@Veti I was only using the 9 points as a quick sanity check for corners (since that's my only manual adjustment points). Not intending to stick with 9 when actually printing. But thanks for the heads up.

Posts made by ClassicStyle

-

RE: Ongoing Mesh Level Compensation issuesposted in Tuning and tweaking

-

RE: Ongoing Mesh Level Compensation issuesposted in Tuning and tweaking

buahahaha!

Resolved with the info on the following page.

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors#Section_Example_for_2_motorsThat made everything work like butter. Yes, tramming was the major issue. I'm no longer even using mesh compensation, just the z-screw leveling. Immediate improvement and adhesion. Now I just need to make sure I'm actually at proper nozzle height, since I appear to be scraping off levels with my nozzle.

Thanks for the tips all.

-

RE: Ongoing Mesh Level Compensation issuesposted in Tuning and tweaking

ugh.....

still no adhesion.

Mirror surface with aquanet. I simply do not understand wth is going on.

I'm trying to print in the center of the bed, but nothing sticks.

For ref:

known-good PLA @200C

Mirror bed with Aquanet at room temp (works on my TronXY XY-2 no problem)

Layer height 0.12mm

Initial layer at 0.12mm

0.4mm head

print volume is 380^3 -

RE: Ongoing Mesh Level Compensation issuesposted in Tuning and tweaking

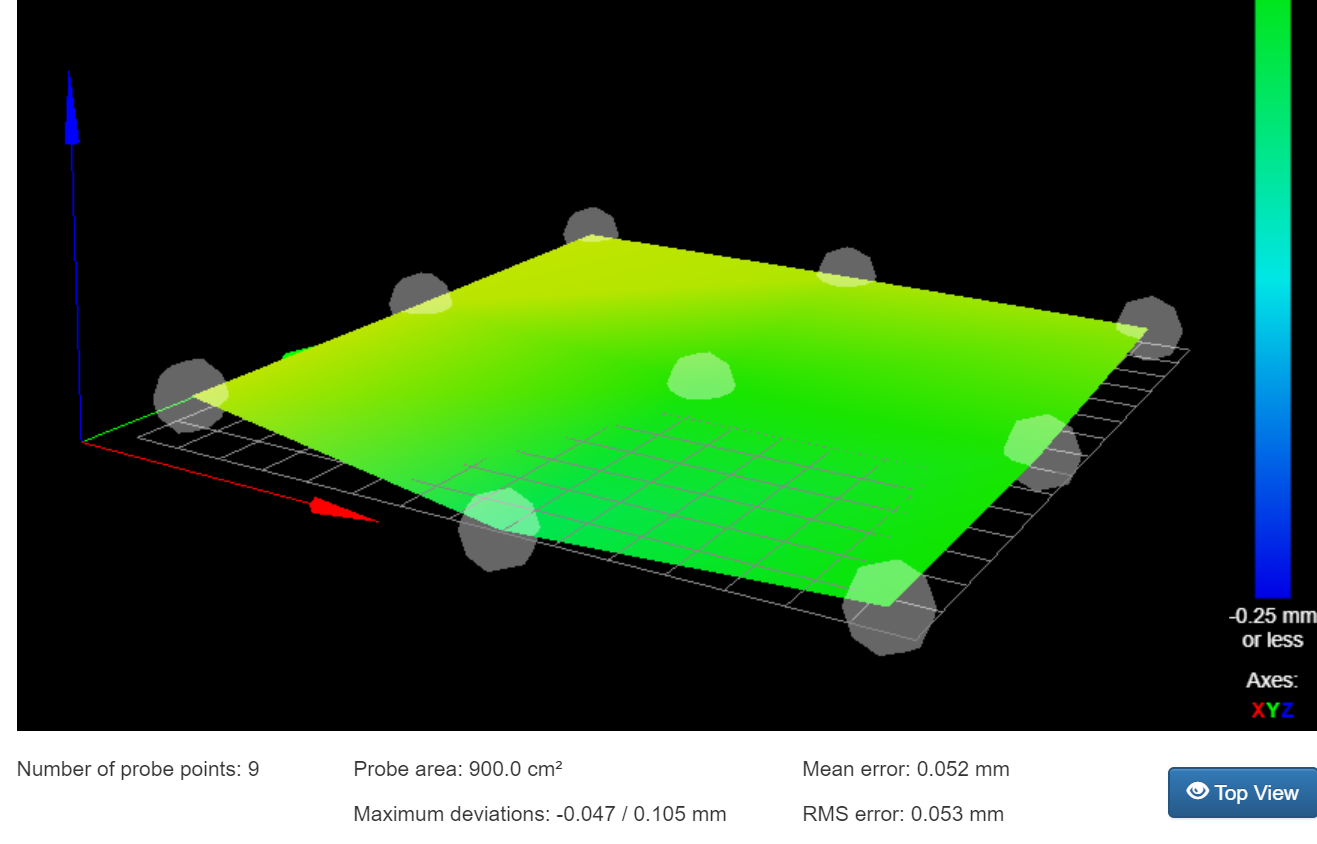

bed is much more level, but same symptoms.

