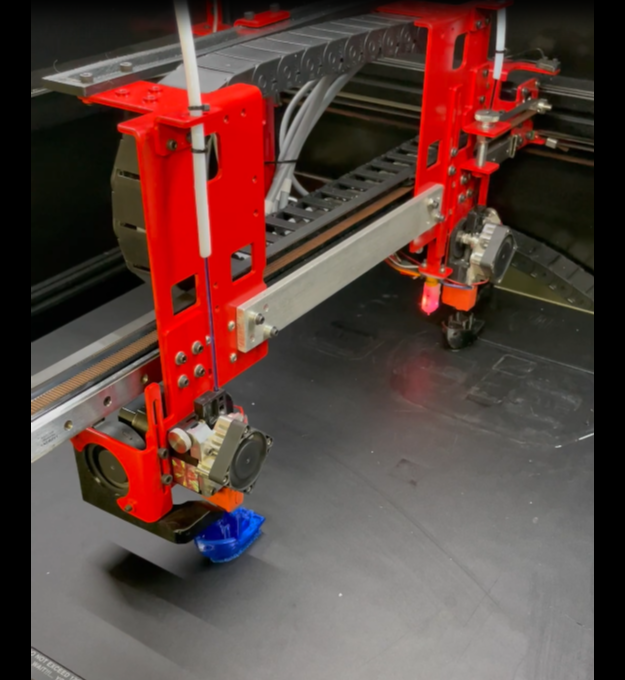

I've been working with a modix big 60 and my company wanted to double the output in the same floor space for medium and small parts. It's a little bit of a Frankenstein's monster, but its working great!

I got a duplicate gantry and made some aluminum parts to lock the gantries to the same axis. The first test were some classic benchys. They actually came out at a great quality, even the slave gantry!

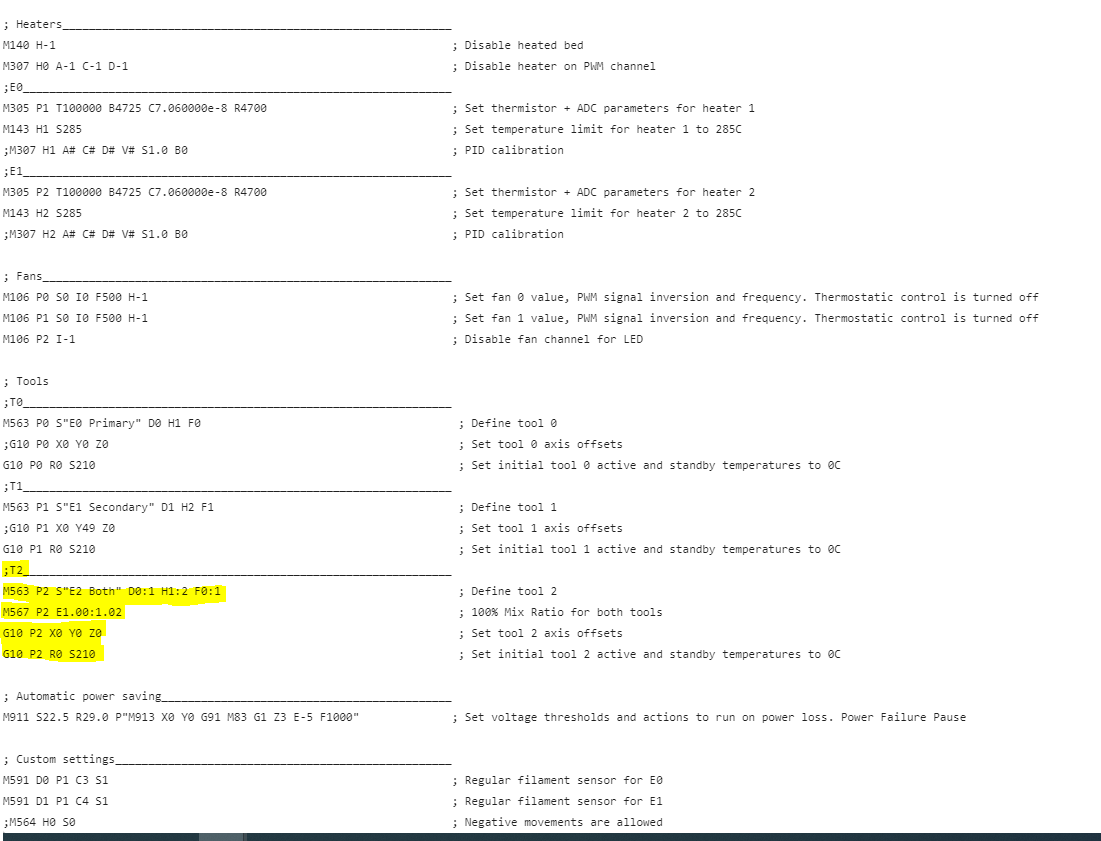

Here is the config file adjustment! I created a third tool that runs both of the extruders and heats them up to the same temperatures.

