Perfect, thanks!

Posts made by cdthomas9

-

RE: Heater scale at 2000 degreesposted in General Discussion

I recently updated to 3.2 for DWC and the firmware, could there be something in DWC I need to change?

-

RE: Heater scale at 2000 degreesposted in General Discussion

DWC 3.2.0

Duet 2 WiFi/Ethernet 3.2 (2021-01-05)

Duet WiFi Server Version: 1.25 -

RE: Heater scale at 2000 degreesposted in General Discussion

; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin M208 X-7 Y0 Z0 S1 ; Set axis minima M208 X252 Y153 Z155 S0 ; Set axis maxima (reduced by offset above) ; Enable Panel Due Connector M575 P1 S1 B57600 ; Enables connector and sets baud rate ; Endstops M574 X1 S1 P"!xstop" ; X min active high endstop switch M574 Y1 S1 P"!ystop" ; Y min active high endstop switch ;Manual Bed Leveling M558 P9 C"^zprobe.in" H5 F500 T4000 X0 Y0 Z1 ; Set Z probe type/mode 9. H=Dive Height. F=Speed the bed moves G31 P25 X-36 Y0 Z2.885 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment M557 X40:190 Y20:145 S20 ; Define mesh grid ;M671 x144:94:191 Y10:160:160 P0.5 ; Manual screw adjustment locations ; Drives M569 P0 S1 ; Drive 0 goes backwards M569 P1 S1 ; Drive 1 goes backwards M569 P2 S0 ; Drive 2 goes forwards M569 P3 S0 ; Drive 3 goes forwards M569 P4 S1 ; Drive 4 goes backwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X88.573186 Y88.573186 Z400 E96.27520187033366 ; Set steps per mm M566 X900 Y900 Z300 E1200 ; Set maximum instantaneous speed changes (mm/min) M203 X1080000 Y1080000 Z600 E96000 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z100 E2000 ; Set accelerations (mm/s^2) M906 X800 Y800 Z400 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M584 X0 Y1 Z2 E3:4 ; Set drive assignments ; Heaters M140 H0 M143 H0 P0 S160 T0 A2 ; Set maximum bed heater temperature to 160C M143 H1 P1 S290 T1 A2 ; Set maximum heater 1 temperature to 290C M143 H2 P2 S290 T2 A2 ; Set maximum heater 2 temperature to 290C M308 S0 P"bed_temp" Y"thermistor" T100000 B3974 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1 M308 S2 P"e1_temp" Y"thermistor" T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 2 M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 M950 H2 C"e1_heat" T2 ; heater 2 uses the e1_heat pin and sensor 2 M307 H0 A103.7 C787.7 D1.0 S1.00 B0 ;M307 H0 A38.5 C41.1 D1.4 V24.4 B0 ; Set PID values for Heatedbed - derived from autotune M307 H1 A250.2 C139.5 D5.4 V24.4 B0 ; Set PID values for Extruder 1 - derived from autotune M307 H2 A387.6 C209.9 D5.9 V24.4 B0 ; Set PID values for Extruder 2 - derived from autotune M307 H3 A-1 C-1 D-1 ; Disable the 4th Heater to free up PWM channel on the Duex board. ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 ; Define tool 1 G10 P1 X34 Y0 Z0 ; Set tool 1 axis offsets G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C M207 S1.2 F1200 ; Set 1.2mm retract distance for G10 command ; Network M550 P"Rep2X-EnStein" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S1 ; Enable FTP M586 P2 S0 ; Disable Telnet ; Fans M950 F0 C"fan0" Q500 ; Set fan 0 value, PWM signal inversion and frequency. M950 F1 C"fan2" Q500 ; Set fan 1 value, PWM signal inversion and frequency. M106 P0 T40:50 H1 ; Set fan 0. Thermostatic control is turned on M106 P1 T40:50 H2 ; Set fan 1. Thermostatic control is turned on M950 S0 C"exp.heater3" ; Define BLTouch probe M564 H0 ; Allow Movement while axes are NOT homed -

