Man, I sure wish the Maestro didn't get kicked out of the party before this issue was resolved.

Posts made by CCS86

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

-

RE: DSF 3.5.1 Install Error: Failed to uploadposted in Firmware installation

Sounds like operator error!

I could have sworn in the past, I had to upload a 3rd file when upgrading RRF and DWC. I thought it was DSF, but must have been something else.

-

RE: DSF 3.5.1 Install Error: Failed to uploadposted in Firmware installation

Maestro. No SBC.

m122 === Diagnostics === RepRapFirmware for Duet 2 Maestro version 3.5.1 (2024-04-19 14:40:37) running on Duet Maestro 1.0 Board ID: 08DJM-956DU-LLMS4-7J9F6-3SN6Q-KBM2Q Used output buffers: 1 of 26 (22 max) === RTOS === Static ram: 23480 Dynamic ram: 67060 of which 0 recycled Never used RAM 22236, free system stack 178 words Tasks: NETWORK(1,ready,26.2%,202) ACCEL(6,nWait 5,0.0%,345) HEAT(3,nWait 5,0.1%,338) Move(4,nWait 5,0.0%,310) TMC(4,nWait 5,1.8%,109) MAIN(1,running,64.3%,791) IDLE(0,ready,7.7%,30), total 100.0% Owned mutexes: === Platform === Last reset 00:35:22 ago, cause: software Last software reset at 2023-06-16 21:25, reason: User, Gcodes spinning, available RAM 17184, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 MCU temperature: min 39.2, current 40.7, max 41.1 Supply voltage: min 24.1, current 24.2, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/7, heap memory allocated/used/recyclable 2048/224/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, read errors 0, write errors 1, ifcnt 22, reads 26058, writes 9, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, read errors 0, write errors 1, ifcnt 22, reads 26058, writes 9, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, read errors 0, write errors 1, ifcnt 22, reads 26058, writes 9, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, read errors 0, write errors 1, ifcnt 17, reads 26061, writes 6, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, read errors 0, write errors 1, ifcnt 13, reads 26061, writes 6, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2024-04-19 13:19:01 Slowest loop: 475.41ms; fastest: 0.19ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 9 SD card 0 detected, interface speed: 15.0MBytes/sec SD card longest read time 2.2ms, write time 96.0ms, max retries 0 === Move === DMs created 83, segments created 3, maxWait 1895171ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 4, maybepossible 0 === DDARing 0 === Scheduled moves 10, completed 10, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1, chamber heaters -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.2 Heater 1 is on, I-accum = 0.2 === GCodes === Movement locks held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is doing "M190 R60" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Q0 segments left 0 Code queue 0 is empty === Filament sensors === check 340708 clear 5979184 Extruder 0 sensor: ok === Network === Slowest loop: 1020.20ms; fastest: 0.01ms Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 Interface state active, link 100Mbps full duplex Socket states: 1 5 5 2 2 2 -

DSF 3.5.1 Install Error: Failed to uploadposted in Firmware installation

I am trying to upgrade from 3.5.0b4 to 3.5.1, and have already gotten the firmware and DWC installed on my Maestro.

But, every time I try to upload the DSF, it fails on this file:

Failed to upload DuetControlServer.SPI.Communication.FirmwareRequests.AbortFileHeader.html Your Duet rejected the HTTP request: could not create fileI'm actually not even sure if this is a requisite installation.

-

RE: Progress on Path Smoothing / Lookahead?posted in Firmware wishlist

@dc42 is this just not going to be explored?