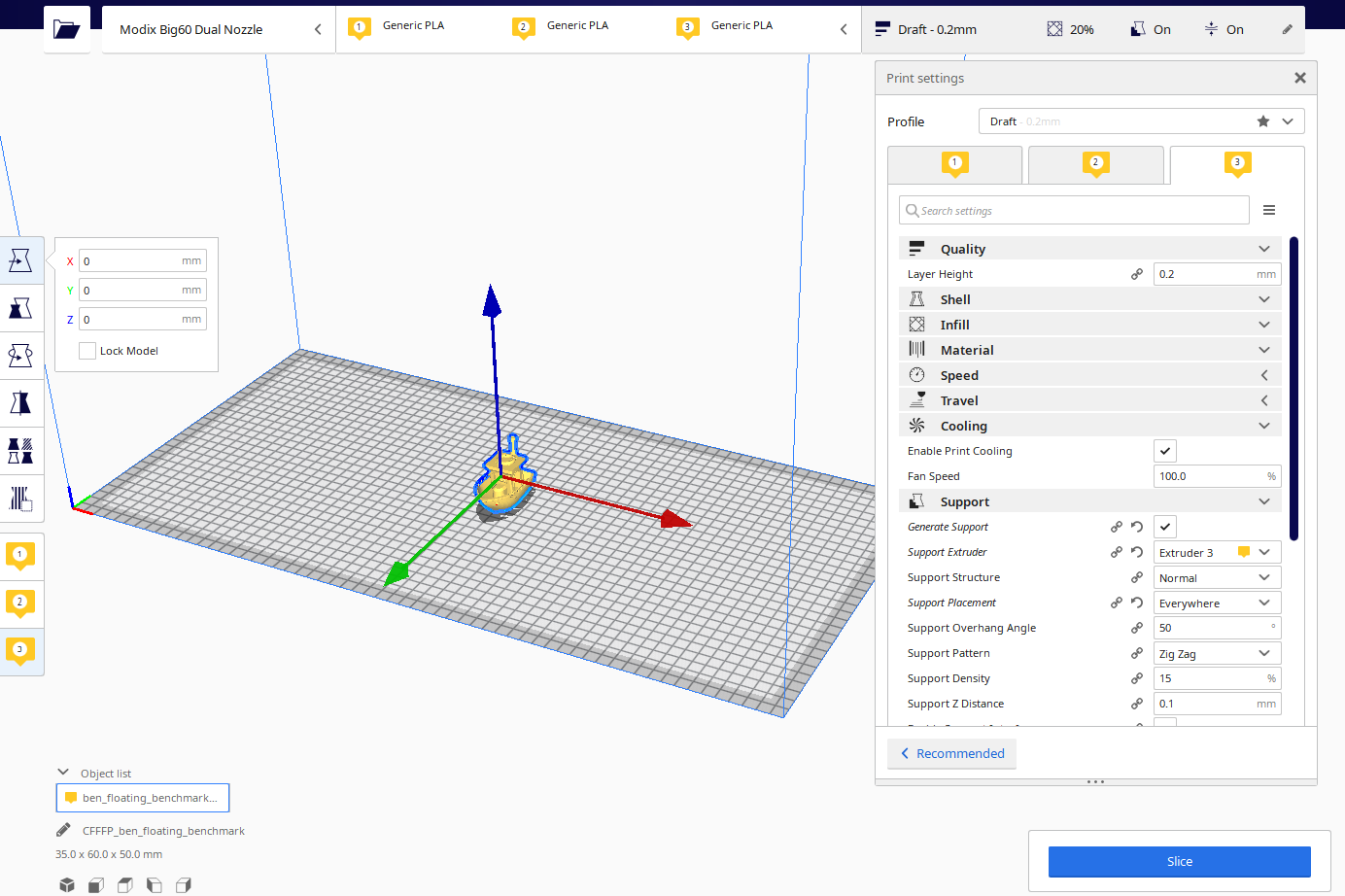

Lastly, I had to create a cura profile that would work. Basically, I created a third tool in cura and cut the y-axis in half for the offset of the second tool head.

The machine thinks it is only creating one object, but actually outputting two!

Let me know what you think!