RE: Heater scale at 2000 degreesposted in General Discussion

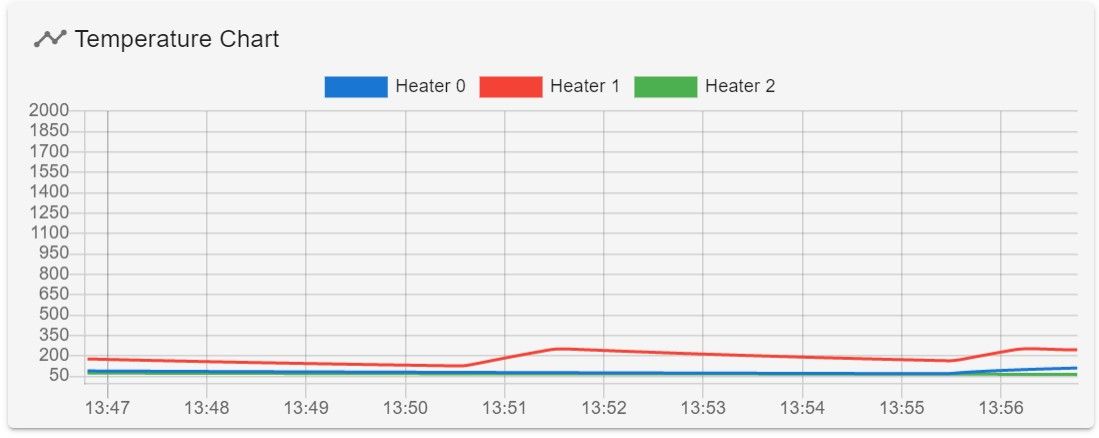

I still get the same scale. I can see that it changes to a max of 300 degrees for a second, when restarting the board, but then it jumps to 2000 again.

-

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

I had already ordered a replacement Duet2. The 3 seems overkill for this little printer, and I hadn't even considered the Mini 5, I actually had never read anything about that board at all. I would go for it but no one sells it.

-

RE: Heater scale at 2000 degreesposted in General Discussion

So remove the M143 I have and add in this?

M143 H0 P0 S160 T0 A2

M143 H1 P1 S290 T1 A2

M143 H2 P2 S290 T2 A2 -

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

Thanks, I'm going to order a new board, and the parts to try to fix this one. I have the tools needed but I've never done any SMD work so this will be a learning experience

-

RE: Heater scale at 2000 degreesposted in General Discussion

; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin

M208 X-7 Y0 Z0 S1 ; Set axis minima

M208 X252 Y153 Z155 S0 ; Set axis maxima (reduced by offset above); Enable Panel Due Connector

M575 P1 S1 B57600 ; Enables connector and sets baud rate; Endstops

M574 X1 S1 P"!xstop" ; X min active high endstop switch

M574 Y1 S1 P"!ystop" ; Y min active high endstop switch;Manual Bed Leveling

M558 P9 C"^zprobe.in" H5 F500 T4000 X0 Y0 Z1 ; Set Z probe type/mode 9. H=Dive Height. F=Speed the bed moves

G31 P25 X-36 Y0 Z2.885 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment

M557 X40:190 Y20:145 S20 ; Define mesh grid

;M671 x144:94:191 Y10:160:160 P0.5 ; Manual screw adjustment locations; Drives

M569 P0 S1 ; Drive 0 goes backwards

M569 P1 S1 ; Drive 1 goes backwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes backwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X88.573186 Y88.573186 Z400 E96.27520187033366 ; Set steps per mm

M566 X900 Y900 Z300 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X1080000 Y1080000 Z600 E96000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z100 E2000 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z400 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M584 X0 Y1 Z2 E3:4 ; Set drive assignments; Heaters

M140 H0

M143 S260 ; Set maximum heater temperature to 260C

M308 S0 P"bed_temp" Y"thermistor" T100000 B3974 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M308 S2 P"e1_temp" Y"thermistor" T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 2

M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0

M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1

M950 H2 C"e1_heat" T2 ; heater 2 uses the e1_heat pin and sensor 2

M307 H0 A103.7 C787.7 D1.0 S1.00 B0

;M307 H0 A38.5 C41.1 D1.4 V24.4 B0 ; Set PID values for Heatedbed - derived from autotune

M307 H1 A250.2 C139.5 D5.4 V24.4 B0 ; Set PID values for Extruder 1 - derived from autotune

M307 H2 A387.6 C209.9 D5.9 V24.4 B0 ; Set PID values for Extruder 2 - derived from autotune

M307 H3 A-1 C-1 D-1 ; Disable the 4th Heater to free up PWM channel on the Duex board.; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 ; Define tool 1

G10 P1 X34 Y0 Z0 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C

M207 S1.2 F1200 ; Set 1.2mm retract distance for G10 command; Network

M550 P"Rep2X-EnStein" ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S0 ; Disable Telnet; Fans

M950 F0 C"fan0" Q500 ; Set fan 0 value, PWM signal inversion and frequency.

