@Phaedrux Yes it's direct, I'll look into gear extruders

Posts made by Duetfan223

-

RE: How to PID tune dual heater cartridges wired in parallel?posted in Using Duet Controllers

-

RE: Homing direction reversed after firmware updateposted in Firmware installation

@dc42 I see. I had upgraded from 1.21.2 to 1.22.6, FWIW.

-

RE: Homing direction reversed after firmware updateposted in Firmware installation

Upon closer examination, X and Y axis are correct but their directions are wrong. Z is unaffected.

I changed the stepper direction in config.g from:

M569 P0 S1 M569 P1 S1to:

M569 P0 S0 M569 P1 S0Since P0 and P1 are the steppers attached to the X and Y axis (on my machine). Now it's working properly.

@droftarts said in Homing direction reversed after firmware update:

@Duetfan223 I think that gotcha is in the firmware release notes https://github.com/Duet3D/RepRapFirmware/wiki/Changelog-RRF-1.x-&-2.x#version-121 but I can’t find it right now.

Ian

I see now, thank you. I'll keep that in mind next time I encounter strangeness.

-

Homing direction reversed after firmware updateposted in Firmware installation

My config.g files and homing files seem unchanged. I have a CoreXY machine running off a 0.8.5 board.

I was running 1.21.2 and upgraded to 1.22.6. For now I will change the homing direction in home_.g files to compensate for this.

Has anyone else experienced this behavior before?

-

RE: How to PID tune dual heater cartridges wired in parallel?posted in Using Duet Controllers

@dc42 @hackinistrator said in How to PID tune dual heater cartridges wired in parallel?:

@Duetfan223 i'm glad that it works , but honestly i don't think that its the right solution .You don't really need that second heater .

I have been running a 24v 50 watt cartridge heater on the regular E3D Volcano and can't seem to heat the plastic as fast as I'd like. It's likely a pitfall of using 3mm filament. The SuperVolcano seemed like the logical next step but the standard 24v 80 watt heaters are out of stock. They're nearly 48mm long and I assumed part of the "magic" was having heating elements the whole length of the heater block.

So that's why I decided to go with two 50 watt heaters for now, and I'll buy the 24v 80 watt whenever that becomes available. I had figured I'd set these 50 watt cartridges to S0.8 PWM for "80" watts but I guess it doesn't really work that way?

I still have a lot of 3mm filament I'd like to use up before switching over to 1.75mm. I'd imagine the smaller filament will solve a lot of the problems I've been having with the filament being unevenly heated at higher print speeds.

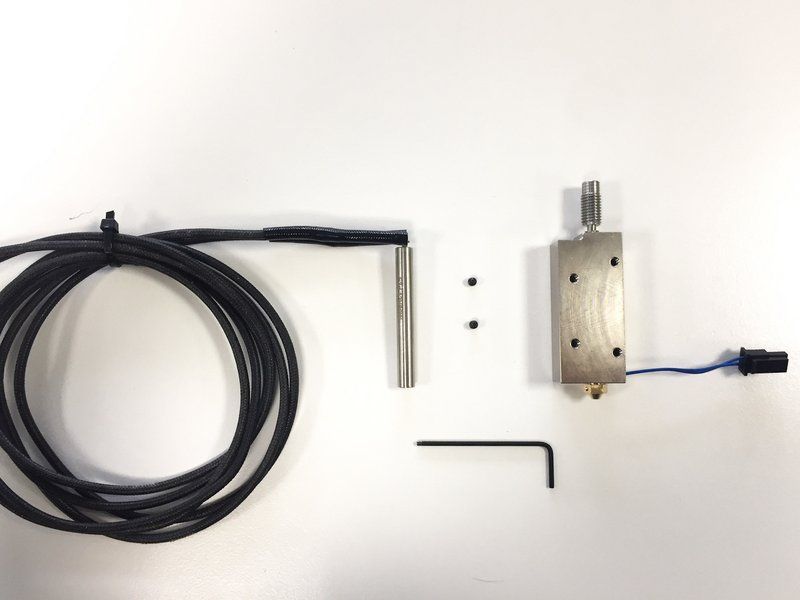

SuperVolcano block & cartridge for reference

2.85mm "bargain basement" PLA, 1650 mm/min at 230 temperature. Notice the "pulsed" affect the filament has on the far side of this print? Is that the heater switching on/off for PID? I updated the firmware and I'll run Auto Tune a few more times. Takes FOREVER to cool down with that sock on there... but that's a good thing, right?

