Hi,

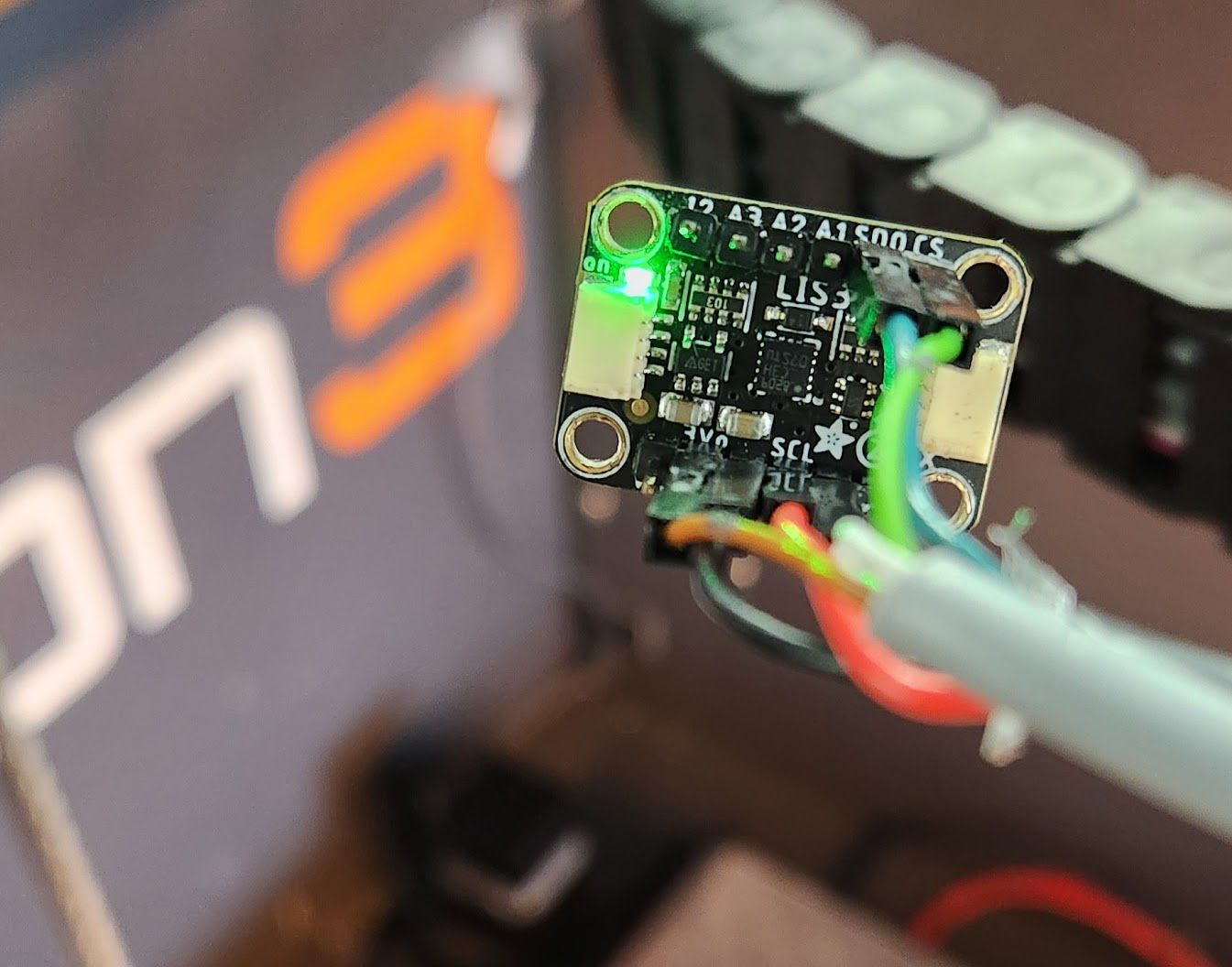

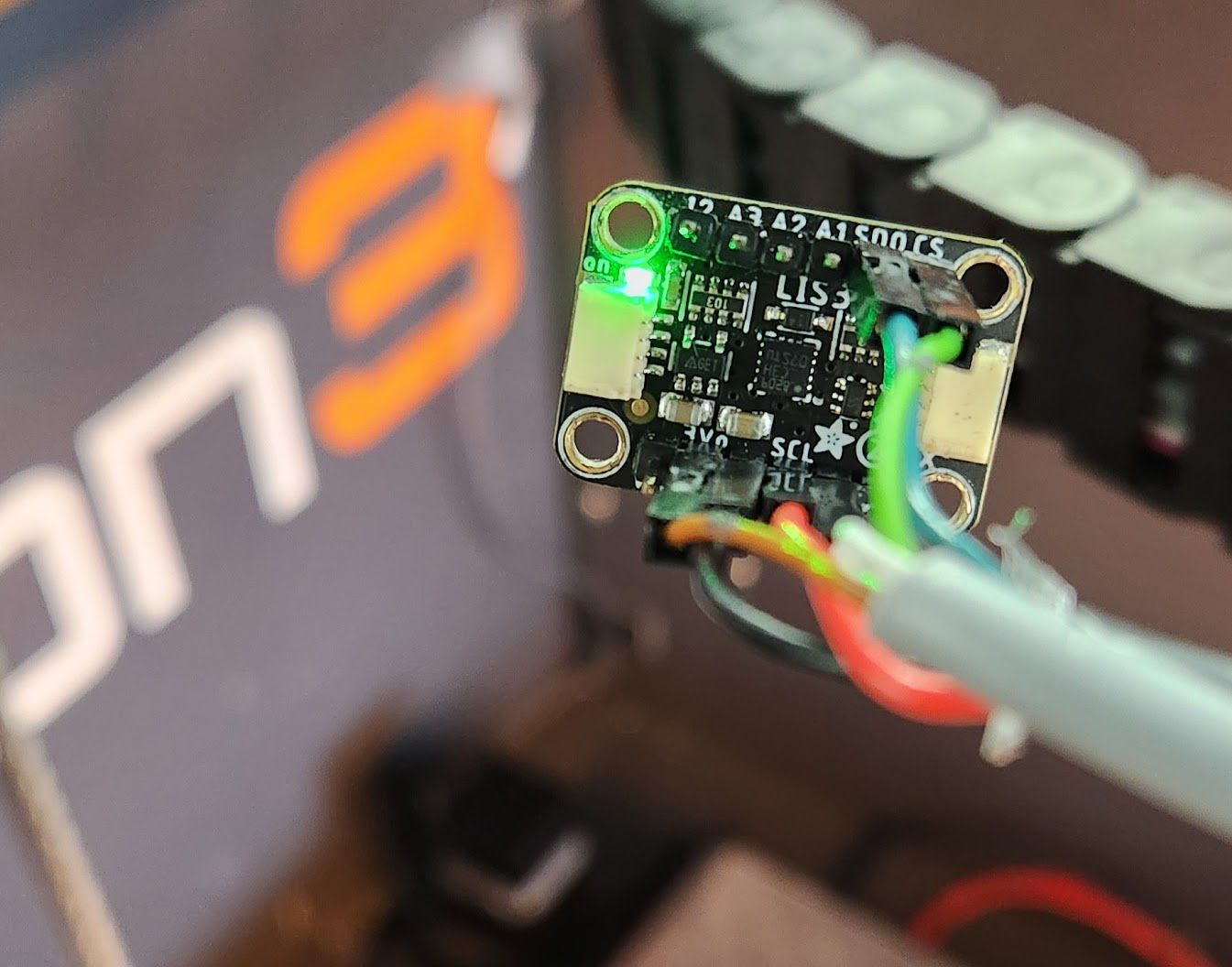

I've been struggling to get my Duet 2 Ethernet to recognize the LIS3DH accelerometer I wired up. (https://www.amazon.com/gp/product/B01BU70B64/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1).

I've wired it according to the guide posted on the docs page, using the daughter board connector. I have the same accelerometer that was used in the post but I can't get my system to recognize it's connected. I verified continuity and pin locations several times just to make sure it wasn't a bad connection. I have a green light showing I have power. Still nothing. At this point I'm out of my depth and not sure what to do next.

Running on DWC 3.4.5 and Config is below.

Any help is much appreciated.

