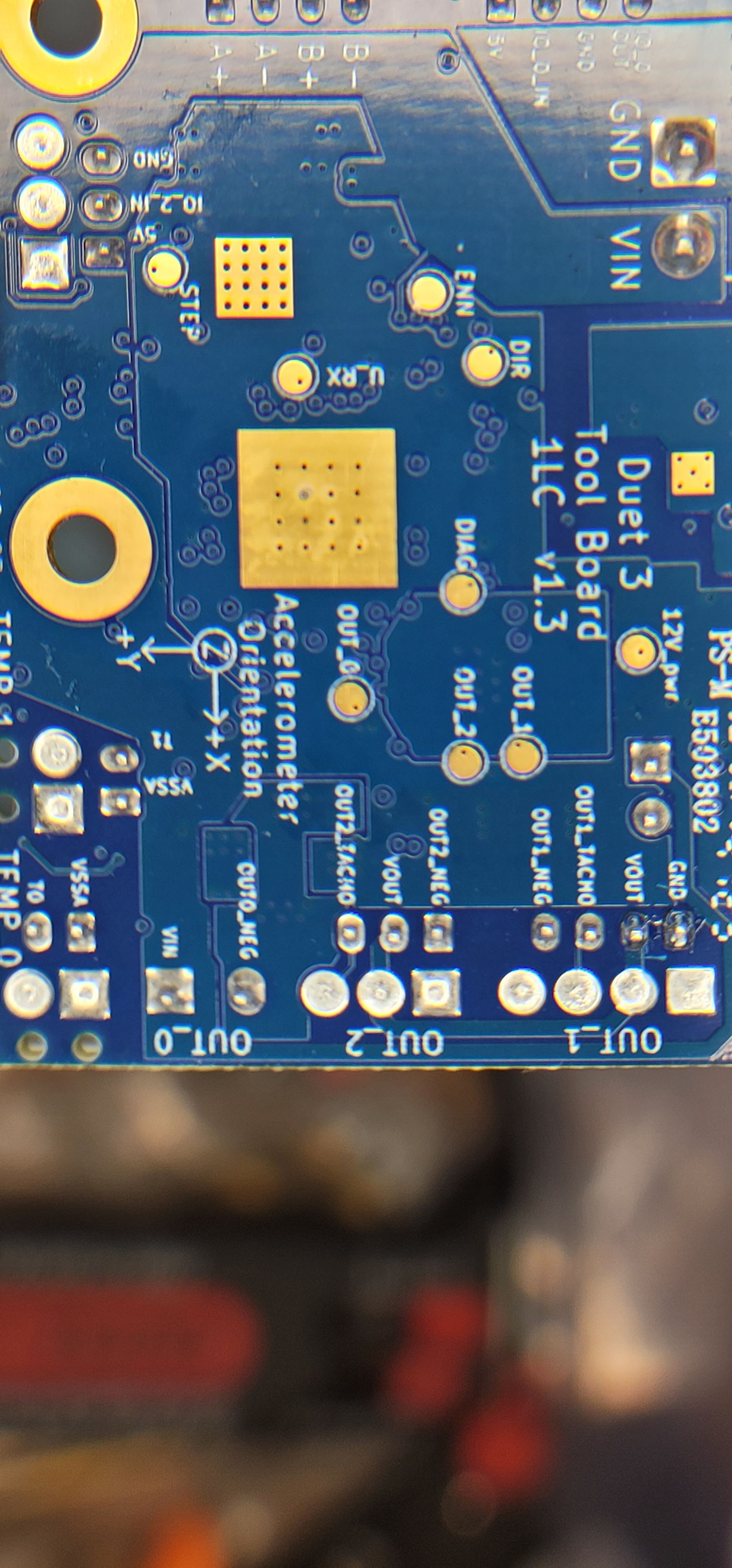

I am standing up a Duet3 Mini 5+ and 3 x 1LC (v1.3) boards that are connected to Obriter 2.0 extruders.

I'm banging my head against the printer trying to figure out what I am missing here.

I am unable to get the Orbiter motor to engage when connected to the 1LC. If I connect the motor to an open driver on the Duet (driver 0.4) I can get it to engage.

I am running the following Macro to test the motor operations:

M302 P1

T0 P0

echo "Begin Move"

G1 E100 F100

echo "End Move"

T-1 P0

M302 P0

When doing this with the motor connected to (0.4) on the Mini I see the motor turn. However, when I put the motor back to the 1LC (21.0) and execute the macro above I see the system show "Busy" in the web browser, but the motor never turns.

I've tried unplugging the motor and getting the same effect, the system never tells me any errors or wiring problems when on (21.0), but when on (0.4) it returns the expected error:

Warning: Driver 0.4 warning: phase A may be disconnected, phase B may be disconnected

I attempted to probe the B- & B+ / A- & A+ terminals after executing the Macro above on while connected to (21.0) I see no voltage. When I perform the same test with the motor connected to (0.4) I can see voltage.

