@zapta Thank you for the info. I will try it. That sound good.

Posts made by DK90

-

RE: Cura Script to Automatically Probe Only Printed Areaposted in General Discussion

-

RE: Cura Script to Automatically Probe Only Printed Areaposted in General Discussion

oh

yes that sounds good....that was my mistake...:D Thank you

yes that sounds good....that was my mistake...:D Thank you -

RE: Cura Script to Automatically Probe Only Printed Areaposted in General Discussion

@tcj said in Cura Script to Automatically Probe Only Printed Area:

C:\Users\Dominic\AppData\Local\Programs\Python\Python36-32\python.exe "C:\Program Files\Prusa3D\PrusaSlicer\duet3d_automesh.py"

Oh

thank you now ot works

thank you now ot works

but wehn i start the print, there is now mesh leveling ....

where is my error?Start G-Code

M83 ; extruder relative mode M140 S[first_layer_bed_temperature] ; set bed temp M190 S[first_layer_bed_temperature] ; wait for bed temp ; For automesh M557 TBD ; parameters will be set automatically G28 ;home ;G29 S1 P"heightmap.csv"; Hoehenkarte Laden M109 S[first_layer_temperature] ; wait for extruder temp ;G29 S1 P"heightmap.csv"; Hoehenkarte Laden ; Reinigungs Fahrt G1 X-3.0 Y-10 F1500.0 ; go outside print area G92 E0.0 G1 Z0 G1 E8 ; Purge Bubble G1 X60.0 E9.0 F1000.0 ; intro line G1 X100.0 E12.5 F1000.0 ; intro line G92 E0.0G-Code layer change setting

; Automesh: begin layer [layer_num] -

RE: Cura Script to Automatically Probe Only Printed Areaposted in General Discussion

@zapta said in Cura Script to Automatically Probe Only Printed Area:

--meshable=-30:250,-3:280

Hello, i have the following error when i am trying to ad the postprocess

can some one help me please?Thanks

Post-processing script C:\Users\Dominic\AppData\Local\Programs\Python\Python36-32\python.exe C:\Program Files\Prusa3D\PrusaSlicer\duet3d_automesh.py file on file D:\2_Projekte\3D Druck\2_Modelle\28_R2D2_Did3D\R2D2_Did3D_SW_FullPack_h\STL_Final\zumdruckenbereit\Cube_PLA_Center foot_0.2mm_PET_2h24m.gcode failed. Error code: 2 ```~~~~ -

RE: Endstop isusseposted in Tuning and tweaking

@phaedrux ehm i think so

here is the code for the macro.

;ZELDATREASUREnopause;

