@dc42 thank you for your answer helpfull as usual

Can you suggest me a fully compatible driver just in case?

Thank you

Andrea

Posts made by claustro

-

RE: Wort investing in Bed levelling with independent Z motors?posted in General Discussion

-

RE: Wort investing in Bed levelling with independent Z motors?posted in General Discussion

@jay_s_uk

thank you all ,

Can I use a DRV8825? I have several available. Am I correct in thinking that using the expansion board for the extruder won't affect performance, even if a less capable driver is used -

RE: Wort investing in Bed levelling with independent Z motors?posted in General Discussion

@droftarts thank you very much for your comprehensive answer.

I didn't know about the BTT-EXP-MOT option, it seems a very cheap option. Does it have some problem I can incur using it?

I could use it to drive my single extruder letting the duet drive the 3 lead screws. Will still be possible to use a panel due connected with a 4-wire connection?Andrea

-

Wort investing in Bed levelling with independent Z motors?posted in General Discussion

I have a CoreXY printer evolved from a D-Bot, equipped with three lead screws for the Z-axis.

I'm considering converting it to use three independent lead screw motors. I already have the motors, but since I’m using a Duet 2 WiFi, I’m looking for the most cost-effective option to add an extra stepper driver.Recently, I bought a Bambulab P1S, and I’ve come to appreciate the convenience of greater automation in the calibration process

Thank you all

-

E3D revo six and Galileo 2 mounting optionposted in General Discussion

Hi guys , I asked yesterday a question about changing extruder on a corexy with revo six hotend. Actually I have a titan extruder .

I was thinking about mounting a Galileo 2 or trying a belt drive Papilio .

I am stuck on how to mount the hot end and the E3D extruder. Can someone direct me on the right path?this is my actual setup ( i have a filament sensor non pictured in this cad)

-

Extreuder suggestion for an "old" corexyposted in General Discussion

Hy guys,

I am running a 300x300x300 3 leadscrew corexy with a Titan extruder that is nearing its end of life and needs to be replaced.

Can someone suggest whether I should stick with Titan or switch to something " better / newer"?Thank you