I don't have everything configured on the 1LC, but so far I have validated all the other components are working so I know that the board is still good (same issue across 3 x 1LC's so far).

Any suggestions on what I can do to get some feedback from the 1LC as to why it's not working?

Below is the diagnostics right after attempting a move while the motor is connected to (21.0)

M122 B21

Diagnostics for board 21:

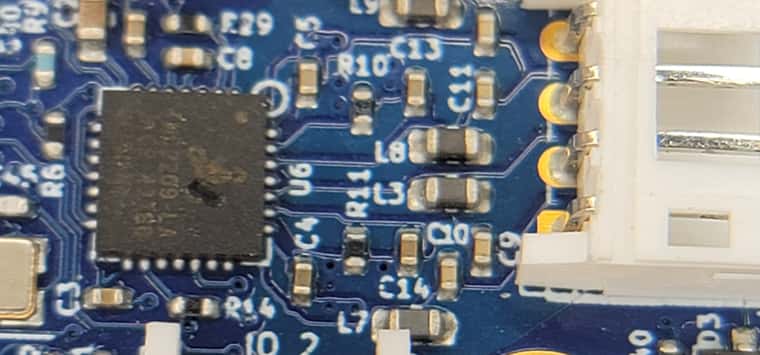

Duet TOOL1LC rev 1.1 or later firmware version 3.6.0-rc.1 (2025-02-28 15:03:36)

Bootloader ID: SAMC21 bootloader version 2.8 (2023-07-25)

All averaging filters OK

Never used RAM 7528, free system stack 94 words

Tasks: Move(3,nWait 7,0.0%,96) TMC(2,nWait 6,0.5%,52) HEAT(2,nWait 6,0.3%,112) CanAsync(5,nWait 4,0.0%,58) CanRecv(3,nWait 1,0.0%,70) CanClock(5,nWait 1,0.0%,58) ACCEL(3,nWait 6,0.0%,72) MAIN(1,running,94.4%,318) IDLE(0,ready,0.0%,26) AIN(2,delaying,4.8%,112), total 100.0%

Owned mutexes:

Last reset 00:11:33 ago, cause: power up

Last software reset data not available

Moves scheduled 1, hiccups 0 (0.00/0.00ms), segs 3, step errors 0 (types 0x0), maxLate 0 maxPrep 95, ebfmin 0.00 max 0.00

Peak sync jitter -3/8, peak Rx sync delay 212, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 3867598156 ticks, disabled

VIN voltage: min 24.3, current 24.4, max 24.4

MCU temperature: min 20.4C, current 36.4C, max 36.4C

Driver 0: pos 68999, 690.0 steps/mm, not present

Last sensors broadcast 0x00000002 found 1 173 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 13892, send timeouts 0, received 6086, lost 0, ignored 0, errs 0, boc 0, free buffers 18, min 18, error reg 0

dup 0, oos 0/0/0/0, rxMotionDelay 292, adv 37067/37067

Accelerometer: LIS3DH, status: 00

I2C bus errors 0, naks 3, contentions 0, other errors 0

config.g (while connected to 1LC)

G90 ; absolute coordinates

M83 ; relative extruder moves

M911 S19.8 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

;;;;;;;;;;;;;;;;;;;

;;; Network ;;;

;;;;;;;;;;;;;;;;;;;

M552 S1 ; configure WiFi adapter

M586 P0 S1 ; configure HTTP

;;;;;;;;;;;;;;;;;;;;;;;;;

;;; Smart Drivers ;;;

;;;;;;;;;;;;;;;;;;;;;;;;;

M569 P0.0 S0 D2 ; driver 0.0 goes forwards (Z0 axis)

M569 P0.1 S0 D2 ; driver 0.1 goes forwards (Z1 axis)

M569 P0.2 S1 D2 ; driver 0.2 goes forwards (X axis)

M569 P0.3 S1 D2 ; driver 0.3 goes forwards (Y axis)

M569 P20.0 S0 D3 V4000 ; Tool Changer

; Motor Idle Current Reduction

M906 I30 ; set motor current idle factor

M84 S30 ; set motor current idle timeout

;;;;;;;;;;;;;;;;

;;; Axes ;;;

;;;;;;;;;;;;;;;;

M584 X0.2 Y0.3 Z0.0:0.1 ; set axis mapping

M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation

M906 X800 Y800 Z800 ; set axis driver currents

M92 X200.0157 Y200.0157 Z1601.584008 ; configure steps per mm

M208 X0:427 Y0:410 Z0:380 ; set minimum and maximum axis limits

M566 X900 Y900 Z12 ; set maximum instantaneous speed changes (mm/min)

