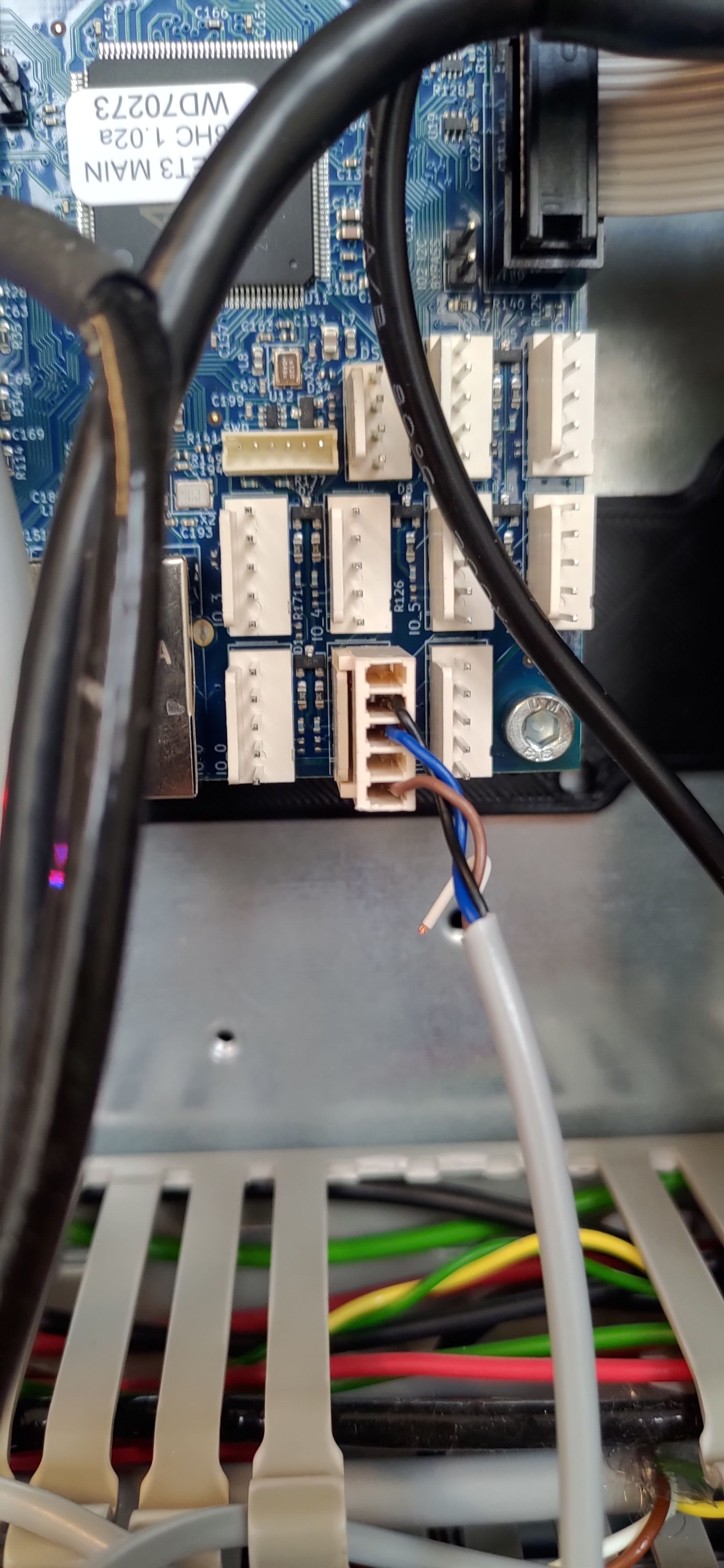

@Mr-Crispin Why do you think that? I connected BN to 5V_EXT, BU to GND. And BK to iO.in. I might switch black/white to use the NO closed contact but the rest seems correct I think?

