I had several not enough movement errors when I first installed the mag sensor. I was able to flash the firmware up to version 3 which did not really help, but it did show that the agc was in a good place, stays around 70. I had to really go through my printer and make sure everything was spot on. Delta, 1 meter Bowden tube, E3d V6 hot end and Duet smart effector. The big break through was reducing the exstruder motor current from 2400 to 2150 and then setup PTFE tubing from the filament spool to the monitor so that there is about 6 inches of tubing that directs the filiment straight into the monitor, no binding at monitor entrance. I have had this setup for some months now and rarely have movement issues and when I do there is always a reason, usually a slightly clogged nozzle. My printer is truely a load and go machine thanks to this monitor and the turning I had to do to make it work properly.

Posts made by DarylMcM

-

RE: Spurios "sensor not work" and not enough movement faultsposted in Filament Monitor

-

RE: Problem with Magnetic Sensorposted in Filament Monitor

dc42, I do have a minimal distance between the monitor and the extruder entrance. About 3mm. I do not have PTFE in that small area. I do have PTFE restraining the filament from the reel to the entrance of the monitor keeping it straight.

Does the 'A' parameter of the M591 entry need to be set in order for the retractions to be Taken into account? -

RE: Problem with Magnetic Sensorposted in Filament Monitor

14 hours later and About 100 meters of filament to go on this 445 meter job. After tweaking sensitivity, ratios, extruder rate, print speed and closely visually monitoring print quality, I found the filament monitor setting that work with this less than satisfying wood PLA filament.

They are not ideal, but unless one is down with running about 75 % print speed, this is what worked. Slowing the print speed increased the min reported back up to upper 60s percentage.

Extrusion at 100%, speed at 100% (80mm/sec max), temp mid range of filament noted temp range (200c in this case) and the following:**8:23:33 AM

M591 D0

Duet3D magnetic filament monitor on input 3, enabled, sensitivity 28.02mm/rev, allow 20% to 130%, check every 12.0mm, version 3, mag 131 agc 70, measured sensitivity 27.91mm/rev, min 28% max 113% over 13183.3mm(From M122report)

=== Filament sensors ===

Extruder 0: pos 350.16, errs: frame 16 parity 0 ovrun 0 pol 2 ovdue 0**

The above was taken after reloading filament this AM.Note the agc has climbed to 70 while the mag has continued to fluctuate from 130 to 132. AGC usually stands for automatic gain control and my assumption of the mag number has to do with magnetic strength, but I'm just guessing. The need for a sensitivity setting I still find remarkable, but again assuming, it is probably due to reading a magnetic rotation instead of having a direct drive.

The monitor did save my job by detecting a very slight blockage in the nozzle, noted by the tell tail curving of the filament as it is extruded. The min reported was 19%. It also properly paused the job when the filament ran out.

My big takeaway from this job is Not All Filaments are Monitored Equally. Wood filament is a strange animal anyway. I have two more runs of this job to go on this printer and I am anxious to move on to some peg jobs to see how that goes.

All in all I am very satisfied with this monitor. It would be great to have the report to include the current measured percentage. This would allow one to note the current trend. A means of distinguishing a monitor pause from a button pause would also be a fine feature.

Like any other new trick, it just takes some training to get the dog to rollover and speak.

-

RE: Problem with Magnetic Sensorposted in Filament Monitor

Changed length of measurement to 12mm and things improved somewhat. Updated sensitivity also.

Noted a fluctuation in the mag parameter being reported.5:57:31 PM

M591 D0

Duet3D magnetic filament monitor on input 3, disabled, sensitivity 27.21mm/rev, allow 30% to 130%, check every 12.0mm, version 3, mag 131 agc 69, measured sensitivity 27.31mm/rev, min 58% max 110% over 32428.9mm

5:56:25 PM

M591 D0

Duet3D magnetic filament monitor on input 3, disabled, sensitivity 27.21mm/rev, allow 30% to 130%, check every 12.0mm, version 3, mag 132 agc 69, measured sensitivity 27.31mm/rev, min 58% max 110% over 32039.7mm -

RE: Problem with Magnetic Sensorposted in Filament Monitor

well, as I reported to Tony, I ran 5 meters of filament on a small job and the monitor worked perfectly. No pauses and well within the 70%/130% parameters over 3mm.

ver 3 monitor firmware reported mag 132 agc 69. generic PLA 195c 0.4 nozzle.Now I'm running a 450 meter job wood PLA filament, 200c 0.6 nozzle. mag still 132 agc still 69. No love. can't get through a layer without a pause and the sensitivity and percentage number are not consistent. I had to disable the monitor in order to continue the job. the filament is laying down perfectly, no gaps, good solid layers. No grinding, no jumping on the extruder motor.