M203 X6000 Y6000 Z180 ; set maximum speeds (mm/min)

M201 X500 Y500 Z20 ; set accelerations (mm/s^2)

; Tool Changer Start (C-Axis) ;

M584 C20.0 ; Set Axis Motor

M906 C400 ; Set Motor Currents (mA)

M350 C8 I0 ; Set Interpolation

M92 C100 ; Set Microstepping

M201 C500 ; Set Accellerations

M203 C5000 ; Set Maximum speed (mm/min)

M566 C2 ; Set maximum instantaneous speed changes (mm/min)

M208 C0:240 ; Set axis Min/Max travel

;M915 C S3 F0 H200 R0 ; Stall Detection

; Tool Changer End ;

; Kinematics

M669 K1 ; configure CoreXY kinematics

M575 P1 B115200 S1 ; PanelDue communications

;;;;;;;;;;;;;;;;;;

;;; Probes ;;;

;;;;;;;;;;;;;;;;;;

; Z-Axis (BLTouch)

M558 K0 P9 C"20.io0.in" H5 F120 T6000 ; configure BLTouch probe via slot #0

G31 P500 X0 Y0 Z0.7 ; set Z probe trigger value, offset and trigger height

M950 S0 C"20.io0.out" ; create servo #0 for BLtouch

; Z-Axis End

;; Sensor to right (negative X) of hotend

G31 P25 K0 X31.75 Y-34.4 Z0.90 ; Z probe trigger value, offset in relation to nozzle. Larger trigger brings hotend closer to bed.

M557 X40:360 Y40:340 S40 ; Define mesh grid Offset X to account for Z-Trigger.

;;;;;;;;;;;;;;;;;;

;;; Endstops ;;;

;;;;;;;;;;;;;;;;;;

;M574 X1 S3 ; configure X axis endstop

;M574 Y1 S3 ; configure Y axis endstop

M574 X1 S1 P"!20.io1.in" ; X-Axis Switch High Trigger

M574 Y1 S1 P"io6.in" ; Y-Axis Switch High Trigger

M574 Z1 S2 ; Z-Axis end stop is probe.

;;;;;;;;;;;;;;;;;;;

;;; SENSORS ;;;

;;;;;;;;;;;;;;;;;;;

M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B4725 C7.06e-8 ; configure sensor #0

M308 S10 Y"mcu-temp" A"MCU"

M950 J0 C"!20.io3.in" ; Tool Optical Sensor

;;;;;;;;;;;;;;;;;;;

;;; Heaters ;;;

;;;;;;;;;;;;;;;;;;;

M950 H0 C"out0" T0 ; create heater #0

M143 H0 P0 T0 C0 S140 A0 ; configure heater monitor #0 for heater #0

M307 H0 R2.43 D5.5 E1.35 K0.56 B1 ; configure model of heater #0

G4 S1

; Heated beds

M140 P0 H0 ; configure heated bed #0

;;;;;;;;;;;;;;;;;

;;; Tools ;;;

;;;;;;;;;;;;;;;;;

;; Tool0 ;;

; !!! DEFINE MOTOR FOR EXTRUDER !!!

M584 E21.0 ; set extruder mapping

M906 E1000 I10

M350 E16 I1 ; configure microstepping with interpolation

; NOTE: See Smart Drivers section for motor currents

M92 E690 ; configure steps per mm

M566 E300 ; set maximum instantaneous speed changes (mm/min)

M203 E7200 ; set maximum speeds (mm/min)

M201 E3000 ; set accelerations (mm/s^2)

;; TEMP SENSOR

M308 S1 P"21.temp0" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #1

;M308 S2 P"21.temp1" Y"thermistor" A"Tool0_Temp_Extruder" T100000 B4725 C7.06e-8 ; configure sensor #1

;; Heater

M950 H1 C"21.out0" T1 ; create heater #1

M143 H1 P0 T1 C0 S285 A0 ; configure heater monitor #0 for heater #1

M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1

;; FANS

;;; Tool Fan

M950 F0 C"21.out2" ; create fan #0

M106 P0 S0 B0.3 H1 T45 ; configure fan #0

;;; Extruder Fan

;M950 F1 C"21.out1" ; create fan #1

;M106 P1 C"Tool0_Fan_Extruder" S0 L0 X1 B0.1 H2 T45 ; configure fan #1

;;; Extruder Fan

;; Create Tool0

M563 P0 D0 H1 ; create tool #0

M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C

;; Tool0 End ;;

;M98 P"/sys/CAN_22.g"

;M98 P"/sys/CAN_23.g"

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

;M98 P"/sys/custom_global_vars.g"

I was running v3.5.4, but upgraded to 3.6.1 rc1 last night in an attempt to see if maybe it was just a bug, but no change.