Thanks in advance!

My 3d printer uses a Titan extruder and a standard brass nozzle.

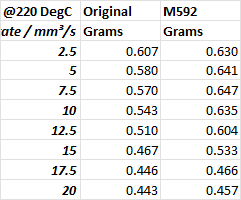

I was performing some flow-underextrusion testing and found that the Titan Extruder has a very linear slip based on extrusion speed.

mm/s UnderExtrusion

1 0%

2 -3%

3 -3%

4 -7%

5 -11%

6 -15%

7 -18%

8 -21%

I learned about M592, did some calculations and want to add an "A" coefficient value of 4.44%.

I added "M592 D0 A0.0444 B0 L1" to my configuration file, as seen below.

Every time that i power cycle and attempt to do additional Flow-UnderExtrusion testing, i get the same results as before i added M592.

Am i using the wrong extruder number in M592? or is there some additional things needed to activate M592?

I have also upgraded to Firmware V3.4.6

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Tue Feb 26 2019 21:31:01 GMT+0000 (Greenwich Mean Time)

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Delta Settings

M665 L440.380 R227.19 H453.864 B185.0 X-0.61 y-0.41 z0 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X-0.18 Y1.63 Z-1.46 A1.09 B-0.61 ; Put your endstop adjustments here, or let auto calibration find them

;M665 L440.380 R226.821 H460 B185.0 X0 y0 z0 ; Set delta radius, diagonal rod length, printable radius and homed height

;M666 X0 y0 z0 A0.00 B0.00 ; Put your endstop adjustments here, or let auto calibration find them

; Network

M550 P"Anycubic Predator" ; Set machine name

M551 P"" ; Set password

M552 P0.0.0.0 S1 ; Enable network and acquire dynamic address via DHCP

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

M552 s1 ; Enable Wifi Automatically

; Drives

M569 P0 S0 ; Drive X goes backwards

M569 P1 S0 ; Drive Y goes backwards

M569 P2 S0 ; Drive Z goes backwards

M569 P3 S1 ; Drive Extruder forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E406 ; Set steps per mm

M566 X600 Y600 Z600 E800 ; Set maximum instantaneous speed changes (mm/min)

M203 X7200.00 Y7200.00 Z7200.00 E420 I0.5 ; Set maximum speeds (mm/min)

M201 X4000.00 Y4000.00 Z4000.00 E4000.00 ; Set accelerations (mm/s^2)

M906 X1200.00 Y1200.00 Z1200.00 E1200.00 I70 ; Set motor currents (mA) and motor idle factor in per cent

M592 D0 A0.0444 B0 L1 ; NonLinear Extrusion Compensation - Titan extruder has a linear slip based on extrusion speed.

M84 S30 ; Set idle timeout

; Retraction

;M207 S2.5 F7000 R0.1 T2500 Z0.5 ; Firmware retraction

; Axis Limits

M208 Z0 S1 ; Set minimum Z

; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop

; Z-Probe

M558 P5 C"e0stop" H8 F120 T2400 R0.2 S0.02 A5 ; Set Z probe type to switch and the dive height + speeds

G31 P100 X0 Y0 Z18.35 ; Set Z probe trigger value, offset and trigger height

; Bed Heater

M308 S0 A"Heated Bed" P"bedtemp" Y"thermistor" T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 A137.8 C533.3 D1.5 V24.3 B0 ; Disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; Map Bed Heater to Heater0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

; Extruder Heater

M308 S1 A"Extruder" P"e0temp" Y"thermistor" T100000 B4300 C0 R4700 ;Set thermistor + ADC parameters for Hetater 1

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

;M305 P1 X200 ; Set thermistor + ADC parameters for heater 1

M307 H1 R2.113 C92.0 D10.07 S1.00 V24.7 ; Disable bang-bang mode for the bed heater and set PWM limit

M143 H1 S260 ; Set temperature limit for heater 1 to 240C

;Heated Chamber

M308 S2 A"Chamber" P"e1temp" Y"thermistor" T10000 B4950 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create chamber heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit

M141 H2 ; map chamber to heater 2

M143 H2 S100 ; set temperature limit for heater 2 to 100C

; E-Stop Buttom

M950 J1 C"e1stop" ; Configures pin input

M581 P1 T0 C0 ; Configure EStop to trigger on Rising Edge All of the time.

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

; Automatic saving after power loss is not enabled

; Custom settings are not configured

;M591 D0 P2 C4 S1 ; Activate filament sensor

M404 N1.75 ; Set for print monitor

M575 P1 B57600 S1 ; Paneldue baud rate

; Mesh Compensation

G29 S1 ; Enable Mesh Compensation by Default

M376 H25 ; Set Taper Compensation Height.

M557 R180 S20 ; Define mesh grid

; Miscellaneous

M501 ; Load saved parameters from non-volatile memory