Simplified the sample size just to be able to iterate faster. The 380 X,0 Y corner is still a bit out, but overall much better. Still no adhesion at anywhere other than the 0,0 corner.

-

RE: Ongoing Mesh Level Compensation issuesposted in Tuning and tweaking

@droftarts Thanks for the notes. I realize it's possible for my machine to need tramming, just not sure how I can get 0.5mm of accuracy on any tools I have, when I do not have a fixed frame of reference to measure against. I'll investigate though.

@greenlee Didn't know about G29. Adding it to my print start g code in cura.

@aidar Cool tip, I've updated this value and will report back.

-

Ongoing Mesh Level Compensation issuesposted in Tuning and tweaking

Re: [Mesh Calibration Issues (Duet Maestro 1.0](FW 2.02)

I finally got some time in my life to go back and continue working on my HyperCube. I designed a new x-carriage/extruder mount combo block that I'm quite happy with, and am now trying to get my printer to finally work. In the post I reference above, I got realllllllly close prior to the x-carriage breaking and wiping out a lot of my progress.

Current problem

Between X20Y20 and X20Y200, I can lay down a straight line of PLA essentially without issue. Anywhere else on my print bed, and I get no adhesion.Current Equipment

- Bowden-type hot end

- BLTouch

- Mirror glass print bed

- Lots of AquaNet!

The question

Is there some way to ensure I have mesh leveling operating correctly? It seems very odd that I am unable to get anything to adhere to glass with as flat a surface as the one attached.

I'm not even getting scraping, the bed seems too far from the head, but not everywhere, leading me to think mesh compensation isn't working.

config.g zprobe section

; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M558 P9 H1.5 F360 T9000 ;A5 B1 ; Set Z probe type to bltouch and the dive height + speeds

G31 P500 X10 Y-25.3 Z0.40 ; Set Z probe trigger value, offset and trigger height

M557 X20:320 Y20:320 P8 ; Define hi-res mesh gridOpen to thoughts, please!

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

For the first time in 2 weeks, I made it to layer 5 on a print with no errors.

That elation tho.

Thank you guys for the help. All of the combined knowledge you guys shared should be part of a book, or wiki, or something for Duet, cause that was extremely helpful and useful. Seriously, @Phaedrux @grizewald @Veti thank you guys!

The glass combined with the solve on the X-gantry made a massive difference!

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

Well, I found tonight that I am a moron. I had forgotten two X-gantry retaining screws to hold the gantry rods in place on one side. There was a non-trivial amount of torsion on the print head as a result. Wondering if that was the source of the "scraping" of the print.

Second, I'm getting closer now that my mirror arrived.

Going to try printing in a bit.

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

@phaedrux I'm so frustrated cause I feel what you're saying, but nothing frigging sticks!!!

Blue painter's tape? Yup, tried it. Half the 400mm^2 bed is covered in it, and glue stick, and hair spray.

Obviously I didn't do them all in one go, but one after another. Throw the tape away, try another round. I can barely get one line to stick, but the second the nozzle changes directions, the print lifts off the surface. I've tried print temps from 190-210, and bed temps from 45-65.

Obviously I didn't do them all in one go, but one after another. Throw the tape away, try another round. I can barely get one line to stick, but the second the nozzle changes directions, the print lifts off the surface. I've tried print temps from 190-210, and bed temps from 45-65.  Last resort is glass. If that doesn't work, not sure what I'm going to do.

Last resort is glass. If that doesn't work, not sure what I'm going to do. -

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

@grizewald I updated my firmware to latest, that made my results look much more like yours.

Bed compensation in use: mesh, comp offset 0.000

Going to try re-printing now, even though my bed is still unlevel af.

Here's hoping. Well, here's hoping the mirror gets here soon so I can clamp it to the bed and be done with this stupidness.

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

My Z Probe section:

; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M558 P9 H1.5 F120 T6000 ;A5 B1 ; Set Z probe type to bltouch and the dive height + speeds

G31 P500 X-25.3 Y0 Z0.675 ; Set Z probe trigger value, offset and trigger height

M557 X25:200 Y25:200 S20 ; Define hi-res mesh grid <-- OMG I didn't know about the "P" argument... So many maths could have been saved

;M557 X35:365 Y35:365 S330 ; Define low-res mesh grid -

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

Indeed.

