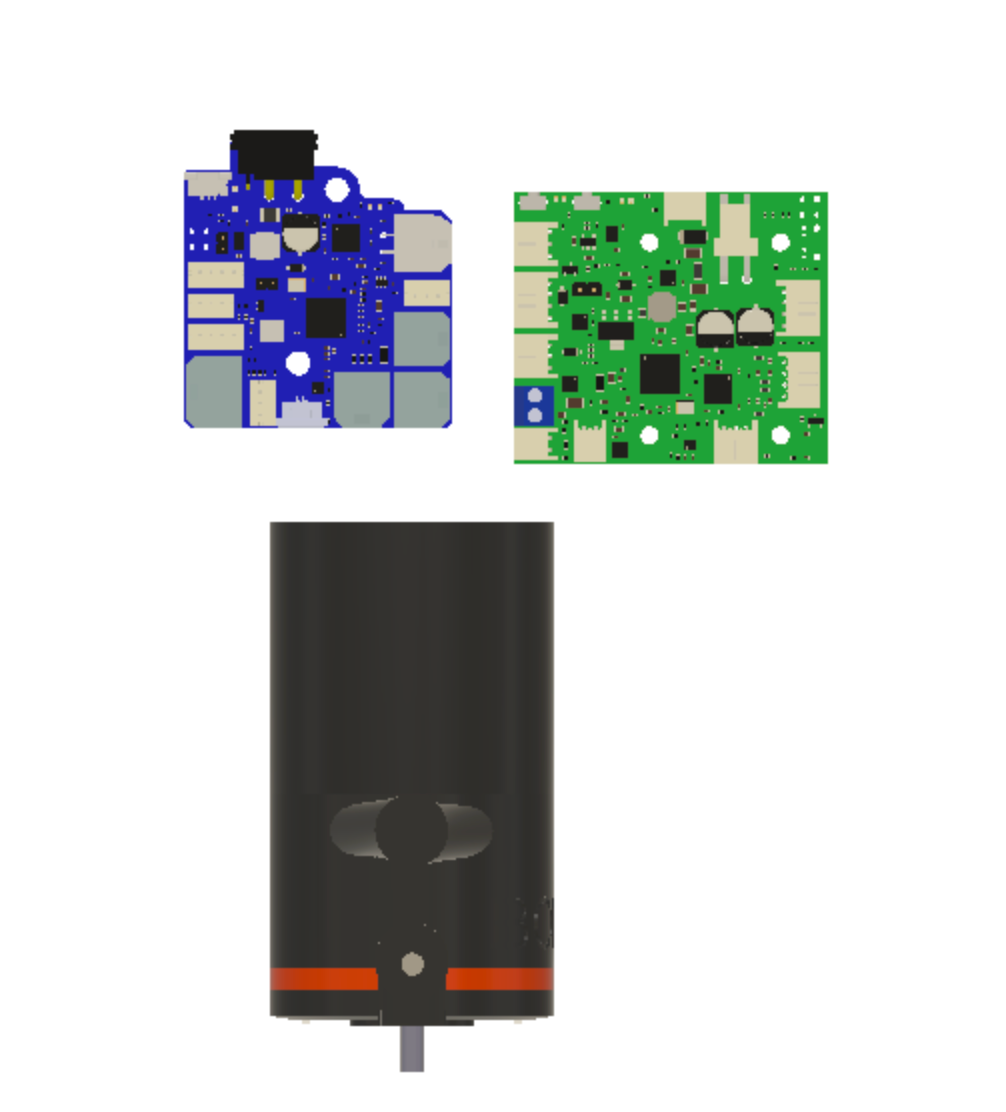

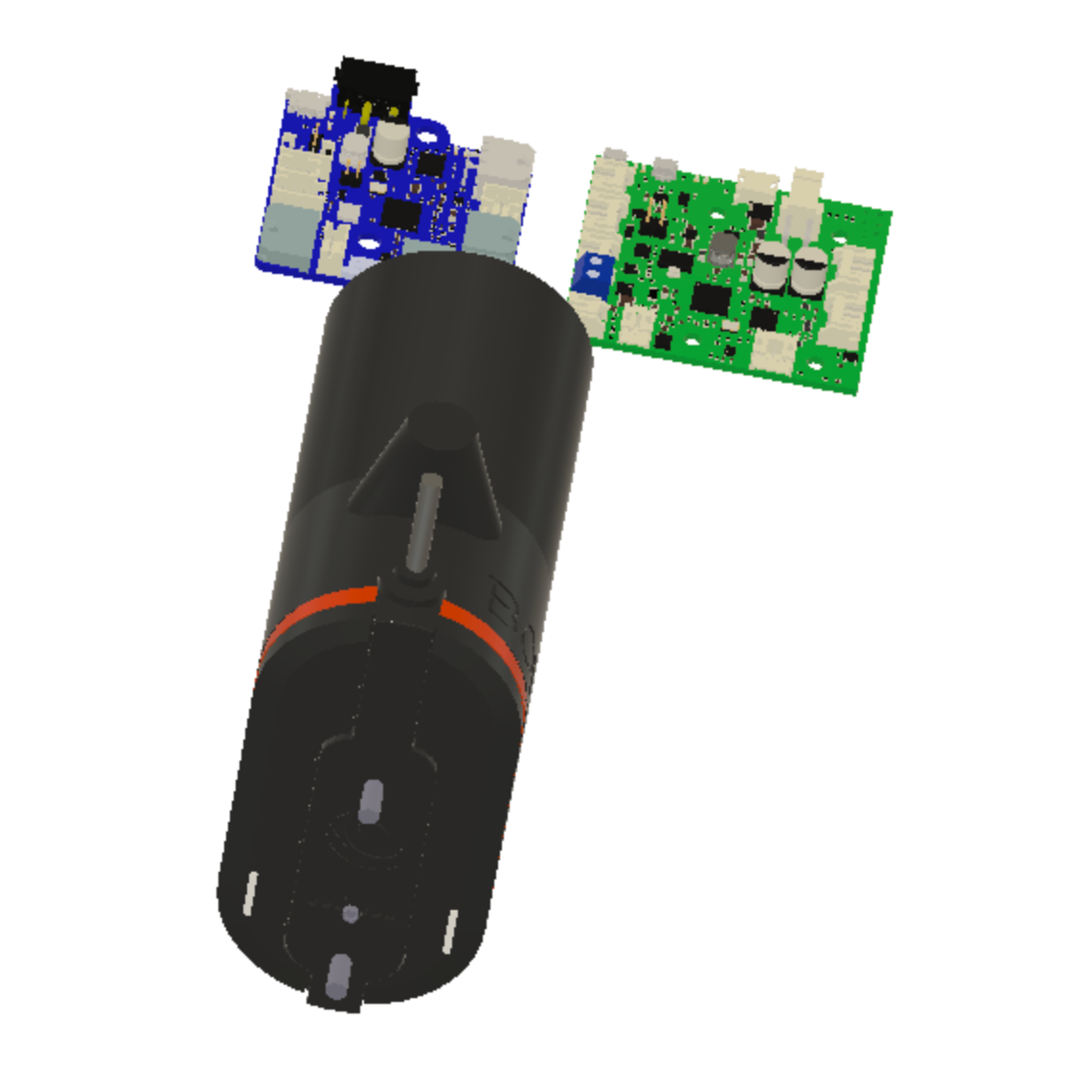

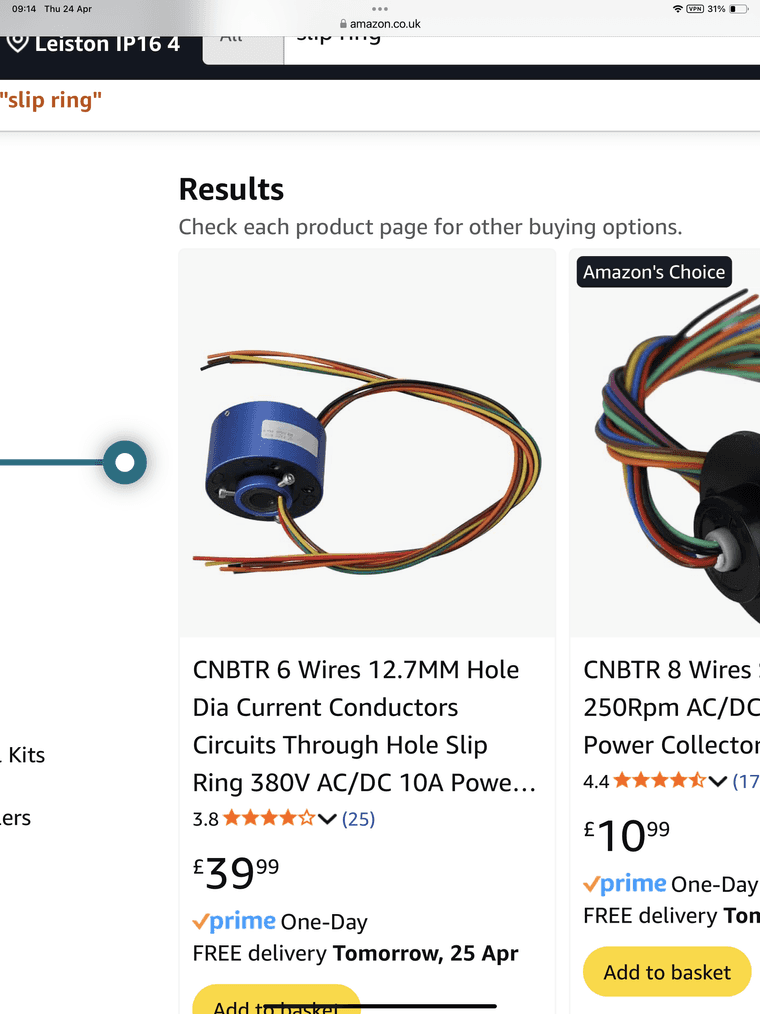

@o_lampe thanks good idea about doubling up - that slip ring has 6 connections and I only need 4 - so I can double up the heater ones - 20A 230v would be masses more than I need.