4:05:17 PMM591 D0

Duet3D magnetic filament monitor on input 3, disabled, sensitivity 25.74mm/rev, allow 30% to 130%, check every 3.0mm, version 3, mag 132 agc 69, measured sensitivity 27.15mm/rev, min 2% max 112% over 8897.1mm4:10:58 PMM122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 2.04 running on Duet WiFi 1.02 or later

Board ID: 08DGM-917DA-G4MSJ-6JTD8-3S46L-TSPRB

Used output buffers: 3 of 24 (17 max)

=== RTOS ===

Static ram: 25680

Dynamic ram: 92736 of which 20 recycled

Exception stack ram used: 452

Never used ram: 12184

Tasks: NETWORK(ready,628) HEAT(blocked,808) MAIN(running,3808) IDLE(ready,200)

Owned mutexes:

=== Platform ===

Last reset 01:42:00 ago, cause: power up

Last software reset at 2019-11-09 15:38, reason: User, spinning module GCodes, available RAM 12408 bytes (slot 3)

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d

Error status: 0

Free file entries: 9

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest block write time: 0.0ms, max retries 0

MCU temperature: min 40.0, current 43.0, max 43.3

Supply voltage: min 23.7, current 23.9, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

Driver 0: ok, SG min/max 367/1023

Driver 1: ok, SG min/max 286/1023

Driver 2: ok, SG min/max 0/1023

Driver 3: ok, SG min/max not available

Driver 4: standstill, SG min/max not available

Date/time: 2019-11-10 16:10:57

Cache data hit count 4294967295

Slowest loop: 2.83ms; fastest: 0.08ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Move ===

Hiccups: 0, FreeDm: 156, MinFreeDm: 144, MaxWait: 0ms

Bed compensation in use: none, comp offset 0.000

=== DDARing ===

Scheduled moves: 4711, completed moves: 4703, StepErrors: 0, LaErrors: 0, Underruns: 0, 0

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1

Heater 0 is on, I-accum = 0.1

Heater 1 is on, I-accum = 0.4

=== GCodes ===

Segments left: 1

Stack records: 3 allocated, 0 in use

Movement lock held by null

http is idle in state(s) 0

telnet is idle in state(s) 0

file is doing "G1 X-40.873 Y-125.908 E124.08205" in state(s) 0

serial is idle in state(s) 0

aux is idle in state(s) 0

daemon is idle in state(s) 0

queue is idle in state(s) 0

autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 242.77ms; fastest: 0.08ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 1 of 8- WiFi -

Network state is running

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 2

WiFi firmware version 1.23

WiFi MAC address 80:7d:3a:3f:f6:0f

WiFi Vcc 3.39, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 23376

WiFi IP address 192.168.20.25

WiFi signal strength -44dBm, reconnections 0, sleep mode modem

Socket states: 0 0 0 0 0 0 0 0

=== Filament sensors ===

Extruder 0: pos 97.38, errs: frame 8 parity 0 ovrun 0 pol 0 ovdue 0

- WiFi -

-

RE: Problem with Magnetic Sensorposted in Filament Monitor

Quick update while waiting for tools...I reconfigured the filament path so that it is pulled straight into the filament monitor from about 20 mm away. It had followed a path where is was pulled at a slight angle as it entered into the monitor. After the modification was able to run several meters of filament with a min 97% max 110%. I have only run this one print with these results. More testing to come, but this might be something for others to investigate.

-

Paused by Filament Monitor or buttonposted in Filament Monitor

Is there a method to determine if the monitor caused the pause or the pause button was pressed? The firm ware knows when an external trigger causes the pause, it puts up a message. How can one determine how the pause was executed?

-

RE: Problem with Magnetic Sensorposted in Filament Monitor

I’m in the US and bought the unit from Filastruder.

-

RE: Problem with Magnetic Sensorposted in Filament Monitor

I also am experiencing these exact Issues, now with the second magnetic monitor I have tried. The first had the idler parts missing and was replaced. Other than more resistance while inserting filament, I have not seen any change in the results between the two monitors.

I created a mount that places the monitor 3 mm prior to the extruder and keeps it firmly in place. Through taglia doesn't mention it, based on how he has mounted the monitor, one could assume that the printer uses a Bowden tube, as does mine. I have a Duet 2 Wifi 2.03 and other than that the M122 report looks very much the same as taglia's..

In the documentation an 'A' parameter is mentioned and I haven't tried including that, but I will and report back. What is the default for that parameter?

I have noticed that prints with little to no retractions being made, reports much more consistent than a print with several.

Lastly, I am curious as to why the need for a mm per revolution setting. The hobbled wheel has a set circumference and as long as filament is not slipping, the mm per revolution should always be the same and thus the mm per degree of rotation. I ask because the L parameter is rather elusive. I get a sensitivity reported over 10 of meters of filament, change the L parameter to that number and the reported sensitivity changes greatly, most of the time much higher and a couple of times even negative. It is just not consistent. -

missing spring and idlerposted in Filament Monitor

My magnetic monitor is working pretty much as expected, with the exception of an occasional dip way down on the minimum percentage, like -10% one time. I hit resume 99% of the time in it will run for hours before the next one.