-

RE: Scratched alluminium bedposted in General Discussion

@oliof

Thank you sent an email to the seller. -

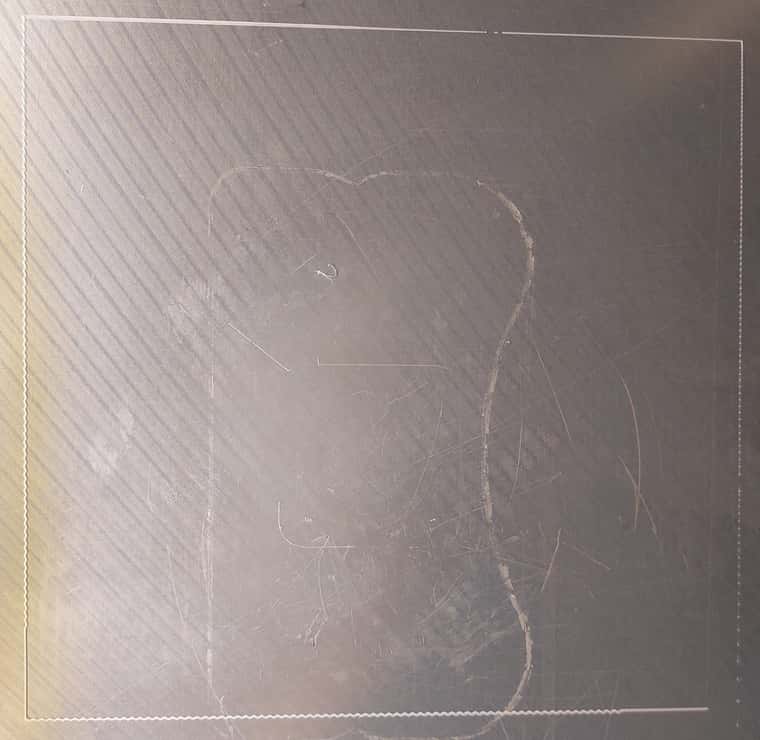

Scratched alluminium bedposted in General Discussion

Hi guys,

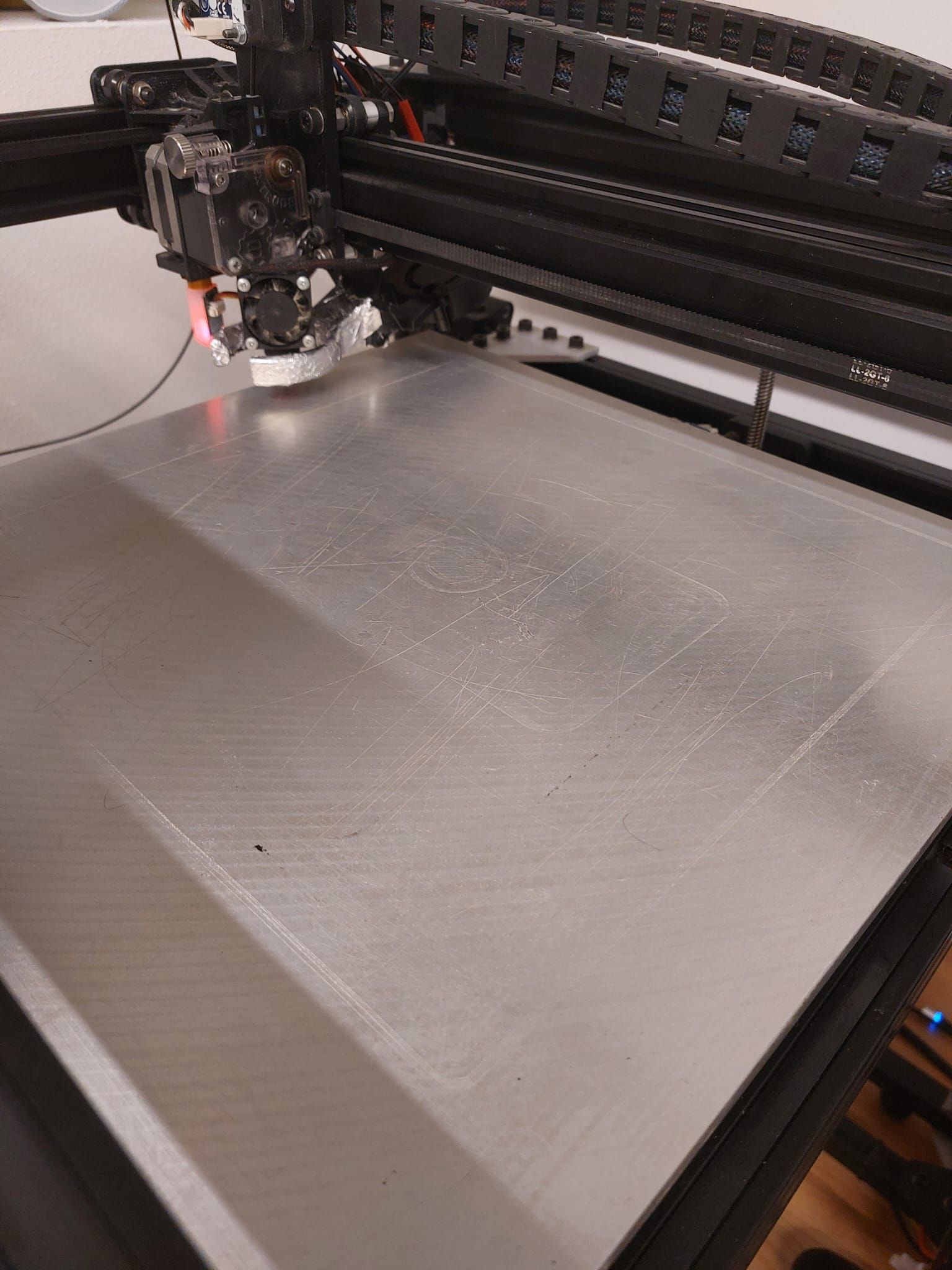

My printer has a scratched bed (PEI aluminum).

I would like to switch to a magnetic bed, but I need some magnetic adhesive as an interface. Is this a viable option, and where can I find a good heat-resistant magnetic interface?

Thank you[link text](link url)

-

G32 results are different with 3 or 4 probing pointsposted in Tuning and tweaking

