I use a magnetic heated bed to attach a piece of spring steel to print on. My bed is heating up relatively fast and I noticed that the piece of spring steel is warping excessively because the center of the bed is hot faster than the edges. Is there a way define a rate in °C per second somewhere to limit the heating rate?

Posts made by dgrat

-

Control heat rate of the bedposted in Tuning and tweaking

-

Checksum Calculation for Smart Effector v3 brokenposted in Duet Hardware and wiring

I think the checksum calculation is broken again. For the old revision I suggested a fix once..

I think the issue in code looks very similar. -

RE: File seems to crash the firmware (Maybe Line Endings?)posted in Firmware installation

Do you think it makes sense to check encoding in the firmware and reject the file to avoid UB.

-

RE: File seems to crash the firmware (Maybe Line Endings?)posted in Firmware installation

@dgrat

I think it might be the coding. I was piping the output of a python script with powershell. Maybe a coding check (warning) in the web-app or firmware would be beneficial. -

RE: File seems to crash the firmware (Maybe Line Endings?)posted in Firmware installation

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.1 (2022-06-01)

Duet WiFi Server Version: 1.26 -

File seems to crash the firmware (Maybe Line Endings?)posted in Firmware installation

I noticed that the firmware/WebApp seems to crash if I upload and execute this file.

Copying the content with Notepad++ into a new file seems to work. -

RE: smarteffector v4posted in Smart effector for delta printers

An accelerometer would be nice, I guess.

-

RE: Maybe Bug: Redoing height maps add sometimes random offsetsposted in Tuning and tweaking

Thanks all for gcode and explanation

-

RE: Maybe Bug: Redoing height maps add sometimes random offsetsposted in Tuning and tweaking

I wonder if G29 depends on another command e.g. g30 to create a datum.

Shouldn't be heightmap creation defined in a gcode macro which the user defines?

-

RE: Maybe Bug: Redoing height maps add sometimes random offsetsposted in Tuning and tweaking

@fcwilt

I thought that is only necessary before starting a print?

Where is written that G29 requires that and why the offset changes? -

RE: Maybe Bug: Print started with cold hotendposted in Tuning and tweaking

@arnold_r_clark

Cura 4.13 -

Maybe Bug: Print started with cold hotendposted in Tuning and tweaking

I noticed at least one time with firmware 3.4 that a print started with cold hotend.

So the heating failed for some reason and then the print started.

This happened after starting a print after breaking an old one.; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.4 on Mon Dec 09 2019 20:31:57 GMT+0100 (Mitteleuropäische Normalzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender" ; set printer name ; Panel Due M575 P1 S1 B57600 M667 S0 ; select Cartesian mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80 Y80 Z3200 E830 ; set steps per mm M566 X1200 Y1200 Z120 E3000 ; set maximum instantaneous speed changes (mm/min) M203 X12000 Y12000 Z600 E450 ; set maximum speeds (mm/min) M201 X1200 Y1200 Z120 E3000 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z800 E630 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X225 Y225 Z220 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; Set active high and disabled endstops M574 Y1 S1 P"ystop" ; Set active high and disabled endstops M574 Z2 S1 P"zstop" ; Set active high and disabled endstops ; Disable heaters H3-H7 to free up pins M950 H3 C"nil" M950 H4 C"nil" M950 H5 C"nil" M950 H6 C"nil" M950 H7 C"nil" ; Z-Probe M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H8 F100 T6000 ; Set Z probe type to bltouch and the dive height + speeds G31 P500 X-25.5 Y37 Z1.95 ; Set Z probe trigger value, offset and trigger height Z / before trigger: 1.7 M557 X40:220 Y00:180 S60 ; Define mesh grid ; Heaters M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M307 H0 S1.00 V23.9 M140 H0 M308 S1 P"e0_temp" Y"pt1000" M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 M143 H1 S265 ; Set temperature limit for heater 1 to 240C M307 H1 A271.1 C122.4 D24.0 S0.25 V24 B0 ; limit the hotend heater to 25% power ; Fans M950 F0 C"fan0" Q500 M106 P0 S0.0 I0 H-1 C"Print Fan" ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M950 F1 C"fan1" Q500 M106 P1 T50 H1 C"Hotend Fan" ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M950 F2 C"fan2" Q500 M106 P2 T50 H1 C"Case Fan" ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; enable: config-override.g M501 -