G4 P1000 ; wait

M300 S392 P200 ; G4

M300 S440 P200 ; A4

M300 S493.88 P200 ; B4

M300 S554.37 P200 ; C#5

M300 S392 P195 ; G4

M300 S440 P195 ; A4

M300 S493.88 P195 ; B4

M300 S554.37 P195 ; C#5

M300 S415.3 P190 ; G#4

M300 S466.16 P190 ; A#4

M300 S523.25 P190 ; C5

M300 S587.33 P190 ; D5

M300 S415.3 P185 ; G#4

M300 S466.16 P185 ; A#4

M300 S523.25 P185 ; C5

M300 S587.33 P185 ; D5

M300 S440 P180 ; A4

M300 S493.88 P180 ; B4

M300 S554.37 P180 ; C#5

M300 S622.25 P180 ; D#5

M300 S440 P175 ; A4

M300 S493.88 P175 ; B4

M300 S554.37 P175 ; C#5

M300 S622.25 P175 ; D#5

M300 S466.16 P169 ; A#4

M300 S523.25 P169 ; C5

M300 S587.33 P169 ; D5

M300 S659.25 P169 ; E5

M300 S466.16 P163 ; A#4

M300 S523.25 P163 ; C5

M300 S587.33 P163 ; D5

M300 S659.25 P163 ; E5

M300 S493.88 P158 ; B4

M300 S554.37 P158 ; C#5

M300 S622.25 P158 ; D#5

M300 S698.46 P158 ; F5

M300 S523.25 P151 ; C5

M300 S587.33 P151 ; D5

M300 S659.25 P151 ; E5

M300 S739.99 P151 ; F#5

M300 S554.37 P144 ; C#5

M300 S622.25 P144 ; D#5

M300 S698.46 P144 ; F5

M300 S783.99 P144 ; G5

M300 S587.33 P137 ; D5

M300 S659.25 P137 ; E5

M300 S739.99 P137 ; F#5

M300 S830.61 P887 ; G#5M300 S349.23 P25 ; F4

M300 S523.25 P25 ; C5

M300 S880 P25 ; A5

M300 S349.23 P25 ; F4

M300 S523.25 P25 ; C5

M300 S880 P25 ; A5

M300 S349.23 P25 ; F4

M300 S523.25 P25 ; C5

M300 S880 P25 ; A5

M300 S349.23 P25 ; F4

M300 S523.25 P25 ; C5

M300 S880 P25 ; A5M300 S369.99 P25 ; F#4

M300 S554.37 P25 ; C#5

M300 S932.33 P25 ; A#5

M300 S369.99 P25 ; F#4

M300 S554.37 P25 ; C#5

M300 S932.33 P25 ; A#5

M300 S369.99 P25 ; F#4

M300 S554.37 P25 ; C#5

M300 S932.33 P25 ; A#5

M300 S369.99 P25 ; F#4

M300 S554.37 P25 ; C#5

M300 S932.33 P25 ; A#5M300 S392 P25 ; G4

M300 S587.33 P25 ; D5

M300 S987.77 P25 ; B5

M300 S392 P25 ; G4

M300 S587.33 P25 ; D5

M300 S987.77 P25 ; B5

M300 S392 P25 ; G4

M300 S587.33 P25 ; D5

M300 S987.77 P25 ; B5

M300 S392 P25 ; G4

M300 S587.33 P25 ; D5

M300 S987.77 P25 ; B5M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6

M300 S415.3 P25 ; G#4

M300 S622.25 P25 ; D#5

M300 S1046.5 P25 ; C6G4 P1000 ; wait

-

RE: Endstop isusseposted in Tuning and tweaking

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Thu Sep 13 2018 11:57:39 GMT+0200; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Network

M550 PIDEX ; Set machine name

M552 S1 ; Enable network

M587 S"DarkSide" P"DarkSide" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M584 X0 Y2 Z1 E3:4 U5 ; Driver 0 controls the X motor, 1 controls Y, 2 control Z motors,3 and 4 control E motors and 5 the U motor

;M584 X0 Y1 Z2 U3 E4:5 ; create the U axis and assign stepper driver 3 to it

M569 P0 S0 ; Drive 0 goes backwards X

M569 P1 S0 ; Drive 1 goes forwards Z

M569 P2 S1 ; Drive 2 goes forrwards Y

M569 P3 S0 ; Drive 3 goes forwards E0

M569 P4 S0 ; Drive 4 goes forwards E1

M569 P5 S0 ; Drive 5 goes backwards UM350 X16 Y16 Z16 E16:16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z400 U80 E120:100 ; Set steps per mm

M566 X600 Y600 U600 Z12 E120:120 ; Set maximum instantaneous speed changes (mm/min) /////Orginal Werte: 600

M203 X20000 Y20000 U20000 Z180 E1200:1200 ; Set maximum speeds (mm/min) ´ //// Orginal Werte: 6000

M201 X1000 Y1000 U1000 Z250 E250:250 ; Set accelerations (mm/s^2) //// Orginal Werte: 500

M906 X800 Y900 Z800 U900 E800:800 I30 ; Set motor currents (mA) and motor idle factor in per cent //Orginal Werte: 800mA

M84 S15 ; Set idle timeout; Axis Limits

;M206 Y-5 ; offset Y-Achse nach referenzfahrt

M208 X0 Y0 Z0 U60 S1 ; Achsen Limit minumum

M208 X151 Y189 U 200 Z200 S0 ; Achsen Limit Maximum

M564 H0 ;Erlaube Jogbewegung ohne zu homen

; Endstops

M574 X1 S0 ; Set active high endstops

M574 Y2 S1 ; Y-Endstop hight end

M574 U2 S0 ; U-Endstop high end; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