Hi all ,

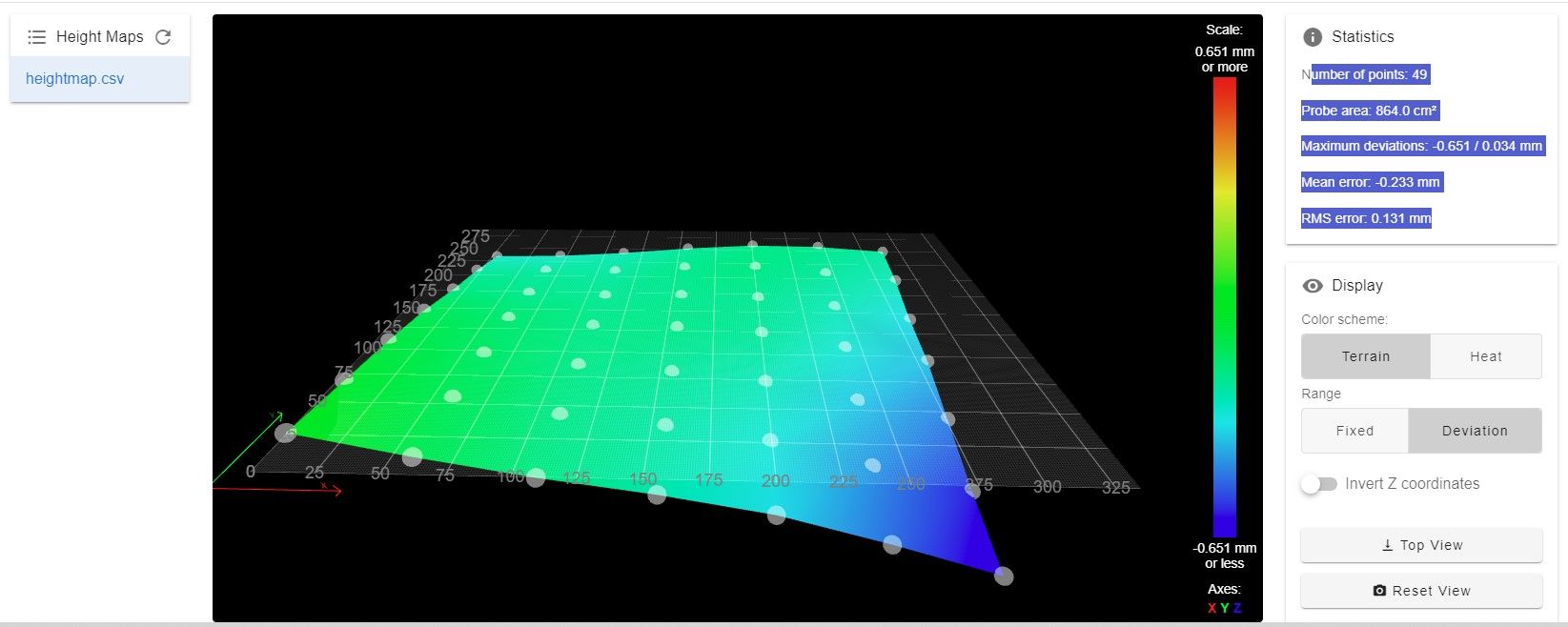

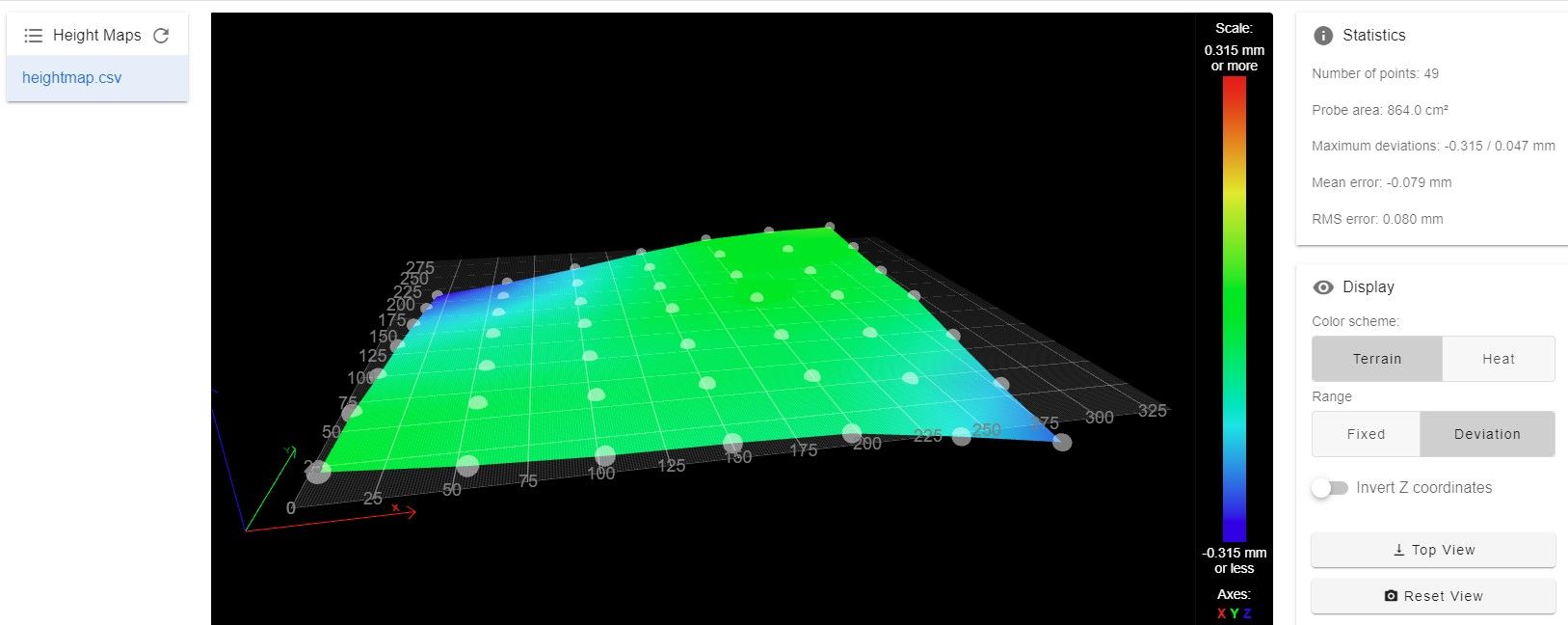

I am experimenting on probing point and G32 .

If I use 3 probing points I receive :G30 P0 X9 Y284 H0 Z-99999 G30 P1 X301 Y269 H0 Z-99999 G30 P2 X162.5 Y19 H0 Z-99999 S3Manual corrections required: 0.00 turn up (0.00mm) 0.02 turn up (-0.01mm) 0.03 turn up (-0.01mm)

If I use 4 probing point the result is

G30 P0 X9 Y284 H0 Z-99999 G30 P1 X301 Y284 H0 Z-99999 G30 P2 X301 Y19 H0 Z-99999 G30 P3 X9 Y19 H0 Z-99999 S3Manual corrections required: 0.00 turn up (0.00mm) 0.73 turn up (-0.37mm) 0.49 turn up (-0.24mm)

If I do a height map using 3 or 4 probing points the result are as follows.

3 points

4 points

What should I use?

are these results coherent?Thank you

Andrea -

RE: Fast print results, what can I improve?posted in Tuning and tweaking

@mrehorstdmd Thank you for your answer.