I did a test print of that stl Phaedrux provided. It failed to print well directly on aluminum, but I did have M122 added to the end of the gcode. Here's the relevant portion:

Bed compensation in use: mesh

Bed probe heights: 0.000 0.000 0.000 0.000 0.000I don't understand the purpose behind the probe heights line - I only have g28 hitting Z probe at one coordinate - the middle of the print bed. Anything to be concerned about?

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

I don't know why it took me so long to realize I should be using my feeler gauges to level the platform.

But here's the latest. Now that it's mostly flat, I'll worry about raising it to 0-ish tonight. Now time to start increasing resolution.

But here's the latest. Now that it's mostly flat, I'll worry about raising it to 0-ish tonight. Now time to start increasing resolution.

Edit: ugh, just re-homing the Z should get it to zero-ish. I'm clearly firing on all cylinders today.

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

@grizewald Thanks for all the insight about 3-point mounting. Something I had definitely never realized. I actually have a Tronxy XY-2 as my first printer and went through the 4-sprung corner madness and said "no thanks, this sucks" to repeating that for my hypercube. I'm solid mounted to a 6-bar 2020 frame. Essentially it's a square frame of 4x2020 extrusion, then two 2020 extrusions are laid across the frame, resting on top of it. It's then solid mounted to the frame, and the bed is solid mounted to those two 2020s via v-nuts. I know it sounds overly complex, but I wanted a lot of adjustability while I dialed in the machine.

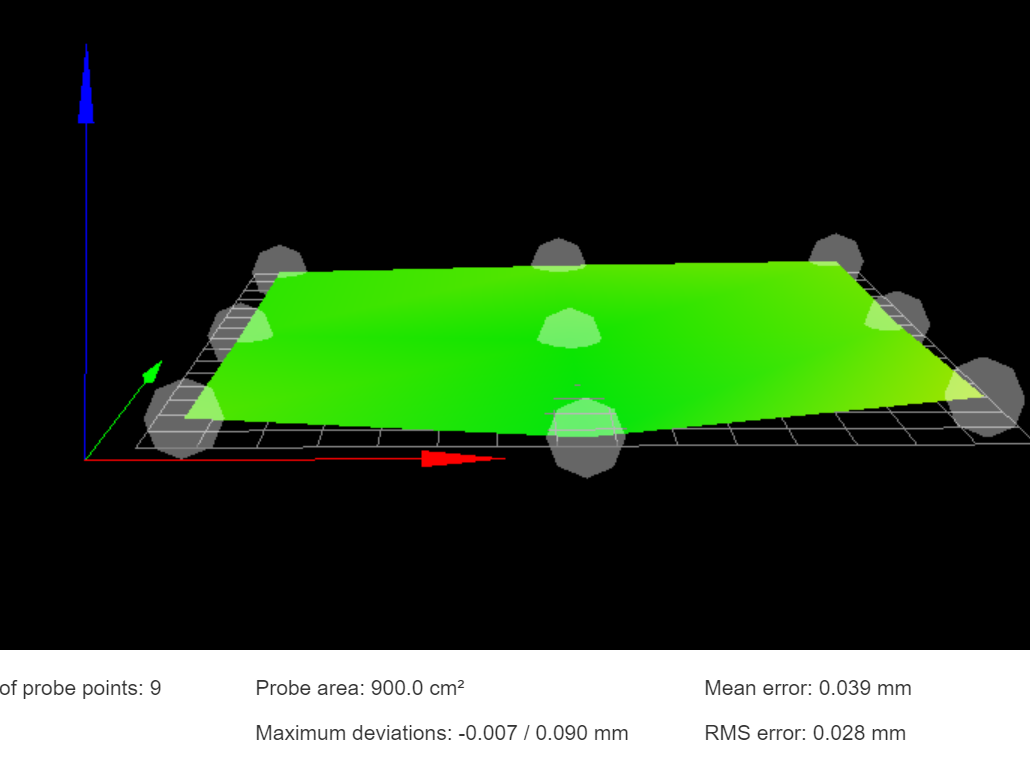

You reminded me that my 90 degree frame-to-2020 mounts are slotted, so I've been trying to dial that in since about 2 messages ago, starting with a simple 9-point grid to rough-in the level, then I'll up the resolution once I have all four corners roughly leveled and as close to 0.00 Z as possible. Getting closer....

For the moment I'm ignoring the middle blue points because I can actually see the swale in aluminum from where I'm sitting.

I have a mirror on the way to hopefully help this problem long term.

I have a mirror on the way to hopefully help this problem long term. -

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

@grizewald Thanks for the clarity about m122.

I actually have been trying things most of the night and this morning. It seems like every time the wind changes direction, the corners that are above or below zero change. I'm running a dual-z hypercube with 4 12mm guides. I think I'm going to have to figure out a pilot bearing for the top of the cube to make the lead screws more stable cause they do allow the build plate to wobble some.

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

Is there a way to verify that mesh compensation is occurring? (besides it just working)?