;M558 P4 H5 F120 T6000 ;//mechanischer endschalter Set Z probe type to switch and the dive height + speeds

M558 P5 H3 F500 ;Induktiver Sensor

G31 P500 X0 Y0 Z0.2 ; Set Z probe trigger value, offset and trigger height -0.835

M557 X25:150 Y35:180 S40 ; Define mesh grid; Heaters

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C

M305 P2 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 2

M143 H2 S280 ; Set temperature limit for heater 2 to 280C

M305 P101 S"DuetDriversTemp" ; Driver Duet

M305 P103 X3 S"Gehäuse-unten" T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 2; Fans

M106 P0 S0 I0 F500 H-1 C"BT-Kühler1" ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H1 T50 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H2 T50 ; Set fan 7 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P4 S0 I0 F500 H-1 C"BT-Kühler2" ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

;---Gehäuselüfter---

;M106 P3 F40 ; Part cooling fan (P3 is PWM Fan 3 on the Duex2 10Hz)

M106 P3 T45:65 H100:101:102:P103; Tools

M563 P0 D0 H1 S"X_Tool" ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 X3 S"U-Tool" ; Define tool 1

G10 P1 X0 Y0 Z0 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C''' Create a tool that prints 2 copies of the object using both carriages'''

M563 P2 D0:1 H1:2 X0:3 F0:4 S"Clone" ; tool 2 uses both extruders, hot end heaters and fans, and maps X to both X and U

G10 P2 X25 Y0 U-35 S0 R0 ; set tool offsets and temperatures

M567 P2 E1:1 ; set mix ratio 100% on both extruders; Automatic saving after power loss is not enabled

; Custom settings are not configured

and the homing.g file

; homex.g

; called to home the all axis

;; --------Grundbedinugung ------------

;G1 Z5 F6000 S2 ; lift Z relative to current position

;------Y-Achse---------G91 ; relative positioning

G1 Z5 F6000 S2 ; lift Z relative to current position

G1 S1 Y215 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y-10 F6000 ; go back a few mm

G1 S1 Y215 F360 ; move slowly to Y axis endstop once more (second pass)

;G1 Z-5 F6000 S2 ; lower Z again

G90 ; absolute positioning;----------X-Achse-------------

M400 ; make sure everything has stopped before we make changes

M574 X1 Y1 S3 ; set endstops to use motor stall

M913 X50 Y50 ; drop motor currents to 50%

M915 X Y S1 R0 F0 ; set X and Y to sensitivity 3, do nothing when stall, unfiltered

M566 X500 Y500 ; Set maYimum instantaneous speed changes (mm/min)

M201 X500 Y500 ; Set accelerations (mm/s^2)

G91 ; use relative positioning

G1 S1 X-200 F3000 ; move left 100mm, stopping at the endstop

G1 S1 X10 F2000 ; move away from end

G90 ; back to absolute positioning

M400 ; make sure everything has stopped before we reset the motor currents

M913 X100 Y100 ; motor currents back to 100%

M566 X1200 Y1200 ; Set maYimum instantaneous speed changes back to normal (mm/min)

M201 X3000 Y3000 ; Set accelerations back to normal (mm/s^2)

M574 X1 Y1 S0 ; Define active low and unused microswitches

G1 X11 F6000;;----------U-Achse------------

; homeu.g

; U AXIS

M400 ; make sure everything has stopped before we make changes

M574 U2 S3 ; set endstops to use motor stall

M913 U50 ; drop motor currents to 50%

M915 U S1 R0 F0 ; set X and Y to sensitivity 3, do nothing when stall, unfiltered

M566 U500 ; Set maYimum instantaneous speed changes (mm/min)

M201 U500 ; Set accelerations (mm/s^2)

G91 ; use relative positioning

G1 S1 U300 F3000 ; move left 100mm, stopping at the endstop

G1 S1 U-22 F2000 ; move away from end

G90 ; back to absolute positioning

M400 ; make sure everything has stopped before we reset the motor currents

M913 U100 ; motor currents back to 100%

M566 U1200 ; Set maYimum instantaneous speed changes back to normal (mm/min)

M201 U3000 ; Set accelerations back to normal (mm/s^2)

M574 U2 S0 ; Define active low and unused microswitches;-----Z-Achse------------

G90 ; absolute positioninn

G1 X50 Y100 F2000 S2 ; move to bed centre for probing

G30 ; probe the bed and set Z height

G1 Y10 X10;;---Bestätigungs Tone----------

M98 P0:/macros/Tunes/Zelda2.g

-

RE: Endstop isusseposted in Tuning and tweaking

Thanks.