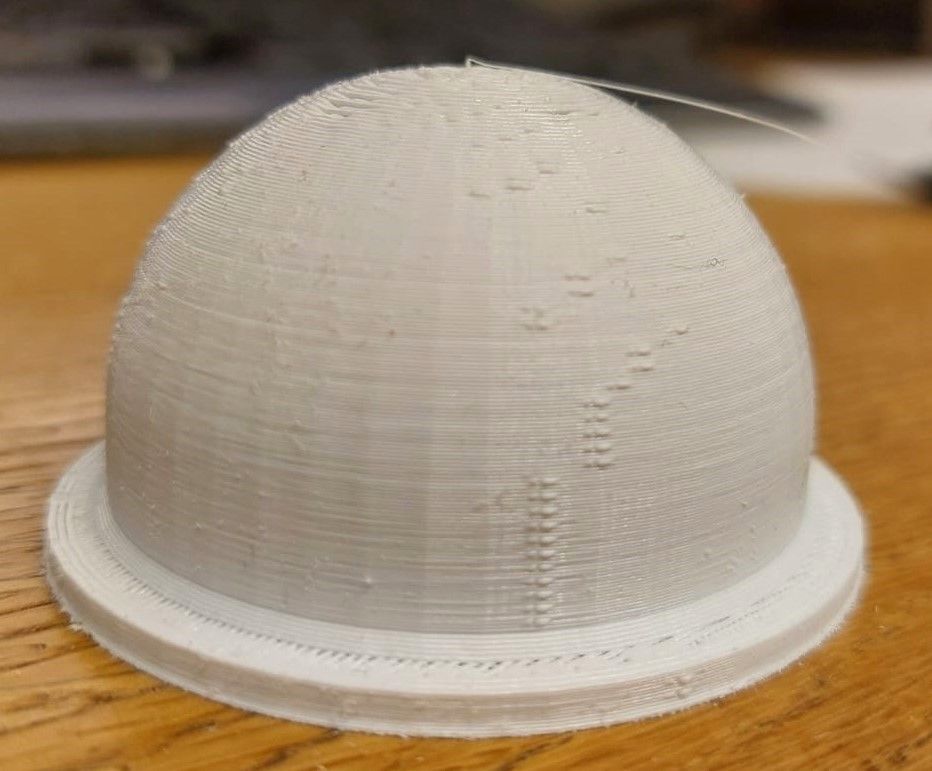

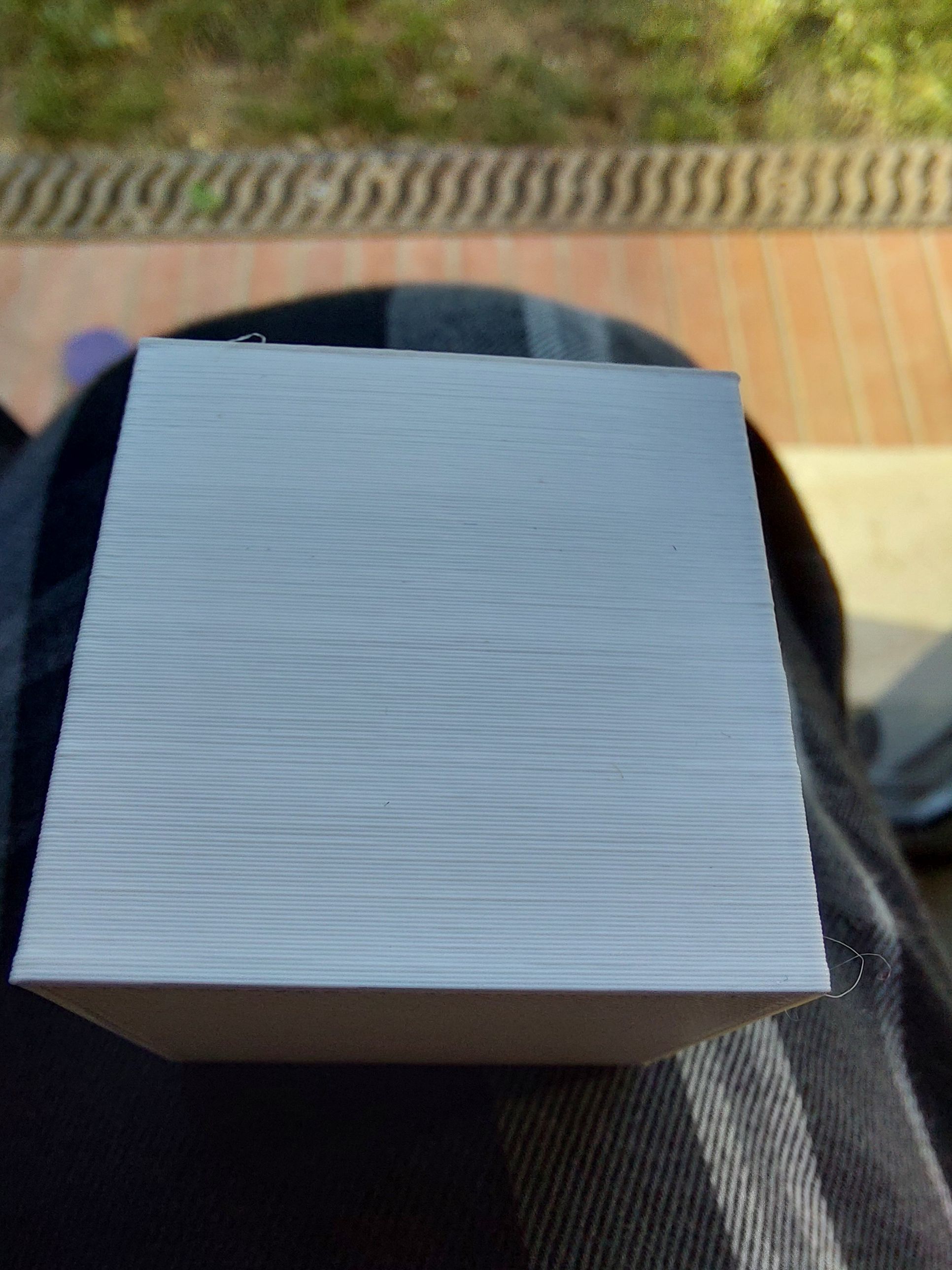

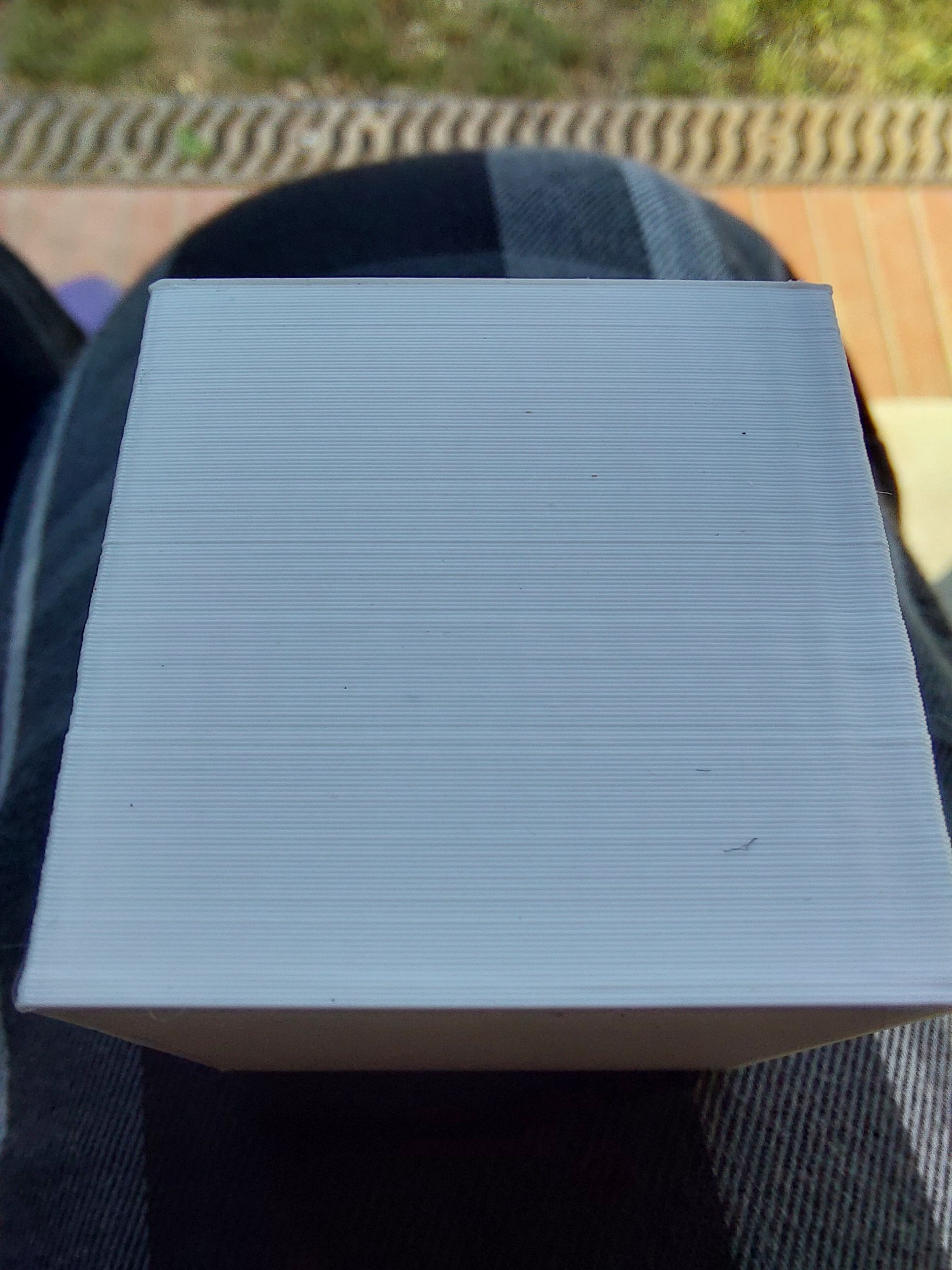

I made another test at the same speed with a triple-layer perimeter circular pattern.

My setup is a Revo Six hot end with a Titan extruder driven by a slightly underpowered Nema motor than the one suggested by E3D for Titan.The pulleys and belts are okay, and the hot end attachment seems rock solid. My concern lies with the mini V wheels or the wheel bearings, which could deteriorate over time. I am searching for a reliable European seller to buy good-quality V wheels.