; Fusion3 F410 Firmware configuration file with BLTouch

; For Duet 3.0+

; Revision 2/6/23

; For Serial Number 5592

; Created By Danny Jacobs

; reference - https://www.youtube.com/watch?v=tAr4zIbRgZs

M111 S0 ; Debug off

M550 P"Fusion3 F410" ; Machine name MUST HAVE A "P" IN FRONT OF IT(can be anything you like)

M551 Pfusion3 ; Machine password MUST HAVE A "P" IN FRONT OF IT

M540 P0xBE:0xEF:0xDE:0xAD:0x55:0x92 ; MAC Address (replace last 2 blocks with 4 digit s/n)

;=== Adjust the following 3 lines to suit your network ===

M552 P192.168.58.101 S1 ; IP address (0 = use DHCP)

M554 P192.168.58.1 ; Gateway

M553 P255.255.255.0 ; Netmask

;=========================================================

M555 P2 ; Set output to look like Marlin

M575 P1 B57600 S1 ; comms params for paneldue

G21 ; work in mm

G90 ; absolute coords

M83 ; relative extruder movements

; Machine configuration

M669 K1 ; set CoreXY mode

M584 X0 Y1 Z2 E3 ; set Drive Mapping

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S0 ; Drive 3 goes backwards

M569 P4 S0 ; Drive 4 goes backwards

;Mirco stepping

M350 X16 Y16 Z16 E16 I1

; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop

;Motor Currents

M906 X1300 Y1300 Z1400 I60 ;Set motor currents (mA) with 60% idle current (M906 X1300 Y1300 Z1400 I60)

M906 E1200 I10 ;Extruder motor current 1.2A idle current 10%

;Machine Limits

M201 X1250 Y1250 Z300 E10000 ; Accelerations (mm/s^2) - M201 X2000 Y2000 Z300 E4000 (set at 1250)

M203 X10000 Y10000 Z2500 E7200 ; Maximum speeds (mm/min) - M203 X33000 Y33000 Z2500 E10000 0.6MM Nozzle - M203 X3600 Y3600 - 0.4MM - M203 X5000 Y5000

M566 X600 Y600 Z40 E300 ; Maximum jerk speeds mm/minute - M566 X600 Y600 Z40 E950

M208 X355 Y325 Z309.5 ; set axis maxima

M208 X0 Y0 Z0 S1 ; set axis minima

;Steps per mm

M92 X35.56 Y35.56 Z426.67 E677.57 ; set axis steps/mm (675.782) X43.59 Y43.59

;Pressure Advance

M572 D0 S0.02 ;pressure advance

;*****Thermistors and heaters

;** Bed

M308 S0 P"bedtemp" Y"thermistor" T100000 R4700 B4036

M950 H0 C"bedheat" T0

M307 H0 A153.5 C534.2 D6.7 V24.1 B0 S1 ; Configure H0 (bed) heater model (ADC Corrections)

M140 H0

M143 H0 S140

M570 H0 S360

;** Hotend

M308 S1 P"e0temp" Y"thermistor" T100000 R4700 B4725 C7.06e-8

M950 H1 C"e0heat" T1

M307 H1 R1.670 K0.317:0.187 D4.82 E1.35 S1.00 B0 V23.3

M143 H1 S320

M570 H1 S360 ;Saftet timeout 1 min

;*** Fans

M950 F0 C"fan0" Q500 ;Part Fan - not thermistatically controlled

M106 P0 S0 H-1

M950 F1 C"fan1" Q500 ;Hotend Fan - turns on at 70°

M106 P1 S1 H1 T70

;*** Tool Definitions

M563 P0 D0 H1 ;Define tool 0

G10 P0 S0 R0 ;standby and operating temps

;*** Z Probe (review as of 2/6/23)

M558 P1 C"^zprobe.in" H5 F120 T6000; ;Set probe type and if it's used for axis homing (no in our case) (WAS P1 - CHANGED TO P9)

G31 X-1.25 Y62.0 Z3.466 ;Set the probe height and threshold (larger number is closer to the bed)

M557 X10:330 Y65:305 S80 ; probe from X=10 to 190, Y=10 to 190mm with a mesh spacing of 100mm (y -65 - 365)

M950 S0 C"exp.heater3" ;pin location for bltouch

;**Screw Adjustment Locations

M671 X371.3:-22.5:-23.9:371.1 Y328.75:332:-25:-26.25 P0.7 ; adjusting screws at Rear right (371.3,328.75), Rear left (-22.5,332), front left (-23.9,-25) and front right (371.1,-26.25) thread pitch 0.7mm

;**** Accelerometer

M955 P0 C"spi.cs4+spi.cs3"

T0 ; select first hot end