Wasnt sure if I should start a new thread, hopefully its ok just to add here, I printed the concept above from brunofporto with the latest changes by adrian52.. but I don't have the right bearings on hand to properly test. Was going to take a while for bearings to get delivered..

So I decided to have a go at trying to come up with my own design. The goal was to use some decent quality bearings I had on hand - 5x10x4 (mr105) and because I figured it would be something I would be printing different version of, something that was quick & easy to assemble.

So here's my attempt:

I have tried various sensor to bearing surface distances so far.. and I'm finding that around 9mm seems to be the most consistent.

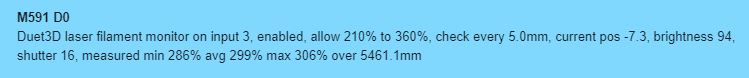

Here is a output from a recent print:

So far it seems to work really well - quite similar to adrian52's results. If you normalise the raw average figure of 299 to be 1 (or 100%) then the lowest reading is 0.956 (4.5% below the average) and the highest reading is 1.023 (2.3% above the average.

I have short tube of around 25mm between the sensor and my extruder input.. so I have set the check to be every 5mm instead of the 3mm in the example which still allows plenty of time to pause the printer if there is an issue, but the slightly longer check also seems to help a bit with consistency.

I have put my stl's and .scad file on thingiverse for anyone to use/mod/try