This is the result of the print at 130 mm/s. During the print, I could hear a rhythmic noise pattern coming from the Y-axis. This is the reason I am considering a wheel problem.

-

RE: Fast print results, what can I improve?posted in Tuning and tweaking

@mrehorstdmd Thank you very much for your suggestions.

Can you give me some hints on were to start to backtrace where the problem with under extrusion could be?

The extruder is a Titan extruder with a lot of print on the shoulder, maybe I could try to replace it but I don't know if replace it with another Titan or something else, I am tempted by BMG even If I have to design a new hot end carriage)Thank you

Andrea -

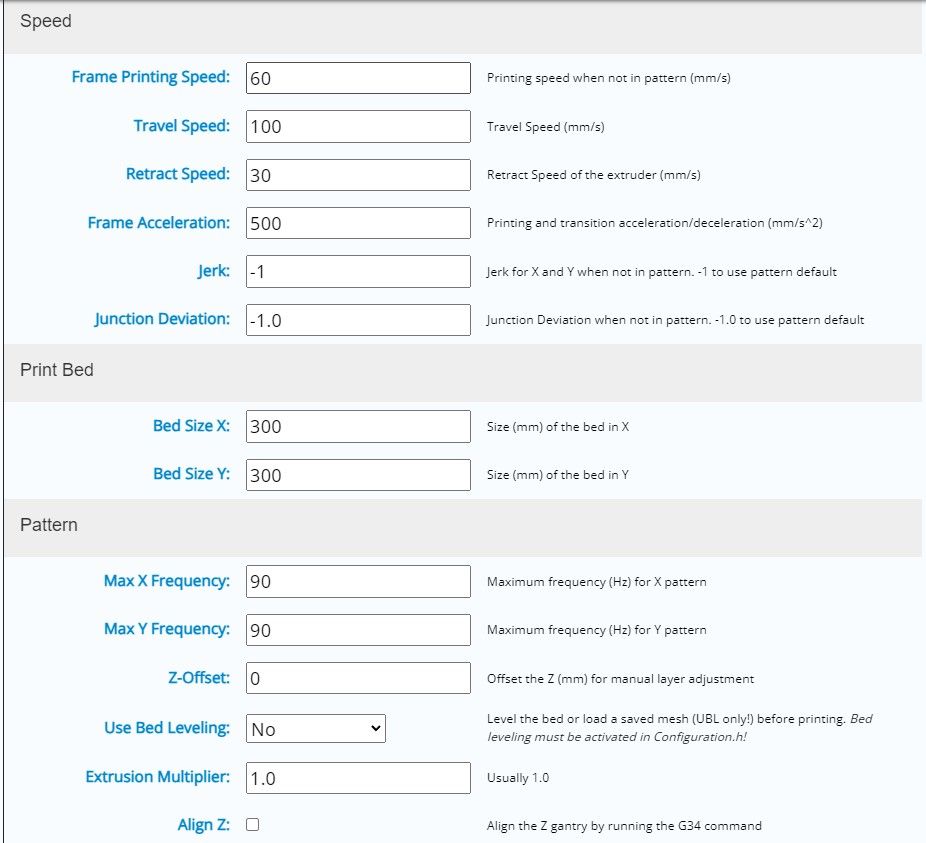

Fast print results, what can I improve?posted in Tuning and tweaking

Hi guys.

I am trying to psuh my homemade corexy 3d printer to limit.

What do you think I could improve?