M950 F1 C"fan2" Q500 ; Set fan 1 value, PWM signal inversion and frequency.

M106 P0 T40:50 H1 ; Set fan 0. Thermostatic control is turned on

M106 P1 T40:50 H2 ; Set fan 1. Thermostatic control is turned on

M950 S0 C"exp.heater3" ; Define BLTouch probeM564 H0 ; Allow Movement while axes are NOT homed

-

RE: Heater scale at 2000 degreesposted in General Discussion

I've got:

M143 S260

in the config.g file

-

Heater scale at 2000 degreesposted in General Discussion

My heater temp readout in DWC has a max of 2000 degrees, which makes it hard to see where the graph is since its mostly at the bottom. Can I change this somehow?

-

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

Ah, yeah that makes sense. I wasn't thinking about that, that's probably exactly what happened, thanks.

-

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

And if that's what happened how can I fix it?

-

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

Why would that happen? Do they draw too much current? Just operating a fan?

-

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

No joy on that, I also tried this for fan2 as well, no control for any fan PWM channel it seems. I haven't had this board long at all either.

-

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin M208 X-7 Y0 Z0 S1 ; Set axis minima M208 X252 Y153 Z155 S0 ; Set axis maxima (reduced by offset above) ; Enable Panel Due Connector M575 P1 S1 B57600 ; Enables connector and sets baud rate ; Endstops M574 X1 S1 P"!xstop" ; X min active high endstop switch M574 Y1 S1 P"!ystop" ; Y min active high endstop switch ;Manual Bed Leveling M558 P9 C"^zprobe.in" H5 F500 T4000 X0 Y0 Z1 ; Set Z probe type/mode 9. H=Dive Height. F=Speed the bed moves G31 P25 X-36 Y0 Z2.885 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment M557 X40:190 Y20:145 S20 ; Define mesh grid ;M671 x144:94:191 Y10:160:160 P0.5 ; Manual screw adjustment locations ; Drives M569 P0 S1 ; Drive 0 goes backwards M569 P1 S1 ; Drive 1 goes backwards M569 P2 S0 ; Drive 2 goes forwards M569 P3 S0 ; Drive 3 goes forwards M569 P4 S1 ; Drive 4 goes backwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X88.573186 Y88.573186 Z400 E96.27520187033366 ; Set steps per mm M566 X900 Y900 Z300 E1200 ; Set maximum instantaneous speed changes (mm/min) M203 X1080000 Y1080000 Z600 E96000 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z100 E2000 ; Set accelerations (mm/s^2) M906 X800 Y800 Z400 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M584 X0 Y1 Z2 E3:4 ; Set drive assignments ; Heaters M140 H0 M143 S260 ; Set maximum heater temperature to 260C M308 S0 P"bed_temp" Y"thermistor" T100000 B3974 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1 M308 S2 P"e1_temp" Y"thermistor" T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 2 M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 M950 H2 C"e1_heat" T2 ; heater 2 uses the e1_heat pin and sensor 2 M307 H0 A103.7 C787.7 D1.0 S1.00 B0 ;M307 H0 A38.5 C41.1 D1.4 V24.4 B0 ; Set PID values for Heatedbed - derived from autotune M307 H1 A250.2 C139.5 D5.4 V24.4 B0 ; Set PID values for Extruder 1 - derived from autotune M307 H2 A387.6 C209.9 D5.9 V24.4 B0 ; Set PID values for Extruder 2 - derived from autotune M307 H3 A-1 C-1 D-1 ; Disable the 4th Heater to free up PWM channel on the Duex board. ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 ; Define tool 1 G10 P1 X34 Y0 Z0 ; Set tool 1 axis offsets G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C M207 S1.2 F1200 ; Set 1.2mm retract distance for G10 command ; Network M550 P"Rep2X-EnStein" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S1 ; Enable FTP M586 P2 S0 ; Disable Telnet ; Fans M950 F0 C"fan0" Q500 ; Set fan 0 value, PWM signal inversion and frequency. M950 F1 C"fan2" Q500 ; Set fan 1 value, PWM signal inversion and frequency. M106 P0 T40:50 H1 ; Set fan 0. Thermostatic control is turned on M106 P1 T40:50 H2 ; Set fan 1. Thermostatic control is turned on M950 S0 C"exp.heater3" ; Define BLTouch probe M564 H0 ; Allow Movement while axes are NOT homed !