-

RE: JavaScript error updating 0.8.5 firmware via web interfaceposted in Firmware installation

@Phaedrux Thank you, that did the trick!

-

RE: JavaScript error updating 0.8.5 firmware via web interfaceposted in Firmware installation

No, just RepRapFirmware.bin

-

JavaScript error updating 0.8.5 firmware via web interfaceposted in Firmware installation

Hello

Was running firmware 1.21.2 on a Duet 0.8.5 and decided to update to the newest version, to see how it affects tuning hot ends... I downloaded the RepRapFirmware.bin from this release:

https://github.com/Duet3D/RepRapFirmware/releases/tag/2.05.1

And proceeded to update via web interface.

The firmware seemed to update and under settings, the General tab show Firmware Version 1.26.1 (2020-02-09B1)

The interface gives an error though and disconnects from the machine immediately:

JavaScript Error

A JavaScript error has occurred so the web interface has closed the connection to your board. It is recommended to reload the web interface now. If this happens again, please contact the author and share this error message:

Message: Uncaught TypeError: Cannot read property 'current' of undefined

URL: http://192.168.1.7/js/dwc.js

Line: 1813:27

Error object: {}Any ideas? I power cycled the board after waiting about 5 minutes, and it still gives same error and disconnects immediately

-

RE: How to PID tune dual heater cartridges wired in parallel?posted in Using Duet Controllers

@hackinistrator ok, I tried with M303 H2 P0.3 S220. Took another minute to heat up but it was even more accurate this time, and did not fail.

M307 H2 Heater 2 model: gain 863.9, time constant 606.6, dead time 7.7, max PWM 0.30, calibration voltage 0.0, mode PID, inverted no, frequency default Computed PID parameters for setpoint change: P16.3, I0.239, D87.7 Computed PID parameters for load change: P16.3 Warning: Heater 2 appears to be over-powered. If left on at full power, its temperature is predicted to reach 888C. Auto tune heater 2 completed in 748 sec Use M307 H2 to see the result, or M500 to save the result in config-override.g Auto tune phase 3, peak temperature was 228.4 Auto tune phase 2, heater off Auto tune phase 1, heater on M303 H2 P0.3 S220 Auto tuning heater 2 using target temperature 220.0°C and PWM 0.30 - do not leave printer unattendedSo, I will set heater 2 in config.g to read:

M307 H2 A863.9 C606.6 D7.7 S0.3I should be able to print now.

Thank you!

-

RE: How to PID tune dual heater cartridges wired in parallel?posted in Using Duet Controllers

@hackinistrator said in How to PID tune dual heater cartridges wired in parallel?:

maybe try M303 H2 P0.5 S220

That seems to help, this time the overshoot was only 13.3 degrees.

Warning: Auto tune of heater 2 failed due to bad curve fit (G=1505.2, tc=605.4, td=7.5)

11:14:53 AMAuto tune phase 3, peak temperature was 233.3So I have adjusted config.g to:

M307 H2 A1505.2 C605.4 D7.5 S0.5If I run M303 H2 S220 command without a P parameter, does it default to 1.0 or does it use the values saved in M307 H2?

-

RE: How to PID tune dual heater cartridges wired in parallel?posted in Using Duet Controllers

Thanks for the quick response

Are they wired in parallel

Yes, all 4 leads attached to only Heater 2's + and - terminals. I am sure it's wired right.

They do seem to function as intended, they just overshoot the target temp by too much and my edits to the values in M307 don't seem to have any effect.

I don't think this is a firmware issue so much as likely user error but I will definitely consider updating the firmware.

For now, I will adjust M570 for 35 degree excursion so I can at least start running some test prints with this setup.

-

How to PID tune dual heater cartridges wired in parallel?posted in Using Duet Controllers

I am running a 0.8.5 board with firmware 1.21.2beta1 and 24v power supply

I'm having some difficulty wrapping my head around this PID tuning stuff with dual 50 watt cartridge heaters

I'm using two 24v 50 watt heater cartridges in a SuperVolcano heater block with glass mat & silicone sock, wired in parallel. The reason being the 80 watt 24v heaters are still sold out, so I wanted to see if I could improvise.