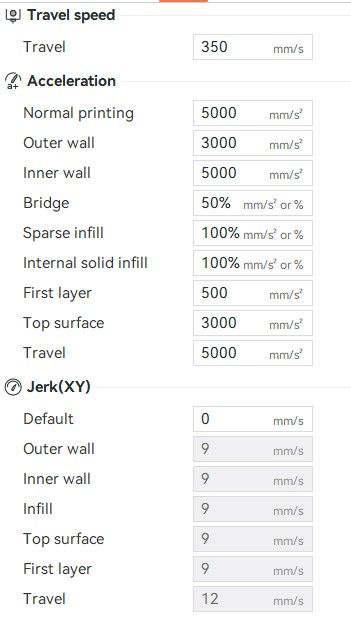

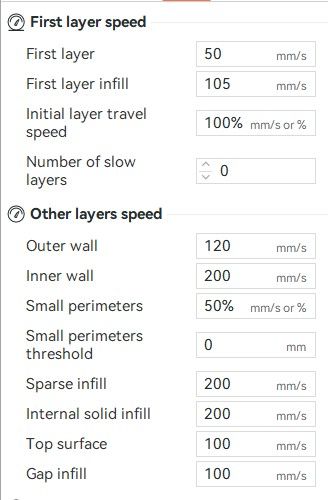

I still have to configure pressure advance.Variabile speed form 120 to 200 mm/s

I

-

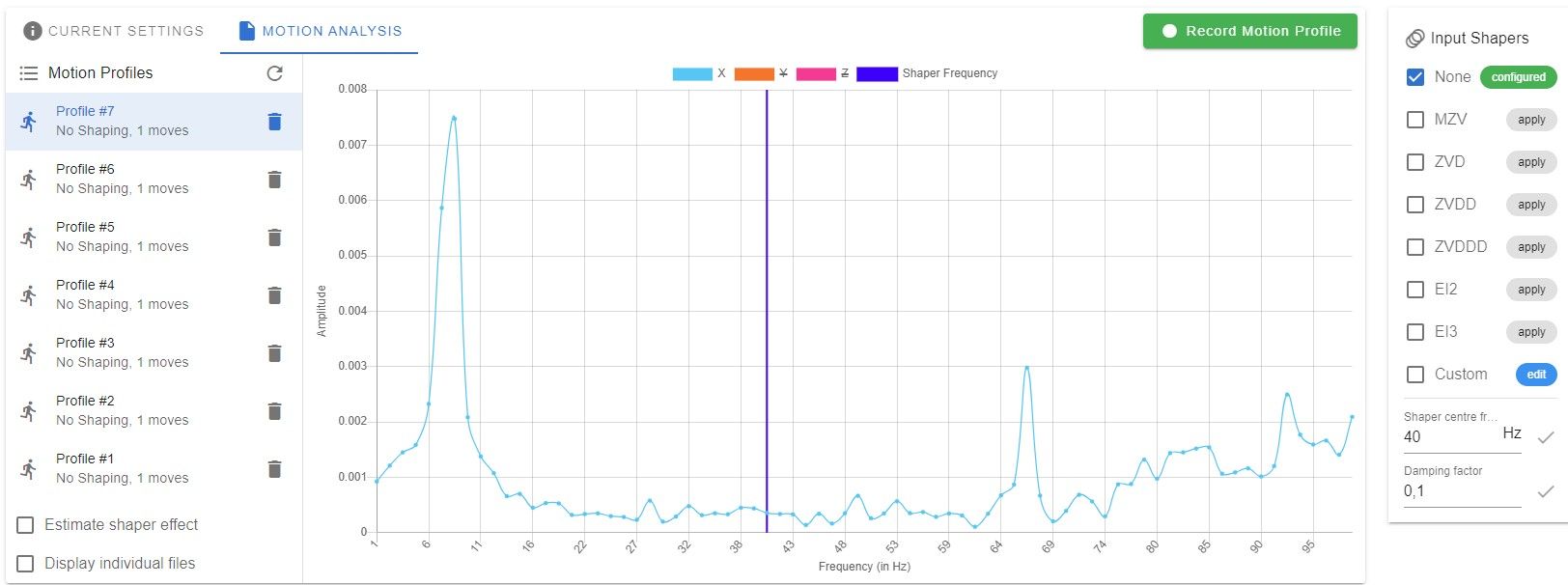

RE: Can you take a look at this accelerometer measurement?posted in Tuning and tweaking

@oliof Thank you for your answer.

My firmware movement speeds are

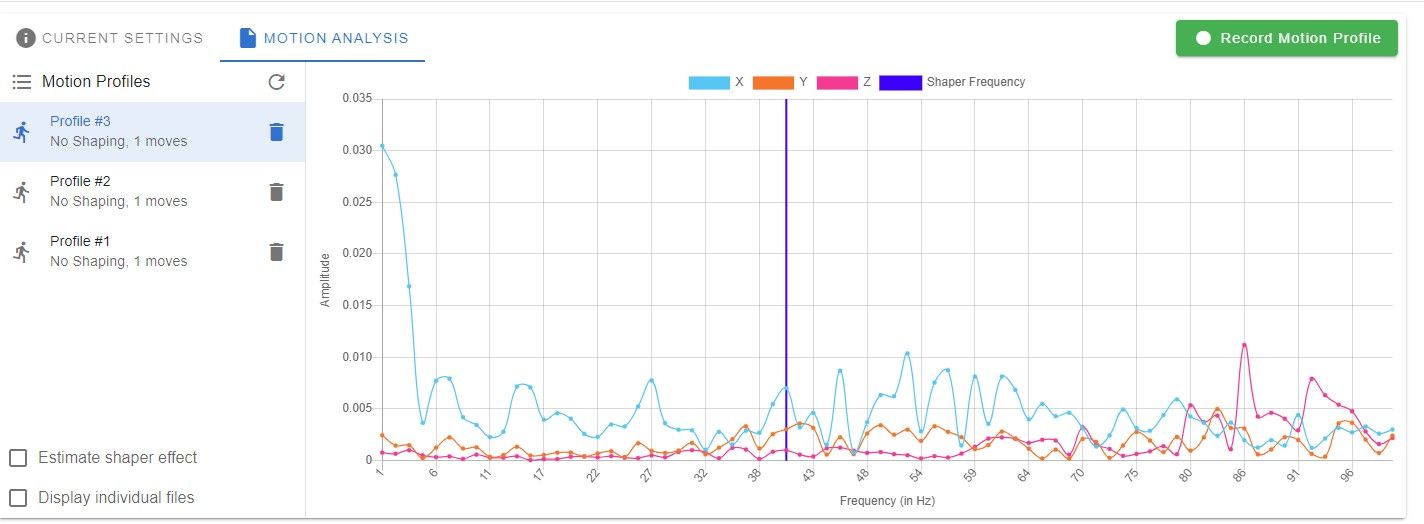

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X100.00 Y100.00 Z1000.00 E412.00 ; set steps per mm M566 X600.00 Y600.00 Z300.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y15000.00 Z300.00 E1200.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z400.00 E4000.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1300 E800 I30 ; set motor currents (mA) and motor idle factor in per centIncreasing the acceleration from 1500 to 3000 I obtained this accelerometer pattern

I run the test you pointed me out but I don't know if I settled up correctly.