I haven't done enough actual printing on the SV08 to find any heat bed issues - but it seems to maintain temps ok - although I did get a failure with the PID tuning,

Point taken about the project approach.

One of the advantages of not having a sponsor is not being restricted to specific goals, dates or budgets.

But you might be right that there is a risk of me losing interest in the project - especially as I've just booked a QM2 cruise - so really want to do a model of that ship before I go - so that I can get some comparison photos.

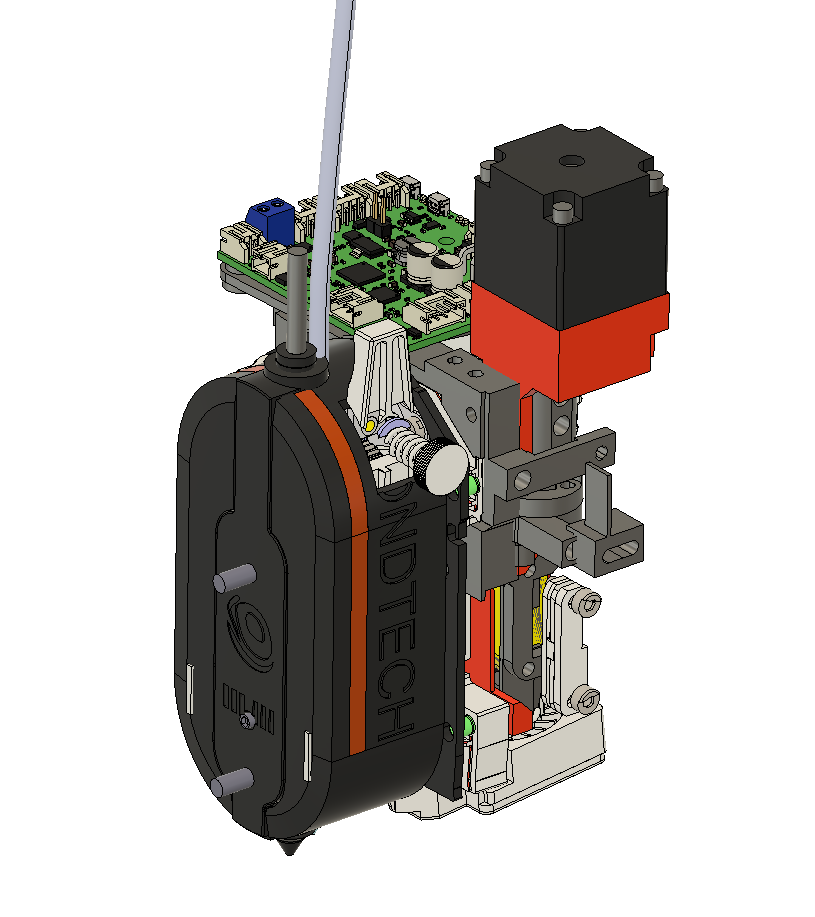

So far all of my changes are just reordering things that were already in the plan (or when better technology like INDX vs Stealthchanger comes along).