When I try to PID tune this setup using M303 H2 s220 (Yes it's wired to Extruder 2 heater) I get:

-Peak temperature 250

-Warning: Auto tune of heater 2 failed due to bad curve fit.It also gives me the A, C, D values which I used to update the M307 entry for heater H2 inside config.g...

M307 H2 A3249.8 C542.5 D6.8and have also added to config-override.g., just in case.

Even with the new A, C, D, values in config.g, I set the hotend to 220 and it overshoots by 30 degrees again, and gives this error:

Error: Heater 1 fault: temperature excursion exceeded 15.0°C

I know I can change these values in M570 for a 30+ degree overshoot... but I would rather make adjustments that would lead to less of an overshoot.

Any ideas?

Do I have to double the A value from the failed PID tuning because I'm using 2x heater cartridges?

-

RE: Hot Melt Glue Gun extruderposted in Using Duet Controllers

Sounds good, will try this out. Thank you Alan!

-

Hot Melt Glue Gun extruderposted in Using Duet Controllers

Hello

I want to attach an inexpensive 110v hot melt glue gun to my printer. The idea is to wait about 5 minutes for the nozzle to reach proper temperature and then hit "go" on the print.

Is there a way to disable or circumvent the heater / thermistor setup on the Duet 085, so that I can use the 110v hot glue gun instead?

(Worth noting: I understand the danger involved with what I'm asking about and accept full responsibility for any outcome. Thank you in advance for any concerns)

-

RE: 24v 40watt cartridge can't keep upposted in Duet Hardware and wiring

The 60 watt heater worked like a charm! The heater has no trouble keeping up now. The board didn't even seem warm while running the 60w cartridge heater. It's ready to print at 340 Celsius in less than 30 seconds and has no trouble maintaining temperature, even without a silicone sleeve.

I guess I'll save the "dual 40 watt cartridge heaters wired in parallel" trick for when I get around to running 6mm filament/3mm nozzles (should be soon).

-

RE: 24v 40watt cartridge can't keep upposted in Duet Hardware and wiring

I've got the 24v 60w heater in now, I'll report back with my findings

-

RE: 24v 40watt cartridge can't keep upposted in Duet Hardware and wiring

@elmoret said in 24v 40watt cartridge can't keep up:

so ~2mm^2 layers and 20mm/sec printhead speed? 40mm^3/s is about all a Volcano can manage, regardless of the heater you mount into it.

3dmntbighker is on the right track though, if you're directing a lot of air at the heaterblock, it'll need to be insulated.

I'd insulate the heaterblock before trying to add heaters/heater cartridges.

I see heaters of 60 watt and higher available. But I also have a few extra 24v 40 watt cartridges unused, and I'm only running 1 nozzle.

What is the maximum heater cartridge wattage the Duet 0.8.5 can support?

Is it practical or even possible to use both heater cartridges on 1 extruder? The only other thing I can think of is maybe just adding more mass, making the hot-end longer, and/or changing the material from aluminum to something else.

I appreciate your help!

-

RE: 24v 40watt cartridge can't keep upposted in Duet Hardware and wiring

Excellent advice! I added a sleeve to the heater block and the heater is staying within 5c now

I have two ducted fans, they do tend to blow on the block a bit, that may have been contributing to it

I believe I did run a PID tune at this temperature at one point early on, but I will run it again to make sure I have the right values

-

24v 40watt cartridge can't keep upposted in Duet Hardware and wiring

I'm pushing the limits of the machine to see whats possible.

Filament: 2.85mm PETG

Temperature: 320cNozzle Diameter: 2.25mm

Layer Height: 1.0mm

Print speed: 1200mm/min24v 40 watt heater cartridge

The print goes fine for a layer or two, but eventually the machine stops and says "Temperature excursion exceeded 15 degrees" and stops printing. I think it's just having a hard time heating up that much plastic quickly.

What is the solution?

Can I add an additional heater cartridge by connecting a second into the same terminals one in parallel with the first?