@sinned6915, @jay_s_uk I figured this one out. I thought the shaking was part of the macro but is was the machine moving to its origin, which was where I placed the dock. When the extruder entered the dock, the macro started, which I think caused the shaking. It would then move on and finish. I solved it by changing the x bed limit, which put the doc in negative space rather than X0:Y0. This has stopped the behavior, but the machine still acts in unpredictable ways sometimes. For example, yesterday it stopped everything right before printing and did nothing. I restarted, rebooted, and did everything I could think of. Finally, I called it a night and then when I woke up today, tried it again and it worked. What would you make of that?

I posted my macros to the probe discord but can post them here too if you wish. Thank you for your help. I usually try to figure these things out for myself but I seem to be going in circles.

dmbe11

@dmbe11

Professor of Interactive Media Design. In addition to being the Program Chair, I teach courses in Interactive Media, Digital Design, and Photography. I am starting to get interested in IOT and have about 500 projects all going at once. I have been 3D printing for a couple of years and most recently with the Duet 3 6HC. It is a wonderful board and the firmware is quite good too. Looking forward to learning more about it and creating

Latest posts made by dmbe11

-

RE: Euclid Probe behavior questionposted in Tuning and tweaking

-

RE: Euclid Probe behavior questionposted in Tuning and tweaking

@jay_s_uk have you noticed any strange behavior when running the macros from time to time? Like going strait to the dock without my slow down points and then when it arrives is shakes for 5 or 6 seconds before moving on?

thx

-

Euclid Probe behavior questionposted in Tuning and tweaking

I have set up the Euclid probe and it's functioning ok but has a quirk that I am pretty sure is due to a bad setting somewhere. When I run the bed.g macro (true bed leveling), it returns the probe to the dock between each probe. I have a corexy with 2 leadscrews so it picks up the probe makes its way to the first point, probes it and instead of going to the other side it returns the probe to the dock. After undocking, it goes back, picks up the probe, and does the second point. I've been looking at this thing for several hours and I am sure it is something silly but I am missing something. Perhaps someone might have an idea. If you need to see any of my files I will be happy to post them.

-

RE: Voron Z offset questionposted in Tuning and tweaking

@wbrokow1 What kind of probe are you using? If it is an inductive or any type that does not need to be in contact with the bed to work then your want it to be higher than the nozzle. However, if it is a probe that contacts the bed like a Euclid then it would need to be lower than the nozzle but after docked, higher than the nozzle. For something like a BLtouch then the probe should sit higher than the nozzle but close enough that the pin when dropped hits the bed. The correct setting for the firmware is the M558 for setting the type and the G31 for Trigger value, offsets, and trigger height. The easiest way is to look at the G-code reference on the duet3 website: https://docs.duet3d.com/en/User_manual/Reference/Gcodes

-

RE: PID tuning and heater controlposted in Tuning and tweaking

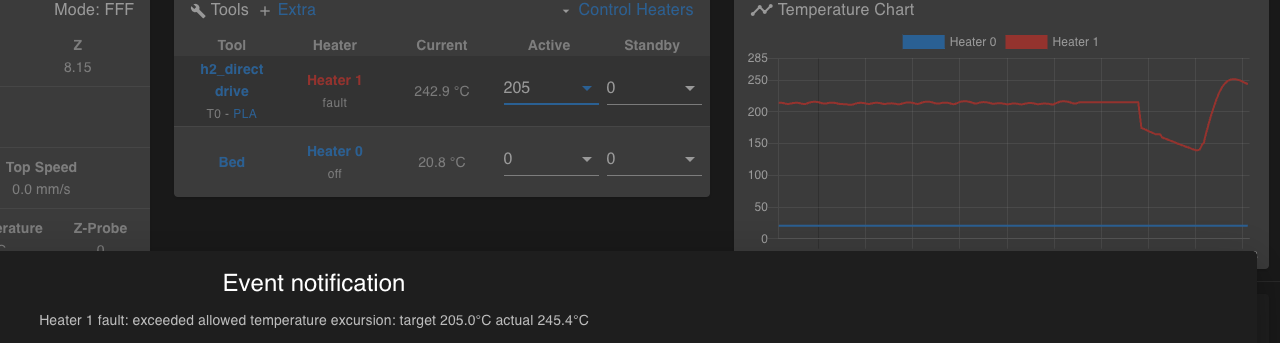

the error was monitor 0 was triggered

-

RE: PID tuning and heater controlposted in Tuning and tweaking

@Phaedrux here is the graph and error

As you are likely aware, the drop at the end of the graph was after the error and lasted the time it took me to find my screenshot app and click the button, thus the final dropping curve