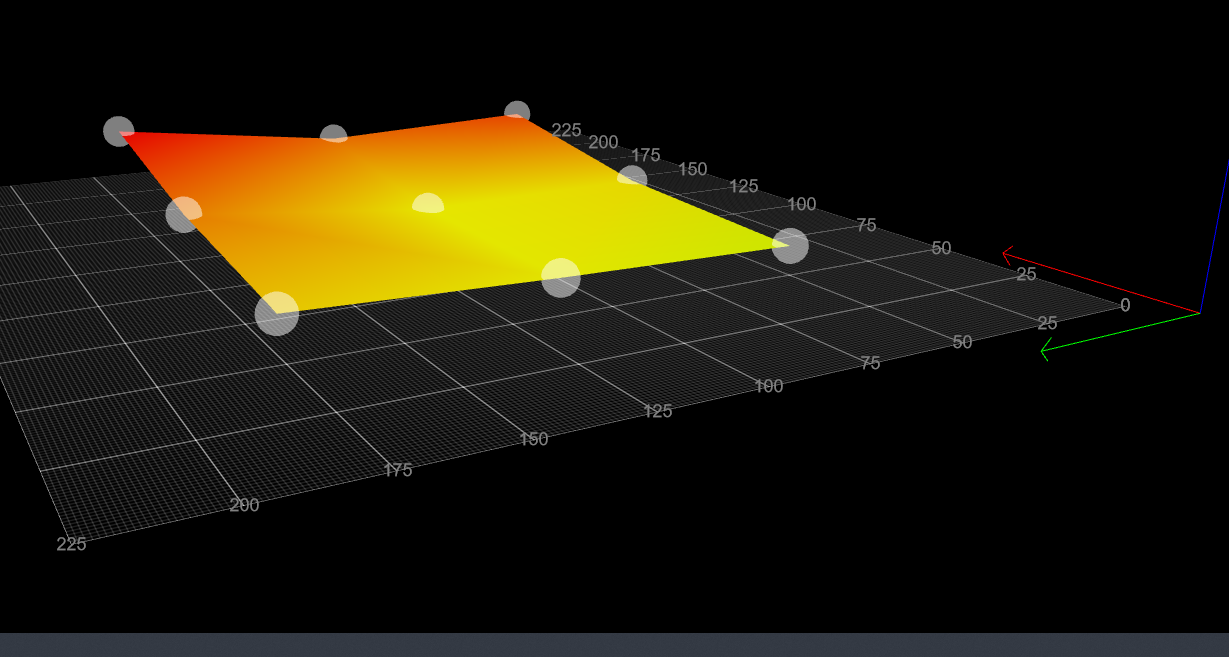

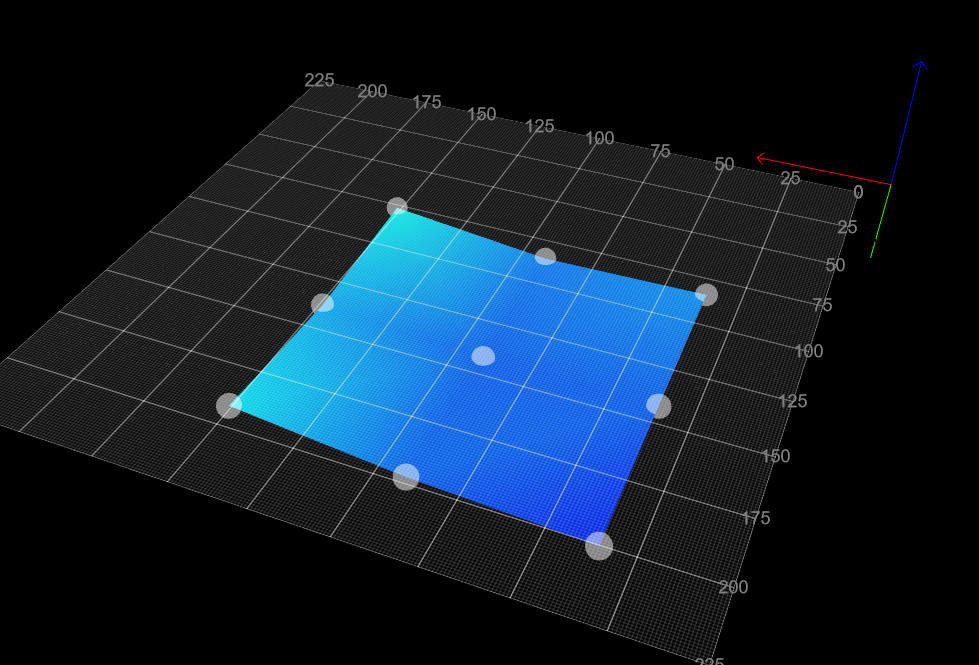

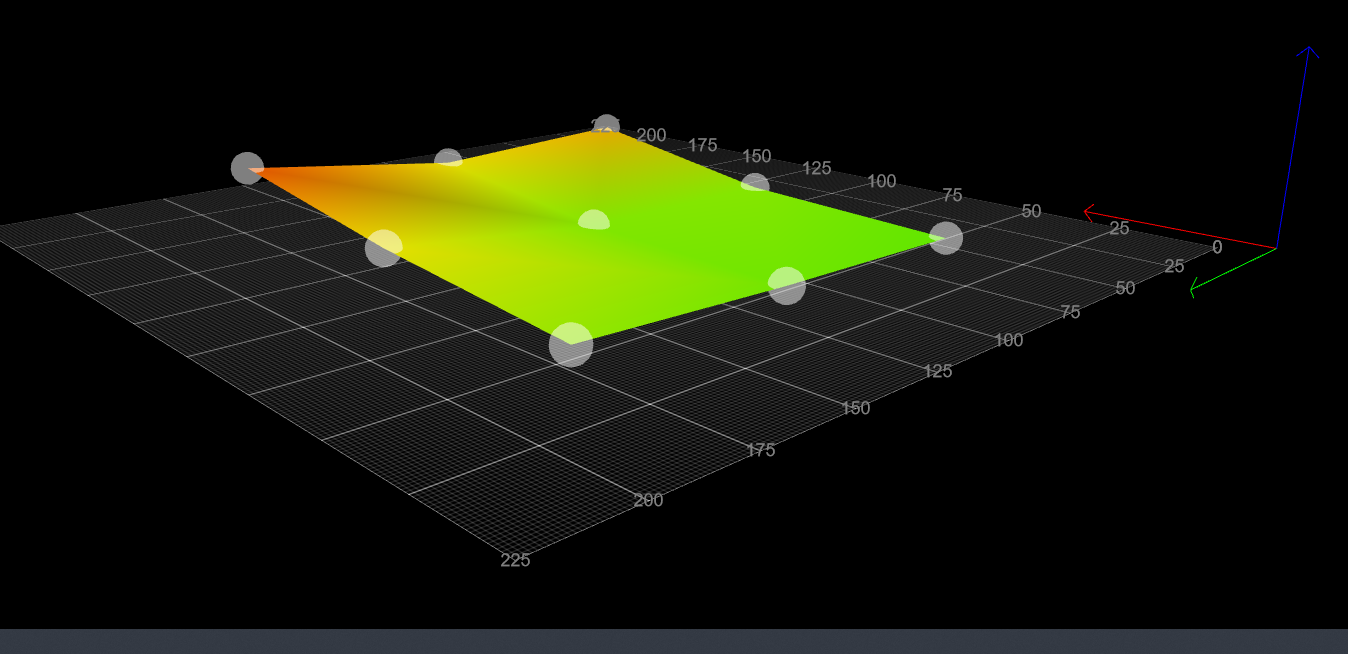

Maybe Bug: Redoing height maps add sometimes random offsetsposted in Tuning and tweaking

I think this is a firmware bug, I noticed already since a while. It is still present in 3.4.

When I redo height maps the height maps shift sometimes by a constant amount.

Here I played with a z-offset of 1.9 mm and 1.95 mm. The offset became quiet drastic (+/- up to 0.5 mm).

I noticed that behavior on all my printers. This behavior is rather random. Sometimes the height maps are fine.The trigger height seems always correct and does not change, because the reported z-value upon triggering is always the same value.

Seems like the firmware is adding a random number to the height estimate.

After powering off the printer entirely (no reset via firmware), I often get a correct height map again.Any ideas?

Steps to reproduce:

Duet Wifi 2

call: G31 P500 X-25.5 Y37 Z1.95Example shows a G29 after a print I ended.

And here just after redoing after soft-reset which disappeared only after head-reset

-

RE: Mesh Bed Compensation: Z axis not working during printposted in Tuning and tweaking

@dgrat I found the issue. I forgot to set the X/Y offset of my sensor. It was correcting for the wrong spot..

-

RE: Mesh Bed Compensation: Z axis not working during printposted in Tuning and tweaking