Also, I'm hoping this is the case, but does compensation interpolate between data points?

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

Yeah, my build surface is about as smooth as 80 grit sandpaper, which really sucks cause I honestly thought it was very flat.

Has anyone ever tried floating out the surface of an aluminum build plate with some catalyzed resin-like products, then polishing it?

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

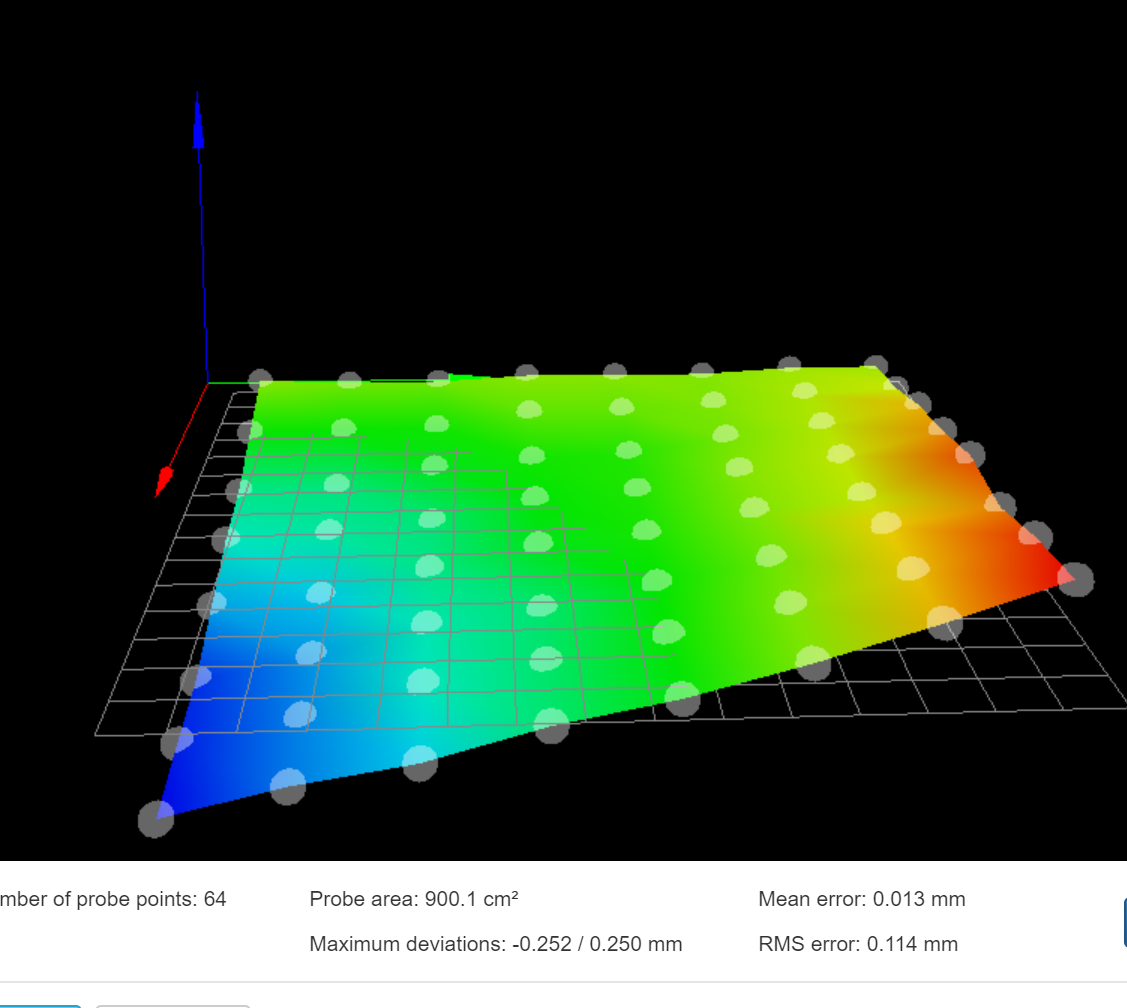

Someone mentioned an image of my calibration. I upped the sample count to 225, and here's what I got:

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

@grizewald said in Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch):

G32 causes the macro 'bed.g' to be called. There's nothing that requires you to perform a mesh levelling before every print, that's the whole idea with having a command to load a saved mesh.

That's the piece I was mentally missing, thank you! I added the G32 to the start code and have the G29 S1 added to bed.g. Wish me luck! Or don't, in any case I'm going to give it a go shortly!

Thanks again for the generous information @grizewald!

-

RE: Mesh Calibration Issues (Duet Maestro 1.0, FW 2.02, BLTouch)posted in Tuning and tweaking

@grizewald Do I need to run g32 on every print start? I have a mesh stored already, or am I missing the point of G32? Thanks for the tip about G29 S1, the S1 was missing from the command!