-

RE: PID tuning and heater controlposted in Tuning and tweaking

@Phaedrux

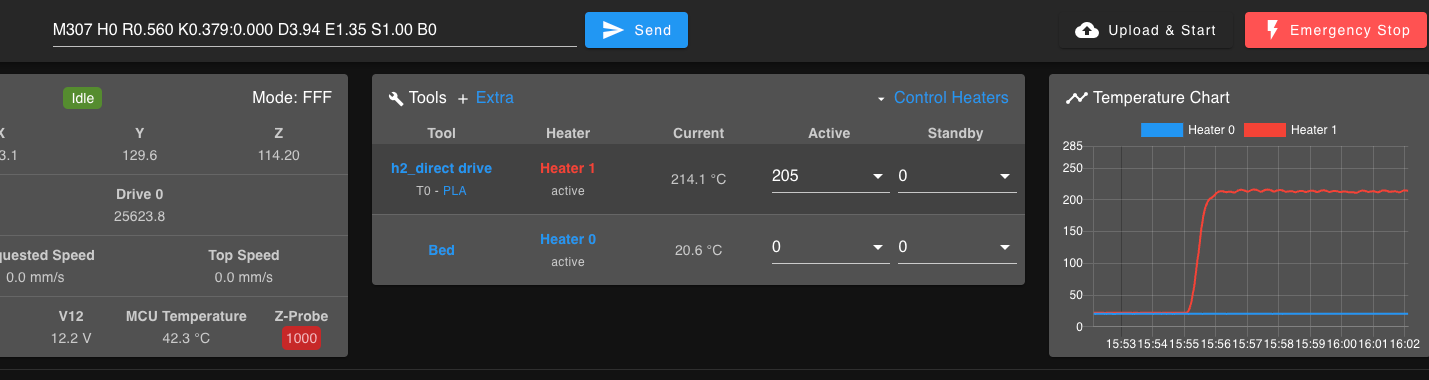

It looks like a rocket. However last night I was trying to print something and I found this Gcode command, which I must admit I don't fully understand so it was pretty dumb to try it, but being who I am I did it anyway. I did keep my hand close to the abort switch.Here is the code:

M307 H0 R0.560 K0.379:0.000 D3.94 E1.35 S1.00 B0 code_text

code_textThe result is usable but as you can see it adds about 9c to my set temp of 205 c. So I know it is not correct. I provided it as it might be a clue to help you determine what my issues are.

-

RE: PID tuning and heater controlposted in Tuning and tweaking

M303 H1 S210The heater came with the BTT H2 V2S Lite:

Heater info:

Thermistor Type: NTC100K

Heater Cartridge Power: 70W

Heater Cartridge Voltage: 24VNo silicone sleeve so I used PTFE tape

-

PID tuning and heater controlposted in Tuning and tweaking

hello,

I have a duet D 6HC board and am having issues tuning my H1 extruder. I have run the PID tuning program several times and then yesterday I added this line to my config is:

M570 H1 P8 T25This worked for a single print then things got worse and now it charges right past my set temp and I get an Error: Heater 1 fault: heater monitor 0 was triggered. (previously I got the error that prompted me to add the M570 line.

Here is what I get when I run an M307 h1

Heater 1: heating rate 3.203, cooling rate 1.805, dead time 18.22, max PWM 1.00, mode PID, calibrated at 24.1V

Predicted max temperature rise 152°C

PID parameters: heating P3.1 I0.107 D39.0, steady P3.1 I0.117 D39.0It seems I need some additional help with my tuning` process, Here is my config info in case it is needed:

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; generated by RepRapFirmware Configuration Tool v3.3.13 on Wed Oct 05 2022 20:45:45 GMT-0400 (Eastern Daylight Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M669 K1 ; select CoreXY mode ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.3 S0 ; M569 P0.4 S0 ; physical drive 0.4 goes backwards M584 X0.0 Y0.1 Z0.2:0.3 E0.4 ; set drive mapping M671 x3:360 y200:200 ; Lead screw probing locations M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E932.00 ; set steps per mm M566 X900.00 Y900.00 Z180.00 E720.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z900.00 E1200.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z500.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-3 Y-35 Z-0.5 S1 ; set axis minima M208 X393 Y355 Z395 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io1.in M574 Y1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io2.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P8 C"io3.in" H5 F900 T6000 ; set Z probe type to unmodulated and the dive height + speeds G31 P50 X-23 Y21 Z3.15 ; set Z probe trigger value, offset and trigger height M557 X15:370 Y35:320 S40 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.548 K0.441:0.000 D4.48 E1.35 S1.00 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S125 ; set temperature limit for heater 0 to 100C M308 S1 P"temp1" Y"thermistor" T100000 B4616 C9.145674e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 1 to 285C M570 H1 P8 T25 ; An anomaly on heater 1 must persist for 8 seconds, and must be greater or less than 25C from the setpoint, to raise a heater fault. ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0.5 H-1 ; set fan 0 value. Thermostatic control is turned off ; Tools M563 P0 S"h2_direct drive" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first toolI use the config override file too so here is my heater update:

; config-override.g file generated in response to M500 at 2022-10-16 21:08 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R0.548 K0.441:0.000 D4.48 E1.35 S1.00 B0 M307 H1 R3.203 K1.805:0.000 D18.22 E1.35 S1.00 B0 V24.1Please let me know fi I can provide any additional information.

thank you

-

RE: Corexy printer with duel z drives, only one z drive worksposted in Duet Hardware and wiring

@jay_s_uk Thank you that's it. I looked closer and that is exactly what I did. That was a good catch.