I did have a bulge in the crap filament I am using where they spliced the roll and it got lodged inside the monitor. So I took it apart to see why I couldn't manually move the filament through it and found the bulge.

I also found that there is no idler bearing or spring in the unit. There is a place for them, and the monitor seems to work OK without them, but the documentation says they are suppose to be there. This unit was received fully assembled and I had no reason to take it apart until the bulge.

Could this be contributing to the occasion drop in movement reported?

Any explanations on why it is not assembled as the documentation says? -

RE: constant pauseposted in Filament Monitor

I just installed our magnetic filament monitor and about 4 layers into a 400 layer print, I was optimistic, it started pausing. Tried a bunch of things but nothing worked. It would pause within seconds of resuming. I ended up setting the R parameter to 1/330 and it started printing again. Realizing that almost defeats the purpose of the monitor, I ran the 591 reports every few minutes.

They showed a somewhat smaller sensitivity then the 28.4 I started out with and a min variation of 2% while the max variation was around 113%.

I reset the L parameter on the fly with the gcode console to a value close to what it was reporting, 26.4 I believe and immediately got a pause, which I immediately resumed. Within a few layers the min variation was up to 28% and the max was 117%. After a few more layers the sensitivity was reading 27.13 and kinda holding there so again I set the L parameter on the fly and again got a pause and resumed.

The print is 75% done and I just changed the L parameter to 27.88 and now the min variation is 48% and the max is 112%. So it is really close to the 60% spread of the original 70/130.

The print show some impact at 4-6 layer area because of the the stuff I was trying, but it is not a wasted print.

I think the big problem is crap filament that the customer supplied and is the reason for the filament monitor purchase in the first place.

I guess the takeaway is patients and insist on buying your own filament.

I do notice that the monitor we received blinks red and green, one flash each constantly if filament is not moving. This behavior is not mentioned anywhere in the documentation, but it dose not seem to indicate anything other than no motion.

Don't know if this applies to the original posting, but it may help someone. -

RE: Duet3D magnetic filament sensor wiring confusionposted in Filament Monitor

TP3Tony

Yes, the new documentation layout makes much more sense. The output pin is now next to the 2 pin switch header. The original showed the ground next to that header.Now a 1 to 1 connection between the connectors makes sense as well.

Knowing what the pin of any header is suppose to be does matter, else one might find a destroyed accessory or worse yet a very expensive control board. -