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.4 on Mon Dec 09 2019 20:31:57 GMT+0100 (Mitteleuropäische Normalzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender" ; set printer name ; Panel Due M575 P1 S1 B57600 M667 S0 ; select Cartesian mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80 Y80 Z400 E830 ; set steps per mm M566 X1200 Y1200 Z120 E3000 ; set maximum instantaneous speed changes (mm/min) M203 X12000 Y12000 Z3000 E3000 ; set maximum speeds (mm/min) M201 X5000 Y5000 Z120 E3000 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X225 Y225 Z220 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; Set active high and disabled endstops M574 Y1 S1 P"ystop" ; Set active high and disabled endstops M574 Z2 S1 P"zstop" ; Set active high and disabled endstops ; Disable heaters H3-H7 to free up pins M950 H3 C"nil" M950 H4 C"nil" M950 H5 C"nil" M950 H6 C"nil" M950 H7 C"nil" ; Z-Probe M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H8 F150 T6000 ; Set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z5.04 ; Set Z probe trigger value, offset and trigger height Z+ pousouva osu Z smerem dolu k podlozce (stará tisková hlava X7.9 Y58.8) M557 X40:220 Y00:180 S20 ; Define mesh grid ; Heaters M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M307 H0 S1.00 V23.9 M140 H0 M308 S1 P"e0_temp" Y"pt1000" M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 M143 H1 S265 ; Set temperature limit for heater 1 to 240C M307 H1 A271.1 C122.4 D24.0 S0.25 V24 B0 ; limit the hotend heater to 25% power ; Fans M950 F0 C"fan0" Q500 M106 P0 S0.0 I0 H-1 C"Print Fan" ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M950 F1 C"fan1" Q500 M106 P1 T50 H1 C"Hotend Fan" ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M950 F2 C"fan2" Q500 M106 P2 T50 H1 C"Case Fan" ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; enable: config-override.g M501 -

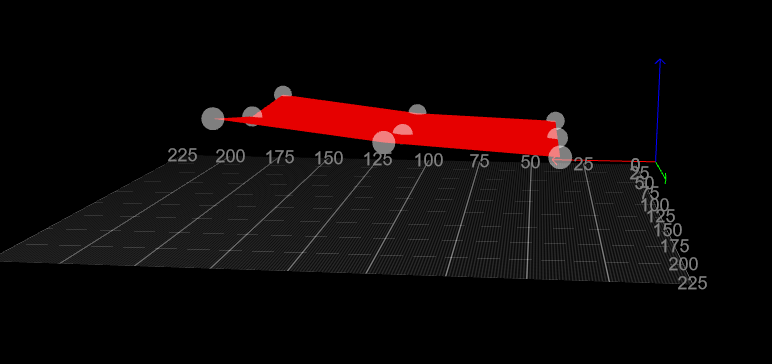

RE: Mesh Bed Compensation: Z axis not working during printposted in Tuning and tweaking

I tested by editing of the heightmap. I think the motor is working but missing microsteps.

Guess the combination of T8-8 spindle with 1.8° stepper is insufficient for compensating minor height differences. -

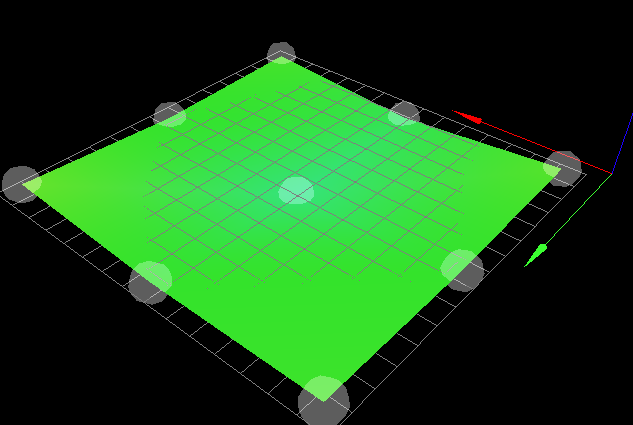

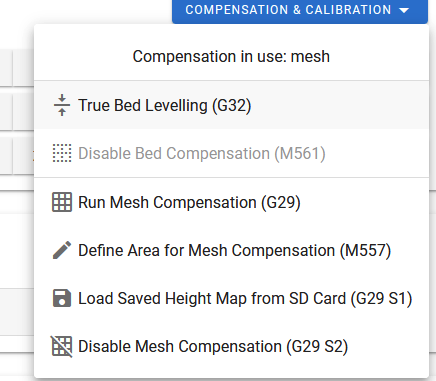

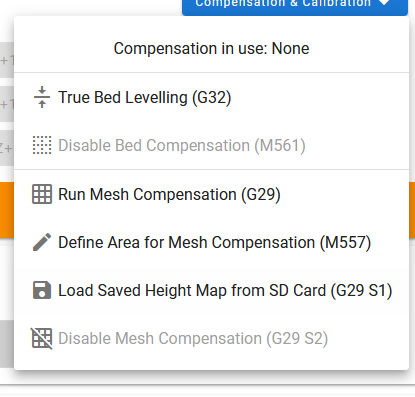

Mesh Bed Compensation: Z axis not working during printposted in Tuning and tweaking

I performed a mesh bed compensation and started a print. I expected to see the z-axis spinning slightly while printing (~0.1 mm). But it is not. Am I missing something?