-

RE: Progress on Path Smoothing / Lookahead?posted in Firmware wishlist

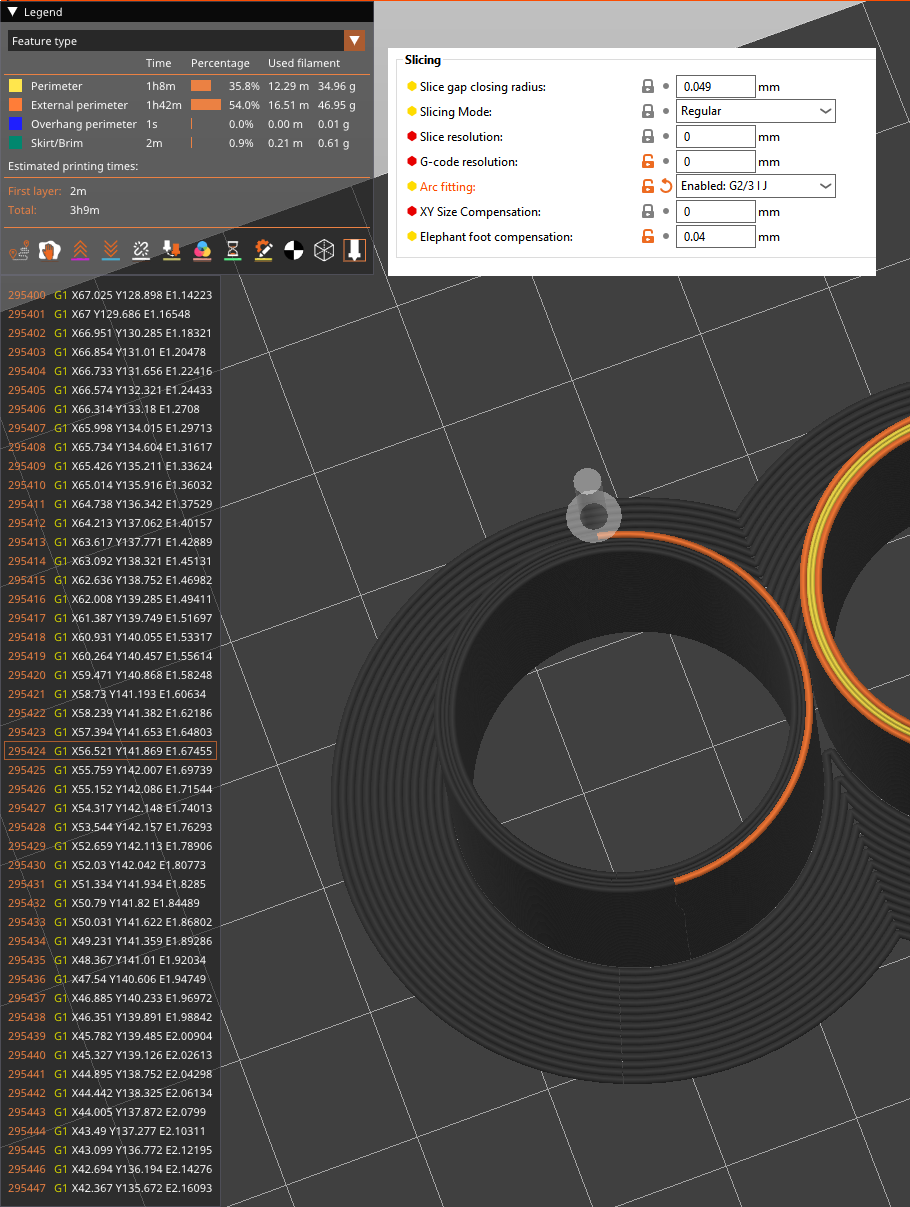

I put my g-code resolution back to the default value and it started generating arcs. It only does it on external perimeters though. So artifacts from linear segmented inner walls can still print through.

But again, for the sake of our discussion, until RRF allows true arc support, the quality with G2/G3 is worse than without.

-

RE: Progress on Path Smoothing / Lookahead?posted in Firmware wishlist

@MJLew said in Progress on Path Smoothing / Lookahead?:

@CCS86 We do not need to argue about this. Fitting arcs will take longer than not fitting arcs, but there are some (many, probably) use-cases and examples where the time difference is trivial. Your experience is vast and your opinion is valid, but it is quite likely that I also have relevant experience.

It's called a discussion, not an argument. That's the whole purpose of this forum.

If you have relevant experience that leads you to a different conclusion, let's hear it. Just saying that you "likely... Have relevant experience" isn't very compelling.

-

RE: Progress on Path Smoothing / Lookahead?posted in Firmware wishlist

@MJLew said in Progress on Path Smoothing / Lookahead?:

@CCS86 Well, all I can say is that the latest PrusaSlicer has arc fitting and it seems to slice as fast with it active as it does without on my Mac M1.

Have you looked at the code?

It's easy to go fast when you don't actually fit arcs.

Plus, even when successfully fitting arcs, they inject some variability into the wall surface. You can see something similar if you make the slicing resolution more coarse.

-

RE: Progress on Path Smoothing / Lookahead?posted in Firmware wishlist

@MJLew said in Progress on Path Smoothing / Lookahead?:

@CCS86 I disagree too, but it is with you I disagree. With modern computers there is no substantial penalty for things that used to be computationally demanding.

If the RepRap firmware uses segments of 1.2mm for an arc of diameter 20mm then the formula for segment lengths is faulty! I have a routine for changing arcs to G1 sequences that I made to accommodate my then new PrusaMK4 which ignored the Z parameter of G2 and G3 commands (now fixed). I found good results for a wide range of radii with the formula of 6*(r+1)^1.5 where r is the radius in mm. That formula gives a segment length of just under 0.3mm for a 20mm diameter. It is easily modified if that is too large.

I'll look at the thread that you linked.

Disagree all you want but proper arc fitting can take a long time, even with powerful modern computers. That is a penalty to the user.