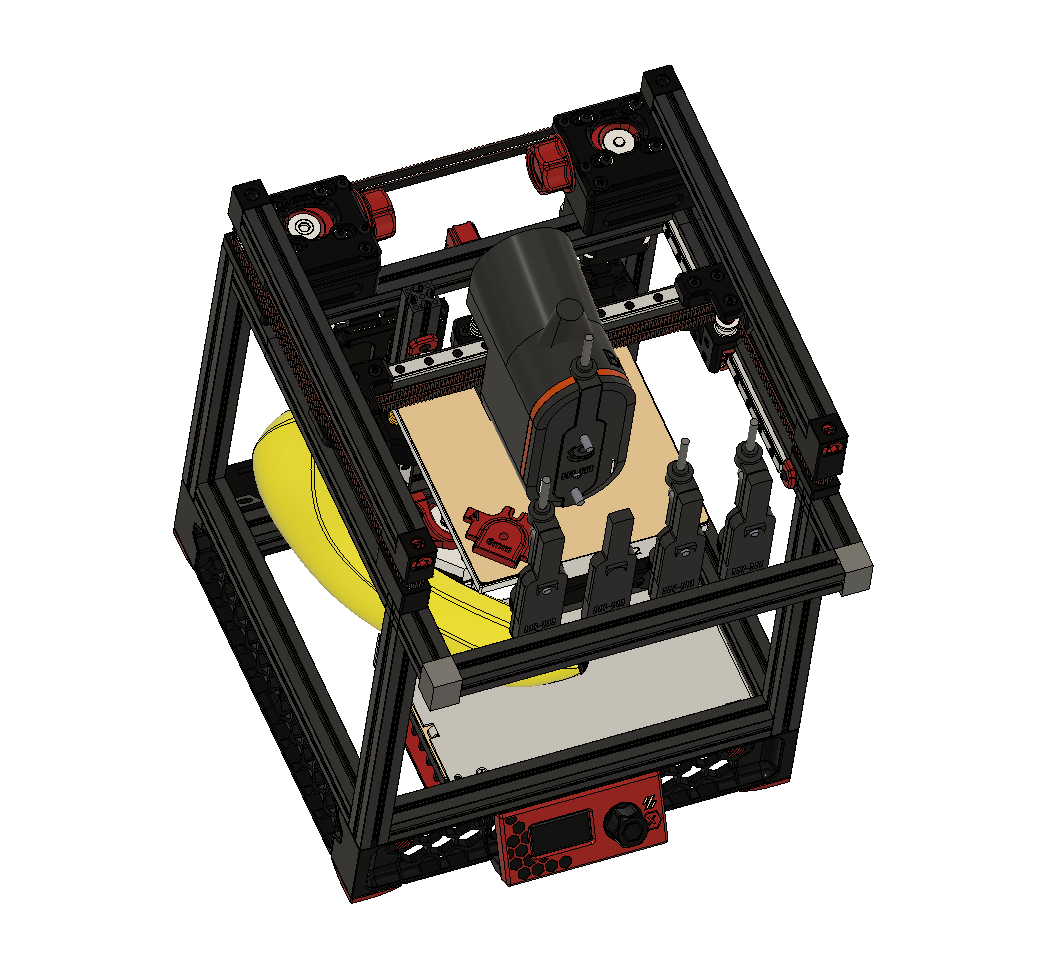

On this subject though I am about to change around my bed slinger approach a fair bit to not have a longer bed - but instead just move about 150mm - and add the ability to link multiple SV08's with this ability together - to get 350x700 or 350x1050 for example - with the build plates slightly overlapping the heated beds.