This is the result

Now I am stuck

Thank you

Andreal

-

Can you take a look at this accelerometer measurement?posted in Tuning and tweaking

Hi guys,

I mounted an accelerometer on my c-bot

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.6 (2023-07-21)

Duet WiFi Server Version: 1.27

It seems to be working fine, I tried hand-shaking it for confirmation.

The " problem " is that it doesn't measure a real "peak" when mounted on my machine, al measurement seems coherent with each other so it seems fine

What should I do next? Where should I put the "peak" here?Here is a video

https://youtu.be/3LwV5iQyo7M

Thank you

-

Power resume after power failure need some helpposted in Tuning and tweaking

Hi guys . I have a C-bot :

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.6 (2023-07-21)

Duet WiFi Server Version: 1.27Z-axis is driven with 3 screws and one single motor. My zero on z axis is done by bl.touch

When I am thinking about zeroing the z-axis after power failure I am thinking at 2 ideas.

- I make zero on the bed using bl-touch probing on a far angle so , ideally , the already printed material isn't caught in the printer axis.

in this case resurrect-prologue.g could be something like this

M116 ; wait for temperatures G28 X Y ; home X and Y, hope that Z hasn't moved G90 ; absolute positioning G1 X20 Y20 F6000 ; go to first probe point G30 ; home Z by probing the bed M83 ; relative extrusion G1 E5 F3600 ; undo the retraction that was done in the M911 power fail scriptDo you think it will work?

- make zero on the other side of the z axis using a mechanical or optical endstop at the and of lead screw . The 3 screws are moved together so no need to level the bed. In this case I should use this zero sensor only for power failure.

In this case where I should hang up the sensor ?

Can you give me some suggestions?

Thank you

- I make zero on the bed using bl-touch probing on a far angle so , ideally , the already printed material isn't caught in the printer axis.

-

RE: Can I use PID tuning with SSR on heater bed?posted in Duet Hardware and wiring

@infiniteloop I am in the process of reducing all possible bending sources in my print, and then I came across this article. So I decided to get rid of this variable

Thank you for your suggestion .

-

Can I use PID tuning with SSR on heater bed?posted in Duet Hardware and wiring

Hi guys.

I have a 220 v heated bed. Safety features are grounded lines, temp fuse, home assistant monitoring temperature and cut line if needed.

I am using bang bang regulation but I would like to switch to pid because teh 1 C° fluctuations make some banding on the print.

Can I safely use pid regulation on an SSR MOSFET

Mine is a crydom d2425Thank you

-

Help Orca slicer : doesn't set extruder temperatureposted in General Discussion

Hi guys,

I would like to try Orca slicer but I am having a problem with it.

If I start the gcode the bed is heated but the print starts with the extruder at ambient temperature.this is the code generated

EXECUTABLE_BLOCK_START M486 S0 A"Cubo_id_0_copy_0" M486 S-1 M73 P0 R10 M201 X9000 Y9000 Z100 E5000 M203 X30000 Y30000 Z720 E3600 M204 P9000 T9000 ; sets acceleration (P, T), mm/sec^2 M566 X420.00 Y420.00 Z24.00 E300.00 ; sets the jerk limits, mm/min M190 S60 ; set bed temperature and wait for it to be reached G10 S205 ; set nozzle temperature ;TYPE:Custom G28 ; home all axes G90 G21 M83 ; use relative distances for extrusion ; filament start gcode M572 D0 S0.05; Override pressure advance value ;LAYER_CHANGE ;Z:0.2 ;HEIGHT:0.2 ;BEFORE_LAYER_CHANGE ;0.2 G92 E0 G1 E-1 F2400 ;AFTER_LAYER_CHANGE ;0.2 ;_SET_FAN_SPEED_CHANGING_LAYER M204 P500 ; printing object Cubo id:0 copy 0 M204 T500 M486 S0 G1 X170.854 Y150.136 F21000 G1 Z.2 G1 E1 F1800 ;TYPE:Inner wall ;WIDTH:0.449999Start Gocode

G28 ; home all axesEnd Gcode

M104 S0 ; Extruder heater off M140 S0 ; Bed heater off M106 S255 ; Fan at 100 to cool nozzle and bed G91 ; Relative positioning G1 E-2 ; Retract filament 2mm G1 Z20 F400 ; Raise nozzle 5mm from printed part G90 ; Absolute positioningAny idea if this is a problem with my setup or a slicer bug?

Thank you

-

RE: Filament monitor measured sensitivity keep decreasing over printposted in Filament Monitor

@infiniteloop thank you for your answer.

I found only now time to answer you.

I disassembled the sensor and I found that the wheel in contact with the filament was deteriorated. Changing it to a new one seems to fix my problem. Regarding the piece of PTFE tube below the sensor, I am having problems using this because it makes the filament load in the titan quite hard. Anyway, I'll try to add it.

Thank you

Andrea -

Bloob on printposted in Tuning and tweaking

Hi guys, lately my printer has started to print badly.

I tried to print the same part with the same setting with 2 different filaments. All the print has the same defect in the perfect same place, can you help me identify the problem?

Thank you

Andrea