It is an „new“ Setup. I have changed something but the endstop Works well in the old Setup.

When i trigger the endstop withe the Hand, the led change and the status change also.In the first run, after a reboot, it works to. But than it dosn‘t works anymore.

-

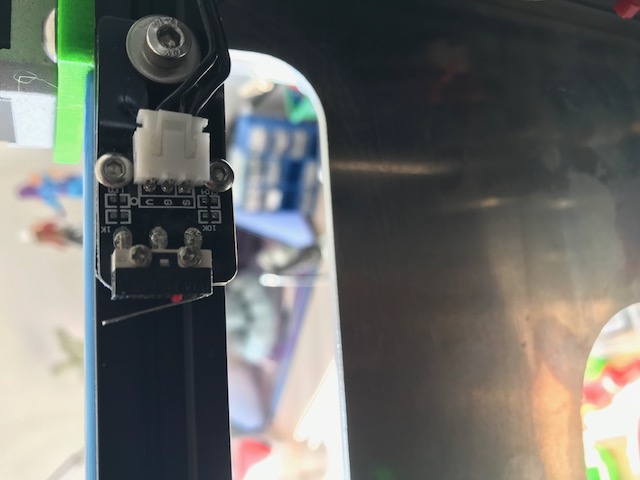

Endstop isusseposted in Tuning and tweaking

Hello, i have an isusse with my Y-Endstop. When i start the Printer and home the Axis, it works well.

But after the Axis is homed or after a print, when i rehome the Y-Axis, the Endstop is still triggerd, so the Axis don´t move to the endstop.

Can anyone help me pleas?; Endstops

M574 X1 S0 ; Set active low endstops

M574 Y2 S1 ; Y-Endstop hight end

M574 U2 S0 ; U-Endstop high end -

RE: Laser Filament Monitor - Testingposted in Filament Monitor

I am also interested in testing the Filament Monitor

-

RE: Setup Duex2posted in Duet Hardware and wiring

@dc42 Do you mean an extra ground wire? I have VIN- and Vin +, connected to the Duet WIFI and Duex2. VIN+ and VIN - are from the same power supply.

I have change the wiring. I thing now it is ok.Thank you

I have an other question.

I want to iluminate the printer, with the led´s. Eg, the hotend is on, Led ->red, the hotend is cold-> LED blue. Can i make this with M106 and thermostatic control or shoud i use the M42 command?

-

RE: Setup Duex2posted in Duet Hardware and wiring

@t3p3tony Ah ok, but with the commands in the console, if have the same problem. Somtimes it works and sometimes it dosen´t works, than i have to restart the duet and then it works, until the next restart.

-

RE: Setup Duex2posted in Duet Hardware and wiring

Okay, but how can i do this ? And it is also by an installed fan not only by the led. Sometimes the fan and the led works and sometimes not. Than i have to restart the board 2 or 3 times and the it works until the next start

-

RE: Setup Duex2posted in Duet Hardware and wiring

@dc42

Ok, the Jumper was one Problem, with a fan on the port it works sometimes. In my config i have ";Duex fan/LED

M106 P3 S1" but why i works sometimes after a reboot and sometime not? -

RE: Setup Duex2posted in Duet Hardware and wiring

Thank your for your replay, with "M106 P3 S1 or S255" it also dosent work. Do i have to edit something els in the config, for steup the duex?

-

Setup Duex2posted in Duet Hardware and wiring

Hello,

I have the duet Wifi + the duex 2 and i would like to controll RGB LED over the LED/Fan Port.When i add „M106 P3“ for example in the Config, there is No reaction.

The led is still of. I have also connected an Fan on Fan-Port3, at the duex. But the Fan dosen‘t work, too.

In the DWC, the duex is recognized.

Can someone help me ?

Thanks.

Thank you

Thank you