Posts made by DieterSw

-

RE: 6HC inductive 4 wire endstop wiringposted in Duet Hardware and wiring

-

6HC inductive 4 wire endstop wiringposted in Duet Hardware and wiring

Hi,

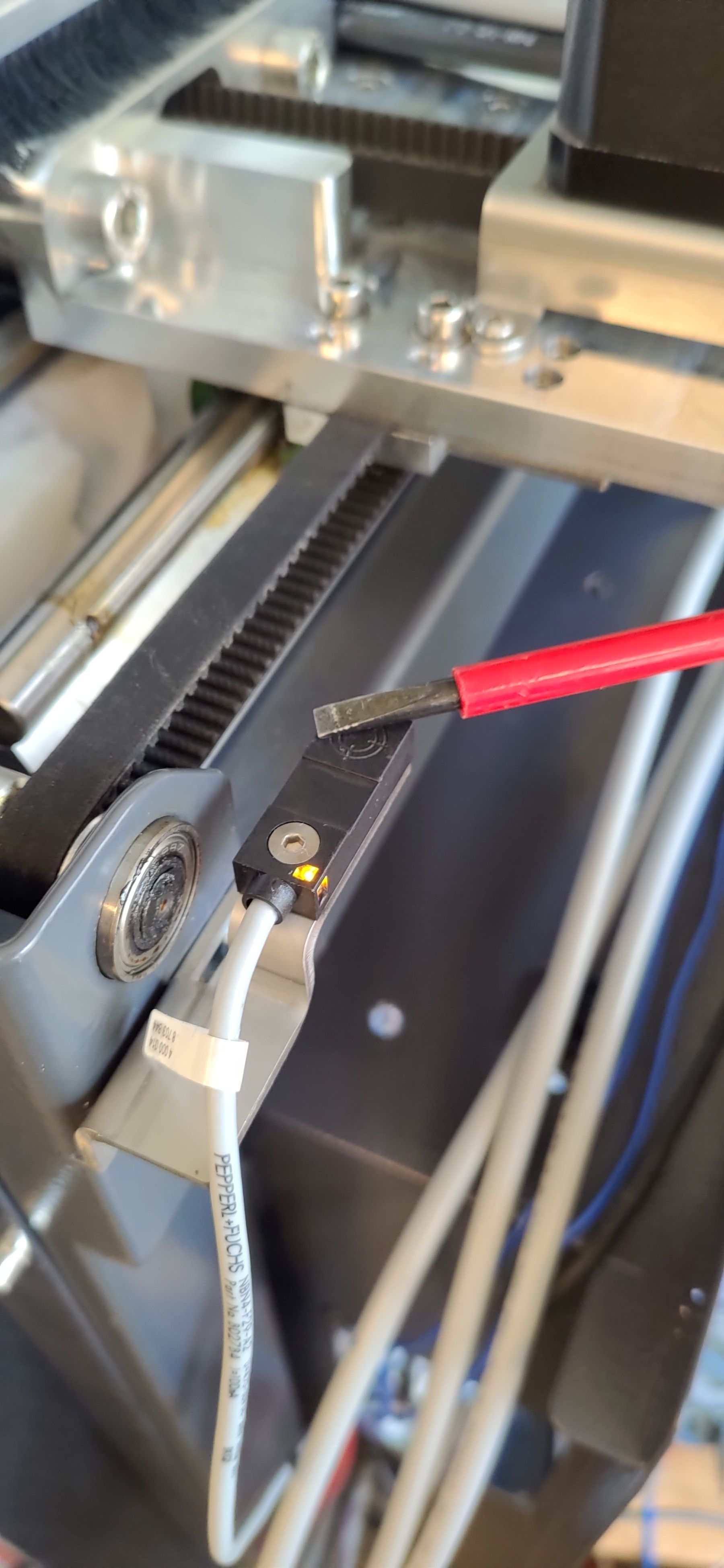

I am using pepperl & fuchs inductive endstops (NBN4-F29-A2

) and haven't been able to get them working. They're 5v sensor. So I wired them to th IO ext5 pin and tried both the normally open and closed contact to the input. But I haven't been able to 'trigger' them in the software. I see them working (LED indicator) but a no point have I been able to use them in software. I tried using the Object model plugin but they never switch states.

I have 3 of them, one for each axis, only one is plugged in the picture```Am I missing something? The NO802784_eng.pdf contact is around 3,2V (between ground) when not triggered, and 5V when trigger). Is 3,2 V to high causing them to always be active? Note: config.g is incomplete, I'm configuring it step by step to troubleshoot it.

; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.0-rc.2+6 on Wed Jan 24 2024 15:15:05 GMT+0100 (Midden-Europese standaardtijd) ; General M550 P"Duet 3" ; set hostname ; Network M552 P0.0.0.0 S1 ; configure Ethernet adapter M586 P0 S1 ; configure HTTP ; Smart Drivers M569 P0.0 S0 D2 ; driver 0.0 goes backwards (X axis) M569 P0.1 S0 D2 ; driver 0.1 goes backwards (Y axis) M569 P0.2 S0 D2 ; driver 0.2 goes backwards (Z axis) M569 P0.3 S1 D2 ; driver 0.3 goes forwards (extruder 0) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.0 Y0.1 Z0.2 ; set axis mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M906 X1600 Y2200 Z2400 ; set axis driver currents M92 X64 Y80 Z400 ; configure steps per mm M208 X0:400 Y0:400 Z0:400 ; set minimum and maximum axis limits M566 X900 Y900 Z12 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y6000 Z180 ; set maximum speeds (mm/min) M201 X500 Y500 Z20 ; set accelerations (mm/s^2) ; Extruders M584 E0.3 ; set extruder mapping M350 E16 I1 ; configure microstepping with interpolation M906 E1200 ; set extruder driver currents M92 E420 ; configure steps per mm M566 E120 ; set maximum instantaneous speed changes (mm/min) M203 E3600 ; set maximum speeds (mm/min) M201 E250 ; set accelerations (mm/s^2) ; Kinematics M669 K0 ; configure Cartesian kinematics ; Endstops M574 X1 P"!io0.in" S1 ; configure X axis endstop M574 Y1 P"!io1.in" S1 ; configure Y axis endstop M574 Z2 P"!io3.in" S1 ; configure Z axis endstop ; Sensors M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B4725 C7.06e-8 ; configure sensor #0 M308 S1 P"temp1" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #1 ; Heaters M950 H0 C"out0" T0 ; create heater #0 M143 H0 P0 T0 C0 S140 A0 ; configure heater monitor #0 for heater #0 M307 H0 R2.43 D5.5 E1.35 K0.56 B1 ; configure model of heater #0 M950 H1 C"out1" T1 ; create heater #1 M143 H1 P0 T1 C0 S285 A0 ; configure heater monitor #0 for heater #1 M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Fans M950 F0 C"out3" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 M950 F1 C"out4" ; create fan #1 M106 P1 S0 B0.1 H1 T45 ; configure fan #1 ; Tools M563 P0 H1 F0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C ; Miscellaneous M501 ; load saved parameters from non-volatile memory code_text