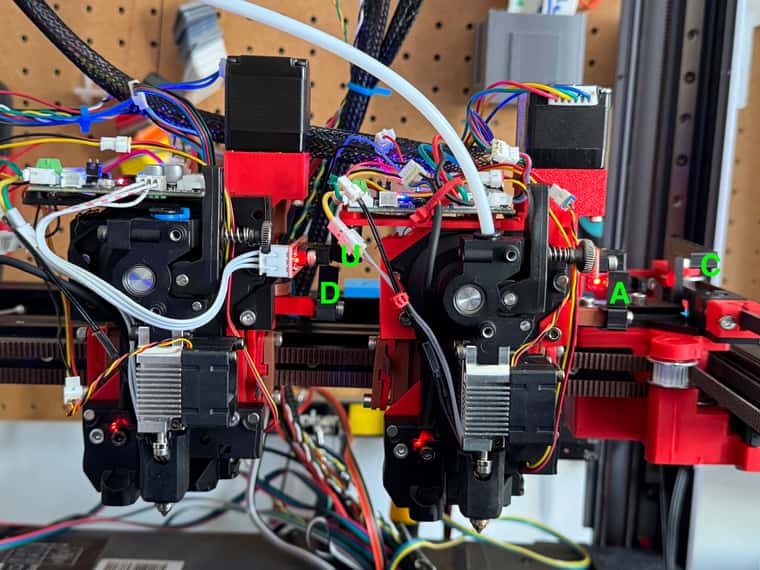

Will probably do dual gantry - but only single heads on the second SV08.

That will then deliver my original plan (and most popular video so far) - see Prusa Multi Mini.

My immediate plans (which I may change)