I run a high tech CNC manufacturing facility. I have half million dollar machines that chew through linearly segmented code and produce super smooth motion. Arc filtering everything is not the answer on the highest end CNC machining, and it for sure is not the answer for 3D printers.

-

RE: Progress on Path Smoothing / Lookahead?posted in Firmware wishlist

@droftarts said in Progress on Path Smoothing / Lookahead?:

@CCS86 this sounds like a slicer problem to me, and reading the paper you linked only reinforces that view to me, ie it’s time to ditch stl and use a proper geometry, eg step, for slicing, to produce G2/3/5 moves (though there is an issue with G5 and 3D printing). Then improve the firmware on those gcodes to the point where microstep-accurate arcs are drawn - I believe RRF splits arcs into 0.1mm straight line segments currently.

Ian

I disagree.

Even in the world of very expensive CAM software packages, "arc fitting" / "arc filtering", or the post processing of linear segmented g-code into arcs, is limited and not applicable to all paths. To expect all these freeware slicers to adopt something that such expensive and advanced software doesn't always do, and is computationally very demanding, is unrealistic.

What is very common and very reliable, as outlined in that paper, is for the NC motion controller to smooth junctions with allowable deviation, to create smooth, continuous motion. Many even have configurable settings to allow the balance between speed and accuracy to be tuned for the current operation.

For RRF arc support, the 0.1mm segment is only the minimum length. In this thread we discussed the formula and for a cylinder of 20mm in diameter, I was getting linear segments of 1.2mm, which is giant compared to what I can achieve with a fine STL and good slicer settings: https://forum.duet3d.com/topic/21825/duet-maestro-struggling-to-produce-smooth-curves/27

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

@deckingman why are you taking this so personally?

You seemed to be suggesting that low jerk could be used generally. I pointed out that your test was very specific an not representative of general printing. Not sure why that would offend you.

-

RE: Progress on Path Smoothing / Lookahead?posted in Firmware wishlist

@gloomyandy said in Progress on Path Smoothing / Lookahead?:

@CCS86 Do you have any examples of controllers that implement or papers describing the sort of move smoothing you are asking for here? RRF already performs a fair degree of lookahead, but expecting it to be able to recognise "small loops" or other features seems like something better suited to a slicer or other preprosessor to me.

This has nothing to do with "small loops". We are talking about locally smoothing the junctions of linear segments to allow smooth motion.

https://www.sciencedirect.com/science/article/abs/pii/S089069551630493X

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

That's one very specific case you tested.

80 mm/s is relatively slow and on a large arc at a slow speed, of course you can reduce jerk significantly, with a finely faceted model.

Things will be different with higher speeds and smaller arcs. All sorts of real world printing scenarios that need to be balanced.

Your point about motor steps being linear is really a moot point. Every CNC machine has a minimum increment of movement, including the most precise, like a wire EDM. These increments are so small, that practically, they are invisible on the finished part. In our application, the issue is with large linear segments interrupting the motion controller's flow. By looking ahead, we can start the change in axis movement speed ahead of the junction, so there isn't such a reliance on jerk, creating much smoother motion.

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

The fact that printing curves composed of linear segments requires moderately high jerk, but input shaping is somewhat defeated by jerk, is the reason that the real path forward is by using look-ahead / path smoothing, as I asked about here:

https://forum.duet3d.com/topic/32942/progress-on-path-smoothing-lookahead

So, get in there and voice your support.

The only other approach that would work is to have true arc support (RRF just decomposes arcs into relatively coarse linear segments, currently), and reliable arc fitting in the slicer (none that I am aware of, currently).

-

RE: [3.5.0-rc1] IS not Being Applied In Areas Where it Shouldposted in Beta Firmware

I was really hopeful for the IS improvements in RC1, but I had a definite reduction in print quality and rolled back. Applying IS to short segments is very important in my eyes, but there are kinks to work out.

-

RE: Create Height Map from Individually Probed Points?posted in General Discussion

That makes sense guys.

I was asking more for the visualization aspect with the DWC plugin, as opposed to using it for mesh leveling.

-

RE: 3.5.0-RC1: Major Issue with Skipped Stepsposted in Beta Firmware

@gloomyandy said in 3.5.0-RC1: Major Issue with Skipped Steps:

@CCS86 Are you running input shaping? If so try disabling it and see if that makes any difference. Also capturing and posting the output from M122 after a failed print might provide some more information.

Yes, I am running IS.

I'm not sure when I will get a chance to test again, as I run pretty steady production on this machine.

-

RE: 3.5.0-RC1: IS Seems Slightly Worseposted in Beta Firmware

This is a Maestro board.

I'm not sure when I will get a chance to test again, as I run pretty steady production on this machine.