RE: Duet3D magnetic filament sensor wiring confusionposted in Filament Monitor

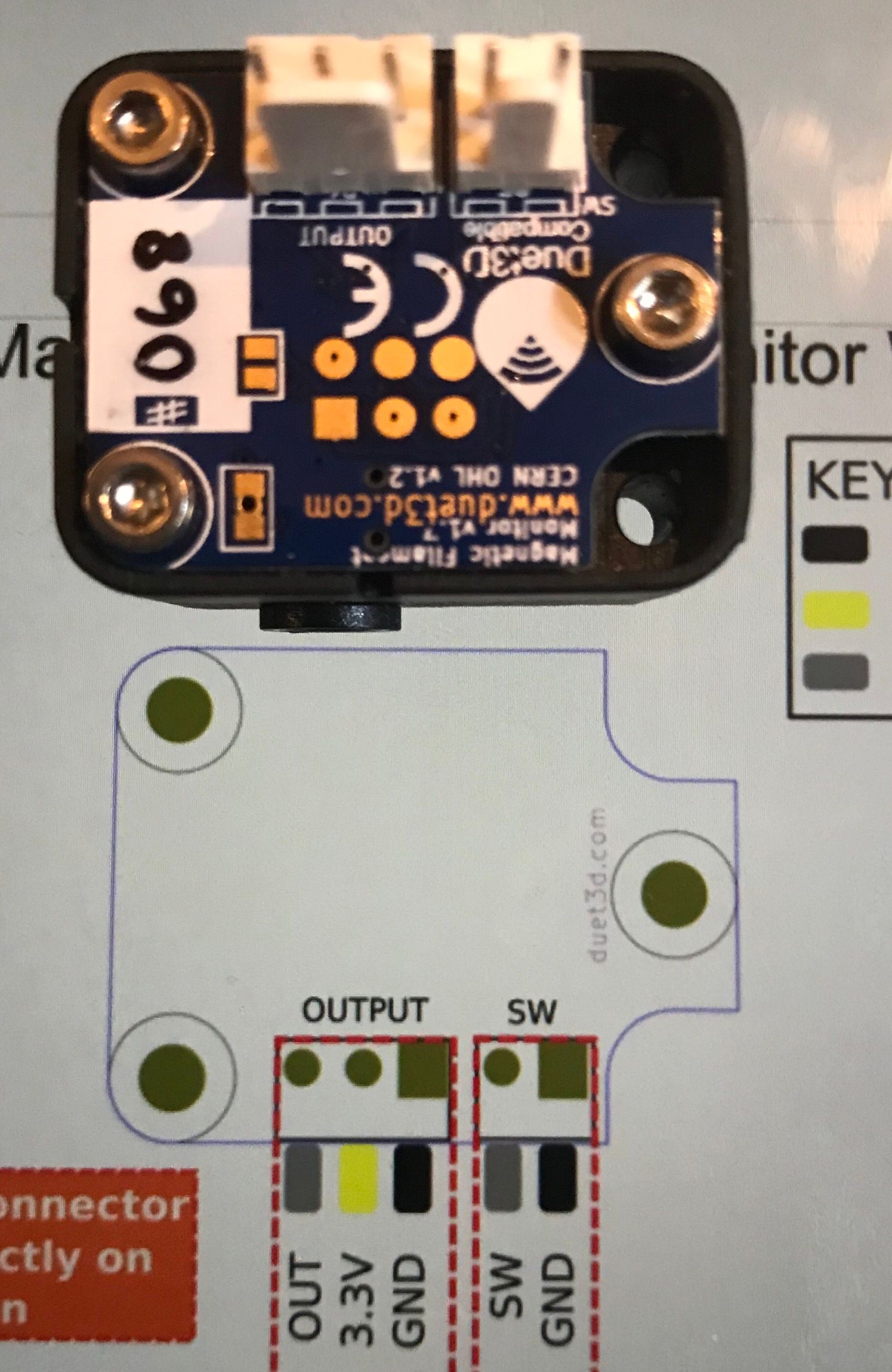

Referring to my pic of the sensor on the diagram, the pin on the right (large square) should be pin 1.

If we wire the connector as it would mount on the sensor, the key would face down and ground would still be on the right with the signal on the left.

On the Duet 2wifi control board those inputs are opposite that. That is viewing the control board with the key tab on E0 stop connector again pointing down, the ground is on the left and the signal is on the right.

So a 1 to 1 wiring would not be what the sensor diagram is showing. It would be what the pic of the installed unit is showing if my assumptions of the wire colors are correct. Ground on the left and signal on the right.

If by placing the wire connectors wiring end to wiring end and connecting the cable straight across, it would match the sensor diagram and the wifi control board, but that would be 1 to 3, 2 to 2 and 3 to 1 connection.

Forgive me if I’m being a little thick here, but it has been a long 6 day week and I haven't recovered quite yet. -

Duet3D magnetic filament sensor wiring confusionposted in Filament Monitor

Setting up a new magnetic filament sensor. Going by documentation diagram, one assumes the diagram is of the component side of the board. We received the sensor fully assembled and don't to disassemble to verify that.

If the diagram is correct, then the connector is wired just opposite of the E0 connector on the Duet WiFi controller board. Yet the picture of an installed unit shows the black wire(assuming ground) and the blue wire(assuming output) installed in the same position as on the control board in relation to the guild key on the connectors.

Here are pics that show what I am speaking of.

Is there a definite diagram that shows the correct wiring so that we do not destroy this new, expensive sensor.

-

RE: Stopped at message different than DWC head positionposted in Smart effector for delta printers

Veti,

Thanks for the reply. I have use dc42's backlash macro and added the codes to do the same test in the Y direction. It has worked very well and I use it often, especially after mods and/or cleaning. the SD/m in the x direct is 0.005 and nan. In the Y direction is 0.006 and nan.

The problem with the reporting error is gone now. I backed up my sd card and did a reset on the board. Kind of harsh, but I needed to get back in production. The DWC now reports head position at -0.15 and the firmware message reports Stopped at -0.151. Not much for the reason why the problem appeared, but it fixed the problem.

Thanks again. -

Stopped at message different than DWC head positionposted in Smart effector for delta printers

I built a large delta printer based on the blogs at Norwegian Creations. It has been performing well and adding the Duet Smart Effector sealed the deal. During Z. Probe calibration using the processes from the wiki, the head position reported in the DWC was always within hundredths of a mm to what was reported by the firmware 'Stopped at' message reported.

I had a bed holder break (layer separation just above the mounting screws) and made a new on to replace it.

I repositioned the Z axis using the paper test which was about 0.7 mm higher than before the bed holder change. G92 to set Z to 0 then several G30 S-1 from a 5 mm dive height.

The DWC shows -0.15 which is reasonably close to what it has always been, but the firmware message reports 'Stopped at 0.839 mm'.

I set the trigger height in the config file to zero and repeated the testing, but the results are exactly the same.

What may have caused this change?