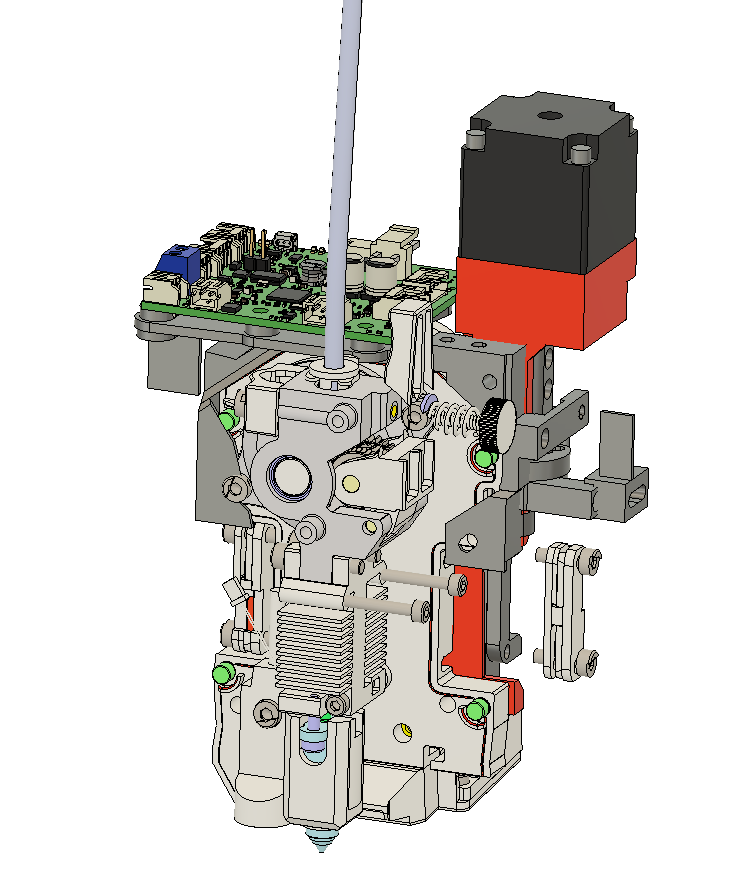

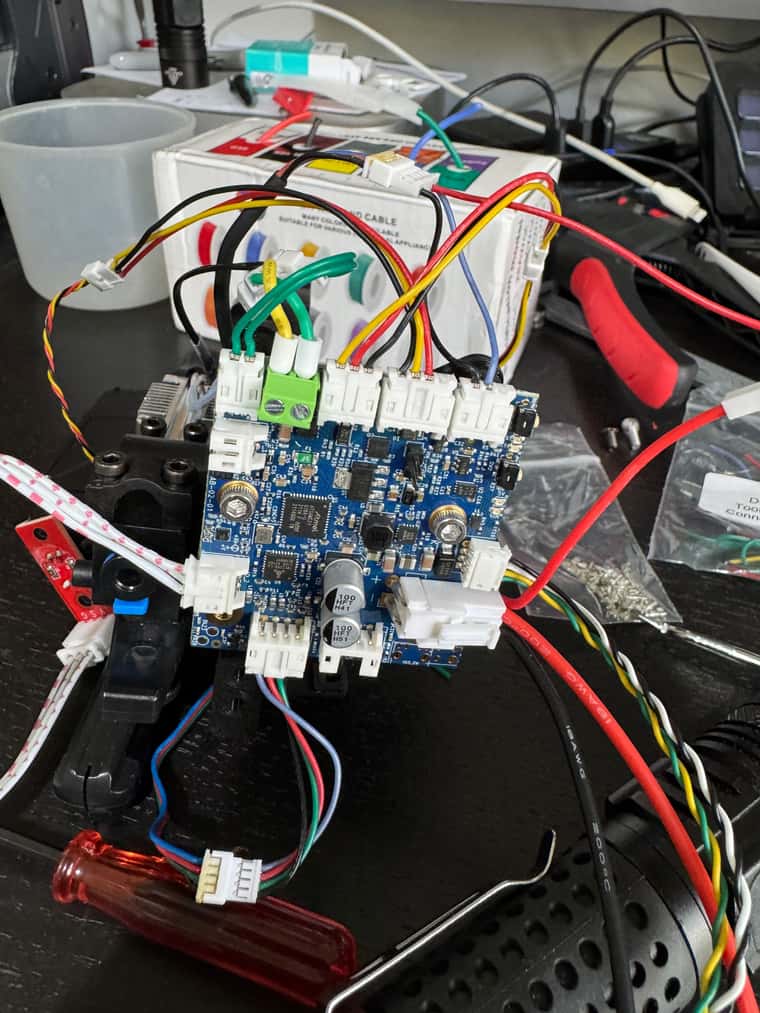

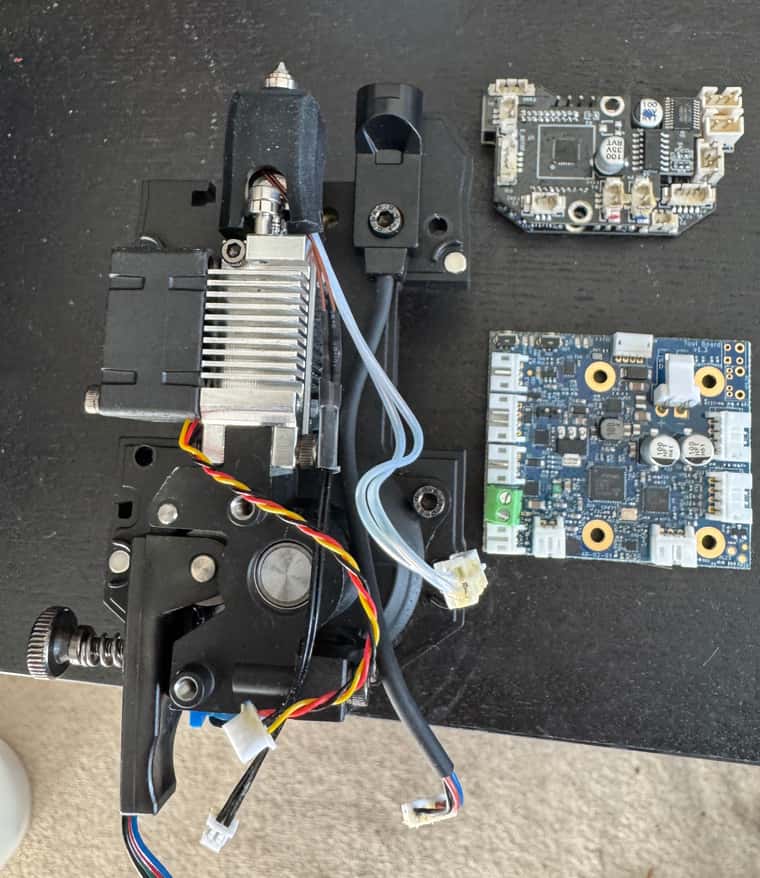

- Get 3 headed build working well - with fully parallel, faster printing

- Rotating bed

- Angled extruder on rotating bed

- 150mm bed slinging

- 2nd linked or independent SV08 with 150mm bed slinging

- 4th print head - probably on stealthchanger to allow for offloading.

- iNDX - which may slot in earlier if previous steps go past December.