!

-

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

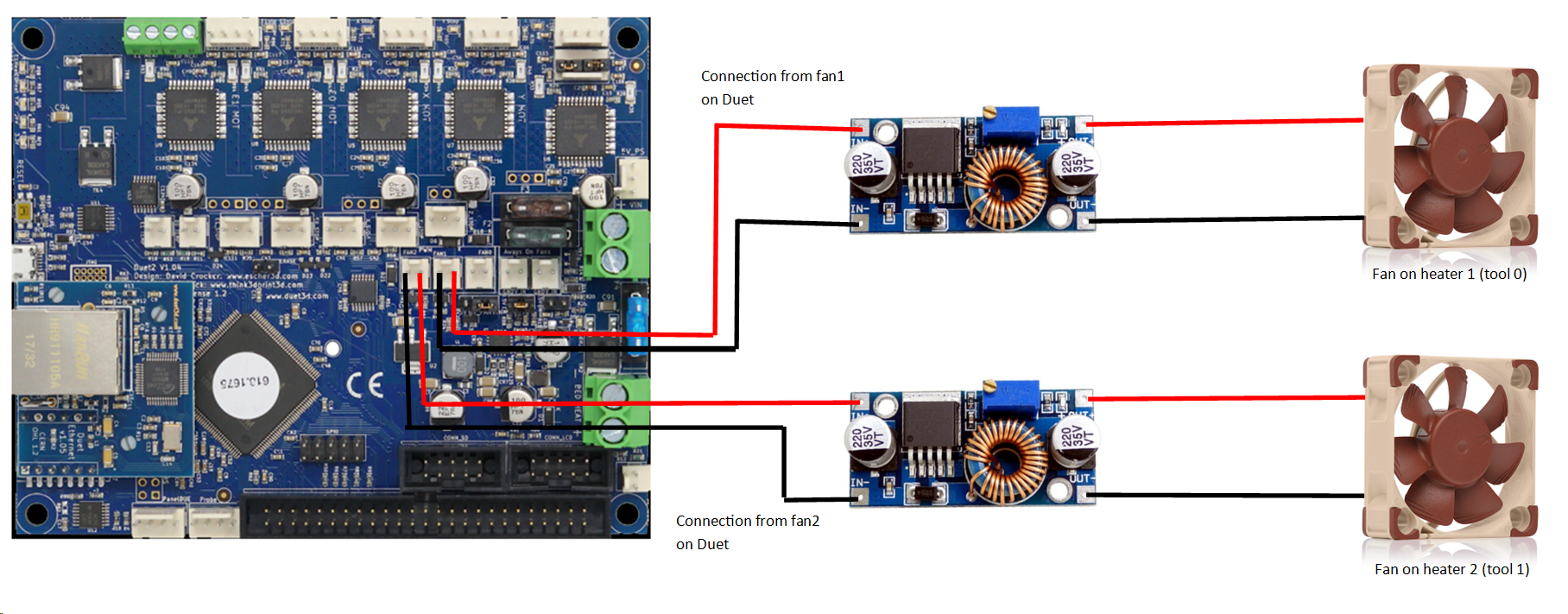

OK, so after rewiring things so that the buck converter is feeding into VFAN, fan1 still runs constantly. I even commented out all of the fan lines in my config.g. Right now I am trying fan0 and fan2, but neither seem to be working. The always on pins and fan1 both get 12v constantly, and fan1 and fan2 don't get anything, even when trying to turn on manually or if I heat up the hot ends.

-

RE: Duet2 Wifi fan runs constantlyposted in General Discussion

Ah, gotcha. Thanks, I'll rewire it then.